Sony PS-X75 User manual

Other Sony Turntable manuals

Sony

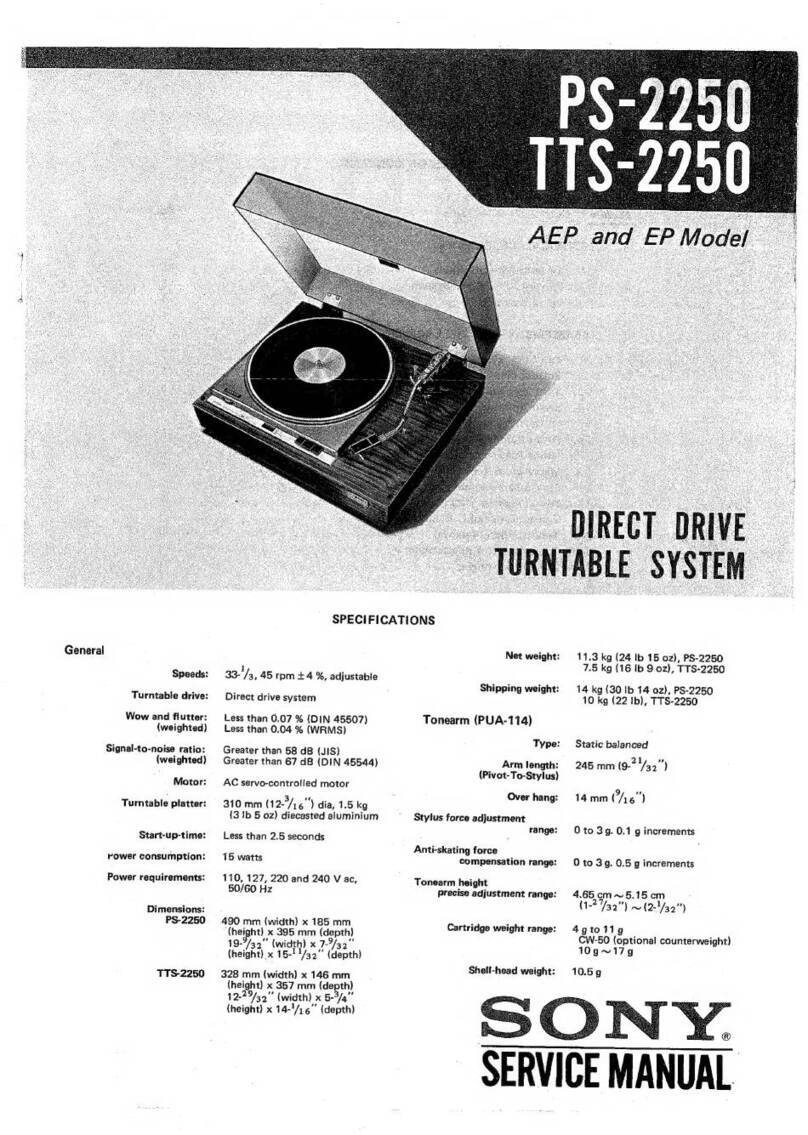

Sony PS-2250 User manual

Sony

Sony Walkman WM-EX162 User manual

Sony

Sony PS-D707H User manual

Sony

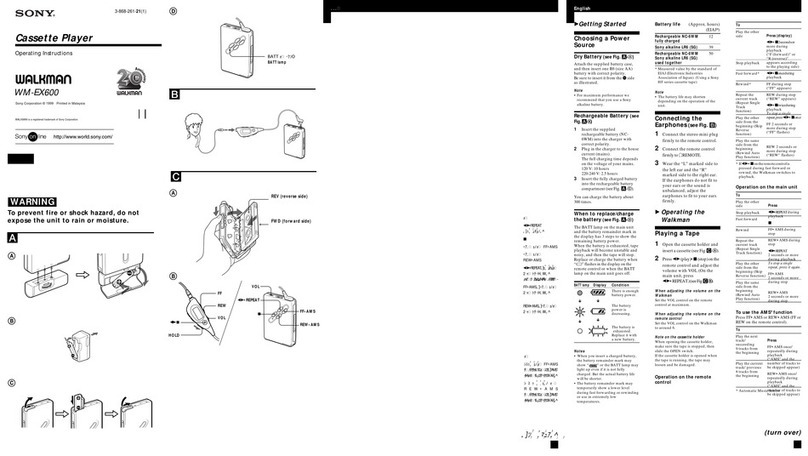

Sony Walkman WM-EX600 User manual

Sony

Sony PS-LX55C User manual

Sony

Sony PS-6750 Setup guide

Sony

Sony PS-LX2 User manual

Sony

Sony HAP-Z1ES User manual

Sony

Sony PS-LX300H User manual

Sony

Sony PS-2250 User manual

Sony

Sony PS-X7 Setup guide

Sony

Sony PS-J10 Primary User manual

Sony

Sony DD-10EX User manual

Sony

Sony PS-LX300USB - USB Stereo Turntable System User manual

Sony

Sony PMW-PZ1 User manual

Sony

Sony PS-LX520 User manual

Sony

Sony DVW-522 User manual

Sony

Sony PS-X6 User manual

Sony

Sony PS-X555ES User manual

Sony

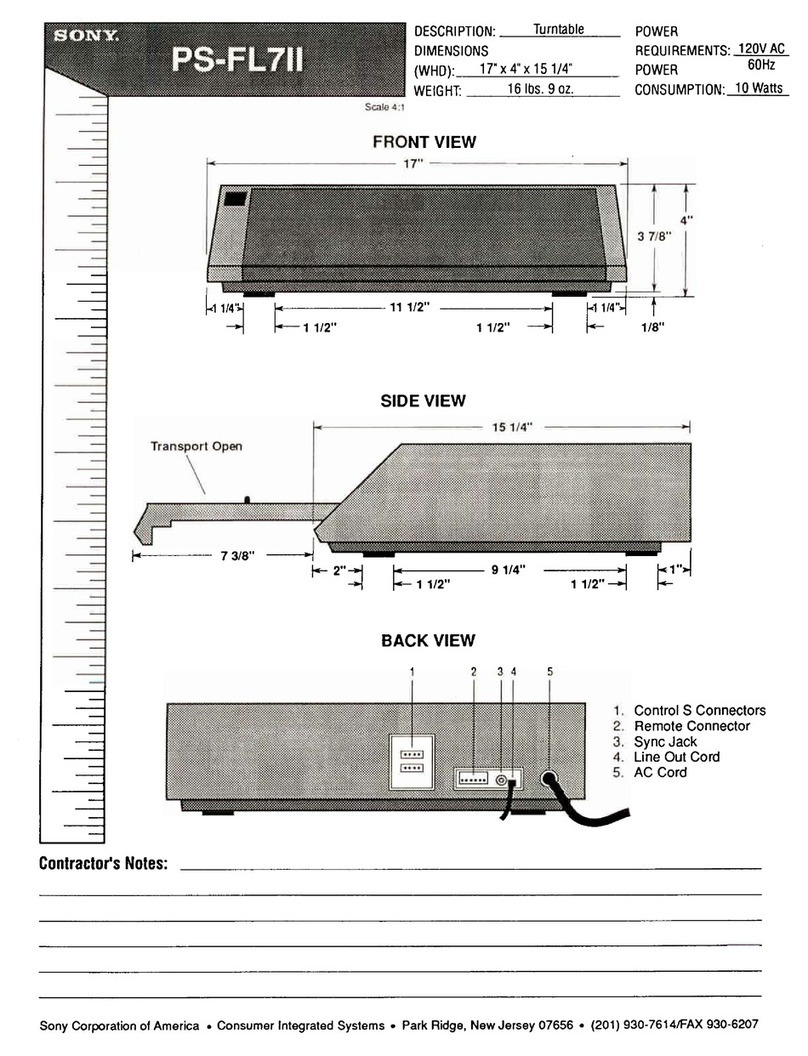

Sony PS-FL7II - Stereo Turntable Parts list manual