Sontex Superstatic 749 User manual

Instruction for Use

Superstatic 749

2Instruction for use | Superstatic 749

Table of contents

1. Notice on this document 3

1.1 Scope of validity 3

1.2 Target groups 3

1.3 Storage of document 3

1.4 Further information 3

1.5 Symbols 4

2. Security 5

2.1 Personel qualication 5

2.2 Intended use 5

3. Scope of delivery, Transport, Storage, Cleaning 7

4. Superstatic 749 thermal energy meter 8

4.1 Dimension qp0.6m3/h L = 110 mm 8

4.2 Dimension qp1.5 m3/h L = 130 & 190 mm 8

4.3 Dimension qp2.5m3/h L= 130 & 190 mm 9

5. Installation 10

5.1 Mounting of the calculator for a cooling application 10

5.2 Wall mounting of the calculator 11

5.3 Mounting of temperature sensors 12

5.4 Sensor pockets overview 13

5.5 Direct mounting in a T tube 13

5.6 Fitting temperature sensor for cooling application 14

6. Installation 14

6.1 Superstatic 749 14

6.2 Mounting of the for the pulse input function 14

6.3 Mounting cable for the pulse output function 14

7. Commissioning 15

7.1 Commissioning from the storage mode 15

8. Error codes 16

9. Display 16

9.1 Display sequence 17

9.2 Detailled display sequences 17

10. Communication 18

10.1 SONTEX Radio 19

10.2 wM-Bus Radio / OMS 19

10.3 LoRaWAN 19

10.4 Powered M-Bus 19

11. Security seals 20

12. Technical data 21

12.1 Superstatic 749 21

12.2 Pressure loss curve 22

12.3 General technical data

13. Declaration of conformity 23

3

Instruction for use | Superstatic 749

1. Notes to this document

This manual provides all the information required for the correct use of the equipment: From

product identication, installation and commissioning to troubleshooting, maintenance and

disposal.

1.1 Scope of validity

This documentation is valid for the Sontex Superstatic 749.

The case of specic details for Superstatic 749 will be explained as a note in the current

manual's different sections.

1.2 Target groups

This documentation is intended for the system operator and the installer.

1.3 Storage of the document

The system operator must ensure that this documentation is accessible to the responsible

persons at all times. If the original document is lost, you can download an up-to-date version

of this document from our Website

https://sontex.ch/en/applications/building-automation/#superstatic-789-2

1.4 Further information

Links to further information can be found at www.sontex.ch.

4Instruction for use | Superstatic 749

1.5 Symbols

Symbol Signicance

DANGER!

Warning, the non-observance of which leads directly to death or

serious injury.

WARNING

WARNING!

Warning, the non-observance of which may result in death or serious

injury.

CAUTION

CAUTION!

Warning, the non-observance of which may result in minor or

moderate injury.

NOTICE NOTICE!

Warning, the non-observance of which may result in damage to

property.

Reference

Information that is important for a specic topic or goal, but not

relevant to security.

Documentation

Reference to documentation.

?Help

Help in case of problems.

Visual check

Check that the item is in order.

CE and UKCA-Marking

The device meets the requirements of the European

directives and of the UK Conformity Assessment.

Disposal

This symbol indicates that electrical and electronic equipment must

be disposed of separately. Do not dispose of the water meter with

household waste.

5

Instruction for use | Superstatic 749

2. Security

Improper installation, pressure tests, modications or incorrect

operation can cause personal injury and damage to property.

Pressure surges in the pipeline can damage the meter!

Existing air pockets falsify the measuring result.

If the seal is damaged or removed, the compact thermal energy meter is no longer approved

for legal metering or legal measurement.

Before installation, check compact thermal energy meter for transport damage.

Do not drop, never hold on to the protective cover of the counter.

If the compact thermal energy meter has been dropped, it must not be installed again.

Only use suitable lubricants for seals.

Compact thermal energy meters may only be installed after a pressure test.

Compact thermal energy meter may only be installed in pipelines that have already been

leak-tested, rinsed and must be well vented before commissioning.

2.1 Personnel qualication

The compact thermal energy meter may only be installed or replaced by qualied personnel for

sanitary, heating and air-conditioning technology.

2.2 Intended use

WARNING

NOTICE

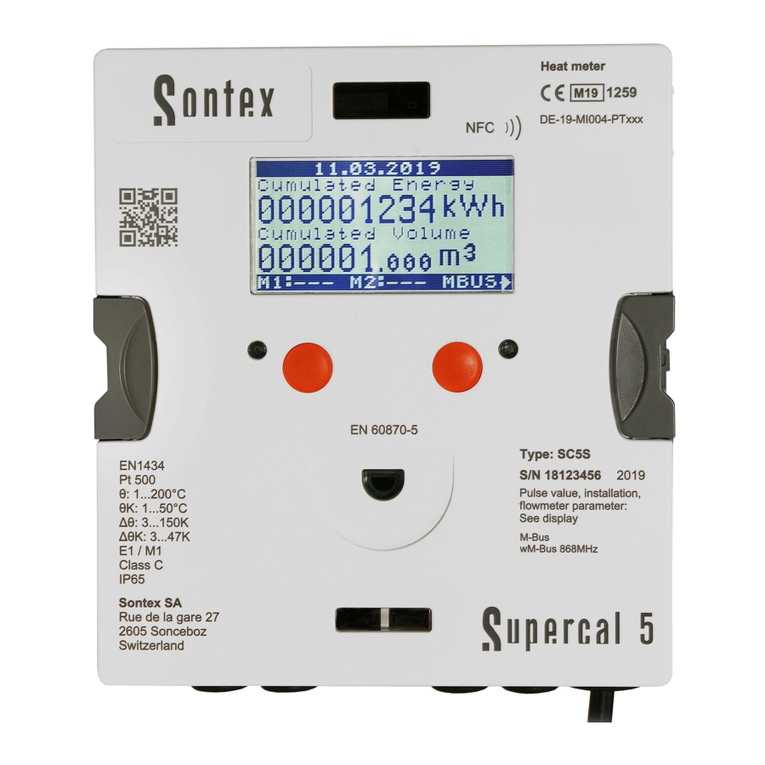

The compact thermal energy meter Superstatic 749 is a precision

measuring instrument approved for individual metering of heating

systems and must be handled with care.

The Superstatic 749 is available in a heating or cooling or heating/

cooling version and determines the thermal and/or cold energy

exchanged by a heat-bearing uid in a heat exchanger circuit.

The Superstatic 749 complies with the requirements of the European

Directive MID 2014/32/EU modules B and D and of the standard EN

1434 class 2.

The thermal energy meter must be used within the conditions indi-

cated on the meter; the metrological seals have to stay intact.

In the event non compliancy to these instructions, the device may

be destroy and the manufacturer declines all liability, warranty and

guarantee for correct metrology.

The manufacturer will not be liable in the event of any modication

of the metrological data or of the measurement parameters if any

of manu-facturer’s seals is damaged. The seals can only be applied

by authorised people in conformity to national legislation related to

legal metrology.

Use only the accessories provided by the manufacturer.

For cleaning, a moist cloth is sufcient. Do not use solvents.

Do not shorten the cable between the ow meter and the calculator

and the cables for the temperature sensors or modify them in any

way whatsoever.

6Instruction for use | Superstatic 749

Before installation

Check the installation data and compare them with the specic

characteristics of the thermal energy meter.

The rules for installation and those relating to the project must be

respected.

The environmental temperature range for the energy meter

is 5...55 ºC.

Make sure that the meter and the labels can be read easily.

All connections must be made at a minimum distance of 300 mm

from high frequency or high voltage cables. Avoid thermal

radiation and interfering electrical elds near the calculator and

connection cable.

As a rule, the calculator must be installed at a distance from

pipes carrying refrigerating uids.

Action must be taken to ensure that no condensation water can

penetrate inside the calculator.

If there is any risk of vibrations, the calculator must be installed

separately on the wall.

If the temperature of the uid within the ow meter regularly

reaches 90°C, the calculator must be installed separately from the

ow meter.

It is advisable to drain the installation before tting the ow

meter. This will allow that any foreign body is withdrawn from the

pipe.

Security with lithium batteries

3V lithium batteries are used. Certain security rules must be respected:

the replacement of batteries or to add a second battery is not allowed.

During recycling, the following points must be respected:

Do not recharge or short-circuit, protect against humidity, do not

expose to heat, do not throw batteries in re, keep out of reach of

children.

NOTICE

WARNING

7

Instruction for use | Superstatic 749

3. Scope of delivery

Transport

Storage

Cleaning

8Instruction for use | Superstatic 749

4. Superstatic 749 thermal energy meter

4.1 Dimension qp0.6 m3/h L = 110 mm

86,8

110,2

L

52

78

D

105

87.5

35.5

5357.2

L

86,8

89

110,2

78

D

110.5

35.5

57.2 53

54.49

90

4.2 Dimension qp1.5 m3/h L = 130 or 190 mm

9

Instruction for use | Superstatic 749

4. Superstatic 749 thermal energy meter

4.3 Dimension qp2.5 m3/h L = 130 or 190 mm

L

D

108

35.5

89

78

110.2

54.6 55.6

52

87.5

10 Instruction for use | Superstatic 749

5. Installation

The prescriptions related in the standard EN1434-6 must be respected when the

Supestatic 749 is installed.

In the standard version, the calculator is parameterised by default for installation on the “cold”

pipe side. Installation on the “hot” pipe side must be specied with the order.

Depending on version and use (heat and/or cooling meter), the energy meter must be tted on

the “cold” or “hot” pipe side of the installa-tion in compliance with the chosen conguration. If

the device was ordered with the conguration option, some parameters can be changed using

the “Cong” menu during commissioning.

In a same installation, mixed mounting positions (horizontal and vertical) can be realized.

Place the ow meter correctly according to the direction of the uid (an arrow can be seen

on the ow meter).

Horizontal mounting with the integrator facing downwards is not permitted. Also avoid tting in

a position which may cause an air bubble to build up inside the mechanical meter.

The energy meter must be tted between two shutoff valves. The ow meter must be installed

ahead of any monitoring valves so as to avoid any potentially interfering inuence. Waterproof

will be checked at the various mounting points.

The heat conveying liquid must be equivalent to water without any additives according to

standard FW510 of the AGFW (German District Heating Association). If additives are added to the

water, the user must ensure the compatibility of the materials used in the thermal energy meter

which are in contact with these additives.

5.1 Mounting of the calculator for a cooling application

Only the ow meter can be fully isolated. Separate the calculator from the ow meter and x

using the wall support aid.

It is recommended to separate the calculator from the ow meter and installed at a sufcient

distance from the ow meter if:

- The meter has to be installed in a conned space

- The meter is in connection with mounting in condensing environments

- To prolong the battery life time

The pipes are generally free from air before the installation is brought into service. Follow the

insulation instructions for cooling installations. Final commissioning must be performed and

documented.

Horizontal mounting position:

The sensor head MUST be placed to the side

+/- 45° in relation to the pipe axis to avoid

inuences of air inclusions (top) or dirt (bottom).

Vertical mounting position:

Mounting in riser or down pipes possible.

After mounting and before commissioning purge system > 10 min at qp to

avoid air bubbles.

11

Instruction for use | Superstatic 749

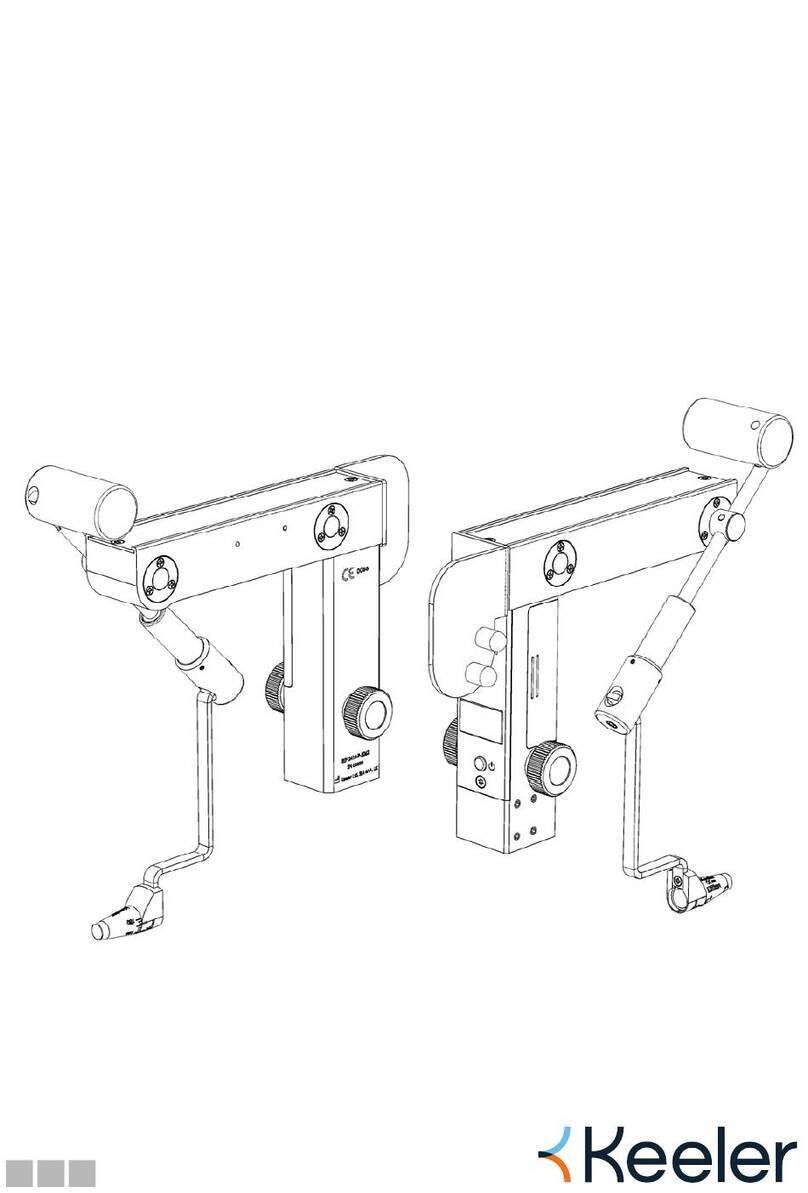

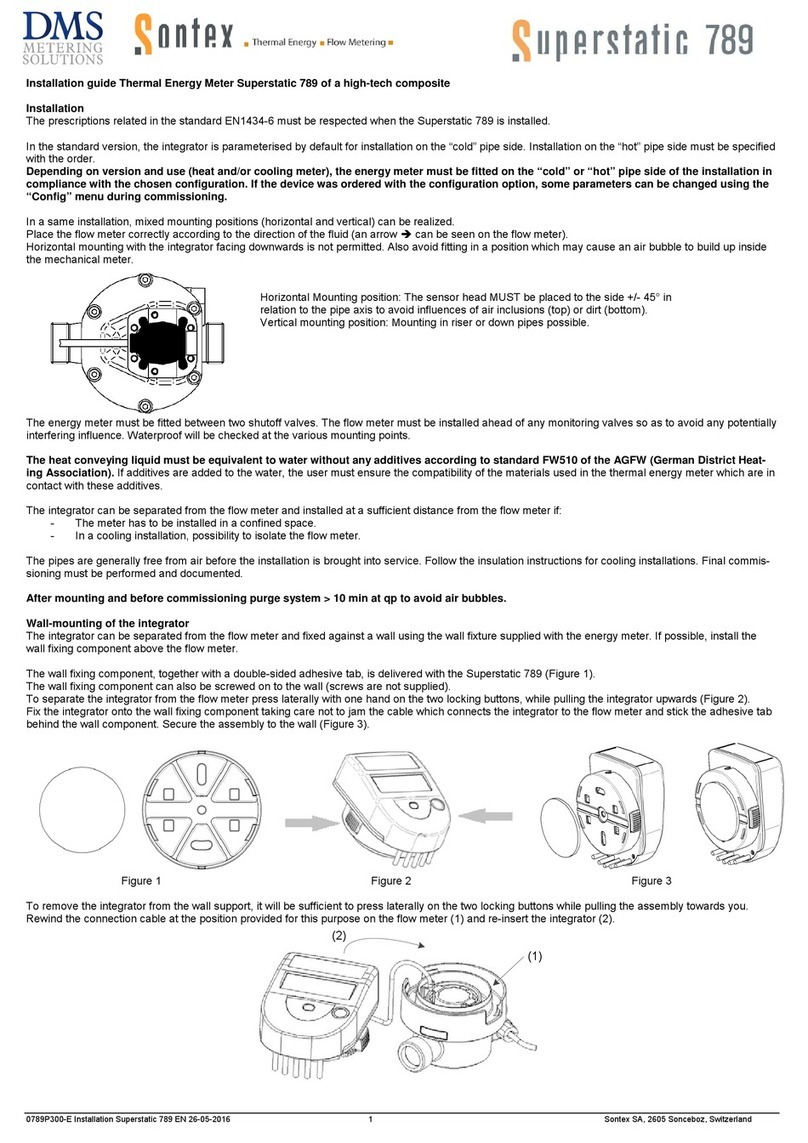

5.2 Wall mounting of the calculator

The calculator can be separated from the ow meter and xed against a wall using the wall

xing component, together with a double-sided adhesive tab delivered with the Superstatic 749

(Figure 1). If possible, install the wall xing component above the ow meter.

The wall xing component can also be screwed on to the wall (screws are not supplied).

To separate the calculator from the ow meter press laterally with one hand on the two locking

buttons, while pulling the calculator upwards (Figure 2).

Fix the calculator onto the wall xing component taking care not to jam the cable which

connects the calculator to the ow meter and stick the adhesive tab behind the wall component.

Secure the assembly to the wall (Figure 3).

Figure 1 Figure 2 Figure 3

To remove the calculator from the wall support, it will be sufcient to press laterally on the two

locking buttons while pulling the assembly towards you.

Rewind the connection cable at the position provided for this purpose on the ow meter (1) and

reinsert the calculator (2).

1

2

12 Instruction for use | Superstatic 749

5.3 Mounting of the temperature sensors

The temperature sensor in the ow meter has no black frame marking on the label.

The temperature sensor with the black frame mark on the label indicates that the sensor must

be mounted in the pipe “opposite” to the Superstatic 749.

Example: If the ow meter is installed on the warm side (Hot Pipe), the temperature sensor with

the black frame mark will be mounted in the cold side (Cold Pipe).

The Superstatic 749 is delivered with temperature sensors having a cable length of 1.5 m.

The temperature sensors form a sub-assembly with the calculator. The temperature sensor

cables must be neither shortened nor lengthened.

The temperatures of use displayed on the label must be respected.

A temperature sensor may be tted directly in the Superstatic 749 ow meter. The temperature

sensors will preferably be tted directly, in other words one temperature sensor will be tted in

the ow meter while the other sensor will be installed on the other side of the heat exchanging

circuit.

Note: The temperature sensors will be xed with a plastic nut. This plastic nut consists of two

half-nuts held together by a rubber band. If the rubber band is removed from the nut, the two

nut halves will no longer be held together on the temperature sensor and one or both nut halves

may separate from the temperature sensor.

1. Remove the O-ring from the temperature sensor. Be careful not to remove the rubber band

(symbolized by the letter "E" on the drawing) from the nut as it may separate into two parts

and fall on the oor.

2. Fit the O-ring on the mounting template pin.

3. Insert the O-ring by rotating it using the tting template in the position provided for the ball valve.

4. Position the O-ring denitively with the other at end of the tting tem-plate.

5. Insert the temperature sensor with the two half-nuts in the thread M10x1 of the ball valve

and screw down by hand as far as it will go (maximum tightening torque of 1 Nm).

Note: The mounting template pin is not included in the delivery and can be ordered separately

(Article number: 0460P348).

When sensor pockets are employed, these must be used specically for the two temperature

sensors and must correspond to the list set out below.

Asymmetrical mounting is also possible. In that case the temperature sensor having a cable

marked with black frame will be tted in the other side of the heat exchanging circuit in a sensor

pocket dened according to the table set out below.

For applications with non-symmetrical integrated temperature sensor pair restricted rated

operating conditions are to be in accordance with the lower limit of the ow value and the lower

limit of the temperature difference: qi ≥ 200 l/h at ∆Tmin = 3K or qi ≥ 60 l/h at ∆Tmin ≥ 6 K.

Make sure that the sensors are mounted until they stall with the bottom of the sensor pocket.

13

Instruction for use | Superstatic 749

Temperature sensors Versions Pocket Art.-N° Material Temperature range

Ø 5x31 mm Pt1000 M10x1 0460A212 Brass 0…100 °C

Ø 5x 31 mm Pt1000 G3/8" 0460A213 Brass 0…100 °C

Ø 5x 31 mm Pt1000 G1/2" 0460A214 Brass 0…100 °C

Ø 5.2x 31 mm Pt1000 M10x1 0460A215 Brass 0…100 °C

Ø 5.2x 31 mm Pt1000 G3/8" 0460A216 Brass 0…100 °C

Ø 5.2x 31 mm Pt1000 G1/2" 0460A217 Brass 0…100 °C

Ø 6x 31 mm Pt1000 M10x1 0460A201 Brass 0…100 °C

Sensor pockets for Universal temperature sensors (with composite tting)

Ø 5 Pt1000 M10x1 SCTW4A1 Brass 0…100 °C

Ø 5 Pt1000 G3/8’’ SCTW4A2 Brass 0…100 °C

Ø 5 Pt1000 G1/2’’ SCTW4A3 Brass 0…100 °C

Ø 5.2 Pt1000 M10x1 SCTW4A4 Brass 0…100 °C

Ø 5.2 Pt1000 G3/8’’ SCTW4A5 Brass 0…100 °C

Ø 5.2 Pt1000 G1/2’’ SCTW4A6 Brass 0…100 °C

Ø 6 Pt1000 G1/2’’ SCTW1A1 Brass 0…100 °C

The temperature sensor is on the same level and perpendicular to

the pipe axis (DN15, DN20)

5.4 Sensor pocket overview

5.5 Direct mounting in a T tube

5.6 Fitting temperature sensors for refrigeration apllications

Insulation will only be provided as far as the xing screw

The temperature sensor xing screw must not be covered by any

kind of insulation. This likewise applies if the sensor is xed directly

in the ow meter.

NOTICE

14 Instruction for use | Superstatic 749

6. Installation of the thermal energy meter

6.1 Superstatic 749

To install the Superstatic 749, the following steps must be respected:

Flush out the installation pipes carefully in compliance with the

DIN/EN standard specication.

Close the shutoff valves before and behind the meter.

Open the drainage valve to reduce the pressure and discharge the

water contained in the pipe between the two shutoff valves.

Consider the direction of ow circulation. Check the ow direction

with the arrow guring on the ow meter.

Place a gasket on each side of the ow meter. Only use appropriate

new gaskets.

Make sure that the gaskets are carefully positioned in relation to the

water pipe and ow meter unions.

Tighten the xing nuts rmly by hand. Then tighten up to the

mechanical end stop using a mounting tool.

Install the temperature sensor.

Turn the display into the desired position for reading.

Check the waterproof of the meter placed under pressure.

Seal the ow meter and the temperature sensors.

6.2 Mounting cable for the pulse input function

The pulse inputs are built with SELV circuits (Safety Extra Low Voltage) and must be only

connected with SELV circuits. The electrical characteristics are displayed on page 22.

6.3 Mounting cable for the pulse output function

The pulse outputs are built with SELV circuits (Safety Extra Low Voltage) and must be only

connected with SELV circuits. The electrical characteristics are displayed on page 22.

15

Instruction for use | Superstatic 749

7.1 Commissioning from the storage mode

7. Commissioning

Ex works the ow meter can be in the storage mode, that is to say, it does not count and the

display shows "Disabled".

The storage mode is active as long as the meter is not sealed "Seal".

In the storage mode, the transition to "Cong" menu is made with a short press on the orange

navigation button. Another short press gives access to the whole sequence of the "Normal" mode

DISABLED

PUSH

SEAL

Long

pression

Normal

Mode

Automatic

change

ConFiG

Short

pression PUSH

Cold.pipe

Pression

longue

PUSH

CHANGE

Long

pression

Automatic

change

000000.01 MWh

Short

pression

PUSH

CHANGE

Long

pression

Automatic

change

000000.01 m3

Short

pression

PUSH

CHANGE

Long

pression

Automatic

change

Short

pression

Cold.pipe

Short

pression 001234.56 MWh

EnergyServiceCounting OFF

Short

pression

//

Short

Pression

In the "Cong" menu (optionally available), a long press will change the settings below:

Flow meter mounting position in the installation. Hot (HOT PIPE) or cold side (COLD PIPE).

Energy unit (0.1kWh, 1 kWh, 0.001MWh, 0.01MWh, 0.001GJ and 0.01GJ).

Volume unit (0.01m3and 0.001m3).

In the "Cong" menu any inaction (i.e. with no pressure on the navigation button) lasting 3 minutes causes the automatic exit

and returns to "Disabled". If changes were made in the "Cong" menu, the data remain stored

16 Instruction for use | Superstatic 749

When "Disabled" is displayed, a long press on the navigation button validates the parameters of

the ow meter. The indication "Seal" ashes four times on the display and it changes to "Normal"

counting mode.

From that moment, the storage mode ("Disabled" and "Cong") is not accessible anymore.

NOTICE

Checking operation

Make sure that the measurements indicated by the meter are coherent using the orange button

which you will nd on the meter. The following values can be shown on the LCD display: ow,

power, hot and cold temperatures. The communication arrows permit display of the controls

(inputs) and responses of the instrument (outputs). All the display parameters will be used to

check and adjust the installation. In particular, you must make sure that the maximum ow rate

of the installation does not exceed the maximum ow rate authorised for the meter. To complete

the functional analysis, the commissioning protocol can be saved using the Prog7x9 software via

the optical interface.

8. Error codes

The Superstatic 749 calculator displays an error message with the 3 letters “Err” and a code. If

several errors occur at the same time, the different codes are added together.

The error is displayed in the rst position of the display menu. It will still be possible to select

all the other display menus by pressing the navigation button. If the navigation button is no

longer pressed for a period of 3 minutes, the error code will automatically appear again in the

rst position of a display menu.

Display of an error automatically disappears when the error is no longer present.

Err 1: Flow higher than 1.2 x qs or defective hydraulic sensor.

Err 2: Measured temperature outside the homologated range or temperature sensor

defective.

To make sure that the temperature sensors have not been cross during assembly, the temper-

ature difference between the outward and return temperatures can be checked on the display.

Depending on the use (thermal or refrigerating), this temperature difference may be either

positive or negative.

9. Display

The Superstatic 749 LCD display has been designed to be large enough and perfectly readable

by the user.

17

Instruction for use | Superstatic 749

9.1 Display sequence

To display general data on the calculator, several windows have been created in the form of

menu/sub-menu functions. Depending on the chosen version of the energy meter, some menus

may be added.

The “Energy” window of the main menu is the basic display.

The navigation button enables the user to change from one menu to another and to access the

different positions within a menu.

Short pressure on the navigation button permits transition from one menu to another or

continuation to the next display while remaining in the same menu.

Long pressure (> 2 seconds) on the navigation button gives access to sub-menu within a menu or

enables the “Energy” window to be dis-played from within a menu.

After 3 minutes, the display automatically reverts to the basic “Energy” window.

9.2 Detailed display sequences in Mormal Mode

Legende

Légende

Legend

Standardanzeige

Position standard

Standard indication

Wird nur angezeigt wenn die Optionverfügbar ist

Affiché seulement si l’option est disponible

Only indicated if the option is available

Wert Monat -2

Valeur au mois -2

Value month -2

Letzter Monastwert

Valeur au mois dernier

Last monthly value

Wert Monat -3

Valeur au mois -3

Value month -3

Wert Monat -4

Valeur au mois -4

Value month -4

Wert Monat -5

Valeur au mois -5

Value month -5

Wert Monat -18

Valeur au mois -18

Value month -18

Kumulierte Wert

Valeur cumulée

Cumulated value

IN1

Zusatzzähler 1

Compteur additionel 1

Additional meter 1

m3

m3

m3

m3

m3

m3

IN1

IN1

IN1

IN1

IN1

m3

IN1

Kurzes Drücken / Pression courte / Short pression on button

Langes Drücken / Pression longue / Long pression on button

Service

K

kW

h

m3/h

Zusatzzähler 2

Compteur additionel 2

Additional meter 2

IN2 m3

m3

m3

m3

m3

m3

IN2

IN2

IN2

IN2

IN2

m3

IN2

Einbauort Durchflusssensor

Position de montage débitmètre

Flowmeter mounting position

Betriebsstunden

Durée d’utilisation

Running hours

Aktuelle Zeit

Heure actuelle

Time of device

Aktuelles Datum

Date actuelle

Date of device

Hoche Temperatur

Température haute

High temperature

Tiefe Temperatur

Température basse

Low temperature

Temperaturdifferenz

Différence température

Delta temperature

Aktuelle Durchfluss

Débit actuel

Actual flow

Aktuelle Leistung

Puissance actuelle

Actual power

Segmenttest

Test des segments

Test LCD

Identifikationsnummer

Numéro d’identification

Identification number

M-Bus Adresse

Adresse M-Bus

M-Bus address

Radio Adresse

Adresse Radio

Radio address

Firmwareversion

Version Firmware

Firmware Version

Energie Tariff 1 Monat -2

Energie Tariff 1 au mois -2

Energy Tariff 1 month -2

Letzter Monastwert Energie Tariff 1

Energie au mois dernier Tariff 1

Last monthly value energy Tariff 1

Energie Tariff 1 Monat -3

Energie Tariff 1 au mois -3

Energy Tariff 1month -3

Energie Tariff 1 Monat -4

Energie Tariff 1 au mois -4

Energy Tariff 1 month -4

Energie Tariff 1 Monat -5

Energie Tariff 1 au mois -5

Energy Tariff 1 month -5

Energie Tariff 1 Monat -18

Energie Tariff 1 au mois -18

Energy Tariff 1 month -18

Kumulierte Energie Tariff 1

Energie cumuléeTariff 1

Cumulated energy Tariff 1 MWh

Energie Tariff 1

Energie Tariff 1

Energy tariff 1

MWh

MWh

MWh

MWh

MWh

MWh

MWh

MWh

MWh

MWh

MWh

MWh

MWh

Energie

Energie

Energy

Energie Monat -2

Energie au mois -2

Energy month -2

Letzter Monastwert Energie

Energie au mois dernier

Last monthly value energy

Energie Monat -3

Energie au mois -3

Energy month -3

Energie Monat -4

Energie au mois -4

Energy month -4

Energie Monat -5

Energie au mois -5

Energy month -5

Energie Monat -18

Energie au mois -18

Energy month -18

Kumulierte Energie

Energie cumulée

Cumulated energy

Datum Stichtag

Jour de relève

Date set day

Energie Stichtag

Energie à la relève

Energy set day

Volumen Stichtag

Volume à la relève

Volume set day

Energie Tariff 1 Stichtag

Energie Tarif 1 à la relève

Energy Tariff 1 set day

Impulseingang 1 Stichtag

Val. Cumul. 1 à la relève

Pulse input 1 set day

Impulseingang 2 Stichtag

Val. Cumul. 2 à la relève

Pulse input 2 set day

Stichtag

Jour de relève

Set Day

MWh

MWh

m3

m3

m3

IN2

IN1

Volumen Monat -2

Volume au mois -2

Volume month -2

Letzter Monastwert Volumen

Volume au mois dernier

Last monthly value volume

Volumen Monat -3

Volume au mois -3

Volume month -3

Volumen Monat -4

Volume au mois -4

Volume month -4

Volumen Monat -5

Volume au mois -5

Volume month -5

Volumen Monat -18

Volume au mois -18

Volume month -18

Kumulierte Volumen

Volume cumulé

Cumulated volume m3

Volumen

Volume

Volume

m3

m3

m3

m3

m3

m3

LoRaWAN

LoRaWAN

Join now

Join maintenant

Start Join jetzt

Join delayed

Join différé

Join mit Verzögerung

Menu LCD 739 UM 2020.07.09 smi

....and continues......

if available

18 Instruction for use | Superstatic 749

10. Communication interfaces and options

The communication interfaces are installed and preset in the factory. When ordering, you must

specify the interface type: remote powered M-Bus or Radio SONTEX, Wireless M-Bus (OMS),

LoRaWAN, or pulse outputs.

Pulse input function

The Superstatic 749 offers the possibility of integrating up to two further pulse input from other

meters, for instance a hot water and a cold water meter.

The value of the pulse factor is programmable via the Prog7x9 software. By default, the pulse

factor will be 1 Pulse/Unit for each pulse input.

The meter data are aggregated separately in totalizers and can be shown on the display as IN1

and IN2; they can also be transferred via the communication interface which is installed in the

calculator. The Superstatic 749 is delivered with a cable length of 1.5 m for the input pulse sig-

nals.

Pulse output function

If ordered the Superstatic 749 offers the possibility of integrating two open collectors pulse

outputs which can represent hot energy, cold energy or volume.

Energy Meter – heating or cooling application:

- Output S1 = Heating or cooling energy

- Output S2 = Volume

Mixed application heating and cooling:

- Output S1 = Heating energy

- Output S2 = Cooling energy

Whenever the smallest energy unit (hot or/and cold) or volume displayed on the screen is

incremented, 1 pulse will be transmitted on the corresponding output cable S1/S2.

Example for energy:

Display 12345678 kWh ==> output pulse value for energy = 1 kWh / pulse

Display 12345,678 MWh ==> output pulse value for energy = 0.001 MWh / pulse

Display 123456,78 GJ ==> output pulse value for energy = 0.01 GJ / pulse

Example for volume:

Display 12345,678 m3==> output pulse value for volume = 0.001 m3/ pulse

Display 123456,78 m3==> output pulse value for volume = 0.01 m3/ pulse

The Superstatic 749 is supplied with a cable length of 1.5 m for pulse outputs.

Electrical characteristics of the pulse outputs: open collector 1 Hz 500 ms.

Optical interface

The optical interface is available on every Superstatic 749.

Communication between the Prog7x9 software and Superstatic 749 can be done by means of an

optical coupler.

The Prog7x9 software is mainly used to congure the non-metrological parameters and for

readout.

The transmission speed is set at 2400 bauds and cannot be changed.

We recommend the use of optical couplers supplied by: www.petechnik.de

Should communication problems occur, please refer to the document User Guide Prog7x9

(integrated as PDF in the software).

For the optical probe listed below, we have noted the lters needed to permit correct

communication with Prog7x9 software:

Optical probe Filter

P+E Technik : "K1-98" or "K1-06" No lter

P+E Technik : "K01-USB" No lter

19

Instruction for use | Superstatic 749

10.1 SONTEX Radio

10.2 wM-Bus Radio / OMS

10.3 LoRaWAN®

The SONTEX Radio communication interface supports communication between all Sontex prod-

ucts having this interface. It must be specied when ordering. The radio module will then be

installed and congured in the factory.

The SONTEX Radio interfaces make use of a bidirectional radio technology which is a highly

reliable and performant solution for a remote metering system (xed or mobile). The technology

employed is based on Radian 0 protocol and works at a frequency of 433.82 MHz.

The products tted with this Radio module can be accessed 365 days a year from 06:00 to 20:00.

The radio address is displayed in the Service menu if it corresponds to the serial number of the

Superstatic 749.

Technical data

Bidirectional communication; FSK Modulation; Frequency 433.82 MHz; Radian 0 radio protocol,

transmission power: 10 dBm (10 mW)

The life cycle is calculated for normal metering. Factors such as: the environmental temperature

during use, the number of readings taken etc. inuence the battery service life.

The Wireless M-Bus module is used to transfer data according to the wM-Bus (EN13757-4) radio

communication protocol and in compliance with the OMS (Open Metering System) Release V4.

To have this interface provided in the Superstatic 749, it is necessary to specify when ordering.

The Wireless M-bus module will be installed and congured at the factory. A specic notice will

be added to the standard documentation.

Technical data

Unidirectional communication, Frequency 868.95 MHz, Mode 5 or 7, Radio telegram C1 or T1,

transmission power: 14 dBm (25 mW)

A LoRa enabled device can be identied as such if the product label is marked “LoRa”. First of all,

the LoRa device must be registered on a LoRaWAN network.

The registration of the device on the network will be done by a JOIN request that can be

started from the Prog7x9 software or directly on the device via the LCD screen.

To register the device on the network, please follow the sequence below:

Technical data

Bidirectional communication, Frequency EU868, transmission power: 14 dBm (25 mW)

By briey pressing the orange

button, look for “LorA OFF” in

the menu.

Long press to conrm

You can choose the option “Joi

now” (JoinNow):

Long press to conrm or press

the orange button briey to..

... start the delayed registration

procedure (JoinDelay) (by default

30 sec) and display “JoidELAY”

Long press to conrm.

rF

LorA OFF

rf

Joi novv

rf

JoidELAY

20 Instruction for use | Superstatic 749

10.4 Powered remote M-Bus

The powered remote M-Bus communication interface is a serial interface which permits com-

munication between different M-Bus devices via a central M-Bus station. It must be specied

when ordering. The powered remote M-Bus module will hence be installed and congured in

the factory.

By default, the primary address will be congured with the address 0 and the secondary address

will correspond to the serial number of the Superstatic 749. To change the value of the secondary

address, you must use the Prog7x9 software or send M-Bus specic orders. The secondary

address corresponds to the identication eld ID. The primary address is displayed in the Service

menu with the indication [Addr:].

Technical data for the M-bus communication system:

M-Bus protocol compliant with standard EN 1434-3; free potential interfacing without polarity

(the voltage measured on the last device must exceed 36VDC); transmission speed 300/2400

Baud; variable data structure. A M-bus device is seen as two M-Bus charges by the Master.

Type of cable recommended: telephone cable JYStY N*2*0.8 mm2

11. Security seals

As sealing varies from country to country, local regulations must be followed. To protect the

system against all unauthorised manipulations, the energy meter, the connection screws, the

temperature sensors and the sensor pockets must all be sealed. The seals may only be removed

by authorised persons. In the event of failure to comply with this instruction, the guarantee

obligation will lapse. It is important for the wire seal to be as short as possible so that it is

slightly taut. This is the only way of preventing malicious interference.

1

1

2

1 Seals installed in the factory on ow meter and temperature sensor of the

Superstatic 749

Seal installed in the factory on the calculator

2

Table of contents

Other Sontex Measuring Instrument manuals

Sontex

Sontex Superstatic 789 User manual

Sontex

Sontex Supercal 531 User manual

Sontex

Sontex 56 Series User manual

Sontex

Sontex Supercal 531 Instruction sheet

Sontex

Sontex Superaqua 1 User manual

Sontex

Sontex Supercal 531 User manual

Sontex

Sontex Supercal 739 Manual

Sontex

Sontex Superstatic 440 User manual

Sontex

Sontex Supercal 739 User manual

Sontex

Sontex Supercal 739 User manual

Sontex

Sontex Supercal 5 User manual

Sontex

Sontex Superstatic 789 User manual

Sontex

Sontex Superstatic 470 SPF User manual

Sontex

Sontex Supercal 5 User manual

Sontex

Sontex Supercal 5 I User manual

Sontex

Sontex Supercal 739 User manual

Sontex

Sontex Superstatic 449 Instruction sheet

Sontex

Sontex Superstatic 789 User manual