3

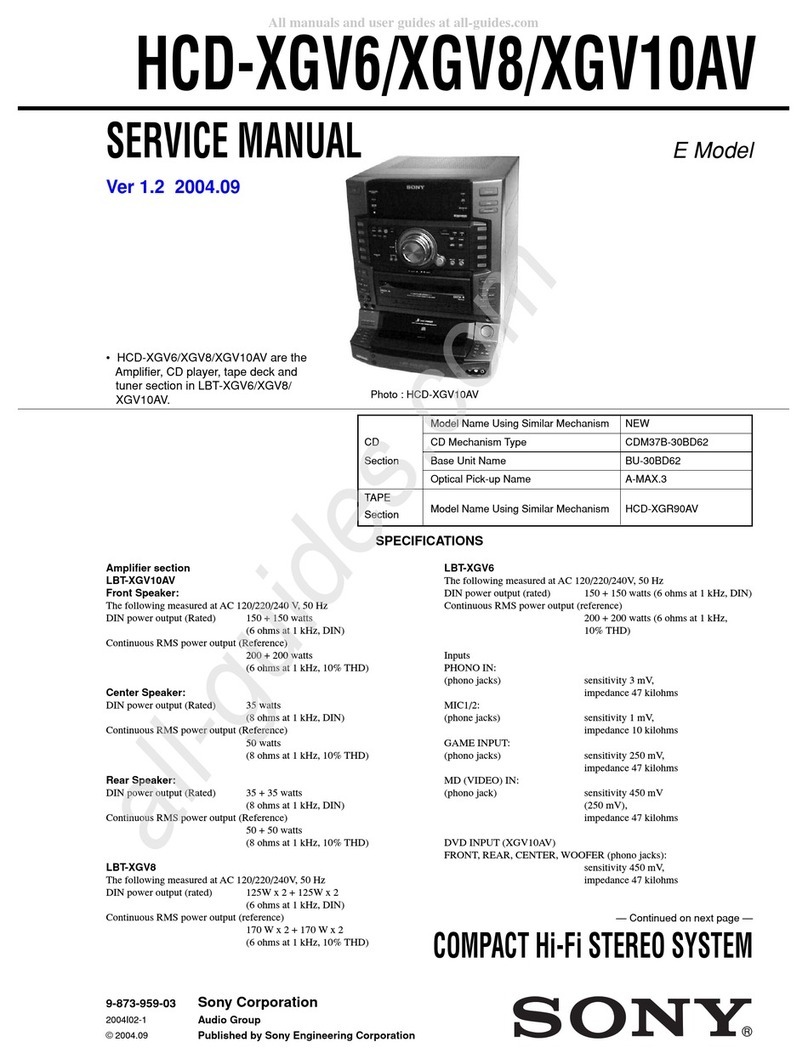

MODEL IDENTIFICATION

— BACK PANEL —

TABLE OF CONTENTS

1. SERVICE NOTE ······························································· 4

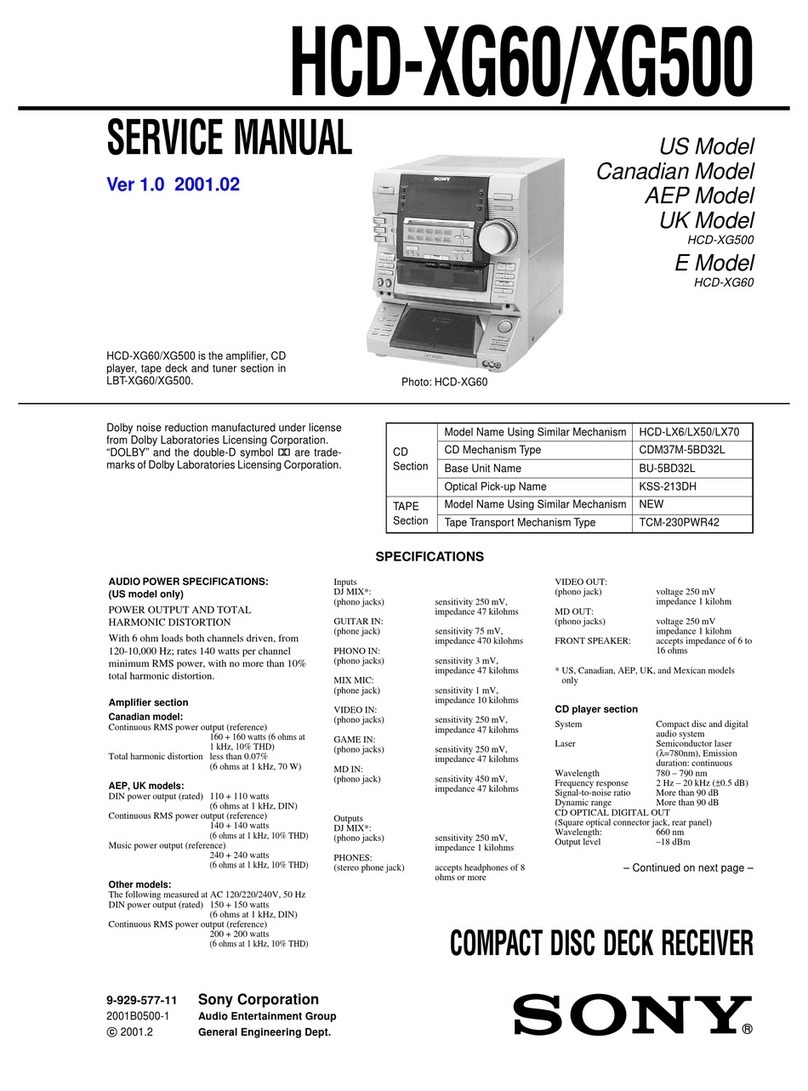

2. GENERAL ·········································································· 5

3. DISASSEMBLY

3-1. Case ···················································································· 8

3-2. Front Panel Section ···························································· 8

3-3. Tape Mechanism Deck Section (TCM-230AWR12) and

MIC Board ·········································································· 9

3-4. Back Panel Section ····························································· 9

3-5. Main Board, Front AMP Board ········································ 10

3-6. CD Base Unit (BU-K2BD37A) ········································ 10

3-7. CD Mechanism Deck Section (CDM53F-K2BD37A) ····· 11

3-8. Fitting Base (Guide) Assy, Bracket (Chassis) and

Fitting Base (Magnet) Assy ·············································· 11

3-9. Tray (Sub) ········································································· 12

3-10. Chassis (Mold B) Section, Stocker Section and

Slider (Selection) ······························································ 12

3-11. Gears Installation ······························································ 13

3-12. Slider (Selection) Installation ··········································· 13

3-13. Stocker Section Installation ·············································· 14

3-14. Chassis (Mold B) Section Installation ······························ 14

4. TEST MODE ···································································· 15

5. MECHANICAL ADJUSTMENTS ····························· 20

6. ELECTRICAL ADJUSTMENTS ······························· 20

7. DIAGRAMS

7-1. Circuit Board Location ····················································· 25

7-2. Block Diagrams ································································ 28

7-3. Printed Wiring Board –BD Section – ······························ 32

7-4. Schematic Diagram –BD Section – ································· 33

7-5. Printed Wiring Board –Video Section – ·························· 34

7-6. Schematic Diagram –Video Section (1/3) – ···················· 35

7-7. Schematic Diagram –Video Section (2/3) – ···················· 36

7-8. Schematic Diagram –Video Section (3/3) – ···················· 37

7-9. Printed Wiring Board –Deck Section – ··························· 38

7-10. Schematic Diagram –Deck Section – ······························ 39

7-11. Printed Wiring Board –Main Section – ··························· 40

7-12. Schematic Diagram –Main (1/3) Section – ····················· 41

7-13. Schematic Diagram –Main (2/3) Section – ····················· 42

7-14. Schematic Diagram –Main (3/3) Section – ····················· 43

7-15. Printed Wiring Board –AMP Section – ··························· 44

7-16. Schematic Diagram –AMP Section – ······························ 45

7-17. Printed Wiring Board –Panel Section – ··························· 46

7-18. Schematic Diagram –Panel Section – ····························· 47

7-19. Printed Wiring Board –Switch Section – ······················· 48

7-20. Schematic Diagram –Switch Section – ··························· 49

7-21. Printed Wiring Board –CD Mechanism Section – ·········· 50

7-22. Schematic Diagram –CD Mechanism Section – ············· 51

7-23. Printed Wiring Board –Power Supply Section – ············· 52

7-24. Schematic Diagram –Power Supply Section – ················ 53

7-25. Printed Wiring Board –MIC Section – ···························· 54

7-26. Schematic Diagram –MIC Section – ······························· 54

7-27. Printed Wiring Board –Leaf SW Section – ····················· 55

7-28. Schematic Diagram –Leaf SW Section – ························ 55

7-29. IC Block Diagrams ··························································· 56

7-30. IC Pin Descriptions ·························································· 58

8. EXPLODED VIEWS

8-1. Back Panel Section ··························································· 69

8-2. Front Panel Section ·························································· 70

8-3. Chassis Section ································································· 71

8-4. CD Mechanism Deck Section-1 (CDM53F-K2BD37A) ·· 72

8-5. CD Mechanism Deck Section-2 (CDM53F-K2BD37A) ·· 73

8-6. Base Unit Section (BU-K2BD37A) ································· 74

8-7. Tape Mechanism Deck Section (TCM-230AWR12) ········ 75

9. ELECTRICAL PARTS LIST ······································· 76

•Abbreviation

SP : Singapore model

MY : Malaysia model

HK : Hong Kong model

TH : Thai model

EA : Saudi Arabia model

MODEL

SP, MY models

HK model

TH model

EA model

PARTS No.

4-226-747-3s

4-226-747-4s

4-226-747-5s

4-226-747-6s

Parts No.

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com