Sorma BSS-134 User manual

Codice di identifi cazione Note

Data di redazione

07/13 BSS/STD-02 GBR (C.P.)

Via delle MELE, 65

47522 Cesena (FC) ITALIA

Tel.: 0547-418611

Fa .: 0547-418612

BSS-134

Operating instructions

Manuale istruzioni

Mode d'emploi

Manual de instrucciones

Gebrauchshandbuch

AUTOMATIC VERT-BAG PACKAGING MACHINE

serial num er:

1

GENERAL INFORMATIONS

BSS-134 CHAP.- 1

AUTOMATIC VERT-BAG PACKAGING MACHINE

mod. BSS-134

1.1 Foreword

This manual defi nes the purpose for which the machine has been constructed and contains information

on performance, technical characteristics, how to use the machine and effect maintenance so as to

ensure correct, problem-free running.

This manual is addressed to the operators and maintenance operators of the machine as well as the

department manager to whom the machine is entrusted.

This manual constitutes integrating part of the machine, it must be completely read before installing

the machine, therefore kept with care (in a protected place, dry, covered from sun rays) for every

further consultation, necessary before carrying out any operation on the machine.

It is recommended that the user read the manual carefully and observe the described standards and

procedures, as they give important information regarding operative safety and maintenance.

orma .p.A. does not undertake liability for any damages to persons or things occurred due to

negligence when executing that written in this manual.

The machine is shipped to the client prepared for installation, after having overcome the tests envisioned

by the manufacturer, in compliance with the laws in force.

orma .p.A. is not responsible for functioning anomalies or general faults, caused by the unauthorised

use of the machine or by interventions and/or amendments made by foreign persons unauthorised

by the same orma .p.A.

1. Manufacturer

SORMA S.P.A.

Via Delle Mele n°65

47522 CE ENA (FC) ITALIA

Tel. 0547/418611 Fax. 0547/418612

http:/www.sormagroup.com

1.3 Confi dentialy

The technical information contained in this manual is the property of orma .p.A. and is strictly con-

fi dential: disclosure or copying (even partial) of such information is therefore forbidden unless written

authorization has been obtained from orma .p.A.. Using the manual for any purpose not strictly

connected to machine installation, operation and maintenance is also forbidden.

2

GENERAL INFORMATIONS

BSS-134 CHAP.- 1

All the information on the plate must be legible at all times.

se the identifi cation data in all correspondence with the manufacturer (e.g. when

requesting spare parts, information, assistance).

1.4 Warnings

The warnings, with instructions on risk-identifi cation procedures, are highlighted by the symbols

shown below. Do not underestimate their importance: machine damage and operator injury are real

possibilities.

DANGER = This symbol informs that the non-compliance with the indications can

cause damages to the equipment and can jeopardise the safety of persons. Care-

fully read the note at the side.

PROHIBITION = This symbol indicates the prohibition of carrying out certain mano-

euvres and/or operations with the machine that, in certain conditions, can threaten

the safety of the operator and of the same machine. Carefully read the note at the

side.

Examine the on-machine sa ety plaques care ully and observe the relevant in ormation.

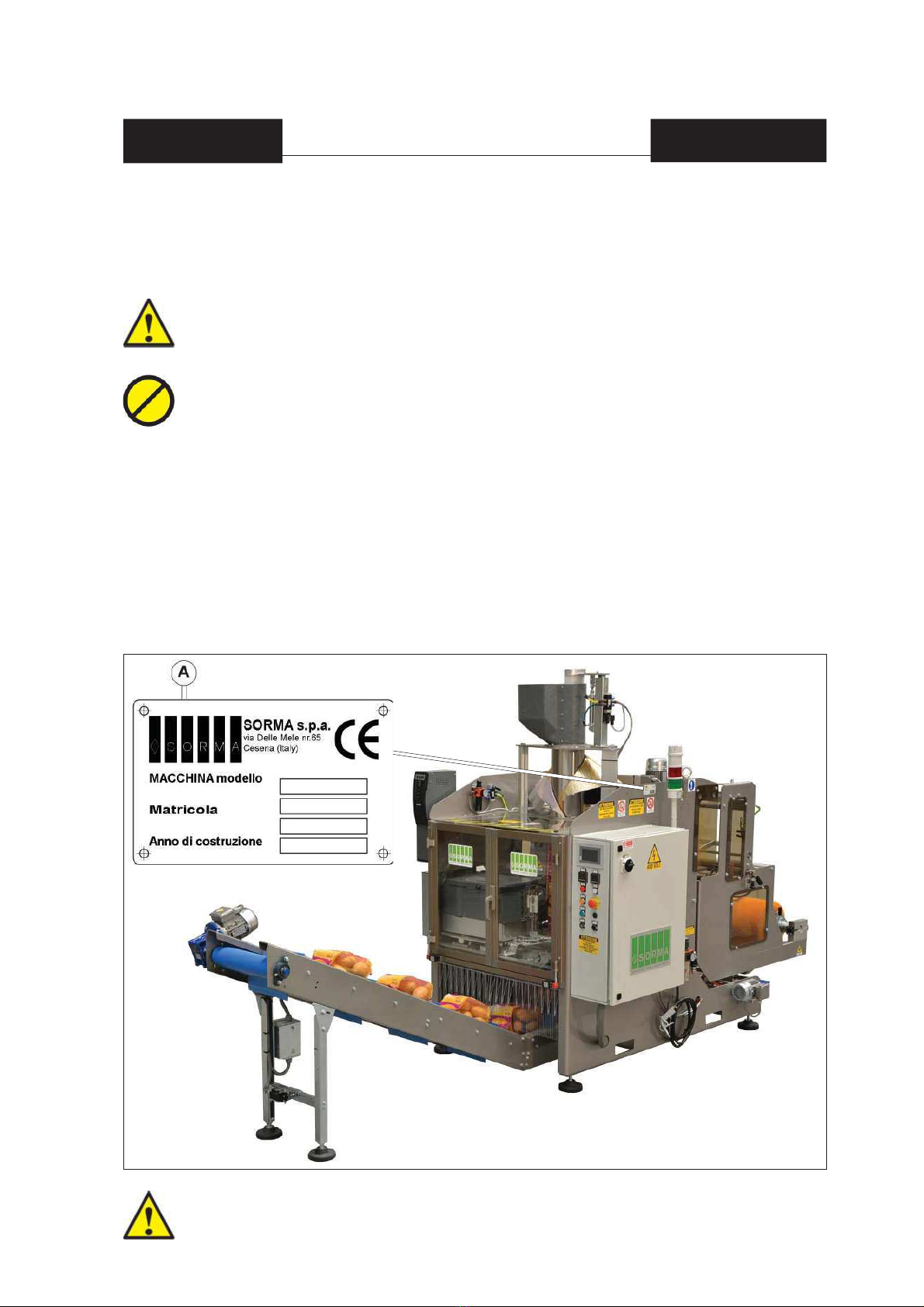

1.5 Machine identifi cation

The identifi cation plate [A] contains the ollowing in ormation:

- MACHINE MODEL

- SERIAL NUMBER

- YEAR OF MANUFACTURE

BSS-134 CHAP.- 1

!

Should the intervention of the Clients After-Sales Technical Assistance Service be required, contact

Sorma S.p.A. at the following address:

Sorma S.p.A.

technical assistance

Tel. 0 47/418611

Fax. 0 47/418612

e~mail: sorma@sormaitalia.com

specifying:

1. type of machine, serial number and year of installation;

2. encountered defects;

3. exact address of the establishment where the machine is installed.

"# $

The warranty terms on material and construction defects, excluding electric, electronic parts and

those subject to wear, are indicated in the sales contract.

4

GENERAL INFORMATIONS

BSS-134 CHAP.- 1

1.8 Declaration of Conformity

SORMA S. .A.

%%[To "0546620155" AGRINTESA SOC AGR COOP ]

Via Delle Mele, 65 47522 Cesena FC

Tel.(+39) 0547 418611

Fax.(+39) 0547 418612

www.sormaitalia.com info@sormaitalia.com

DICHIARAZIONE CE DI CONFORMITÀ

All. IIA DIR. 2006/42/CE

IL FABBRICANTE

DICHIARA CHE LA MACCHINA

Direttiva 2006/42/CE del Parlamento Europeo e del Consiglio del 17 maggio 2006 relativa alle macchine e che modifica la direttiva 95/16/CE.

SORMA S.p.A.

Via delle Mele, 65 47522 FC

Cesena Italia

Azienda

Indirizz Cap Pr vincia

Città Stat

Insacchettatrice mod. BSS 134

Descrizi ne M dell

xxxxxx 2012 05/2012

Serie/Matric la Ann c str. Revisi ne

Insacchettatrice mod. BSS 134

Den minazi ne c mmerciale

È CONFORME ALLE DIRETTIVE

BSS 134

Direttiva 2004/108/CE del Parlamento Europeo e del Consiglio del 15 dicembre 2004 concernente il riavvicinamento delle legislazioni degli Stati membri relative alla

compatibilità elettromagnetica.

Direttiva 2006/95/CE del Parlamento Europeo e del Consiglio del 12 dicembre 2006 concernente il riavvicinamento delle legislazioni degli Stati membri relative al

materiale elettrico destinato ad essere adoperato entro taluni limiti di tensione.

Riferimento norme armonizzate:

EN 12100: 2010 Principi generali di progettazione Valutazione del rischio e riduzione del rischio.

EN ISO 14121-1: 2007 Principi per la valutazione del rischio

EN 60204-1: 2006 + A1: 2009 + AC: 2010 Equipaggiamento elettrico delle macchine

EN ISO 13850: 2008 Arresto di emergenza

EN IEC 62061: 2005 + AC: 2010 Sicurezza funzionale dei sistemi di comando e controllo elettrici, elettronici ed elettronici programmabili correlati alla sicurezza

EN ISO 13849-1: 2008 + AC: 2009 Parti dei sistemi di comando legate alla sicurezza

EN 349: 1993+A1: 2008 Spazi minimi per evitare lo schiacciamento di parti del corpo

EN ISO 13857: 2008 Distanze di sicurezza per impedire il raggiungimento di zone pericolose con gli arti superiori e inferiori

EN ISO 4414: 2010 Impianti pneumatici

EN 1808: 1995 + A2: 2008 – Dispositivi di interblocco associati ai ripari.

EN 619: 2002 + A1: 2010 – Apparecchiature di movimentazione meccanica continua di carichi unitari.

Il fabbricante

Luogo e data del documento

Cesena, 29/01/2012

IL FASCICOLO TECNICO E’ STATO COSTITUITO DA:

Sig. Severi Roberto

Residente in via Dismano

47522 Cesena (FC)

5

TECHNICAL SPECIFICATIONS

BSS-134 CHAP.- 2

2.1 General safety notes

The functioning of the machine is subject to general safety rinci les used in industrial lants.

In particular, given the typical use conditions for this machine, the following prescriptions must be

followed:

A) The protection devices must never be removed or made ineffi cient; in particular, no safety switch

must ever be short-circuit.

When carrying out maintenance wor on the machine, it may be necessary to temporarily deactivate

the safety devices, this operation must be carried out only by authorised and adequately trained

staff.

B) It is forbidden to carry out adjustments or format change if the machine is started.

C) Do not lace the hands near the rotary arts of the machine.

Do not wear clothing that might become tangled in moving parts (scarves, nec erchief, rings,

bracelets, watches, etc.).

For those having long hair, use hair clips or caps to hold them.

2.2 Attached documentation

he following documentation has been attached to this manual:

- WIRING DIAGRAM

- PNEUMATIC PLANT LAYOUT

- SPARE PARTS CATALOGUE

- DECLARATION OF CONFORMITY

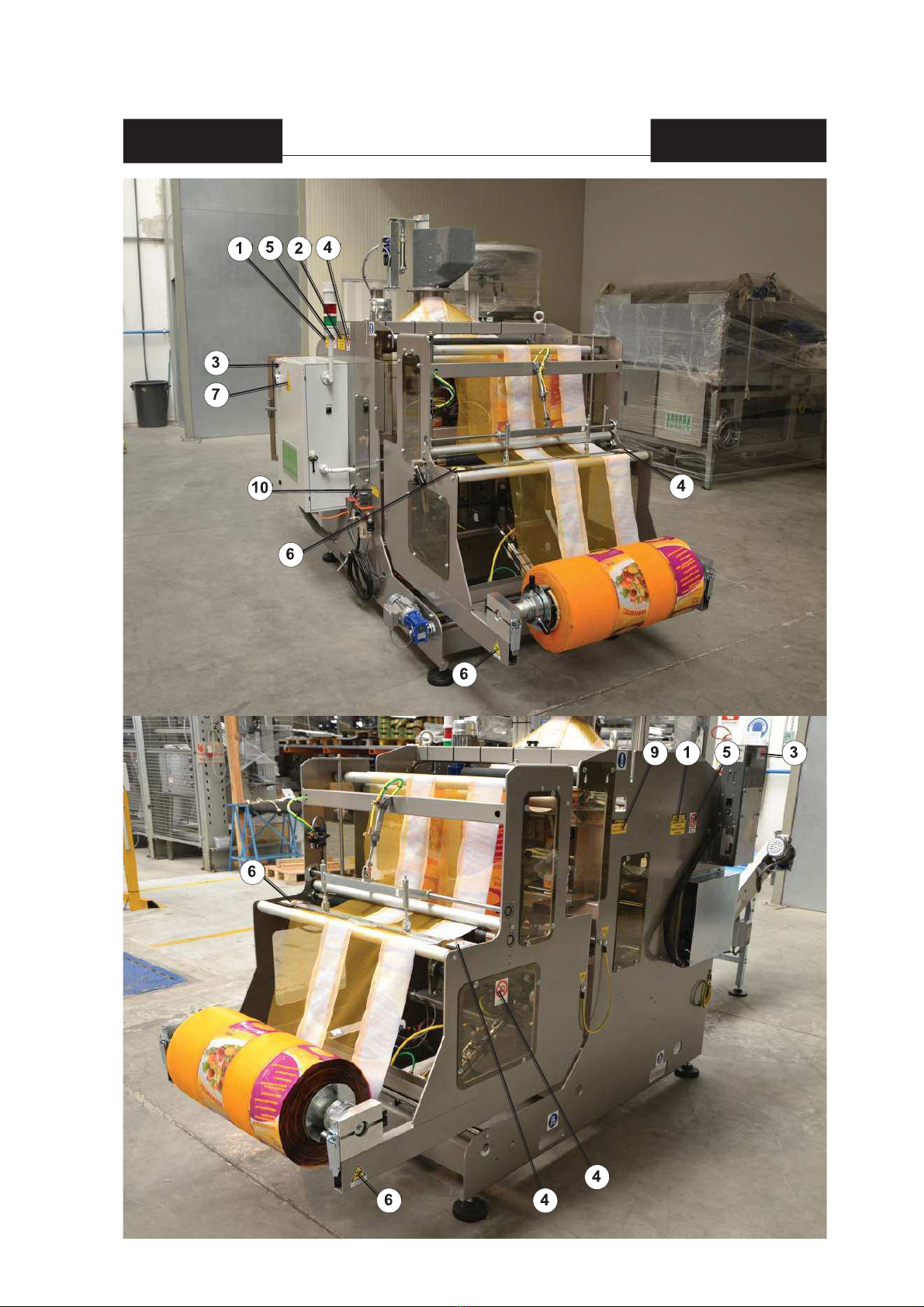

2.3 Technical introduction

Automatic machine to pac fruit and vegetable.

A roll of the material to form the Vert-bags is positioned in the rear part of the machine. This material

is formed by a part of net and a part of fi lm.

Consequently, the 2 sides of the Vert-bag are made of net and the 2 central parts are made of cu-

stomized fi lm.

The vert-bags are closed by a hot-sealing device

The machine may be equipped with an electronic labeller to apply an adhesive label directly on the

band, or with a thermal transfer system.

Weight of the pac s: up to 3 g. (for green-beans 500 – 750 – 1000 gr.)

Standard Tubes:

- for pac s 0,5 to 1,5 g.: tube diam. 140 and 160 mm.

- for pac s 2/2,5 to 3 g.: tube diam. 180 and 203 mm.

The BSS-134 must be used only for the purpose it was expressly designed for. Any other use is to

be deemed improper and hence unreasonable.

The company Sorma S.p.A. shall not be held liable for any damage due to improper, mista en or

unreasonable use of the machine, that may be caused to persons and/or animals and/or things.

All restore o erations must be carried out only when the machine is disconnected

from the ower su ly and neumatic su ly.

Therefore, the operator can restore normal operating conditions and remove the anomaly only after

fully disconnecting the machine.

6

TECHNICAL SPECIFICATIONS

BSS-134 CHAP.- 2

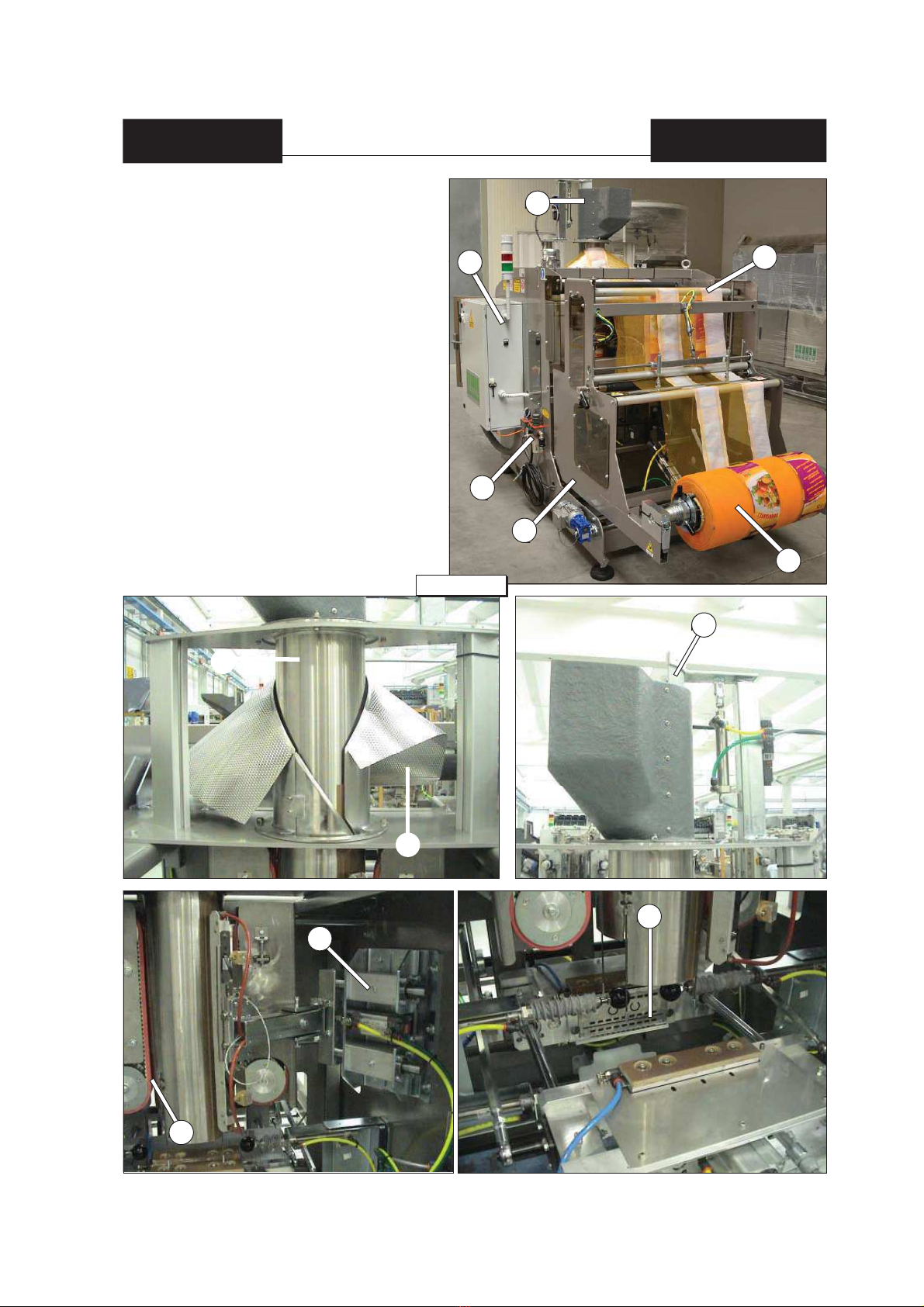

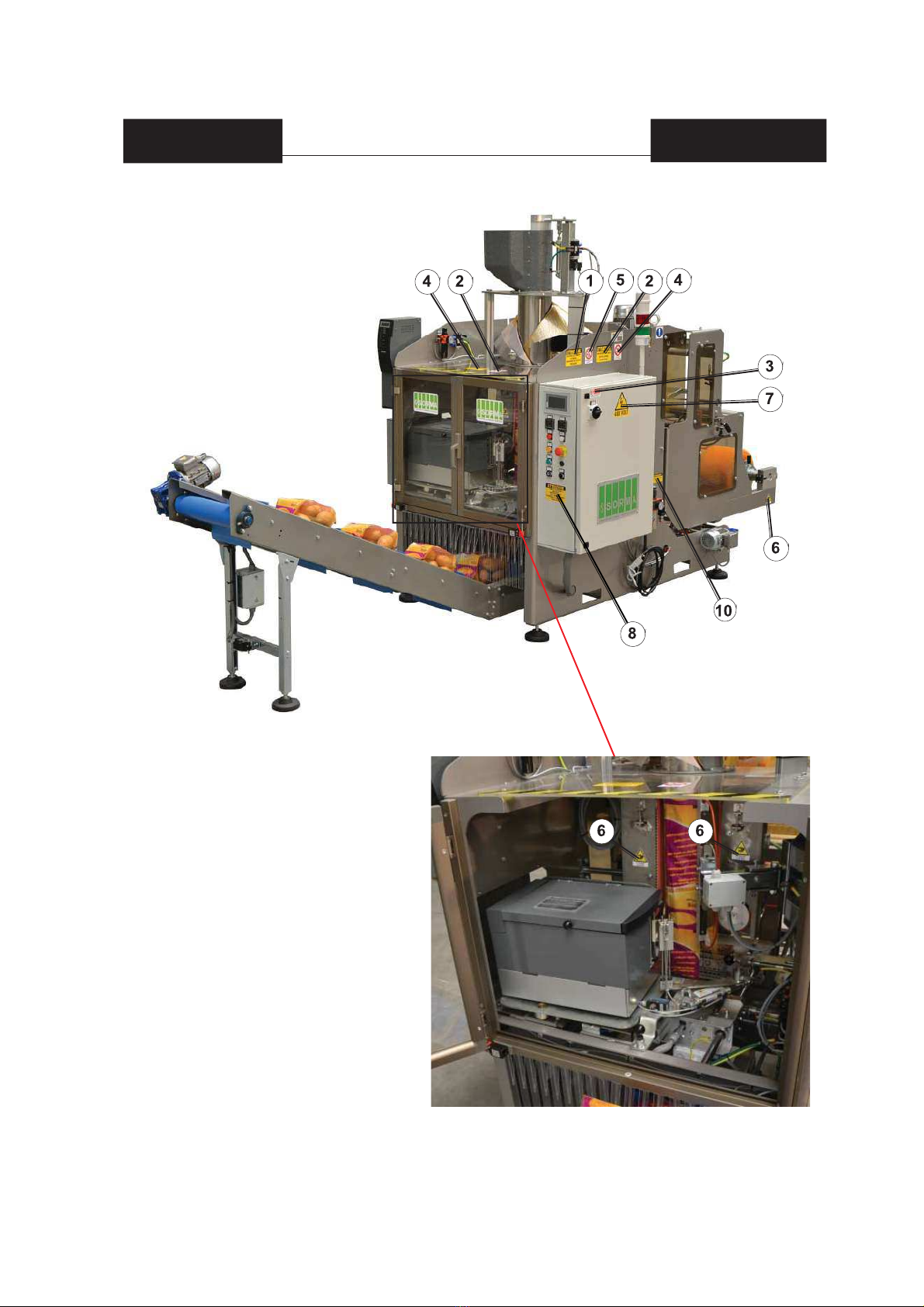

2.4 Machine descri tion

The machine basically consists of:

A = Electrowelded frame

B = Loading hopper

C = Intake

D = Loading t be

E = Carrier tracks

F = Vertical sealing nit

G = Horizontal sealing nit

H = Tensioner rollers nit

I = Air fi lter nit

L = Self-centring reel nit

M = Electric control board

N = Printer

O = Bridge-breaker nit.

D

C

F

G

E

O

B

A

I

L

MH

Fig.1 chap.2

7

TECHNICAL SPECIFICATIONS

BSS-134 CHAP.- 2

2.5 Notes on using the machine

IT IS FORBIDDEN TO:

1. Amend the cycle of the machine;

2. Work different products from those indicated;

3. Replace or amend the speed of the machine components;

4. Replace pieces with non-original spare parts;

. Amend the electric connections to by-pass the safety devices;

6. Remove or amend the protection sumps;

7. Use the machine in environments with explosive and/or aggressive atmosphere.

The non-admitted use of the machine entails the immediate ex iring of the warranty.

2.6 Technical data

- Machine weight: ........................................................................................................... ~ 720 Kg

- Installed electric power: ........................................................................................... ,7 Kw/ 10A

- Power supply voltage: .................................................. 400V/ 0Hz (unless otherwise specifi ed)

- Compressed air working pressure:...................................................................................... 6 bar

- Compressed air consumption:.................................................................................... 740 Nl/min

- Acoustic pressure: ............................................................................................................... 70 dB

- Working temperature: .......................................................................... between + °C and +40°C

- Throughput:................................................. Vert-bag up to 2 kg.: . 32 – 3 packs/minute approx.

Vert-bag 3 kg.: .. 30 – 32 packs/minute approx

N.B.: the maximum electric and pneumatic c nsumpti n, as well as pr ductivity, sh uld be c nsidered

as variables depending n: type f b xes, packages, pr ducts t be pr cessed, c nsumables being

used and perat r’s capacity.

8

TECHNICAL SPECIFICATIONS

BSS-134 CHAP.- 2

2.7 Overall dimensions

Fig.2 chap.2

BSS-134 CHAP.- 3

!" #" ###$!" !

#% !"&

' (%)

* # #%#)

+ ,% !

#%# #"

The operator, before starting work, must know the disposition and the functioning of the controls and

the features of the machine, and must have fully read this manual.

"

1. Always pay particular attention to the precaution, warning or danger signals placed on the

machine.

2. Never wear clothing, ornaments or accessories that might remain entangled in moving parts.

3. Always wear safety glasses, ear protections and every other protection device in the areas

requiring it.

% #% $% " $- % ,

- "!,#!

The individual protection devices that the operators using the machine must be provided with, must

be compliant with the legislation in force and in relation to the action the must perform, maintenance

or normal use, be the following:

#"

The normal use is the activity that the operator carries out for production; the operator must enslave

the machine during the automatic process.

For this activity the following I.P.D. have been identifi ed.

!

The clothing the operators must be provided with must be of resistant materials,

they must also allow perfect mobility during the movements the operator must

perform.

*. /##0

They must have antistress anatomical insole for the comfort of feet and the

upper part must be impenetrable. They must fully cover the ankle overlapping

with the trousers. They must also allow a correct perspiration of the same foot.

1

BSS-134 CHAP.- 3

2!! /# 0

They must be suitable for the hand of the operator that must wear them and

must be suffi ciently long to cover the elastic clothing around the wrist of the

operator. They must guarantee a safe and rapid grip as well as guarantee

high resistance to the product to be handled. They must guarantee comfort

and good sweat absorption.

*#"

They are the activities aimed at resetting the functionalities of the machine, even if developed by

external staff, they must wear the indicated I.P.D..

Different actions are involved, therefore the I.P.D. to be used during the maintenance actions are the

following:

*!

The clothing the operators must be provided with must be of resistant materials,

they must also allow perfect mobility during the movements the operator must

perform.

The ends of this clothing must remain well adhered to the body (elastic type)

especially around the ankles, the wrists, the neck and the stomach, in order

to avoid that a loose part of the clothing comes into contact with moving parts,

generating serious dangers.

**. /##0

They must have antistress anatomical insole for the comfort of feet and the

upper part must be impenetrable. They must fully cover the ankle overlapping

with the trousers. They must also allow a correct perspiration of the same foot.

*3 /# 0

They must be suitable for the hand of the operator that must wear them and

must be suffi ciently long to cover the elastic clothing around the wrist of the

operator. They must guarantee a safe and rapid grip as well as guarantee high

resistance to the product to be handled. They must also agree protections and

comfort against the low and high temperatures and good sweat absorption.

*43 /#% 0

They must be of suitable size to the face of the operator who must wear them.

They must have a visual range such to guarantee a good visualisation of the

environment and of the same machine.

*56" /#0

They must have an excellent resistance to both impacts and contact with the

same product. The harness must be adjustable. The helmet must be provided

with front anti-sweat band and with chinstrap for correct fi xing. The material with

which it is realised must allow resistance to both high and low temperatures.

It must allow the operator to have an excellent comfort to guarantee a correct

and safe development of its own task.

11

MACHINE SAFETY

BSS-134 CHAP.- 4

4.1 Safety warnings

The warnings listed below must be carefully read to become fundamental part of the daily practice in

the running and maintenance of the machine, in order to prevent any type of injury to persons and/

or damages to things.

Do not try to function the achine until the functioning has not been fully under-

stood.

In case of doubts, despite having carefully and fully read this anual, contact the

Clients After-Sales Technical Assistance Service of Sor a S.p.A.

Ensure that all prescriptions relating to safety are aware to all staff involved in the use, cleaning and

maintenance of the machine.

Before starting the achine, the operator ust verify the eventual presence of

visual defects on the sa e and on the safety devices.

In this case, i ediately notify to the Clients After-Sales Technical Assistance

Service of Sor a S.p.A. every evident ano aly.

-The manufacturer declines any responsibility for damage to people or things, due to non-compliance

with safety regulations.

- Any attempt to dismantle, modify or tamper with any part of the machine will invalidate the warranty,

and Sorma S.p.A. will be held harmless for any damage to people or things due to such abuse.

- The assistant operator must possess all the psychological and physical requirements and capacities

needed for using the machine.

- Concentrate properly, and take every precaution, before using the machine in any way.

- The working area in front of the machine must always be kept clean and free for immediate access

to the main switchboard under emergency conditions.

- Effect the working cycle start-up sequence only in the way laid down here.

- Never open machine doors or protections without specifi c authorisation and training, and never

before having cut off the air and power supply.

- Never use the machine with casings or protections removed.

- Never use the machine with protections disabled or damaged.

- Never put your hands, body parts or anything else, near or inside moving or live parts of the ma-

chine, or in the electric cabinet.

- Never modify programme parameters in order to obtain a performance different from the kind pro-

vided for and programmed during design and testing.

- Always work under suitable conditions of lighting in order to always have a clear view of the opera-

ting and working area.

12

MACHINE SAFETY

BSS-134 CHAP.- 4

- Never stand on the machine.

- Never leave the machine or installation unguarded while it is running.

- Notify the maintenance staff of any operational anomaly on special devices.

- Avoid working on the machine while wearing objects which may cause accidents (watch, tie, bra-

celet, ring etc.).

- Never work on the machine with long hair loose.

- Button up the sleeves of your work clothes carefully.

- Work on the machine respecting technical rules, act to guarantee the safety of the operators.

- Examine the safety stickers and plates applied to the machine carefully, and comply with the in-

structions they provide.

- All works on under voltage parts must be carried out only by authorised staff.

Before starting work, disconnect the electric current using the appropriate main switch located on

the front of the electric control board and remove the pressure from the pneumatic circuit.

- Do not perform seals of any kind in the electric connections of the electric circuits.

- Do not intervene for any reason on moving parts, even if to unblock an entanglement.

- Maintain the ground of the surrounding area of the machine constantly clean from encumbrances

and water.

- Always wear protection glasses, ear protectors and every other personal protection device in the

areas requiring it.

- Always pay particular attention to the precaution, warning and danger signals placed on the machine.

- Apply and ensure the safety rules are always complied with, in case any doubt should arise, consult

this manual again before acting.

- It is forbidden to inhibit the safety devices.

- It is forbidden to inspect the machine during functioning.

- It is forbidden to sit and/or rest on the personal protection devices.

- It is forbidden to respect on the machine during functioning.

- It is forbidden to sit and/or rest on the machine components.

- It is forbidden to amend parts of the machine.

- It is forbidden to apply further devices to the machine.

- Clean the machine components, the panels and the controls using soft and dry cloths.

- For the research or removal of any fault or inconvenience, use all precautions, described in the

manual, suitable for preventing any damage to persons and/or things and/or animals.

13

MACHINE SAFETY

BSS-134 CHAP.- 4

- It is essential to be extremely attentive and always maintain attention and refl exes alert. Should

the operator be subjected to sickness or unfavourable physical condition, even slight, that might

reduce the degree of supervision, he must avoid functioning the machine or action on accessory

e uipment and must inform his senior.

- Do not activate the machine or the e uipment when under the effect of alcohol, medicines or drugs.

- The use of the machine by disabled persons is forbidden.

- The use of the machine by minors of 18 years is forbidden.

- The improper use of the machine may be cause of dangers for staff in charge of the running and of

damages to the same machine.

- For any eventual problem that should arise during the operational life-span of the machine and,

however, not contemplated in this technical documentation, contact the Clients After-Sales Technical

Assistance Service Sorma S.p.A., in order to solve the problem in the least time possible.

- Daily check the correct functioning of all switches and safety devices.

- The safety devices must not, in any case, go in short circuit.

- During the maintenance, adjustment or repair operations it may be necessary to exclude certain

safety devices from the service. This operation must only be carried out by authorised staff.

- The operator must be expert of the function and position of the STOP and EMERGENCY buttons.

- Replace the faulty parts with original spare parts, guaranteed by the manufacturing company.

Never attempt risky solutions!

Do not work with hands or wet objects when the machine is connected to the electric network.

4.2 Defi nition of the safety ter s

In this manual, with regard to safety, the following terms will be used:

Dangerous area: every area inside and/or near the machine where the presence of an exposed

person constitutes a risk for the health and safety.

Exposed person: any, fully or partially, inside a dangerous area.

Operator: person in charge of installing, functioning, adjusting, carrying out maintenance, cleaning,

repairing, transporting parts of the machine and all activities necessary for the running.

Safety co ponents: component appropriately designed by the manufacturer and placed on the

market separately from the machine to perform the safety functions. It will therefore be considered

safety component that mechanism which lacking in functioning will jeopardise the safety of the

exposed persons.

14

MACHINE SAFETY

BSS-134 CHAP.- 4

4.3 User obligations

The user of the machine must ensure that:

- the achine is destined only and exclusively for the appropriate and agreed uses in contract.

- the service instructions are fully available to staff in charge and that the latter is correctly

trained with regard to the use of the achine, and that it co plies with all safety, accident-

prevention regulations and the specifi cations of the sa e achine.

- access to the protected functions of the achine by key switches is li ited to authorised staff.

4.4 Service staff

The operators are classifi ed as follows:

- GENERAL OPERATOR: staff not specialised, able to run the machine through the use of the controls

on the push button control panel, loading and unloading operations of the materials used for

the production and simple start-up or reset functions of the production following a stand-by.

- MECHANICAL MAINTENANCE OPERATOR: ualifi ed technician able to run the machine in

normal conditions, to work the format change, intervene on mechanical parts to perform

all adjustments, maintenance or necessary repairs.

He is not enabled for interventions on powered electric syste .

- ELECTRIC MAINTENANCE OPERATOR: ualifi ed technician able to run the machine in normal

conditions, is in charge of all electric interventions of adjustment, maintenance and repair.

He is the only one enabled to work in the presence of voltage inside the electric

control board and in the connecting box.

- SUPERVISOR: ualifi ed technician for more complex interventions.

- EXTERNAL TECHNICIAN: ualifi ed technician made available by the producer or distributor, able

to intervene for amendments, repairs or replacements.

- TECHNICIAN Sorma S.p.A.:ualifi ed technician made available by Sorma S.p.A. or by its agent

to perform complex operations, installation and start-up.

NEVER re ove any plate or sticker. Should these be worn away, ask for new ones.

15

MACHINE SAFETY

BSS-134 CHAP.- 4

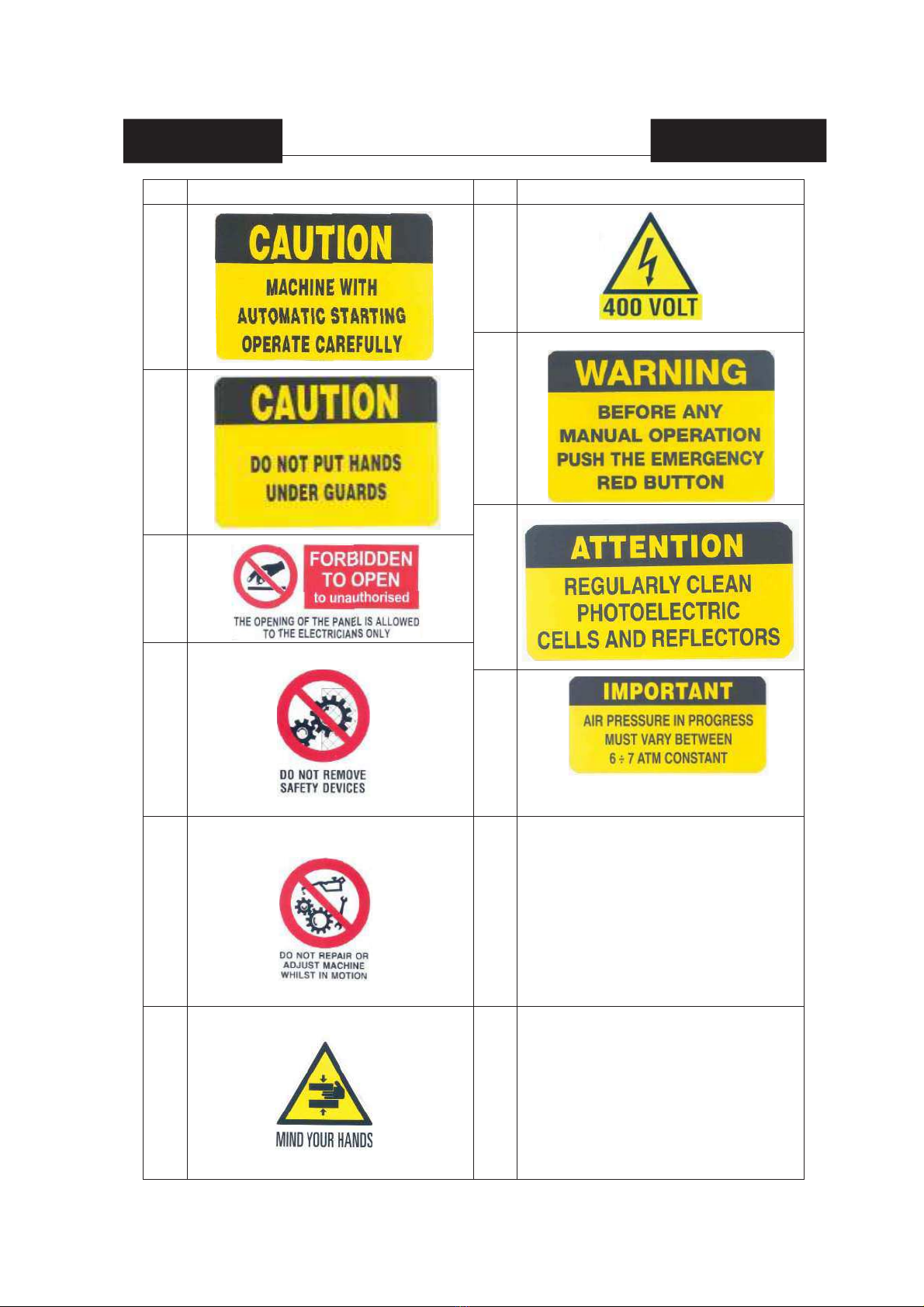

4.5 Safety Pictogra s

16

MACHINE SAFETY

BSS-134 CHAP.- 4

17

MACHINE SAFETY

BSS-134 CHAP.- 4

1

2

3

4

5

6

10

pos. Safety Pictogra s

7

8

9

pos. Safety Pictogra s

11

12

18

MACHINE SAFETY

BSS-134 CHAP.- 4

4.6 Residual risks

The machine has been designed and realised with the opportune warnings in order to guarantee the

safety of the user.

However, there are residue risks which are reported below.

All personnel in charge of operating and conducting aintenance work on the

achine, as well as staff working near it, ust be aware of the following risks.

4.6.1 Auto atic start-up

Danger: Some parts of the machine may start automatically (for instance, the GNR-121 cleated ele-

vator belt conveyor performs a step if a dose of product is unloaded).

Safety measures: Deactivate the machine before conducting any maintenance or cleaning:

- electrically, by acting on the main automatic switch.

- pneumatically, by acting on the slide tap of the fi lter unit.

No-one must approach the machine or touch the mobile parts of the machine while it is moving,

Operators working on the machine or near it must be trained on safety standards and be able to

identify danger areas.

4.6.2 Mobile parts and risk of entangle ent

Danger: Cloths or hats left on the fl oor may get caught in the mobile parts of the machine.

Safety measures: No-one must approach the machine or touch the mobile parts of the machine while

it is moving, Operators working on the machine must wear ade uate clothing with close-fi tting sleeves

and avoid loose-fi tting garments. Operators with long hair who are working on the machine must tie

their hair back. Operators working on the machine or near it must be trained on safety standards and

be able to identify danger areas.

NOTE: The machine may be severely damaged if cloths, fabric, plastic sheets, bags or pieces of

clothing get caught in the machine itself. Therefore, remove all the cloths from the area after cleaning

the machine. Moreover, it is strictly prohibited to leave discarded clothing near the machine.

4.6.3 Sealing Unit

Danger: When the main switch is set to [ON], the sealing unit starts to heat up and is powered on until

the main switch is set to [OFF]. The sealing unit remains hot for approx. an hour after the power is

disconnected via the special main switch at the front of the electrical panel, creating a burning hazard.

Safety measures: No-one must keep their hands or limbs in general on the sealing unit for at least

one hour after the power supply has been disconnected. The sealing unit features a series of warning

messages.

4.6.4 Loading the esh

Danger: To load the mesh into the loading tube, it is possible to activate the carrier motor of the mesh

itself in manual start mode and with the doors open.

Safety measures: This operation must be conducted with care and attention only by ualifi ed and

trained technicians.

19

SHIPPING AND LIFTING

BSS-134 CHAP.- 5

5.1 Safety warnings

This chapter is destined for specialised and ade uately trained staff.

The loading and nloading interventions imply a high risk for persons!

The handling activities described in this chapter must be carried out only by ualifi ed staff, purposely

trained to carry out the loading and unloading and the handling of the batches in safety, using hoisting

e uipment which cranes or lifting trolleys.

For any movement of the machine, it is essential to req est the intervention of Sorma S.p.A.

Sorma S.p.A. will not consider itself responsible for damages deriving from the moving of the

machine witho t its intervention.

5.2 Shipping and lifting

BSS-134 is sent with a cover made of one or more sheets of cellophane adhering.

The machine, when shipped by Sorma S.p.A. with the purpose of reducing its size for shipping, is

partially dismantled.

Upon receipt of the machine, check there are no visual damages; on the contrary immediately inform

Sorma S.p.A.

Check that the supply corresponds to the purchase order specifi cations and verify with the shipment

documents that the supply is complete.

When lifting and moving the machine, take every preca tion to avoid any dangero s

movement liable to ca se accidents or inj ry or damage to people or things.

The machine when moved m st always be in a steady and sec re position.

Before starting to move the machine, there m st be the followingconditions:

- the area involved m st be well lit (see fi g.1 chap.5),

- the operator and the people accessing the moving area m st wear gloves, safety

shoes and safety helmet (see fi g.2 chap.5),

- that the hoisting mean with the relative eq ipment (ropes, hooks, etc.) is s itable

for hoisting the load to be moved.

- that the stability of the load cannot ca se dangers and/or accidents.

The se of ns itable eq ipment can ca se serio s damages to persons in charge

of the handling operations.

Fig.2 chap.5 Fig.1chap.5

Table of contents

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual