Sonny's Buff-n-Dry TOP Series User manual

Buff-n-Dry™

Owner’s Manual

Sonny's Enterprises, Inc.

5605 Hiatus Road

Tamarac, Florida 33321

16v1

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 2 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

*Table of Contents*

WARNING *SAFETY REQUIREMENTS* WARNING..................................................................3

*INTRODUCTION* .......................................................................................................................5

Product Specifications...............................................................................................................6

*INSTALLATION* ........................................................................................................................8

Utilities Requirements ...............................................................................................................8

Dimensions ...............................................................................................................................9

Adjustments and Testing.........................................................................................................19

*GENERAL OPERATION*.........................................................................................................21

*PREVENTIVE MAINTENANCE*...............................................................................................23

*WARRANTY*............................................................................................................................24

*CUSTOMER SERVICE* ...........................................................................................................25

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 3 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

WARNING *SAFETY REQUIREMENTS* WARNING

1. All employees must be thoroughly trained in safe operation and standard maintenance

practices. All employees must review this entire manual monthly.

2. Do not enter the wash tunnel when the equipment is operating. Death or dismemberment

may occur.

3. Do not wear loose fitting clothing or jewelry around moving equipment. Do not allow any

part of your body or other objects (including ladders, hoses or tools) to come in contact

with moving equipment. Entanglement may result causing death or dismemberment.

4. Do not leave a ladder or any other items such as wash down hoses or tools in the wash

tunnel while equipment is running. Vehicle damage and injury, including death, can

occur.

5. Always exercise caution when walking (never run) through the wash tunnel as there may

be slippery conditions. Be careful so you do not bump into or trip over equipment.

6. Only those employees specifically instructed and trained by the location management are

permitted to enter the wash tunnel to perform inspections or maintenance. At least two

qualified maintenance people must be present when performing equipment repairs or

preventive maintenance.

7. Do not perform any maintenance or work on equipment unless you first perform Lock-Out

Safety Precautions. All electrically powered equipment must have manually operated

disconnects capable of being locked in the “OFF” position. Equipment that has been

“locked out” for any reason must be restarted only by the person who performed the “lock

out” operation.

8. When working on any equipment that is higher than your shoulders, always use a

fiberglass ladder that is in good condition.

9. Do not attempt to repair or adjust any pressurized liquid or pneumatic part, hose, pipe or

fitting while that equipment is in operation.

10.Electrical connections and repairs must be performed by a Licensed Electrician Only.

11.Emergency “STOP” buttons must be well marked and their location and proper use

reviewed with all personnel. Any activated “STOP” button must be reset only by the

person who activated it. Clear the wash tunnel of any people, ladders, hoses, tools and

other loose items before restarting the equipment. An audible device must sound to warn

people that the equipment is starting.

12.Do not operate any piece of equipment that requires safety covers with those covers

removed or improperly installed. Do not operate any piece of equipment if any

component of that piece is suspected to be defective or malfunctioning.

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 4 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

13.Store all cleaning and washing solutions and oils in a well-ventilated area. Clean up fluid

spills immediately to prevent hazardous safety conditions. Be certain to follow all safety

procedures on SDS Sheets for each chemical product used.

14.All hydraulic and electric systems in the wash tunnel equipped with a torque relief or

overload should be checked and set at the minimum amount that will allow for proper

functionality under normal washing conditions.

15.No unauthorized people should ever be permitted in the wash tunnel or near the

equipment at any time. * * *

! ! CAUTION ! !

When a piece of equipment must be in operation during inspection or maintenance, one

qualified technician must stay at the power disconnect switch while another qualified

technician performs the inspection or maintenance.

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 5 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

*INTRODUCTION*

This Owner’s Manual contains information that is vital to the successful

installation, operation and maintenance of your SONNY’S vehicle washing

equipment.

Please read, and understand, the full contents of this manual before

installation and operation of the equipment. Keep this booklet in a location

where it may be used for ongoing reference.

Should you have any questions on the operation or servicing of this

equipment please contact

TECHNICAL SERVICES DEPT.

SONNY’S ENTERPRISES INC.

5605 Hiatus Road

TAMARAC, FLORIDA 33321

TELEPHONE: 800-327-8723 FAX: 800-495-4049

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 6 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

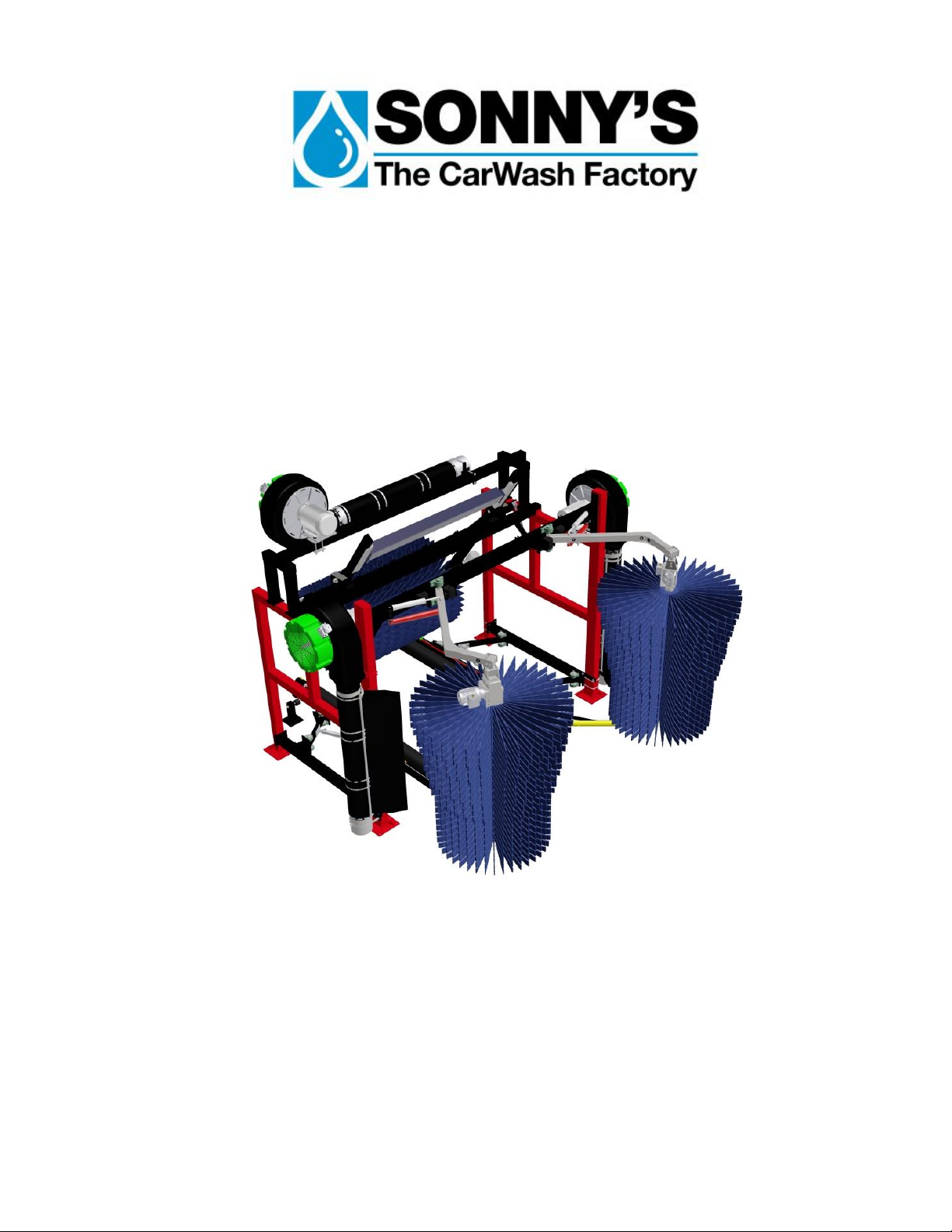

Product Specifications

Designed to occupy 241” of tunnel length and 144” width

4” x 4” aluminum frame and legs for stability and durability

Pivot bearing is solid UHMW and with a grease fitting to increase

smoothness of operation

Double roller bearings on shaft

6” Unihub

New Wrap header for complete retract

Unit is available as electric or hydraulic drive

Hydraulic brush drive motors use 6GPM @ 800PSI

Electric brush drive motors are 1.5 hp each

Pivot shaft constructed of 1½” stainless steel

Hub that doesn’t absorb water with Drytex™

45 degree Restrict-O-Flex coupling for smooth operation

Pneumatic retract controls standard

Stainless steel brush hangers

Brush tracks the contour of the vehicle using only a counterweight

1/2 inch city water connection

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 7 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 8 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

*INSTALLATION*

Utilities Requirements

UTILITIES INTERCONNECTION AND THE MATERIALS REQUIRED FOR

INTERCONNECTION TO SONNY’S EQUIPMENT ARE THE RESPONSIBILITY OF THE

CUSTOMER !

PERFORM ALL TRADES WORK TO ALL APPLICABLE LOCAL AND

NATIONAL CODES !

Water

The Customer's Plumber is to provide and install a 1/2 inch city water line @60PSI

(nominal) to the solenoid valve on the chemical distribution system for the Washer.

Electrical

The Customer's Electrician is to provide and install single phase power from the (24 or

110 VAC as determined at time of order) from the Customer’s Controller system to the

motor starter coil for the hydraulic power pack or VFD feeding the brush.

The Customer's Electrician is to provide and install single phase power from the remote

push-button station through the tunnel equipment programmer to the supplied air

solenoid valve on the Air Distribution Manifold for retract of both washers upon selective

signal.

Where applicable, the Customer's Electrician is to provide materials and install 208VAC

or 230VAC or 460VAC, 3-phase, 60Hz power ot the electric motor on the hydraulic power

pack or VFD panel from a properly sized three pole circuit breaker and motor starter with

three thermal overloads.

Compressed Air

The Customer's Plumber is to provide and install a 1/2 inch compressed air line from the

Air Compressor to the Air Distribution Manifold for the Retract functions.

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 9 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

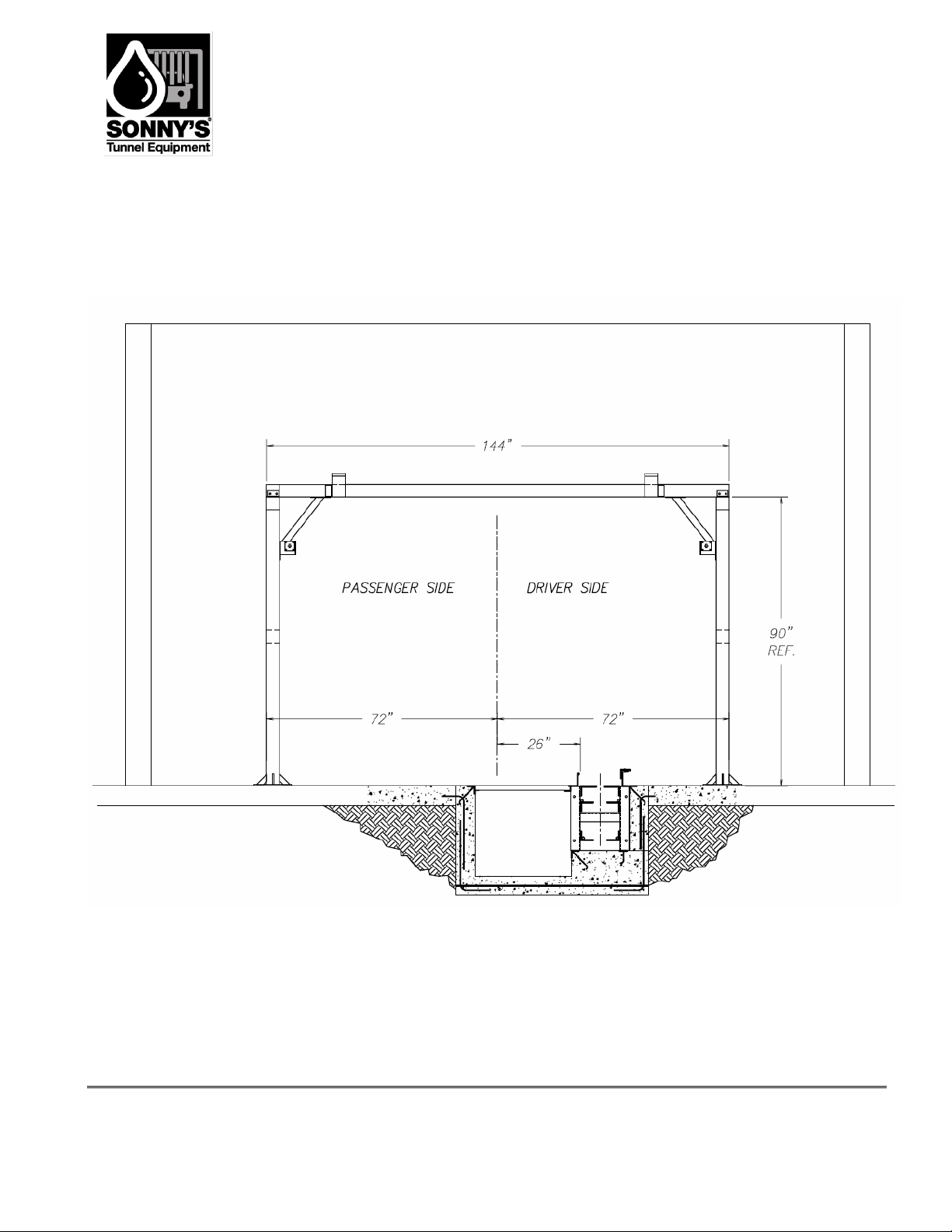

Dimensions

Figure #1

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 10 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

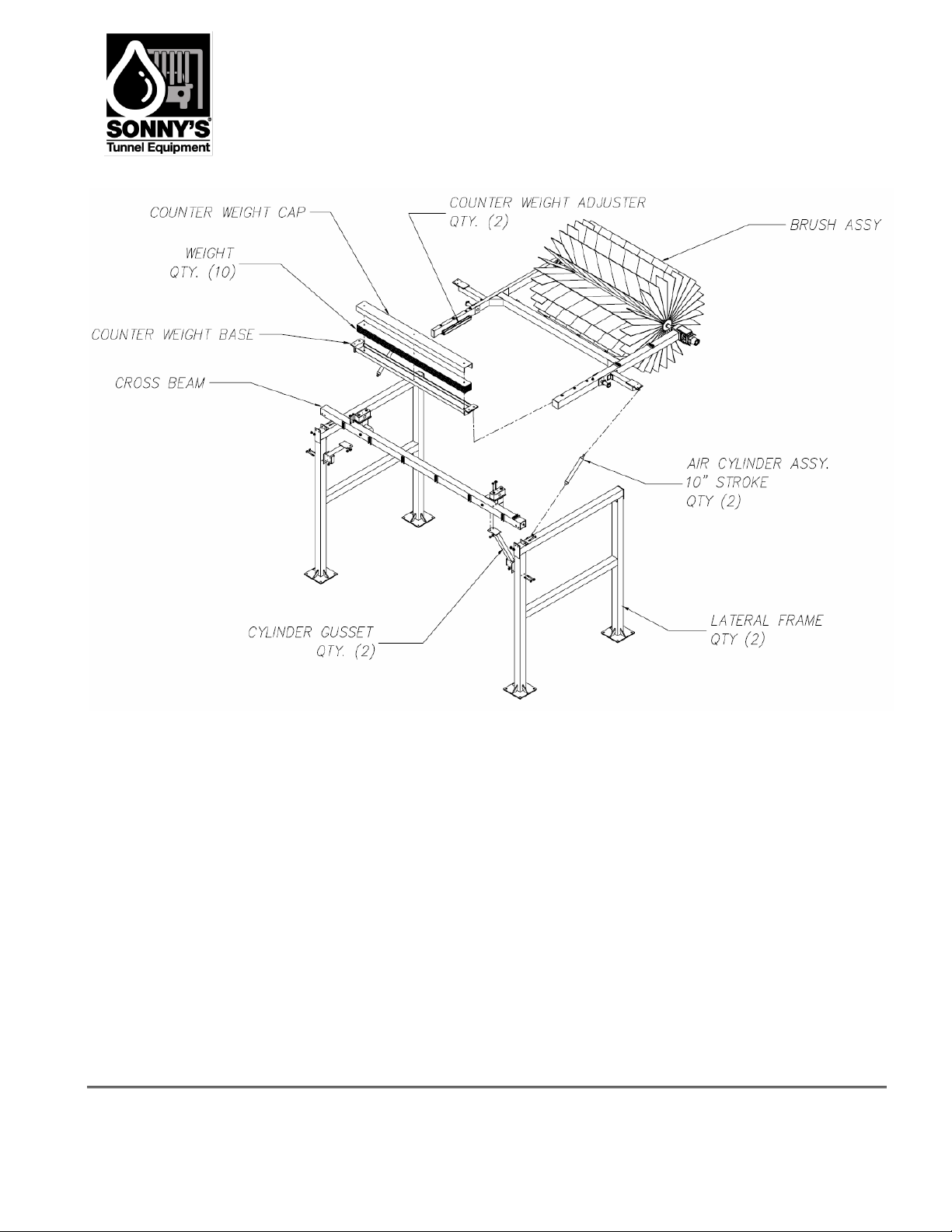

Figure #2

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 11 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Figure #3

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 12 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Figure #4

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 13 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Figure #5

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 14 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Figure #6

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 15 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Figure #7

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 16 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Figure #8

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 17 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Equipment Installation

Buff-n-Dry Installation

Tools

Consumables

1. Safety Glasses

1. Anti-Seize Compound

2. ½” Drive Ratchet Set

2. Marine Grease

3. Standard Combo Wrenches

4. 4' Level

5. Electric Impact Wrench

6. 1" Hammer Drill

7. Tape Measure

8. Sledge Hammer

Work Force

Time (assuming no problems)

Two (2) persons

2.00 –4.00 hours

Installation Steps

1. Determine where the Buff-n-Dry is to be installed (See Figure #1 in the Dimensions

Section and the tunnel layout drawings for your location).

2. Sweep any debris from where the unit will stand.

3. Check all hardware and place a small amount of Anti-Seize Compound on each bolt.

4. Place the assembled frame side legs, cross beams and gussets in the area where the

unit will be permanently located (with the brush counterweight toward the entrance of the

car wash).

5. With the interconnection hardware provided by SONNY'S (boxed and attached to the

assembly frame) join the legs, cross beams and gussets to the frame "finger tight".

6. Place and anchor the unit per the dimensions shown in Figure #1. Be certain that the

entrance and exit cross beams are level (shim mounting feet, if necessary) and that each

of the 4 vertical legs are plumb.

7. Level and square the frame with the centerline of the equipment (see Figure #1 in the

Dimensions Section and the tunnel layout drawings for your location).

Note: Ensure the frame is correctly located before installing any lag bolts. Before lagging

the frame into position have a second person double check all measurements against

your tunnel equipment layout drawings to ensure all measurements were performed

correctly.

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 18 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

8. Place an anchor bolt in each corner. Tighten all hardware.

9. Check each leg for plum and the frame for level, and then install the rest of the anchor

bolts in each leg of the frame.

10.Install brush and counterweight assembly on the frame.

11.Place the Sonny’s lift-a-ma-jig onto the frame of the Wrap and bolt into place. Bring the

forklift into the lift-a-ma-jig.

12.Bring the frame into the building as close to its final position as is practical. Lift the frame

into place.

13.Check that the Passenger Side Brush hanger arm is longer than the Driver Side, if not

the frame is not positioned correctly.

14.Check that the shock absorbers on each Brush Hanger do not "bottom out" in their fully

extended position. If this occurs move the shock mounting position to a different hole on

the mounting bracket to prevent a fully extended condition.

15.Move each brush hanger from the center of the wash tunnel so that it is parallel to vehicle

travel. With each brush hanger in this position check that the hanger is level. Up or down

adjustment of the brush hanger can be achieved by placing shim material under the

brush hanger pillow block bearings.

16.Double check that the bottom pillow block bearing for each brush hanger is EXACTLY

below the top pillow block bearing. This is necessary to provide light brush pressure

against the side of the vehicle.

17.Mount the Brush Head, Shaft and Core assembly to each Hanger Arm. Connect the pre-

plumbed hydraulic lines.

18.Orientation of the Brushes is with vehicle travel. As viewed from the top of each Brush

the DRIVER side turns COUNTERCLOCKWISE and the PASSENGER side turns

CLOCKWISE. Rotation speed of each Brush should be according to the Operating

Speeds Chart in the Adjustments and Testing Section.

19.Install the air retract cylinder and run the air lines to the manifold for the retract operation.

20.If electric run and install the power to each brush.

21. If hydraulic run and connect a 1/2 inch PRESSURE line from the Hydraulic Power

Pack to the 1/2 inch male pipe thread fitting on the BLACK high pressure hose on

the frame.

22.Run and connect the 1/2 inch RETURN line to the Hydraulic Power Pack to the 1/2

inch male pipe thread fitting on the ORANGE/RED high pressure hose on the

frame.

23.Rotation of the top brush is against vehicle travel. As viewed from the driver side

the brush turns COUNTERCLOCKWISE.

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 19 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Adjustments and Testing

Adjust the Cleaning Pressure of the Top Brush

Ensure the air solenoid is manually put in the wash position so there is no air pressure applied

to the retract cylinder. Adjust the position of the counterweight so that when the counterweight

is released the brush slowly moves downward. After initial adjustment manually activate and

deactivate the air retract. When deactivated the brush should fall smoothly to the down position.

Final adjustment of the counterweight can be accomplished while running test vehicles. Once

adjusted properly the cloth penetration should be about three to four inches across the entire

vehicle. If brush bounces too much the counterweight has been adjusted to far out. Adjustment

is easiest if made in small amounts, approximately ¼” to ½” at a time.

Adjust Top Brush for Smooth Retract Operation

To adjust the retract operation the air pressure regulator should be adjusted for approximately

30PSI in the retract position. The tunnel controller should be adjusted so that the brush is put

into the wash position prior to the front of the car arriving at the brush. This will entail

deactivating the retracts before the vehicle reaches the brush and setting the look ahead to

check for the proximity of the next car.

Mechanical Adjustment of the Wrap Hanger Arms

1. Install the unit so that the legs are plumb, the hanger arms are level when at the rest position

and the mounting bearings are positioned perpendicular to floor (no pitch).

2. The rest position will vary with operator preference and region. If front license plates are

present the brushes should be open slightly to clear the plate, approximately one inch

between when spinning. If there are no front plates then when spinning the tips of the cloth

should be penetrating about one inch.

3. The two brushes should return to the rest position (middle of the tunnel) with no air pressure

and no pitch to the bearings.

Operating Speeds Chart

Chain Speed

Wrap Speed

Top Speed

Wrap Air

Pressure Driver

Wrap Air

Pressure Pass

50-70CPH

70-75RPM

75-85

0PSI

0PSI

70-80CPH

80-85RPM

75-85

0-5PSI

0-5PSI

80-90CPH

85-90RPM

75-85

5-10PSI

5-15PSI

90-125CPH

90-95RPM

85-95

10-15PSI

15-25PSI

Equipment Program - Manuals

Buff-n-Dry™ / TOP Series

© SONNY’S The CarWash Factory SonnysDirect.com

This document is confidential and proprietary to SONNY’S and cannot be used, disclosed or Page 20 of 25

duplicated without prior written consent. Content, prices and availability subject to change without notice. 6.7.2016

OwnersManual_Dryer_Buff-n-Dry_16v1

Two Solenoid valves, one for each retract, are recommended for 80 or more cars per hour.

To adjust the operation of the brushes without air pressure you may adjust the position of the

pillow block bearings.

1. TO INCREASE THE PRESSURE ON THE SIDE AND BACK OF THE VEHICLE: Adjust

the bottom pillow block bearing away from the center of the tunnel. Move in 1/8 inch

increments at a time.

2. TO DECREASE THE PRESSURE ON THE SIDE AND BACK OF THE VEHICLE: Adjust

the bottom pillow block bearing towards the center of the tunnel. Move in 1/8 inch

increments at a time.

Cloth penetration should be about three to four inches on the flat surface of the car. Each of the

brushes should cover about two thirds of the back of the vehicle, overlapping in the center.

Speed and Torque Adjustment

Hydraulic

a. The speed can be adjusted on the flow control for the power pack

b. To increase the speed move the handle on the flow control closer to the number ten (10).

c. To decrease the speed move the handle on the flow control closer to the number one (1).

d. The torque must be set prior to operation and should be set between 600-900 PSI. for

information on how to set the torque please refer to the Hydraulic Power Pack manual.

Electric

a. The speed can be adjusted on the VFD (Variable Frequency Drive).

b. To increase the speed adjust the Hertz on the VFD to a higher number.

c. To decrease the speed adjust the Hertz on the VFD to a lower number.

d. The Overload on the Motor Starter protector(s) must be set at the lowest level to allow for

operation.

e. Adjust the amps in accordance with the motor(s) name plate.

Table of contents

Popular Cleaning Equipment manuals by other brands

Denios

Denios Bio.x C500 user manual

Ultrasonic

Ultrasonic BT H Series System manual

Ecolab

Ecolab Hybrid 7 Foamatic MA2iM Directions for use

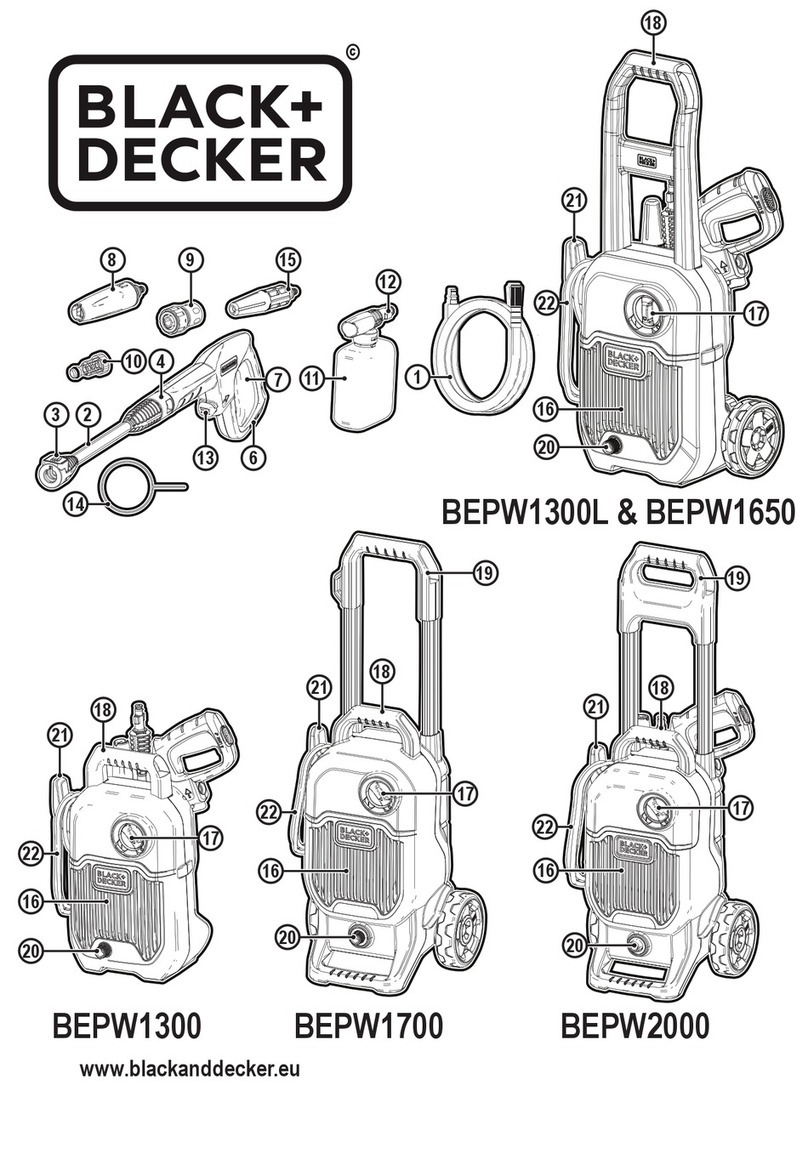

Black & Decker

Black & Decker BEPW1300L Original instructions

Cleantecs

Cleantecs LR-180-GTR operating instructions

Electrolux

Electrolux McCULLOCH Orkan 2200 Important information