Denios Bio.x C500 User manual

Cleaning Table

USERS MANUAL 07/2008

138514_EN_BA_105

bio.x C500 135147 Page 2 of 12 07/2008

Inhaltsverzeichnis

1. General Instructions.......................................................................................................... 2

2. Safety instructions ............................................................................................................ 3

3. Technical data.................................................................................................................... 3

4. Product description........................................................................................................... 4

4.1 Intended use .................................................................................................................. 4

4.2 Layout and how it works................................................................................................. 4

5. Initial Operation ................................................................................................................. 5

5.1 Electrical connection ...................................................................................................... 5

5.2 Filling with the cleaning fluid .......................................................................................... 5

6. Control panel ..................................................................................................................... 5

6.1 Function indicators on the display. ................................................................................. 6

7. Operation............................................................................................................................ 6

8. Maintenance....................................................................................................................... 7

8.1 Fill level .......................................................................................................................... 7

8.2 Additive .......................................................................................................................... 7

8.3 Filter ............................................................................................................................... 7

8.4 Cleaning fluid ................................................................................................................. 7

8.5 Refill items ..................................................................................................................... 8

8.6 Replacement parts (see also product description page 5) ............................................. 8

9. Optional Accessories........................................................................................................ 9

10. Notes regarding disposal.............................................................................................. 10

11. Faults.............................................................................................................................. 10

12. Connection Diagram...................................................................................................... 11

13. EC Declaration of Conformity....................................................................................... 12

1. General Instructions

This user manual is for the bio.x parts cleaning unit C500. It contains all the information needed regarding

correct startup, trouble-free operation, maintenance, removal from service and disposal. The information

and instructions in this user manual have to be observed and adhered to.

If the instructions are strictly followed in accordance with the user manual, we accept liability within the

scope of our conditions for guarantees.

Without approval from the manufacturer no changes, extensions or modifications may be made to the

product. For changes made without approval from the manufacturer no liability is assumed and the

guarantee expires.

National regulations and safety regulations have to be adhered to.

bio.x C500 135147 Page 3 of 12 07/2008

2. Safety instructions

This unit can only be used safely if you read this user manual carefully and strictly follow the instruc-

tions it contains. This user manual is an integral part of this unit and must be available to the person-

nel who operate the unit at all times.

Such staff must be familiarised with the user manual with particular attention being paid to prohibitions

and hazard warnings.

The mains supply connection has to be in accordance with the corresponding regulations (VDE 01000 -

Association of German Electricians). For safety reasons the equipment must be only operated, if a Resid-

ual Current protective Device (RCD) with a release current of 30 mA is connected upstream.

This must be checked by a qualified electrician.

In accordance with the German BGV A3 electrical equipment has to be examined in regular inter-

vals.

The equipment must be set up on a suitable stable, level surface.

Detergents which contain highly flammable substances must not be used. Use only detergents ap-

proved by DENIOS for this unit.

3. Technical data

Dimensions 1010 x 785 x 1140 mm

Net weight 55 kg

Power consumption 1.1 kW

Electrical connection 1/N/PE 230V∼

Pre-fusing 10 A

Work surface height 950 mm

Load capacity 250 kg

Tank LDPE

Maximum fill capacity 100 l

Minimum fill capacity 60 l

Usable work surface 930 x 545 mm

Heater Stainless steel (1.4541) heating element output 1 kW

Level switch Minimum fill level (approx. 60 l)

Operating temperature Set at 41°C in the factory

Pump, flow rate approx. 200 l/h

bio.x C500 135147 Page 4 of 12 07/2008

4. Product description

4.1 Intended use

The bio.x parts cleaning unit is used to clean oil and grease from work pieces in an efficient, environmentally

sustainable way using exclusively cleaning fluids authorised by DENIOS.

Other detergents such as degreasers or alkali cleaning agents must not be used!

Solvents, disinfectants, alkali or acidic fluids, carburettor and diesel fuels or turpentine must not be

poured into the appliance.

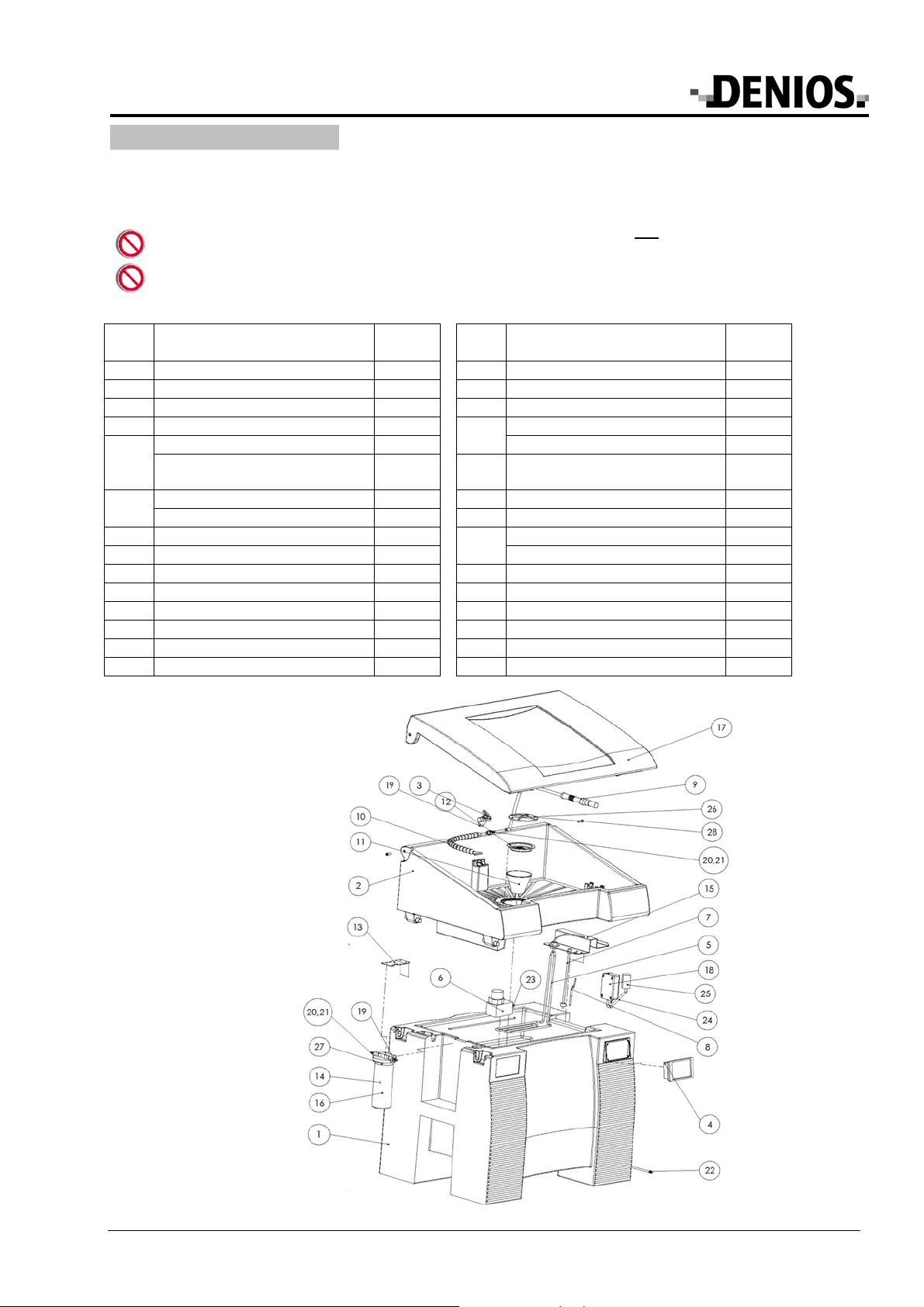

4.2 Layout and how it works

Item Description Mat.

No. Item Description Mat. No.

1 Base with tank - 15 Mounting plate 151683

2 Stand top - 16 Filter insert 135348

3 Ball valve 135279 17 Lid set (optional) 135148

4 Control unit 169678 Aerator 230 V 135310

Heating system 230 V 177340 18 Aerator 115 V 138350

5 Heating system 115 V 177342 19 Screw-on connecting piece

G3/8“

135301

Pump 230 V 134979 20 Connector assembly AD 3/8“ 135304

6 Pump 115 V 134976 21 Tubular pin insert AD 3/8“ 135306

7 Level switch 135274 Power cable 230 V 160517

8 PT 100 temperature sensor 135266 22 Power cable 115 V 142016

9 Brush 135277 23 Screw-on pump 135302

10 Flexible hose with flat nozzle 135289 24 Air hose 175289

11 600 µm filter screen 135256 25 Aerator 138281

12 Coarse filter 135255 26 Brush hose 151100

13 Filter bracket 160677 27 O-ring for filter 150609

14 Filter set (optional) 135149 28 Plug 153098

bio.x C500 135147 Page 5 of 12 07/2008

5. Initial Operation

After removing the packaging, check the unit casing and operating components for any possible damage

caused in transit. If such damage is found, do not connect the unit to the mains. Report damage immediately

to the carrier who delivered the unit and to DENIOS AG at the service number indicated above. The original

packaging should be kept.

Place the unit in a dry, stable location as required.

The floor must be level. If necessary, level out any uneven surfaces with suitable shimming material.

5.1 Electrical connection

The unit is connected to the customer's mains supply via the power cable and plug.

Mains voltage: The voltage of the power source has to comply with the details on the identification place of

the appliance

Warning: The mains supply must be fitted with a residual current protective device in accordance with

DIN VDE (Association of German Electricians) 0100! (See section 2)

5.2 Filling with the cleaning fluid

Two different cleaning fluids can be used in the Part Cleaning Unit C500.

a) Bio-Power cleaning fluid

•Pour 100 l (5 canisters) of Bio-Power cleaning fluid into the tank.

•Connect the unit to the mains. "On" will be shown on the display for 3 seconds. The heating system

switches on automatically. The warming-up process can take up to 2.5 hours, depending on the initial

temperature. The operating temperature is set at 41º C in the factory and cannot be changed. When the

operating temperature is reached, "41" will appear on the display.

The aerator will work continuously after the unit is switched on.

•Once the operating temperature is reached add the additive with the micro-organisms (1 can x 100 g) to

the fluid. The micro-organisms take 24 hours to become active. It is therefore recommended to set up the

unit for operation just before the weekend, for instance.

The parts cleaning unit is then ready for operation.

b) bio.x detergent (ready-for-use solution incl. micro-organisms)

•Pour 100 l (5 canisters) of Bio-Power cleaning fluid into the tank.

•Connect the unit to the mains. "On" will be shown on the display for 3 seconds. The heating system

switches on automatically. The warming-up process can take up to 2.5 hours, depending on the initial

temperature. The operating temperature is set at 41º C in the factory and cannot be changed. When the

operating temperature is reached, "41" will appear on the display.

The parts cleaning unit is then ready for operation.

The aerator will work continuously after the unit is switched on.

The two detergents should not be mixed together as far as this is possible.

Other detergents such as degreasers or alkali cleaning agents must not be used.

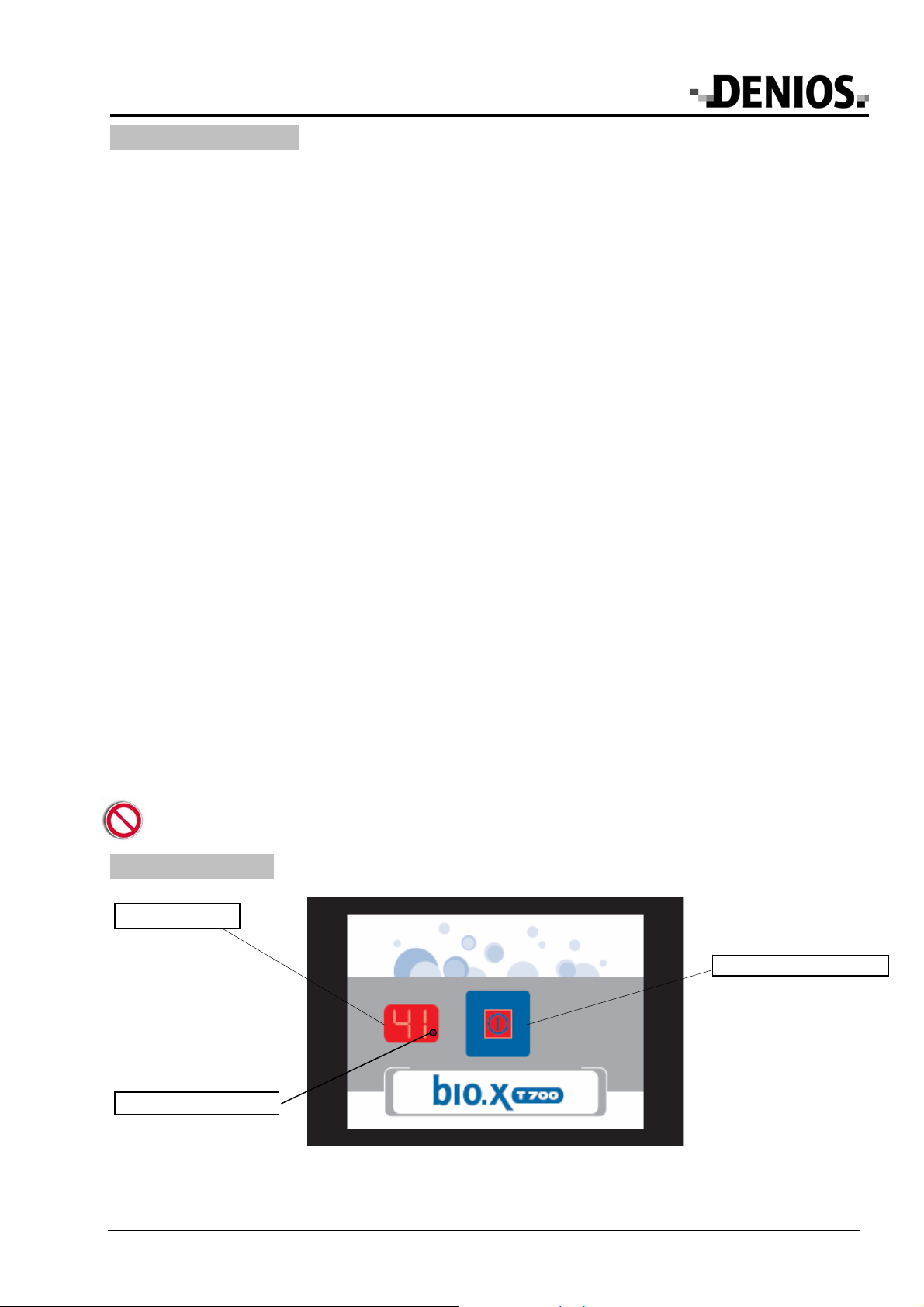

6. Control panel

Multi-control button

Display

LED heater

bio.x C500 135147 Page 6 of 12 07/2008

6.1 Function indicators on the display.

Function Indicator

Warming-up process Display ’41’ flashing, LED heater on

Rising horizontal bars

Operating temperature reached,

heater off

Display ’41’ flashing, LED heater off

Operating temperature reached,

heater on

Display ’41’ flashing, LED heater on

Excess temperature Temperature indicator flashing

when T>41°C

Energy-saving mode Display ‘30’

Fault messages,

see section 6.2 (fault messages)

Display ‘LO’; F1 to F7

7. Operation

Place the parts to be cleaned in the cleaning basin in the bio.x Parts Cleaning Unit.

Do not exceed the maximum load of 250 kg!

Switch on the water pump by pressing the multi-control button on the controls.

Depending on the 3-way ball valve switch setting, parts can be cleaned by:

- rinsing them using the flexible hose and nozzle

- using the brush with detergent running through

Note: When on the middle setting, both outlets are opened.

The dirty detergent runs back into the tank via the middle plug outlet where special micro-organisms remove

oil and grease contaminants.

The water pump automatically switches off after about 60 minutes. The water pump can also be switched on

and off by pressing the multi-control button on the control panel.

Note:

When interrupting work, switch off the water pump only and do not disconnect the unit from the mains, so the

detergent remains warm. The micro-organisms in the detergent require heat and oxygen to degrade the oil

and grease. For this reason, the heating system maintains the temperature of the detergent at 41º C and an

aerator ensures oxygen is permanently fed to the micro-organisms. If the unit is switched off, or it breaks down

for a long period of time, the micro-organisms become inactive.

Energy-saving mode

The unit can be switched to energy-saving mode during downtimes such as night-time, weekends, or com-

pany holidays. To do so, the multi-function button is pressed for 3 seconds. "30" will be shown on the dis-

play. The temperature is maintained at 30º C in energy-saving mode. The micro-organisms remain active at

this temperature and optimum oil and grease degradation is guaranteed.

You can switch from energy-saving mode by just pressing the button again and the unit will heat the deter-

gent to 41º C again. The warm-up stage takes about an hour, depending on the ambient temperature. Once

this temperature is reached and "41" is shown continuously on the display, the unit is ready for operation with

optimum cleaning assured.

bio.x C500 135147 Page 7 of 12 07/2008

8. Maintenance

Warning! Before starting work on the cleaning table fixtures, switch off the electrics and unplug

from the mains! Test the equipment to ensure the power is off!

The unit can be opened at the side for servicing or to fill the tank with fresh detergent. To do so, lift up the

right-hand side of the unit top and prop it up using the bar you can find inside.

Servicing position for unit top

8.1 Fill level

Check the fill level against the markings on the tank wall regularly so you can refill to make up for any losses

through evaporation and removal. If the fill level falls under a minimum of 60 litres (lowest marker line), the

pump and the heating system switch off automatically for safety reasons. In such a case, "LO" is shown on the

display. Re-fill the detergent until the top marker line is reached. The message will disappear once there is

enough detergent in the tank.

8.2 Additive

More additive should be put in every 6 months to replenish the micro-organisms.

After refilling, the detergent must be left to stand for 24 hours so that the micro-organisms can become active.

It is therefore recommended to refill with the additive before a weekend.

8.3 Filter

The washstand is equipped with two filters as standard. A stainless steel perforated filter on the washstand

surface and a synthetic filter for impurities underneath. It is recommended to clean these filters on a daily

basis. To do so, remove the filters from the unit and rinse with water.

8.4 Cleaning fluid

The cleaning fluid has to be replaced if

- there is a significant fall in the cleaning performance

- when checking the fill level there are notable sediment deposits on the floor of the tank

After you have taken out the used cleaning fluid, the tank has to be freed of any sediment residue.

Please follow the same process when inserting the new fluid as for the initial operation.

bio.x C500 135147 Page 8 of 12 07/2008

8.5 Refill items

Accessories Description Item number

Bio-Power cleaning fluid 20-litre canister 175715

Bio-Power cleaning fluid 200-litre drum 169787

Additive for oil and grease degradation 100g can for 100 l detergent 168625

Set (cleaner and additive) for initial filling

and refills

5 x 20-litre canisters of Bio-Power cleaning fluid

100 g can of additives 169789

Cleaning fluid bio.x 20-litre canister 130032

Set for initial filling and refills 5 x 20-litre canisters 130030

8.6 Replacement parts (see also product description page 5)

Description Item number

Hose between filter and tap 167923

Hose between pump and filter 167924

Hose bracket 141247

Hose for aerator 175289

Filter insert for fine filter (optional)

Central support bracket and nylon filter

150043

bio.x C500 135147 Page 9 of 12 07/2008

9. Optional Accessories

Accessories Description Item number

Residual current device

adapter

Adapter for fuse protection for the appliance

Release current: 30 mA,

Protection category: IP44

177335

Protective gloves

(1 pair)

with extra long gauntlet, internally padded with cotton fabric

Length: 640mm

Size: 10

EN388: 4121

Resistance: good protection against detergents, alkali, oils and

greases

163613

Filter The additional fine filter can be installed between the pump and runback. 161718

Filter screen type 454

Fineness 80 μm

Can be used as an alternative for filter screen (12) 161047

Perforated metal insert To protect the work surface of the cleaning table

Makes it possible to work without tilting

152605

Dolly For portable use of the parts cleaning unit 154288

Curved wash brush For cleaning curved edges, prevents signs of fatigue when working for a

long time.

172560

Stainless steel brush To remove heavily crusted dirt from insensitive parts 173926

Wet vacuum cleaner

Type SV 6.16 To completely empty the tank, also suitable for sludge 123224

Fine filter (14)

The optional fine filter, which can be fitted on the left-hand side of the unit, should be checked weekly and

cleaned if necessary. Release the filter cover by turning it anti-clockwise. Remove the filter cartridge and rinse

it thoroughly under running water, or replace it with a new cartridge. Reinsert the cartridge and screw the cas-

ing firmly back into place. Ensure the seal is in the correct position.

A fine filter retrofit should be carried out in accordance with fitting instructions 135149_DE_DE_BA_100.

Draining device

Used detergent can be let straight out via the ball stopcock underneath the tank.

A draining device retrofit should be carried out in accordance with fitting instructions 135151_DE_DE_BA_100.

Lid (17)

Closing the lid reduces loss of detergent due to evaporation, saves on heating costs and prevents the basin

from getting dirty unnecessarily.

Two M8 screw threads are provided on the unit to retrofit a lid. Attach the lid using the socket cap

screws supplied in the accessory kit. Warning: Do not tighten the screws too much as the user must

be able to open the lid easily.

bio.x C500 135147 Page 10 of 12 07/2008

10. Notes regarding disposal

Detergent

The relevant waste code number for a contaminated substance depends on the type of dirt removed and not

on the type of detergent. The applicable waste code number can be found in the European Waste Catalogue.

Contaminated substances can often be disposed of as a water and oil mixture in other hydrous systems.

Unused fluids can be fed into waste water treatment plant while taking into account local regulations regarding

wastewater disposal.

Appliance

According to the electronic and electrical appliance regulations, owners of disused appliances

are legally required to dispose of such items separately. Please help to protect the

environment by not disposing of disused appliances with household waste.

11. Faults

Warning! Before starting work on the cleaning table fixtures, switch off the electrics and unplug from the

mains Test the equipment to ensure the power is off

Display

screen Fault Cause Solution

Detergent cold, heating system not

working

Heating system plug con-

tacts are loose

Check plug contacts to en-

sure connected properly.

F 1 Detergent cold, heating system not

working

1. The pump is not connected

or is faulty;

2. Fuse faulty

3. Temperature limiter has

been triggered

1. Connect heating system;

replace if necessary

2. Replace fuse.

3. Have unit checked, tem-

perature limiter must be ac-

tivated

F 2 Wash pump not working

1. The pump is not connected

or is faulty;

2. Fuse faulty

1. Connect wash pump; re-

place if necessary

2. Replace fuse.

F 3 Aerator not working

1. Aerator is not connected, or

is faulty;

2. Fuse faulty

1. Connect aerator; replace if

necessary

2. Replace fuse.

F 4 Level switch not working Level switch not connected Connect level switch

F 5 Short-circuit in level switch Level switch faulty Replace level switch

F 6 Detergent cold, temperature sen-

sor not working

Temperature sensor not

connected

Connect temperature sen-

sor

F 7 Short circuit in temperature sensor Temperature sensor faulty Replace temperature sen-

sor

LO Heating system and wash pump

not working

1. Fill level fallen below mini-

mum level

2. Float switch dirty and in the

wrong position

1. Refill with detergent

2. Clean the float-switch

mechanism

Overheating

If the maximum permitted temperature (41°C) is exceeded, the current temperature will be shown as a flashing

warning message on the display. If such a case arises, switch off the parts cleaner immediately. Then check

the temperature sensor PT 100 is in the correct position (3).

The equipment is fitted with a temperature limiter to prevent damage from overheating. This switches the heat-

ing system off if the maximum temperature is exceeded.

If overheating is not caused by the temperature sensor being in the wrong position, a service technician must

be called in to find the cause and make necessary repairs.

bio.x C500 135147 Page 11 of 12 07/2008

12. Connection Diagram

Thermal circuit breaker

Heater

Pump

A

ir pump

Level

Foot switch

brown

black

blue

bio.x C500 135147 Page 12 of 12 07/2008

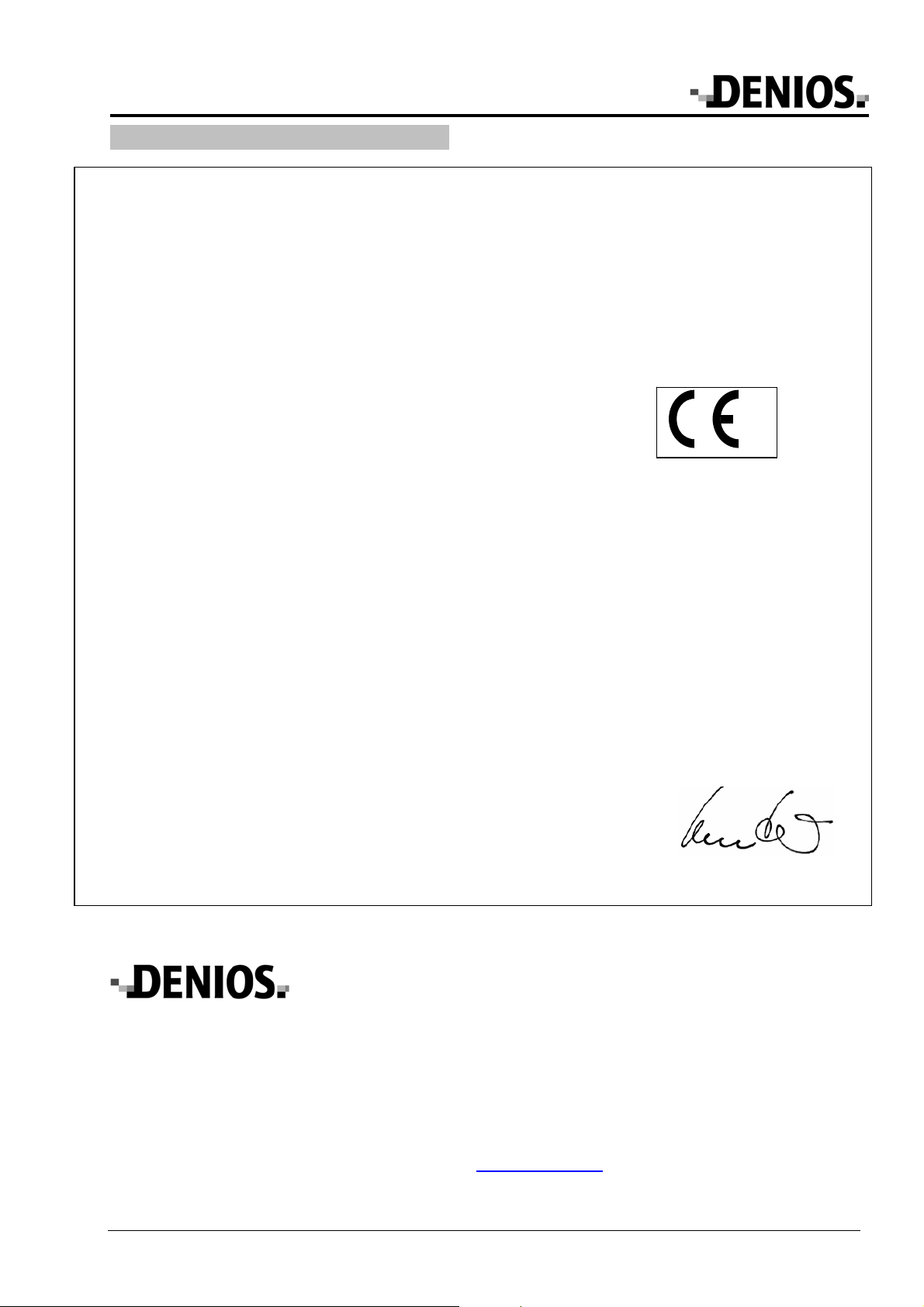

13. EC Declaration of Conformity

EC Declaration of Conformity

For the purpose of the EC Machinery Directive 98/37/EC, Annex II A

Herewith we, the DENIOS AG, Dehmer Straße 58-66, 32549 Bad Oeynhausen, declare that the design

of our product:

Cleaning Table bio.x

complies with the following relevant provisions:

;EC Machinery Directive 98/37/EC

;EC Low Voltage Directive 73/23/EC

;EC Electromagnetic Compatibility Directive 93/68/EC

Applied harmonised standards:

;EN 349

;EN 60 204-1

;EN 12100, -1, -2

to which our declaration refers.

This declaration becomes invalid in the case of incorrect use and product modifications which were

not agreed with the manufacturer.

Bad Oeynhausen 11.09.2007 ..............................................

Theodor Breucker

- - Board of Directors -

DENIOS AG

Dehmer Straße 58-66

32549 Bad Oeynhausen

Tel.: +49 (0)5731 7 53 – 0

Fax: +49 (0)5731 7 53 – 197

You`ll find your local partner on our InterNet side www.denios.com

Table of contents

Other Denios Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

e.ziclean

e.ziclean hobot 388 manual

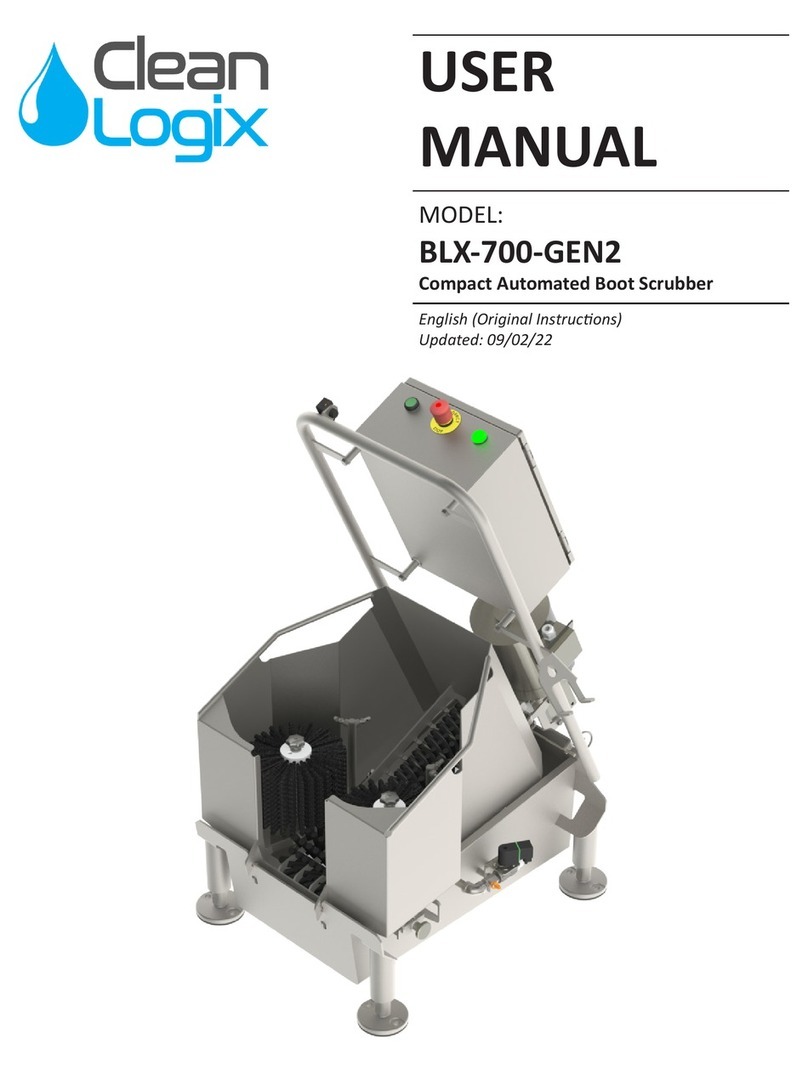

Clean Logix

Clean Logix ALX-PRO user manual

Clean Logix

Clean Logix BLX-700-GEN2 user manual

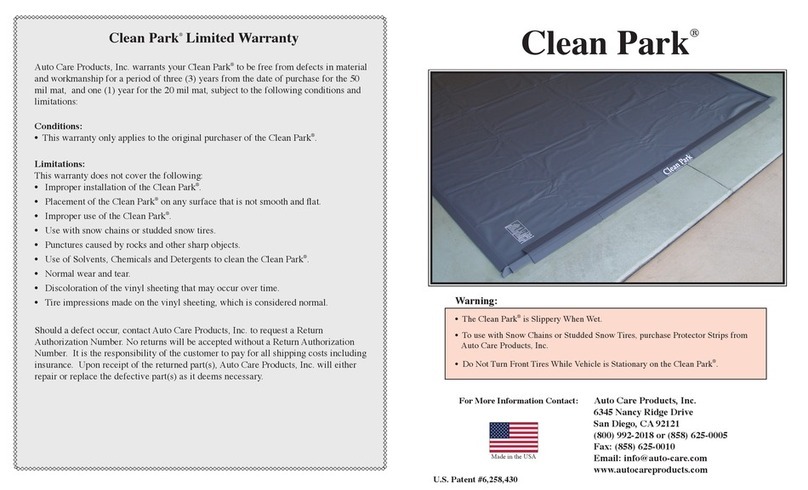

Auto Care Products

Auto Care Products Clean Park quick start guide

Streamline

Streamline STREAMLFO SF-TR25L-000 instruction manual

Parkside

Parkside 102800 original operation manual

Roller's

Roller's Metro 22 operating instructions

Elcometer

Elcometer Sagola Classic P1 instruction manual

Bissell

Bissell CrossWave Cordless 2551 Series Battery removal instructions

Electric Eel

Electric Eel S Operator's manual

Magnum

Magnum XP user manual

Bluerock Tools

Bluerock Tools SDS200 Operational manual