Supercal 5

Installation guide

Installation guidelines for thermal energy meter Supercal 5

General

The static ow sensor and its calculator may only be operated within the conditions outlined

on the identication plate, as well as within the technical specication! In the case of ignor-

ing these default conditions, the manufacturer’s responsibility is void and null.

The manufacturer is not liable for inappropriate installation and operation. Seals may not be

removed and/or only by authorized persons. The country-specic, local regulations, as well

as the manufacturer instructions, must be respected!

If the manufacturer’s seal has been broken or damaged, the manufacturer cannot be made

responsible for the change of the veried and meas-uring relevant data.

When using several heat meters in an installation unit, fair heat consumption measurement

muss be chosen. All of them in the same types of device and installation positions

Before installation

Check the design layout data of the installation.

The pulse value of the calculator and the installation location must match the values

indicated on the ow sensor, consult the identication plate!

The permissible ambient temperature range of the calculator is 5 – 55ºC.

The installation and project prescriptions must be followed.

The readability of the calculator and also the identication plates must be followed.

Remarks on the correct installation:

Conditions to comply with the directive 2014/32/EU (MID)

The calculator is delivered as a heat meter as standard. If it is to be used as a cooling

meter or as a combined cooling/heat meter, this must be specied when ordering. Other

metrological parameters such as installation position or pulse value (Supercal 5 I only) as

well as non-metrological parameters such as M-Bus address can be parameterised with

the Superprog software before sealing. Please note that metrological parameters can no

longer be changed after the calculator has been sealed.

The cable between the ow sensor and the calculator cannot be extended.

All wiring must be installed with a minimum distance of 300 mm from heavy voltage and

high frequency cables.

Radiated heat and interfering electrical elds close to the calculator must be avoided.

In general, the calculator should be installed away from the cooling pipes.

It has to be ensured that no condensed water can run along the wires into the calculator.

If the danger of vibrations in the piping system exists, the calculator should be installed

separately on the wall.

For temperatures over 90°C the calculator must be installed apart from the ow unit.

The ow sensor should be installed between two shut-off valves.

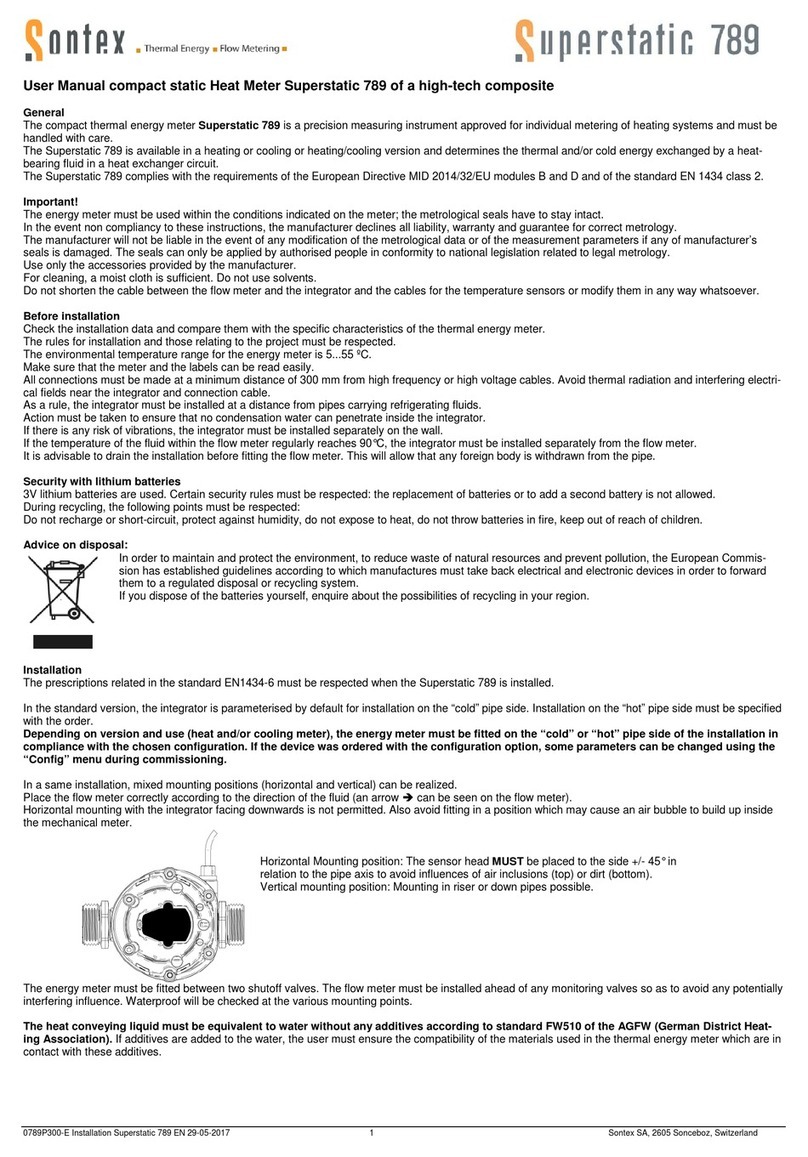

The ow sensor must be mounted with the measuring head to the side

The ow direction of the ow sensor must be respected (arrow on the

ow sensor).

Flush the pipe system before installing the ow sensors. To guarantee that no foreign

particles remain in the pipe.

The ow sensor should be mounted BEFORE any control valve to exclude any potential

parasitic inuences.

During commissioning the pipe system must be purged. Air in the system of the ow

sensor may affect the measurement.

Use only new and appropriate sealing material.

Water tightness of the different connections should be veried.

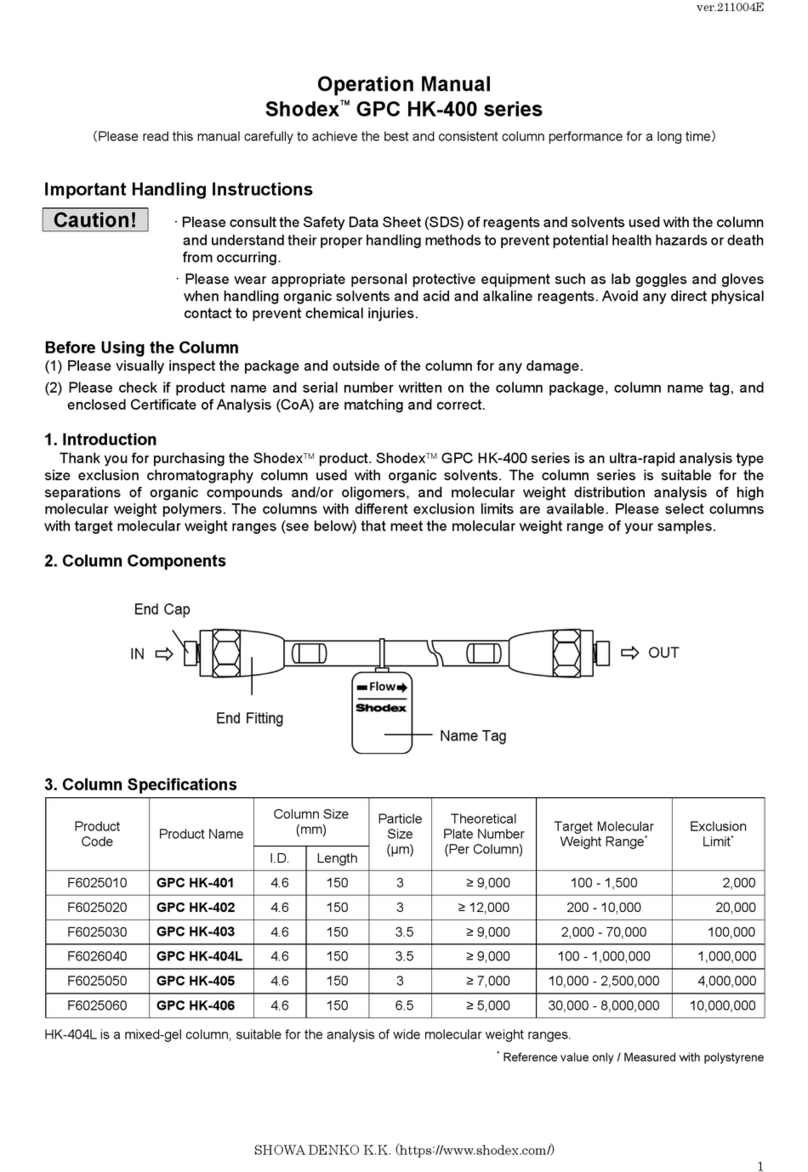

The Supercal 5 is a compact calculator and consists of the following two partial units:

Measuring and calibrating-relevant upper part

Lower part

The pulse values of the calculator and of the ow unit, as well as the resistance value of the

temperature sensors (Pt500) must match. Compare the labels of the devices!

Terminal connection type

5, 6 2-wire direct connection, temperature high

1, 5 and 6, 2 4-wire, temperature high

7, 8 2-wire direct connection, temperature low

3, 7 and 4, 8 4-wire, temperature low

10 (+) pulse inputs ow sensor 440 (white cable)

11 (-) pulse inputs ow sensor 440 (green cable)

9 Power supply of the ow sensor 440 (brown cable)

50 (+) Pulse input, additional pulse input 1

51 (-) Pulse input, additional pulse input 1

52 (+) Pulse input, additional pulse input 2

53 (-) Pulse input, additional pulse input 2

16 (+) Open collector-output 1

17 (-) Open collector output 1

18 (+) Open collector output 2

19 (-) Open collector output 2

24 M-Bus (polarity independent)

25 M-Bus (polarity independent)

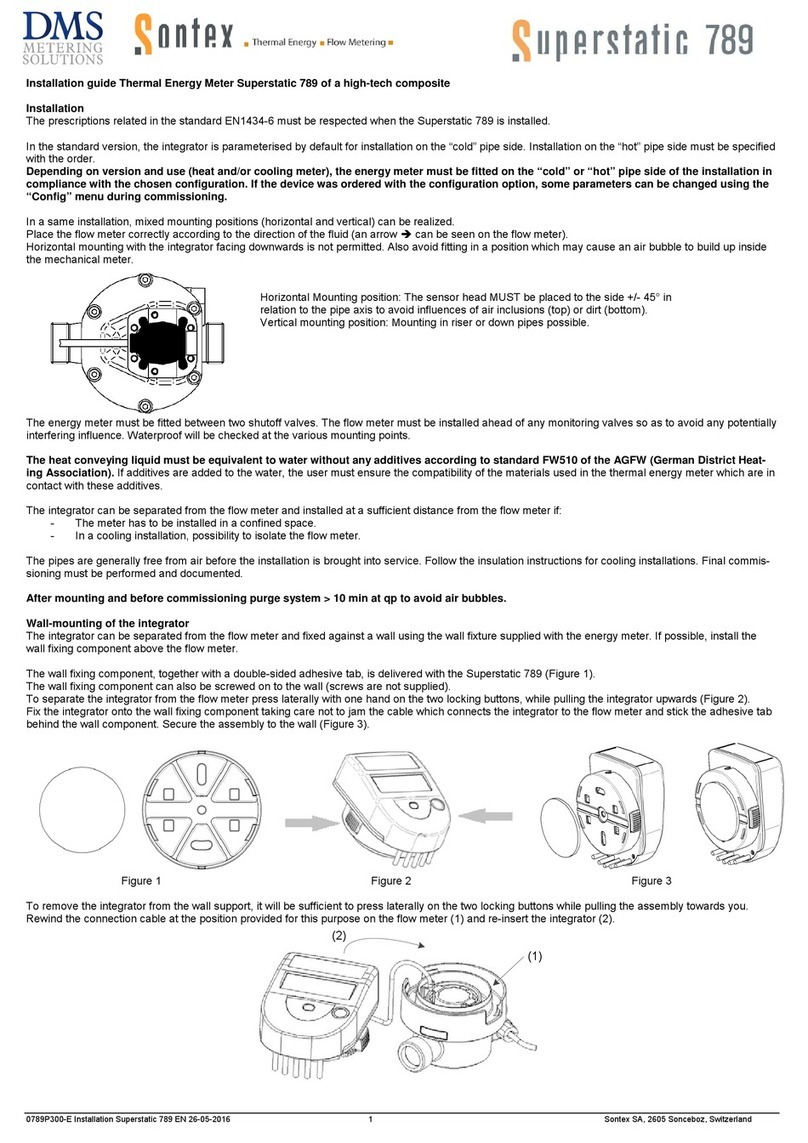

Cable connection

To connect the inputs and outputs the calculator’s upper part must be removed. Shielded

cables must be grounded with a strain relief!

Grounding

It has to be guarantied that all grounding connections (line and power mains and chassis of

the ow sensor) of the total installation are equipotential.

Power supply modules

The power supply modules are connected by means of a plug-in connector to the main board.

Power Supply at the Calculator

The Supercal 5 can be supplied with either battery or mains modules: D Battery 3,6 V, mains

24 V (12 VAC to 36 VAC or 12VDC to 42 VDC), mains 230 VAC (110 VAC to 230 VAC, 50/60 Hz).

These can be converted and retrotted at any time.

The mains module is equipped with a backup battery already installed.

The electrical connection of the mains power supply modules

The electrical connection has to be done in accordance with valid standards, under consid-

eration of local safety regulations and by an authorized person. The electrical main is to be

made in such way that no hot parts (pipes etc. over 80°C) can be touched (danger with dam-

aged isolation). Water contact of the electrical connection must be avoided.

Cable connections

Mains supply

110 ... 230 VAC

Cable connections

Mains supply

12...36 VAC / 12...42 VDC

Backup battery in the calculator upper part

The upper part of the calculator, which is relevant for calibration and measurement, is

equipped with an A-cell battery. This serves as power supply for the LCD display when the

upper part of the calculator is removed from the lower part or when no power supply is avail-

able. The battery has a service life of about 10 years in the backup function.

Safety instructions

The calculator is manufactured and tested according to EN 61010 safety control for measur-

ing units and left the factory in perfect safety tech-nical condition. To maintain this status

and to guarantee the safe operation of the calculator, the user must respect the instructions

contained in this document. When opening covers or removing parts, parts under power can

be accessed. Further connection terminals can be under power. All repair and maintenance

work may be only implemented by a trained and authorized specialist. If the housings and/

or the connect-ing cable show any damage, the calculator unit should be disconnected and

secured against accidentally reset up – put in operation. General-ly, avoid an installation sit-

uation with an accumulation of heat above average. An above-average heat build-up affects

substantially the lifetime of the electronic components.

Heat meters are measuring devices and must be handled with care.

To protect the unit against damage and contamination, the packing should be only removed

at the moment of installation.

For cleaning just use water moistened cloth and no solvent.

The connecting and connection cable may not be fastened on the pipe and under no circum-

stances be isolated together with the pipe.

Function test

After opening the shut-off valves, the system must be checked for leaks. Then, by repeat-

edly pressing the user button, various operating parameters such as ow rate, output and

ow and return temperature can be read on the LCD display of the calculator. If modules

are installed, this is also shown on the LCD display (M1:,M2:). With the Superprog Win-

dows and Superprog Android software, you can read additional information from the unit.

All parameter displays are used to check the thermal energy meter or to adjust the system.

It must be checked that the regulated ow of the system does not exceed the maximum per-

mitted ow of the meter. A commissioning protocol via the optical interface with the readout

software is recommended for a comprehensive functional check.

Pressure Loss Curve

Temperature sensors mounting

The temperatures indicated on the identication plate of the temperature sensors are to be

observed. The temperature sensors are always paired. Only matched pairs are supplied and

may not be separated, extended or shortened, since this affects the measuring accuracy. With

temperature sensor pairs with a cable length longer than 3 m, we exclusively recommend the

use of shielded temperature sensor pairs. In this case, the shields must be installed correctly.

Temperature sensors with protection pockets must be inserted up to the stall – and xed af-

terwards. With unequal cable lengths or longer than 6 m we recommend exclusively the use

of four-wire technology. The temperature sensors can be installed alternatively in protection

pockets or directly in the heating and/or cooling agent however always both in the same

way. Asymmetrical mounting, one sensor direct the other with pockets, isn’t permitted. The

measuring tip of the temperature sensor part must be positioned in the center of the cross

section of the pipe.

Temperature

sensor

Versions Pocket Part number Material Temperature

range

Ø 6 x 31mm Pt500 G3/8" 0460A202 Brass 0 … 1 0 0 ° C

Ø 6 x 31mm Pt500 G1/2" 0460A206 Brass 0 … 10 0 ° C

Ø 6 x 85mm Pt500, DIN G1/2" 0460A207 Stainless 0 … 1 5 0° C

Ø 6 x 134mm Pt500, DIN G1/2" 0460A208 Stainless 0 … 15 0 ° C

Ø 6 x 174mm Pt500, DIN G1/2" 0460A209 Stainless 0 … 15 0 ° C

The resonance frequencies of the protection pockets are outside of the ow velocities at

maximum ow (qs).

List of sensor pockets

Installation in T-tting

Temperature sensor perpendicu-

larly to the axis of the piping in the

same level

Installation with welding sleeve 90º

Temperature sensor axle coincide

with the tubing axle

Installation with welding sleeve 45º

Temperature sensor measuring element

submerged onto the tubing axle

Installation in pipe

Temperature sensor axle perpen-

dicularly to the tubing axle.

Temperature sensors connections

Wire cross section for head sensors ≥ 0,5 mm2 (EN 1434-2)

Temperature sensor installation with cooling applications

95.08

143

158

53.5

3.9

Conditions to comply with the directive 2014/32/EU (MID)

The temperature sensors have to be mounted symmetrically in ow and return and pref-

erably without pockets. If using pocket they must be in accordance with the conformity

declaration. Flow and return sensors must be mounted to the bottom of the pockets.

Installation places in the ow sensor can be used with the symmetrical installation of

the temperature sensor pair. Asymmetrical mounting of the temperature sensor isn’t

permitted.

In case of permanent mounted temperature sensor pairs the connecting cables must not

be shortened. In case of exchangeable temperature sensor pairs according to MID the

maximum equal length is 15 m. Wire cross sections according to EN 1434-2. Connection

to the calculator according to terminal connection on page 2 by respecting the electrical

compatibility Pt 500 of the calculator.

Straight sections of piping of 3 DN in ow and return of any ow meter or heat meter

must be respected. For the Superstatic 440 up to DN 40 (qp10) the straight sections of

piping of 3 DN are already included in the length of the ow sensor.

The selection of the battery has to take placed in such a way that it permits at least a

supply of auxiliary energy over the duration of the application plus 1 year storage period.

Information about the measuring stability is described in the conditions for water meas-

urement in accordance with AGFW requirements FW 510. In case of deviating composi-

tions the thermal energie meter must be submitted to periodic control according to the

guidelines of Sontex.

If a customer specic correction curve is applied, a sticker must be placed on the cover of

the calculator and completed with the serial number of the sensor head. Replacement of

the sensor head, as it is described in the homologation, isn’t possible in this case.

Security seals

Seals are country specic; the local regulations must be respected. Against possible manip-

ulation or unauthorized dismantling, the thermal energy meters, the screw connections, as

well as the temperature sensors and pockets must be protected with user seals. The seals

may be removed only by authorized persons. By neglecting this precaution the guarantee

obligation is void. It is important that the seal wires are kept as short as possible and are

well strained towards the seals. Only this way, the seal is protected against unauthorized

interference.

Manufacturer’s notice:

The heat / cooling meter Superstatic 5 S is congured and adjusted ex factory to the dif-

ferent sizes of uid oscillator ow sensors. An optimal measuring accuracy and stability ac-

cording to EN 1434 class 2 is guaranteed and a free swapping of the sensor head is possible.

Sontex declines all responsibility on specic correction curves of the uid oscillator ow

sensors that we’re not dened by Sontex.

Sealing

The sealing concept is subject to country-specic regulations. The sealing points shown

here were included in the construction of the Supercal 5.

Once the Supercal 5 is manufactured, it come out from factory as unsealed. It mean it has to

be installed at least with the following operations:

Fixing it to its operable and denitive location.

Installing the two temperatures sensor.

Installing the power supply if required

The calculator of the Supercal 5 S is then closed and mounted.

It is then necessary to seal the calculator either via the menu on the display or via Super-

prog Android/Windows. If the installer needs to change other metrological parameters, this

can be done using the Superprog Android or Superprog Windows software. (Android version

is recommended).

From this moment on, and if at any time it is necessary to return to commissioning mode or

the “Unsealed” state, the seal shown in the following image must be broken:

Sontex SA

Rue de la Gare 27

CH-2605 Sonceboz

Tel. +41 32 488 30 00

sontex@sontex.ch www.sontex.ch

0731P300 21/10

Technical support

For technical support contact your local

Sontex agent or Sontex SA directly.

Declaration of conformity

The detailed declaration of conformity can

be found and downloaded on our home-

page www.sontex.ch

Hotline Sontex

support@sontex.ch

+41 32 488 30 04

Technical modications subject to change without notice

Commissioning:

commissioning menu

Conguration via NFC

The sealing can be performed via NFC with the Superprog Android application or via optical

head or M-Bus with the Superprog Windows application.

To perform the conguration with Superprog Android proceed as follows:

Open the application on the phone, select the ‘‘INSTALL/CONFIGURE’’ option and follow

the instructions on the screen.

Once the installation assisted by Superprog Android is nished, Superprog Android will ask

you to Seal the calculator. Select ‘‘YES’’.

Remember that Superprog Windows has more options to congure the Supercal 5.

To perform the conguration with Superprog Windows proceed as follows:

Start Superprog Windows on the computer

Connect to Supercal 5 via the selected interface.

Congure all the desired values.

Once you have congured the desired values, press the ‘‘WRITE’’ button to conrm the

changes and when you are requested to conrm the changes, you can check the checkbox to

Seal the Supercal 5.

If at this point, after conguring the device, you have not yet sealed the Supercal 5, you can

do so manually as indicated in the following menu display.

1× short press on the left

button

S e a l c o n g u r a t i o n

SEAL: seals the conguration and

switches to Default Menu

1× long press (> 2 seconds) on the

left button

Cumulated energy

C u m u l a t e d v o l u m e

Commissioning Menu

Further information

In the case of divergences, the Englisch version takes precedence.

Bei Abweichungen hat die englische Version des Inhalts Vorrang

1

À