TABLE

OF.

CONTENTS

Title

Page

SERVICING

NOTES

ssi

visas

earnctialaenh

bata

alana

ater

MES

1

SECTION

1

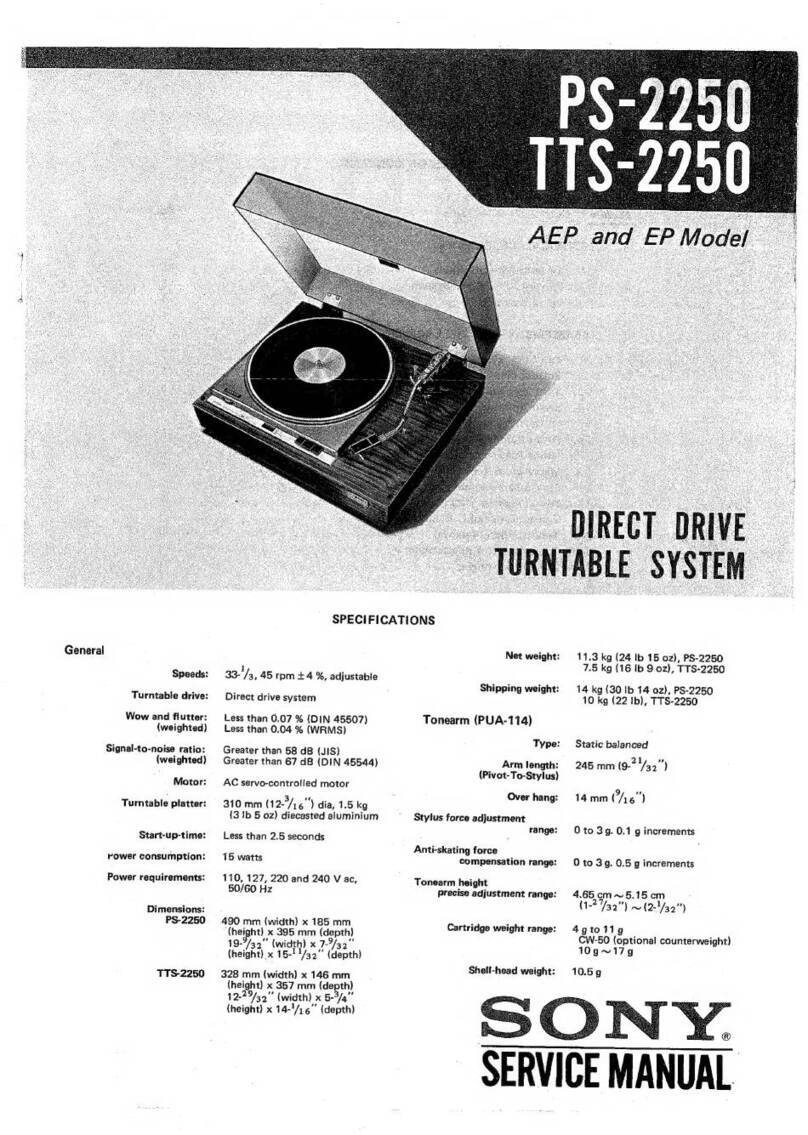

TECHNICAL

DESCRIPTION

1-1.

Technical

Specification

..0.........2:cccccsceeeecseserececcseeersssencessecessesensees

2~3

122)..°

“Circuit?

Analysis)

csiscjocdsccesasactcs

eben

iakek

ccc

cdehcagee

sig

teinsdowesceseeuuesdveses

3~7

13:

“Block.

Diagram.

-scicccsicsceassecgccescsecunsd

caceth

dent

vqustndesaa

sates

etvssssedevssesucsess

wees

8

124;

“Teevel

Diagram:

«23.i.ssideiebidssccecich

eck

sdece

te

tewadentesenssevessvsscavecse?eieesesewsdveceas

9

SECTION

2.

DISASSEMBLY

AND

REPLACEMENT

PROCEDURES

2-1.

Tools:

Requited

9

scccsi.c.

cscs

ccsiecasieceschovsesivevseoventcceccescaceaseseees

10

2-2.

Hardware

Identification

Guide

;

10

2-3,

Top

Cover

Removal

.....ci.cccccccusscsenseccoccessenssonsocnessonctoceccecssesecscasaaees

11

2-4.

Record-Changer

Removal

.00.........ccccsessssseceeseececceceeceneeseneecees

aieeesetes

11

2-5.

Front

Panel

Removal

.........ccccccsecscsssrecccedsccssssccsssssssccssssonssssceensseses

12

2-6.

Wooden

Case

Removal

..........cscccssecseseseseeessesseeesseeesneesaseneneessneesenes

13

2-7.

Dial-Cord

Restringing

.0........scesseseesseesseeesseesneeeeesneennecsensenseee

2-8...

Mechanical

Dial

Calibration

.............cscsscssesscssecsssnsearsnseneiosenesotenees

2-9.

Pilot

Lamp

Replacement

sacedbesccen

seSesevss

dasnwoagenceeceesdegevassessaeserses

seseeeed

.

2-10...

Control

and

Swtich

Replacement

..........s200%

sSecreacbeeoos

QTL.

POR

RemiOval:

<scarssvsiaaspandetarinndertss

:

2-12.

Ac

Outlet

Replacement

.o..c.cccccesseeseeeeeeee

'2+13.

Power

Transistor

Replacement

—...........cc00.

Q-

14:

Chassis

LAV

OME:

ssccosticcussenceshevcsothenectouasiziopas

ee

SECTION:

3

"

ALIGNMENT

AND

ADJUSTMENT

PROCEDURES

3-

i

FM

I-f

and:

Discriminator

Alignment

.........

baatlenis

21

3-2...

FM

Frequency

‘Coverage

Alignment

2122

9,23

RB

FM

Tracking

Alignment.

;

re

ya,

BAS

A-m.

I:

‘Strip’

Mien

ciene.

o

on

25

~:26

3-5;

AST

‘Frequency.

Coverage

and

Tracking

Alignment.

26~

~.

28

ae

Power-Amplifier

Adjustments

‘

.

220

29

"RECORD.

CHANGER

‘SERVICING.

PROCEDURES

7

1,

*

Line‘Frequency

Change-...

ies

,

,Line-Voltage

Change.

wteee

30

:

Cartridge

Replacement

Stylus.

Tip

Replacement

aa

Diagram

-—

Power

ee

a

Power

Supply

Board

—

oiu..eeieccccsssscesssecssrsccsesessseceecsseens

36

~

37

6-4.

Mounting

Diagram

—

Preamplifier

Board

—

oesovensoseserssnsecsseneses

38

~

39

6-5.

Schematic

Diagram

—

Tuner

and

MPX

Section

—

.............

41

~

42

6-6.

Schematic

Diagram

—

Audio

Amplifier

Section

—

...........

43

~

44

SECTION

7

EXPLODED

VIEW

......000

je

desu

cotevcuudensesysbseBonhteckocssees

45

~

47

SECTION

8

ELECTRICAL

PARTS

LIST

.o.ccccccccccscsssoss

RCRA

CON

48

~

52