South N40 Series User manual

Operation Manual

N40 Series

Mechanical Total Station

© South Surveying & Mapping Technology CO.,LTD All Rights Reserved

CONTENTS

PRECAUTIONS…………………...……………………………………………..1

1. INTRODUCTION…………………………………………………………..…2

1.1 Appearance…………………………...………………………………….2

1.2 Keyboard…………………………………………………………………..3

1.3 Screen……………………………………………………………………...4

1.4 Status Icon…………………………………………………………………4

1.5 Abbreviation………………………………………………………………4

1.6 Star Key…………………………………..…………………………………5

1.7 Time & Date………………………………………………………………..7

2. OPERATION………………………………………………………………….8

2.1 Preparation………………………………………………………………..8

2.2 Instrument Setup. ………………………………………………………..8

2.3 Battery…………………………………………………………………….10

2.4 Tribrach…………..……………………………………………………….11

2.5 Eyepiece Focusing……………………………………………………..12

2.6 Input Mode……………………...……………………………………….12

3. JOB…………………………………………….…………………………....13

3.1 New………………………………………………………………………..13

3.2 Open……………………………………………………………………...13

3.3 Delete……………………………………………………………………..14

3.4 Save As………………………………………………………………...….14

3.5 Recycle Bin……………………………………………………………….14

3.6 Information….……………………………………………………………15

3.7 Import………….………………………………………………….………15

3.8 Export………….……………………………………………………..……15

3.9 About………….……………………………………………………..……16

4. DATA………………………………………………………………………..17

4.1 Raw Data……………………………………………………….....……..17

4.2 Coord Data…………………...…………………………………………17

4.3 P-Code……………………...………………………………………….…18

4.4 Graphics…………………..………………………………………….…..18

5. COGO…………………………………………………………………..…..19

5.1 Calculatr…………………………………………………………….…....19

5.2 Cal.XYZ …………………………………………………………………...19

5.3 Inverse…………………………….…………………………………....…20

5.4 Area & Perimeter……………………………….…………………..…..21

5.5 Pt-L Inverse……………………………………………………………….21

5.6 2Pts Intersec…………………………………………………………..….22

5.7 4Pts Intersec……………………………………………………..……….23

5.8 Volume…………………………………………………………….……...23

5.9 Unit Switch...………………………………………………………..…….24

5.10 Meridian Convergence……………………………………..……….24

5.11 Traverse Ad. …………………………………………………………....25

6. SETTING……………………………………………………………………..26

6.1 Unit…………………………………………………………...…………....26

6.2 Angle……………………………………………………………………...26

6.3 Distance…………………………….………………………………….…27

6.4 Coordinate…………………………….…………………………….…..27

6.5 RS232 Comm…………………………………………………………….28

6.6 Bluetooth…………………………………………………...…………….28

6.7 Power Manage………………………………………………………….28

6.8 Others…………………………………………………….……………….29

6.9 Upgrade…………………………………………….…………………….29

6.10 Format………………………………………………………………..….30

6.11 Initialize……………………………………………………….………….30

6.12 App Install………………………………………………………………31

7. ADJUST……………………………………………………………...………32

7.1 Compensator……………………………………………………..……..32

7.2 V0 Adjustment……………………………………………………..…….32

7.3 Constant……………………………………………………………..…...33

7.4 LCD Adjustment………………………………………………………....34

7.5 Gyro Correction………………………………………………………...34

8. MEASUREMENT…………………………………………………………….35

8.1 Angle…………………………………………………………………..….35

8.2 Distance……………………………………………………………….….35

8.3 Coordinates…………………………………………………….………..36

9. STATION………………………………………………………….…………37

9.1 Known Point…………………………………………………….………..37

9.2 Station Ht………………………………………………………………….38

9.3 BS Check……………………………………………………….………...38

9.4 Resection……………………………………………………………..….39

9.5 Gyro Seeking…………………………………………………………….39

9.6 Point to Line………………………………………………..…………….39

9.7 Multi Direction……………………………………………..…………….40

10. COLLECT……………………………………………………..………...…41

10.1 Measure Pt…………………………………………………………..…41

10.2 Dist.Offset……………………………………………………………….42

10.3 Plane Offset………………………………………………...………..…43

10.4 Column Center…………………………………………….…………..44

10.5 MLM……………………………………………………...…………....…45

10.6 Line & Ext Pt………………………………………………………….….46

10.7 Line & Ext Ang……………………………………………...………..…47

10.8 REM…………………………………………………………………..…..48

10.9 F1/F2…………………………………………………………………..…48

10.10 Camera……………………………………………………….……….49

11. STAKE OUT………………………………………………………………...50

11.1 Point S.O…………………………………………………..…………….50

11.2 Ang & Dist. S.O…………………………………………..……………..51

11.3 Alignment S.O………………………………………………………….52

11.4 Reference Line…………………………………………………………52

11.5 Line S.O……………………………………………………...…………..54

12. ROAD………………………………………………………………………56

12.1 Select Road……………………………………………………….……56

12.2 H Alignment……………………………………………………...……..56

12.3 V Alignment…………………………………………………….………58

12.4 Road Stake Out………………………………………………………..59

12.5 Road Coord.…………………………………………………………...60

13. INSPECTION & ADJUSTMENT…………………………………………..61

13.1 Plate Vial……………………………………………………………..…61

13.2 Circular Vial…………………………………………………………….62

13.3 Compensator…………………………………………………………..62

13.4 Inclination of Reticle…………………………………………………..63

13.5 Perpendicularity between Sight of View & Horizontal Axis……64

13.6 Vertical Index (I Angle) & V0 Adjustment…………………………65

13.7 Optical Plummet………………………………………………………66

13.8 Laser Plummet………………………………………………………….67

13.9 Instrument Constant (K)………………………………………………67

13.10 Coincidence between Sight of View % Emitting Axis………....68

13.11 Leveling Screws on Tribrach………………………………………..69

14. SPECIFICATIONS…………………………………………………………70

15. SAFETY GUIDE……………………………………………….……………73

1

PRECAUTIONS

Congratulations on the purchase of SOUTH N40 Series Total Station!

Please read carefully through the User Manual before you switch on

the product.

1. Do not collimate the objective lens directly to the sunlight without a

filter.

2. Do not stare at the laser beam, or point the laser to the others’ eye!

3. Do not store the equipment in extremely high or low temperature.

4. When the equipment is not in use, store it in the case to avoid dust

and humidity.

5. If there is a great difference between the temperature in work field

or store place, you should leave the equipment in the case until it

adapts to the temperature of environment.

6. If the equipment has not been used for a long time, you should

remove the battery for separate storage. The battery should be

charged once a month.

7. When shipping the equipment, please place it in the carry case. The

cushioned material should be used to cover around the case for

support.

8. Clean the optical parts by absorbent cotton or lens-paper only!

9. Clean the surface softly with a woolen cloth. If it gets wet, you should

dry it immediately before switch-on.

10. Please check the power supply, functions, indications and

parameters of the equipment goes well before operation.

11. Do not disassemble the total station by yourself. Please contact

your authorized agency or SOUTH Service Team when you find the

equipment abnormal.

2

1. INTRODUCTION

1.1 Appearance

No.

Description

1

Handle

2

Camera (Optional)

3

Objective Lens

4

Battery Unit

5

Horizontal tangent Screw

6

EDM Trigger Key

7

Tribrach

1

2

4

5

7

6

9

11

12

13

14

8

10

No.

Description

8

Collimator

9

Eyepiece

10

Vertical Tangent Screw

11

Vial Bubble

12

Plummet

13

Display Unit with Keypad

14

Tribrach Lock

3

3

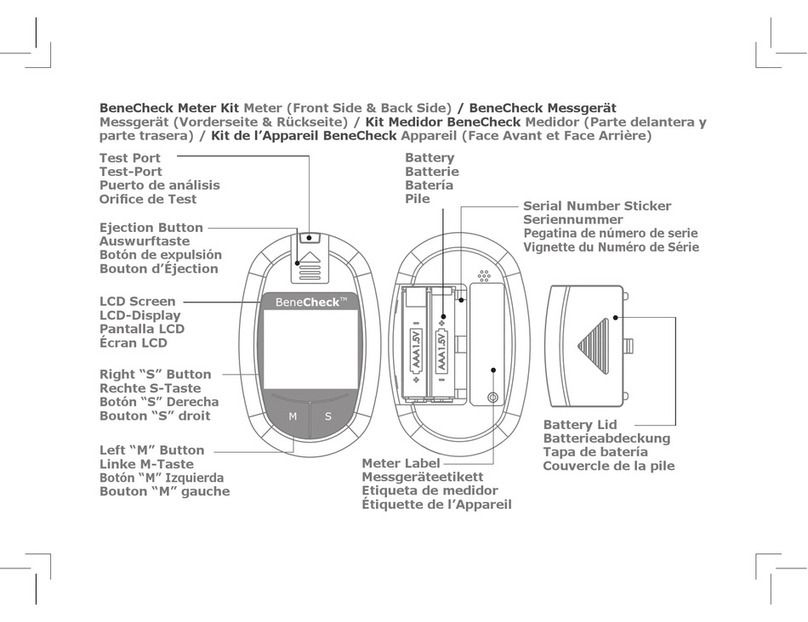

1.2 Keyboard

a) Quick Access Key

b) Functional Key

c) Alphanumeric Keypad

d) Navigation Key

Key

Description

α

Shift the case of alphabets.

Activate the soft-keypad

Star-key

Power On/Off.

Func

Quick-access to angle measurement

Ctrl

Quick-access to distance measurement

Alt

Quick-access to coordinate measurement

Del

Delete characters before cursor

Tab

Switch the cursor in different widget

B.S

Backspace.

Shift

Shift the input mode between alphabets and numbers

S.P

Space.

ESC

Escape.

ENT

Enter.

0-9, .,-

Input numbers, dots, minus, and the other symbols.

Navigation keys.

4

1.3 Screen

It can be divide into four parts:

A) Title

B) Status Bar

C) Active Field

D) Tab Bar

1.4 Status Icon

1.5 Abbreviation

A

B

C

D

Abbr.

Description

V

Vertical angle

HL/HR

Horizontal left/ right

SD

Slide Distance

HD

Horizontal distance

VD

Vertical distance

N/ E/ Z

North/ East/ Zenith

Icon

Description

Display the battery status. Click for power manage.

Bluetooth status.

Star-key. Click to activate the quick-setting page.

Soft-keypad. Click to on or off the soft-keypad.

19:42

Current time. Click to reset time and date.

Click to display the information of the instrument.

Escape to the previous page.

Save the data on the current page.

5

1.6 Star Key

Click [ ] key in any page to activate

the quick-setting page.

1) PPM

2) Target

3) E-Bubble

4) Calculator

1.6.1 PPM

The value of temperature, pressure

and PPM can be detected or

calculated by T&P sensor, or inputted

by manual.

Input range:

Temp: -40

°

~+60

℃

or -22~+140

℉

Press.: 560~1066 hPa, 420~800 mmHg

or 16.5~31.5 inHg

PPM: -99. 9 to +99. 9, Interval: 0 .1PPM

1.6.2 Target

Click or use the navigation key to

select the target among Prism, Sheet

and Non-Prism mode.

The default value of prism constant is

-30, which can be defined by manual.

5) Meas. Mode

6) Pointer

7) Plummet

8) Auto Code

▶PPM

▶Target

▶Star Key

6

1.6.3 E-Bubble

Activate the tilt sensor (electronic

bubble) for levelling.

X: Turn on the sensor by single axis.

XY Turn on the sensor by dual axis.

OFF: Turn off the sensor.

: Click to turn on or off the laser

plummet.

1.6.4 Calculatr

The calculator can handle the simple

formula calculation, like Sin, Cos, Tan,

Log, Square, etc. Refers to Chapter 5.1

Calculatr for further information.

1.6.5 Meas. Mode

Select the measurement mode among

N times (1-99 times, average),

Continuous or Tracking mode.

1.6.6 Pointer

Click to turn on or off the laser pointer

for easier target aiming.

▶Electronic Bubble

▶Measure Mode

▶Laser Pointer

▶Calculator

7

1.6.7 Plummet

Click the status bar to set the

illumination level from class 1 to 5.

If your total station features the Auto

Height function, click [Meas] to

measure the instrument height.

1.6.8 Auto Code

Click to activate the Auto Code

function.

Note: Please refers to Chapter 4.3

P-Code for further information.

1.7 Time & Date

Click the time (eg.14:55) on the right

corner of screen to check or set the

time and date.

▶Laser Plummet

▶Auto Code

8

2. OPERATION

2.1 Preparation

Unpacking

Lay down the case lightly with the cover upward. Unlock the case, and

take out the instrument.

Storage of Instrument

Cover the cap, put the instrument into the case with the vertical clamp

screw tightened and circular vial upwards (lens towards tribrach).

2.2 Instrument Setup

1) Setting up the tripod

A. Loosen the screws on the tripod legs, pull out to the required length

and tighten the screws.

B. Make the center of tripod and the occupied point approximately on

the same plumb line.

C. Step on the tripod to make sure if it is well stationed on the ground.

2) Instrument setup (Laser plummet)

A. Place and fix the instrument carefully on the tripod

B. Press [★]and select [7]LaserPlt to turn on the laser plummet. Hold the

two legs which are not fixed on the ground and decide the position to

fix according to the laser dot. When the laser dot is roughly on the

station point, fix those 2 legs.

9

Instrument setup (Optical plummet)

Adjust the eyepiece of the optical plummet telescope to your eyesight.

Slide the instrument by loosening the tripod screw; place the point on

the center mark of the optical plummet. Sliding the instrument carefully

as to not rotate the axis will allow you to get the least dislocation of the

bubble.

3) Roughly leveling by the circular vial

A. Rotate the foot-screw A and B to

move the bubble in the circular vial, in

which case the bubble is located on a

line perpendicular to a line running

through the centers of the two leveling

screw being adjusted .

B. Rotate the foot-screw C to move the bubble to the center of the

circular vial.

4) Leveling by the plate vial

A. Rotate the instrument horizontally by

loosening the horizontal clamp unit

and place the plate vial parallel to the

line connecting rotating the foot-screw

A and B, and then bring the bubble to

the center of the plate vial by rotating

the foot-screw A and B.

B. Rotate the instrument in 90º(100gon)

around its vertical axis and turn the

remaining leveling screw or leveling C

10

to center the bubble once more.

C. Repeat the steps and check whether the bubble is correctly

centered in all directions.

If the laser or optical plummet doesn’t stay at the center position after

levelling, please slightly loosen the screw under the tripod head and

move the instrument (don’t rotate the instrument) until the equipment is

on the station point. Tighten the screw and level the instrument again.

Repeat these steps until the instrument is precisely centered and

leveled.

Note:

You can also level the instrument precisely by the E-bubble.

When the tilt is over ±4’, the system will enter the adjusting page of tilt

sensor automatically.

2.3 Battery

Inserting

Put the battery into the instrument, push it. Check and insert it correctly

to side into the housing.

Replacing

Press the battery lock on both sides, remove the battery. When the

remaining voltage is less than one grid, please stop your operation and

charge it as soon as possible.

Before remove the battery from the instrument, make sure that the

power is turned off. Otherwise, the instrument may be damaged.

11

Charging

The battery must be charged prior to using before the first time

operation.

The battery LI-39 should be charged only by the official charger NC-III,

which packed together with the instrument. Please connect the power

supply in 220V, among 0°~±45°C.

When the indicator on the charger is red, the charging process has

begun. When indicator turns green, the charging has finished. For

safety, please pull out the battery and charger in time.

In order to get the maximum service life, please charge the battery at

least once in a month.

Note:

a) The operating time depends on the outside conditions, such as

ambient temperature, charging time, the cycles of charging, etc. It

is recommended for safety to charge the battery beforehand or to

prepare spare full-charged batteries.

b) The remaining voltage of battery shows the power regarding to the

current measure mode. The consumption of distance

measurement is higher than angle measurement in normal. When

switching the measurement mode from angle to distance in a low

battery voltage, the equipment might be interrupted.

2.4 Tribrach

Dismounting

If necessary, the instrument can be dismounted from tribrach. Turn the

locking knob in 180° counter-clockwise to disengage anchor jaws,

12

and take off the instrument.

Mounting

Insert three anchor jaws into holes of

tribrach and line up the directing stub.

Turn the locking knob about 180°

clockwise to mounting the instrument.

2.5 Eyepiece Focusing

Sight the Telescope to bright place and rotate the eyepiece tube to

make the reticle clear. Roughly collimate the target by the top of the

triangle mark on EDM cover.

Rotate the focusing screw on eyepiece to make the image clear.

2.6 Input Mode

Swift the input mode between numbers

and alphabets by [Shift] on keyboard or

[123]/[abc] on soft-keypad.

Swift the case of alphabets by [α] on

keyboard.

13

3. JOB

In job management, you can create,

open, delete or save job as the other

file, recover the job from recycle bin,

check the information, or import /

export data via SD card, flash disk,

Bluetooth or Comm Port.

Every time when turn on the instrument,

it will open the previous job as default.

Click the left top-corner of screen to

check the current job.

3.1 New

Create and open a new job, and the

last job will be saved.

The default name of job is the current

date, which can be modified by

maximum 8 characters.

3.2 Open

Open the job from list. The previous job will be saved at the same time.

The current job will be shown in blue.

14

3.3 Delete

[Delete]: Delete the chosen job. It will

be moved into recycle bin.

3.4 Save As

Save the current job as a new job.

Job: Input the name which will be

saved as. Maximum 8 characters.

3.5 Recycle Bin

Recover or delete the files in recycle

bin.

[Restr.]: Restore the chosen job from

recycle bin.

[Delete]: Delete the job permanently

from recycle bin.

Table of contents

Other South Measuring Instrument manuals

South

South N3 Series User manual

South

South A1 Series User manual

South

South ET-02 User manual

South

South N6 Series User manual

South

South NTS-960R User manual

South

South Galaxy G1 User manual

South

South N9 Series User manual

South

South GALAXY G7 User manual

South

South Galaxy G6 User manual

South

South N6+ Series User manual

Popular Measuring Instrument manuals by other brands

Campbell

Campbell TDR200 instruction manual

GPI

GPI 01A31LM manual

PCB Piezotronics

PCB Piezotronics IMI Sensors Spindler 607A61 Installation and operating manual

Onicon

Onicon SYSTEM-30 Installation and operation guide

Siemens

Siemens SITRANS F US SONO 3100 operating instructions

ENS

ENS UV24-MM+ instruction sheet