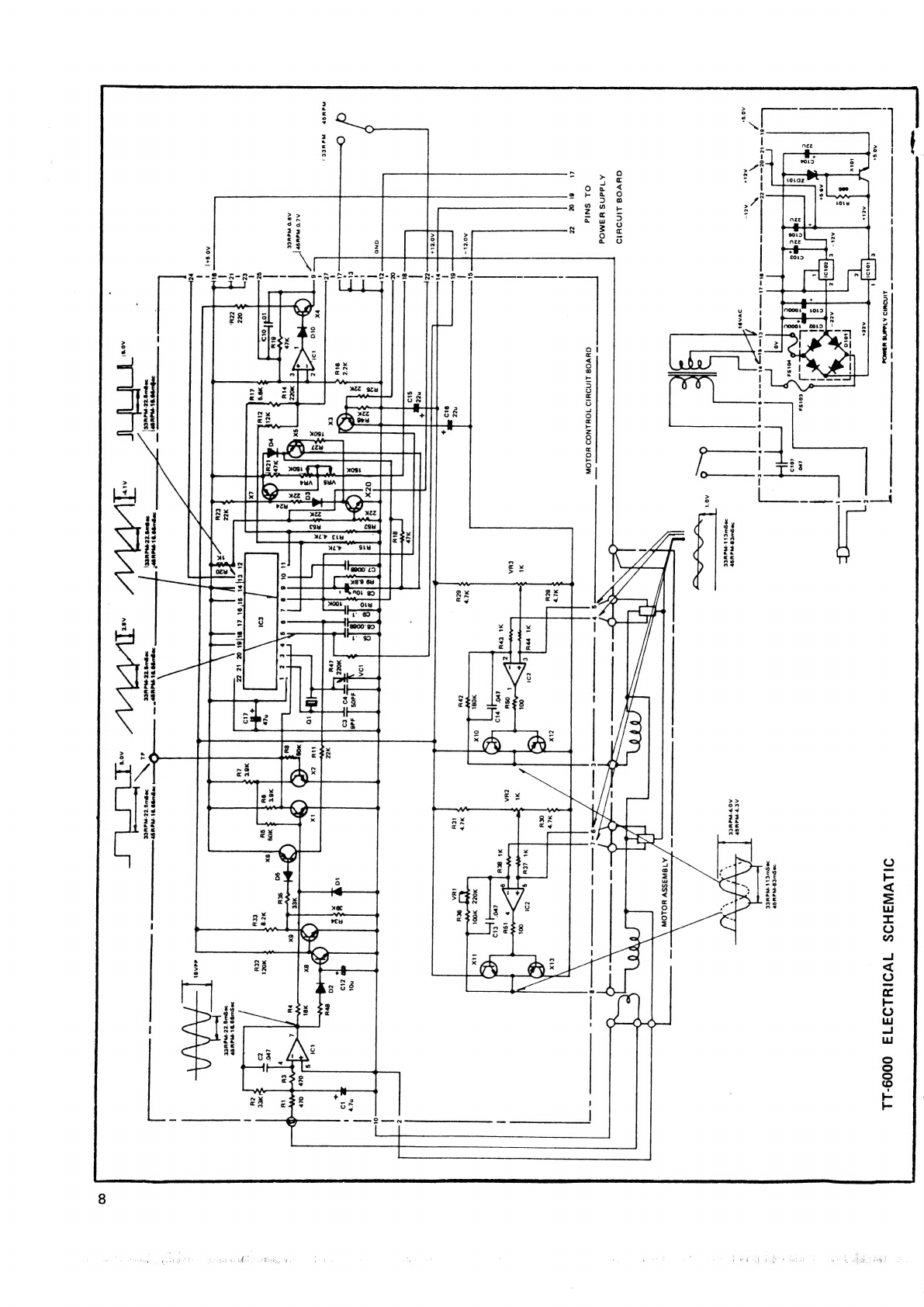

Marantz TT-6000 User manual

Other Marantz Turntable manuals

Marantz

Marantz 6350 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT6200 User manual

Marantz

Marantz TT4200 User manual

Marantz

Marantz TT2200 User manual

Marantz

Marantz 6300 User manual

Marantz

Marantz TT5005 User manual

Marantz

Marantz BD7003 User manual

Marantz

Marantz TT8001 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT-42 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT5005 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT5005 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz 74TT42 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT5005 User manual

Marantz

Marantz TT5005 User manual