SM-A25107/3-ACONTENTS

iv 2021-03-23

CONTENTS

PREFACE........................................................................................................................... i

SAFETY INFORMATION .................................................................................................. ii

Precautions on Product Use..........................................................................................iii

Precautions on Product Disposal ..................................................................................iii

CONTENTS...................................................................................................................... iv

1. PRODUCT OVERVIEW ............................................................................................. 1

1.1 System Overview................................................................................................ 1

1.1.1 System structure........................................................................................... 1

1.2 Instruction Manuals Related to This Product...................................................... 2

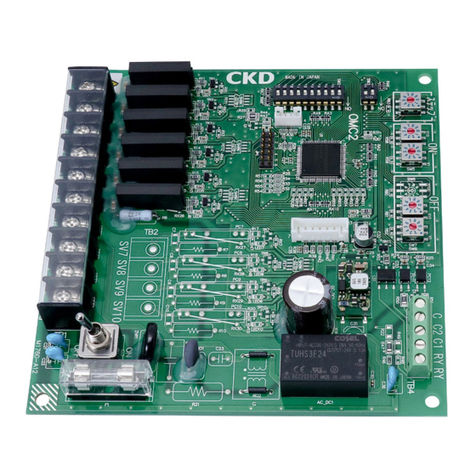

1.3 Names of Parts ................................................................................................... 2

1.3.1 FFLD-08,30 .................................................................................................. 2

1.3.2 FFLD-50 ....................................................................................................... 3

1.4 Model Number Indication....................................................................................4

1.4.1 FFLD Series .................................................................................................4

1.5 Specifications......................................................................................................5

1.5.1 Actuator specifications ................................................................................. 5

1.5.2 Communication specifications...................................................................... 6

2. INSTALLATION ......................................................................................................... 7

2.1 Environment.......................................................................................................11

2.2 Unpacking ..........................................................................................................11

2.3 Mounting ...........................................................................................................12

2.3.1 Body............................................................................................................ 12

2.3.2 Fingers........................................................................................................ 13

2.4 Wiring................................................................................................................14

2.4.1 Connecting to upper level equipment ........................................................ 14

2.4.2 Connecting to S-Tools ................................................................................ 17

3. USAGE..................................................................................................................... 19

3.1 Safety Instructions ............................................................................................19

3.2 IODD file............................................................................................................ 21

3.3 Setting the IO-Link Device................................................................................21

3.4 Communication Format ....................................................................................22

3.4.1 Process data............................................................................................... 22

3.4.2 Service data................................................................................................ 34

3.5 Data Storage (DS) Function .............................................................................46

3.5.1 IO-Link master settings .............................................................................. 46

3.5.2 Download/Upload ....................................................................................... 47

3.6 Parameters .......................................................................................................49

3.6.1 List of parameters....................................................................................... 49

3.6.2 Soft limits .................................................................................................... 51

3.6.3 Home position return operation.................................................................. 52

3.6.4 Automatic point zone.................................................................................. 53

3.7 Point Data ......................................................................................................... 54

3.7.1 Number of point data.................................................................................. 54

3.7.2 List of point data ......................................................................................... 54

3.7.3 Position specification method..................................................................... 55

3.7.4 Operation method....................................................................................... 55

3.7.5 Position....................................................................................................... 58

3.7.6 Stop method ............................................................................................... 59

3.7.7 Point zone................................................................................................... 59