3

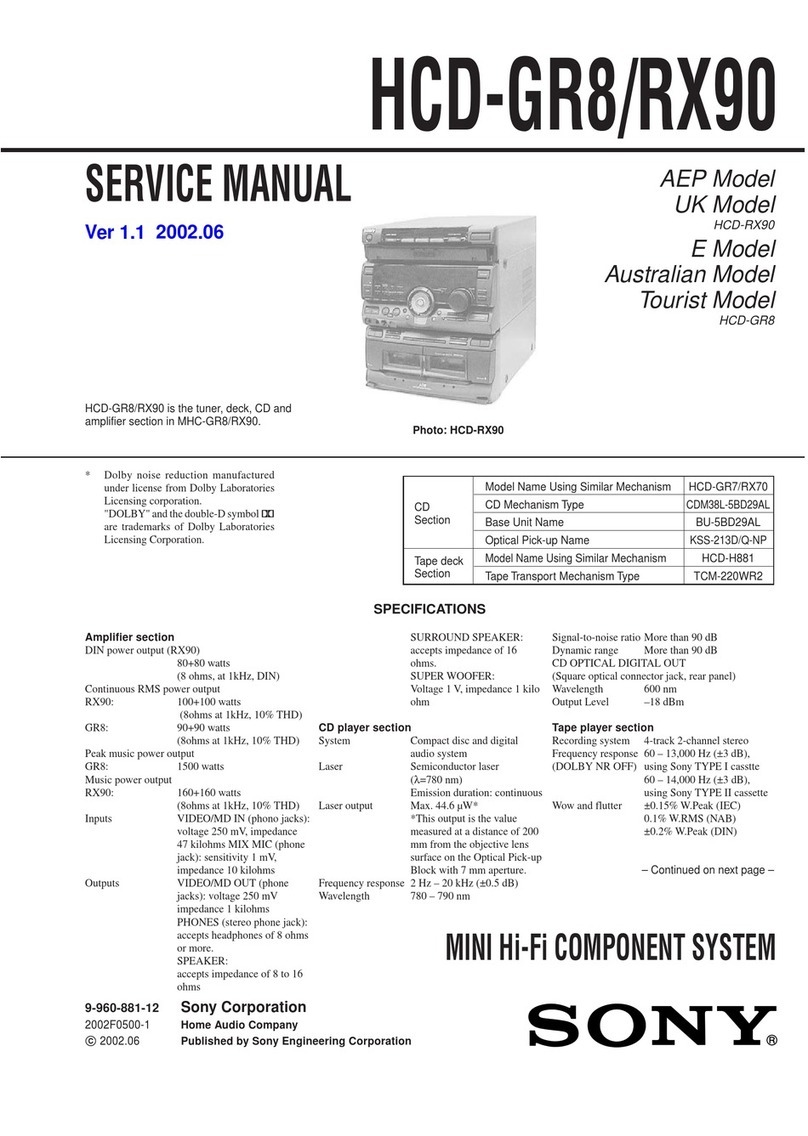

HCD-DX80

MODEL IDENTIFICATION

— BACK PANEL —

MODEL

BR, E2, E51, SP, AR models

MX model

PARTS No.

4-231-580-4s

4-231-580-5s

• Abbreviation

AR : Argentina model

BR : Brazilian model

E2 : 120 V AC Area in E model

E51 : Chilean and Peruvian model

SP : Singapore model

MX : Mexican model

PARTS No.

TABLE OF CONTENTS

1. GENERAL ................................................................... 4

2. DISASSEMBLY ......................................................... 7

2-1. Disassembly Flow ........................................................... 7

2-2. Case (Top) ....................................................................... 8

2-3. Loading Panel.................................................................. 8

2-4. CD Mechanism Deck (CDM58E-30BD60) ................... 9

2-5. Front Panel Section ......................................................... 9

2-6. Tape Mechanism Deck (TCM-230AWR41)................... 10

2-7. Back Panel Section.......................................................... 10

2-8. Main Board...................................................................... 11

2-9. LEAF SW Board, HEAD (A) Board,

HEAD (B) Board ............................................................ 11

2-10. Base Unit (BU-30BD60) ................................................ 12

2-11. DRIVER Board, MOTOR Board, SENSOR Board ....... 12

3. TEST MODE ............................................................... 13

4. MECHANICAL ADJUSTMENTS ........................ 15

5. ELECTRICAL ADJUSTMENTS.......................... 15

6. DIAGRAMS

6-1. Block Diagram –TUNER/CD Section –......................... 21

6-2. Block Diagram –MAIN Section – .................................. 22

6-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 23

6-4. Schematic Diagram –BD Board – .................................. 24

6-5. Printed Wiring Board –BD Board – ............................... 25

6-6. Schematic Diagram –MAIN Board (1/4) – .................... 26

6-7. Schematic Diagram –MAIN Board (2/4) – .................... 27

6-8. Schematic Diagram –MAIN(3/4)/HEAD Board –......... 28

6-9. Schematic Diagram –MAIN Board (4/4) – .................... 29

6-10. Printed Wiring Board –MAIN Board – .......................... 30

6-11. Schematic Diagram

–POWERAMP/SENSOR Board – ................................. 32

6-12. Printed Wiring Boards

–POWERAMP/SENSOR Board – ................................. 33

6-13. Schematic Diagram

–PANEL/VIDEO SWITCH Board – .............................. 34

6-14. Printed Wiring Boards

–PANEL/VIDEO SWITCH Board – .............................. 35

6-15. Schematic Diagram

–CD SWITCH/PAD SWITCH Board – ......................... 36

6-16. Printed Wiring Boards

–CD SWITCH/PAD SWITCH Board – ......................... 37

6-17. Schematic Diagram –LEAF SW Board – ....................... 38

6-18. Printed Wiring Boards –LEAF SW/HEAD Board – ...... 39

6-19. Schematic Diagram

–ADDRESS SENSOR/DRIVER/MOTOR Board – ...... 40

6-20. Printed Wiring Boards

–ADDRESS SENSOR/DRIVER/5MOTOR Board – .... 41

6-21. Schematic Diagram

–MAIN TRANS/SUB TRANS Board – ........................ 42

6-22. Printed Wiring Boards

–MAIN TRANS/SUB TRANS Board –......................... 43

6-23. IC Pin Function Description ........................................... 47

7. EXPLODEDVIEWS

7-1. Cabinet Section ............................................................... 52

7-2. Front Panel Section ......................................................... 53

7-3. Main Board Section ........................................................ 54

7-4. CD Mechanism Deck Section (CDM58E-30BD60) ...... 55

7-5. Base Unit Section (BU-30BD60) ................................... 56

7-6. Tape Mechanism Deck Section-1 (TCM-230AWR41).... 57

7-7. Tape Mechanism Deck Section-2 (TCM-230AWR41).... 58

8. ELECTRICAL PARTS LIST.................................. 59