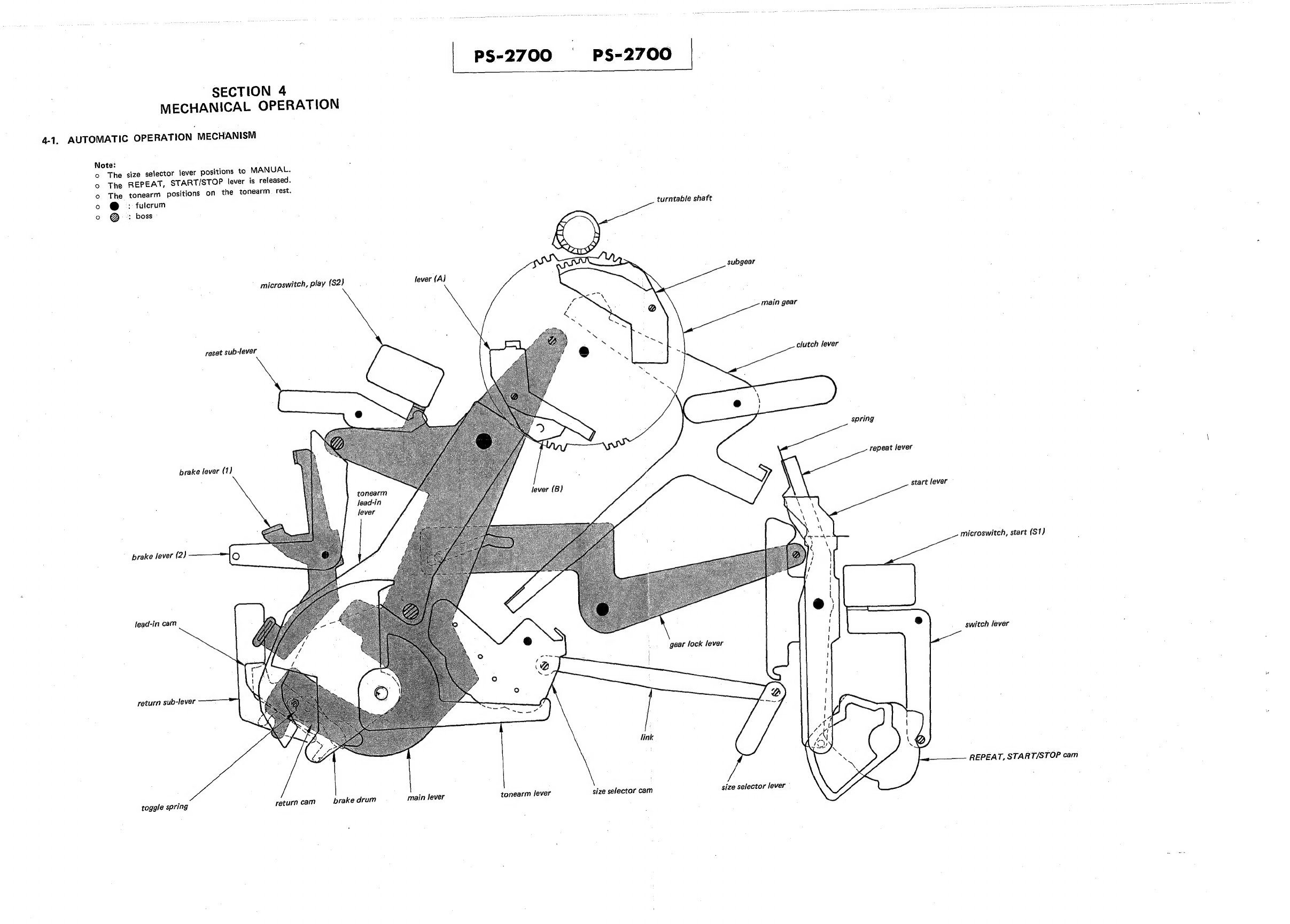

Sony PS-2700 User manual

Other Sony Turntable manuals

Sony

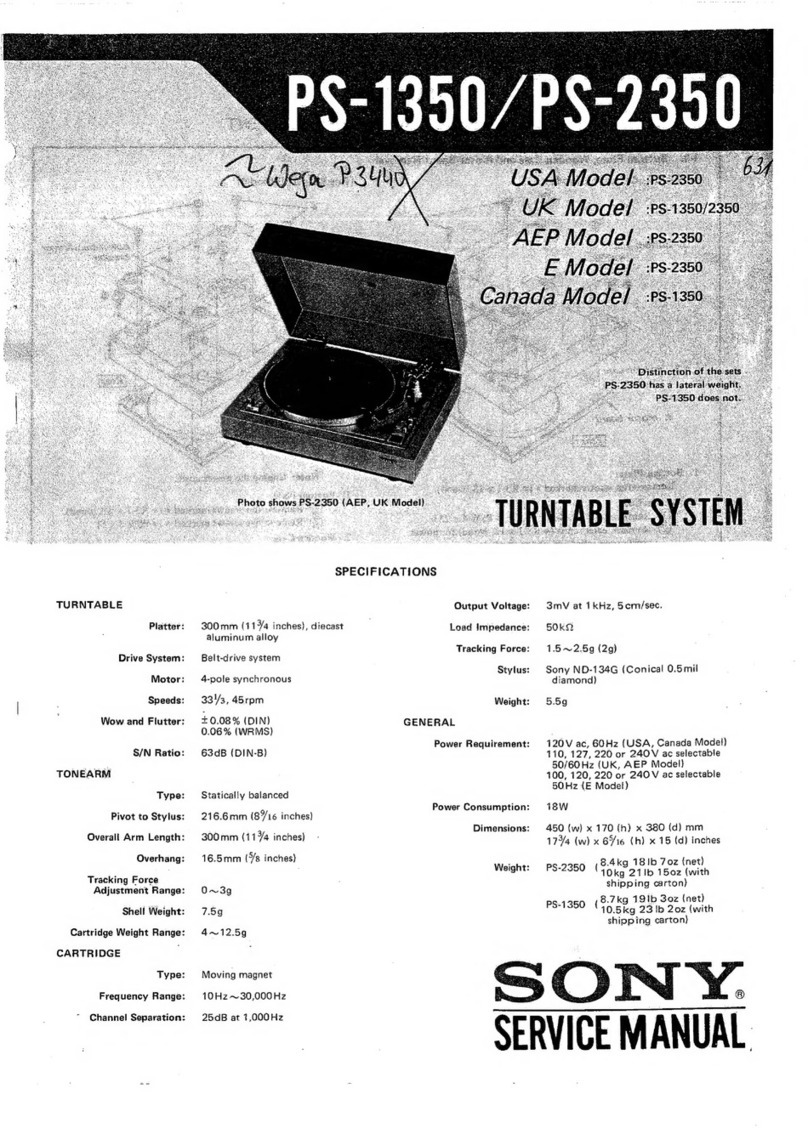

Sony PS-1350 User manual

Sony

Sony PS-X6 Setup guide

Sony

Sony HP-210 User manual

Sony

Sony PS-LX250H Parts list manual

Sony

Sony CDX-GT707UI User manual

Sony

Sony DVW-522 User manual

Sony

Sony PMW-PZ1 User manual

Sony

Sony PS-LX49 User manual

Sony

Sony PS-LX300USB - USB Stereo Turntable System User manual

Sony

Sony PS-X75 User manual

Sony

Sony HAP-Z1ES User manual

Sony

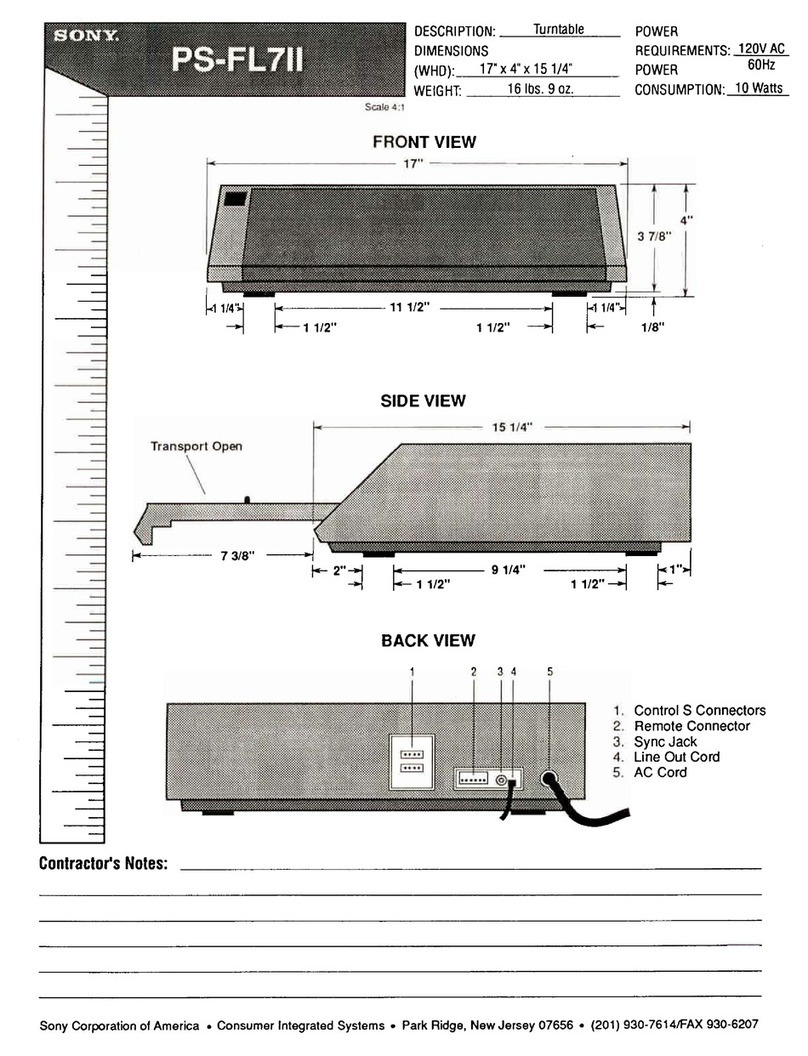

Sony PS-FL7II - Stereo Turntable Parts list manual

Sony

Sony DD-10EX User manual

Sony

Sony PS-LX60 User manual

Sony

Sony MDH-10 User manual

Sony

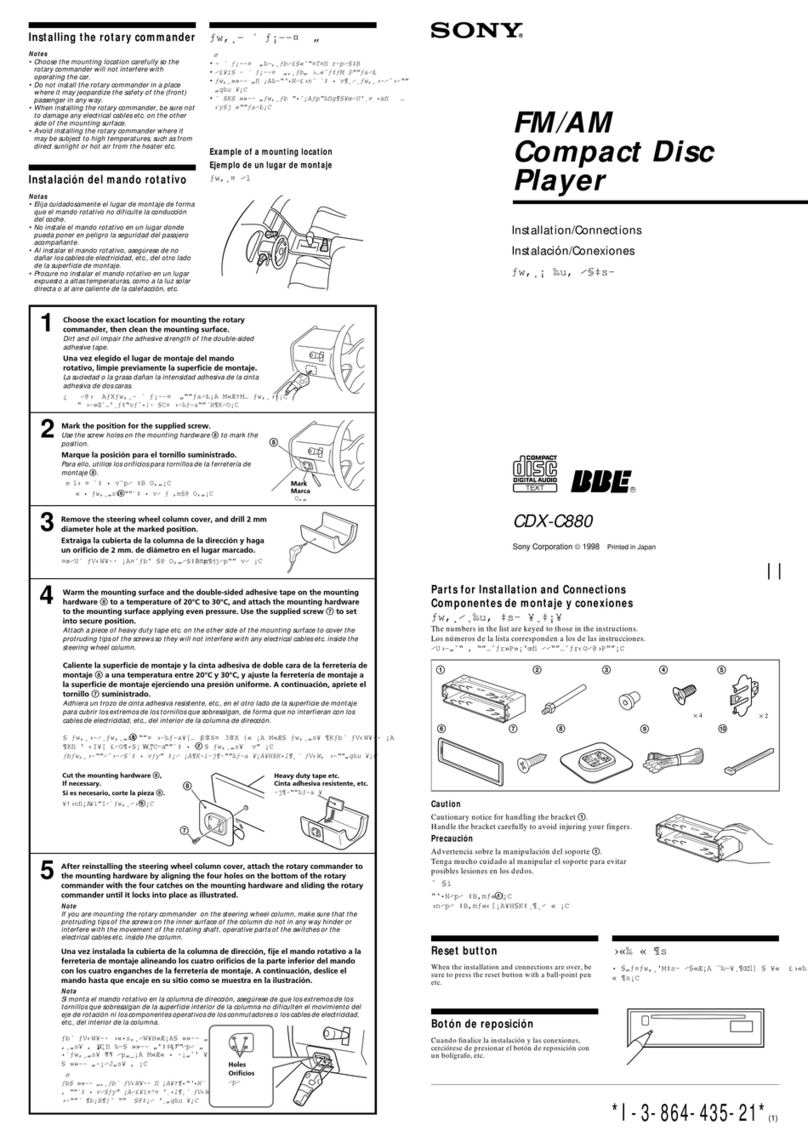

Sony CDX-C800 User manual

Sony

Sony PS-J10 Primary User manual

Sony

Sony NW-A45 User manual

Sony

Sony PS-LX350H User manual

Sony

Sony PS-LX310BT User manual