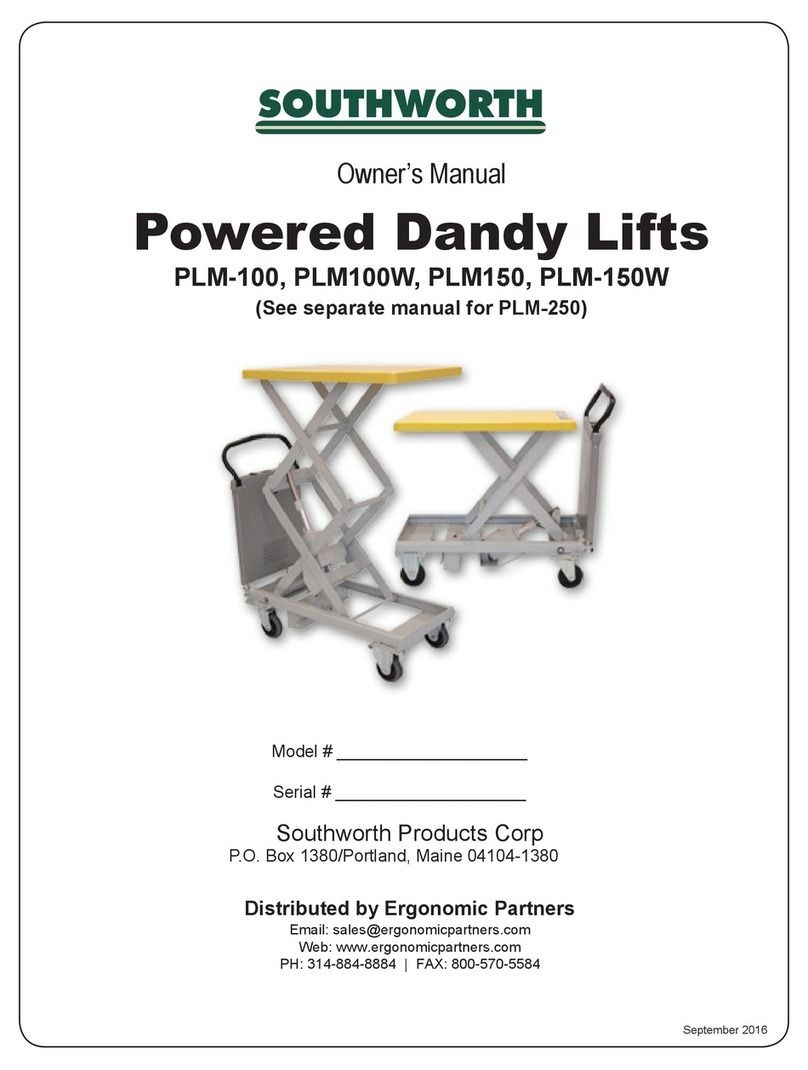

5Southworth Products DDL Dock Lift Manual

1.3

Owners/users shall apply sound principles of safety, training, inspection,

maintenance to the expected operating environment. It shall be the responsibility of the owner/

user to advise the manufacturer where deection may be critical to the application.

- Owners/users shall keep and maintain a copy of the operating and maintenance

manual(s) and ensure its availability to operating and maintenance personnel.

- It shall be the responsibility of the users to inspect and

maintain the machine as required to ensure proper operation. The frequency of inspection and

maintenance shall be based upon the manufacturer’s recommendations and be compatible

with operating conditions and the severity of the operating environment. Machinery that is

not in proper operating condition shall be immediately removed from service until repaired.

Maintenance and repairs shall be made by a qualied person and the repairs shall be in

conformance with the manufacturer’s recommendations.

- Before adjustments and repairs are started on the

machine, the following precautions shall be taken as applicable:

1. Remove the load from the platform.

2. Lower platform to the full down position.

3. Relieve system pressure from all circuits before loosening or removing any components.

4. All controls in the “o” position and all operating features secured from inadvertent

motion by brakes, blocks, or other means.

5. Disconnect power and follow established owner/user lockout/tag out policies.

6. Follow precautions and directions as specied by the manufacturer.

When parts or components are replaced, they shall be replaced with

parts or components approved by the original manufacturer.

- The user shall ensure only qualied personnel inspect and maintain

the machine in accordance with the manufacturer’s recommendations.

- An owner/user, who directs or authorizes an individual to operate the

machine shall ensure that the individual has been:

1. Trained in accordance with the manufacturer’s operating manual.

2. Made aware of the responsibilities of operators as outlined. See Section 1.4

Responsibilities of Operators on page 6.

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the

operator.

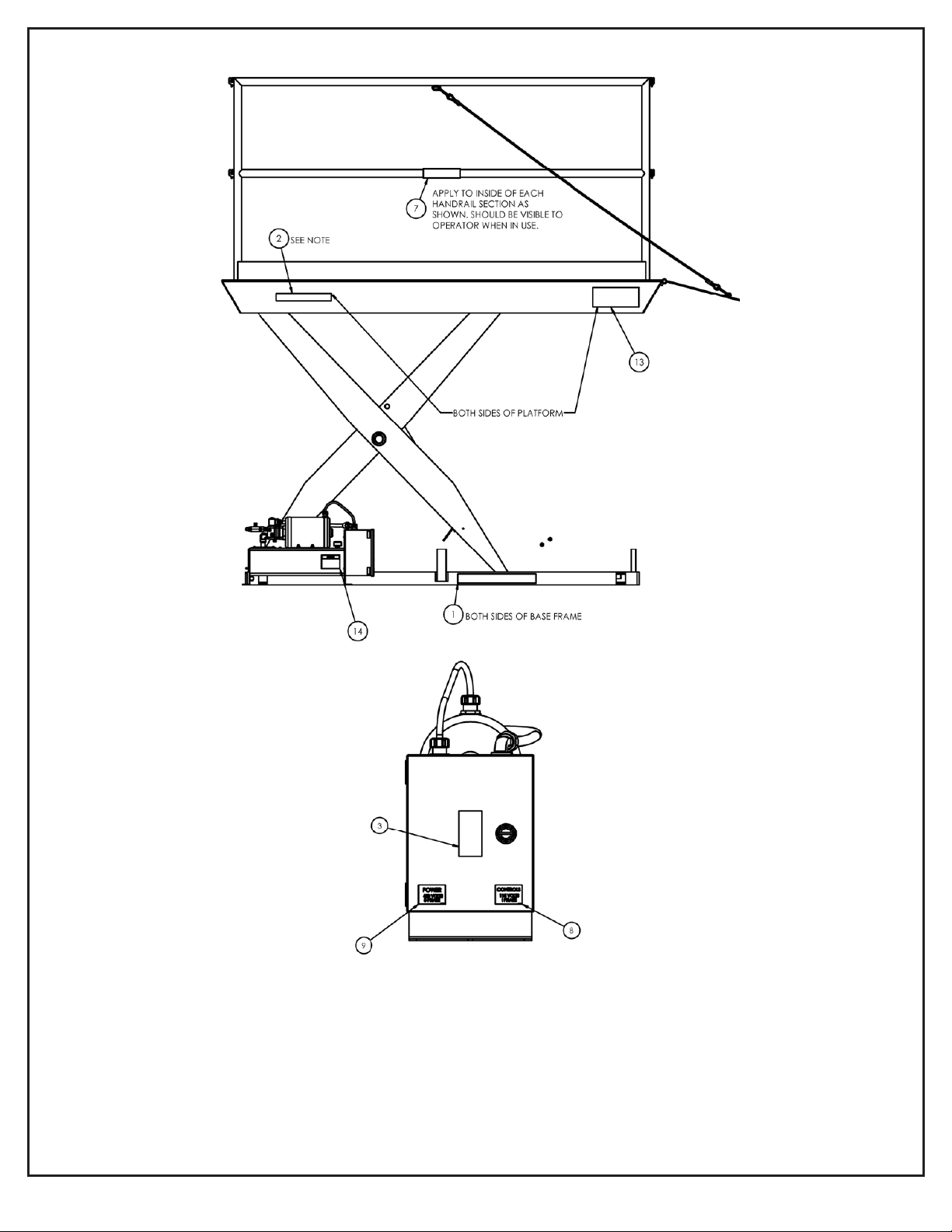

and additions shall not be performed without the manufacturer’s prior written

approval. Where such authorization is granted, capacity, operation, and maintenance

instruction plates, tags, or decals shall be changed accordingly.