Form 483S

Rev Jan 09

Page 17 of 53

5.4.1.3 Ventilation by Natural Air Change

Gas-fired radiant heaters may be operated without any special exhaust system if the exhaust gases are

discharged to the outside atmosphere by a sufficient natural air change in the installation room.

Furthermore, no provision for thermal or mechanical ventilation is required in the following particular cases:

Buildings with natural air change greater than 1.5 volumes per hour

Buildings with a density of operating heat input not greater than 5W/m³

5.4.1.4 Air Supply

Air supply openings are required to admit air and shall be located below the radiant heaters.

The total area of the unobstructed cross-sections of all the air supply openings shall not be smaller than the

total area of the unobstructed cross-sections of all the exhaust openings.

Slits and gaps of fixed cross-section can also be used as air supply openings.

Where the air supply openings can be closed, it shall only be possible to operate the radiant heaters when they

are open.

5.4.2 Flued

If the appliance is to be flued externally, then flue pipe of diameter stated in table 14, and complying

with National and Local Regulations should be used.

IMPORTANT: When flued horizontally, the flue pipe must be arranged to provide a continuous rise from the appliance

of 25mm per 1m length.

The ventilation requirements for flued appliances is set out in BS 6896:1991 and must be applied.

The following is guidance to the standard:

5.4.2.1 Natural Ventilation

Low level ventilation shall be provided in all cases below the level of the heater(s).

Up to and including 60kW - 4.5cm2/kW

Over 60kW - 270cm2+ 2.25cm2 /kW in excess of 60kW total rated heat input.

Where the air supply openings can be closed, it shall only be possible to operate the radiant heaters when they

are open.

5.4.2.2 Mechanical Ventilation

Ventilation shall be provided in all cases at or below the level of the heaters.

Minimum proven air flow - 2.35m3/h/kW of total rated heat input.

It shall only be possible to operate the radiant heaters whilst the ventilation airflow is proven.

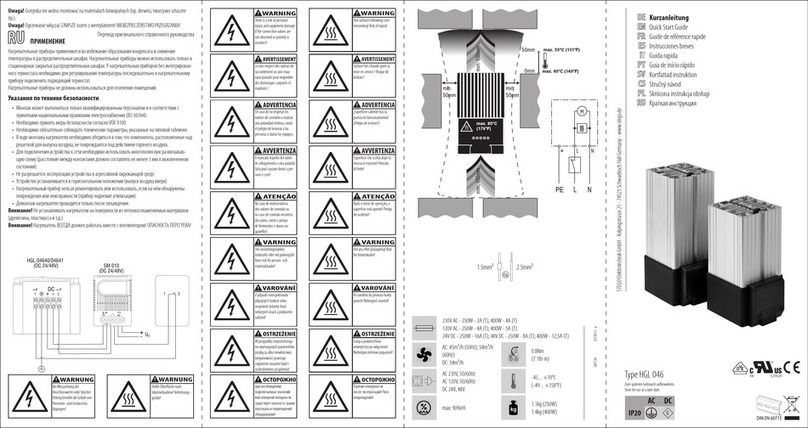

5.4.2.3. The heaters can be installed with different flue and combustion air configurations please review the diagrams

on the following page for the overview of the permitted installations. The permissible maximum lengths

associated with these options are listed in the table below.

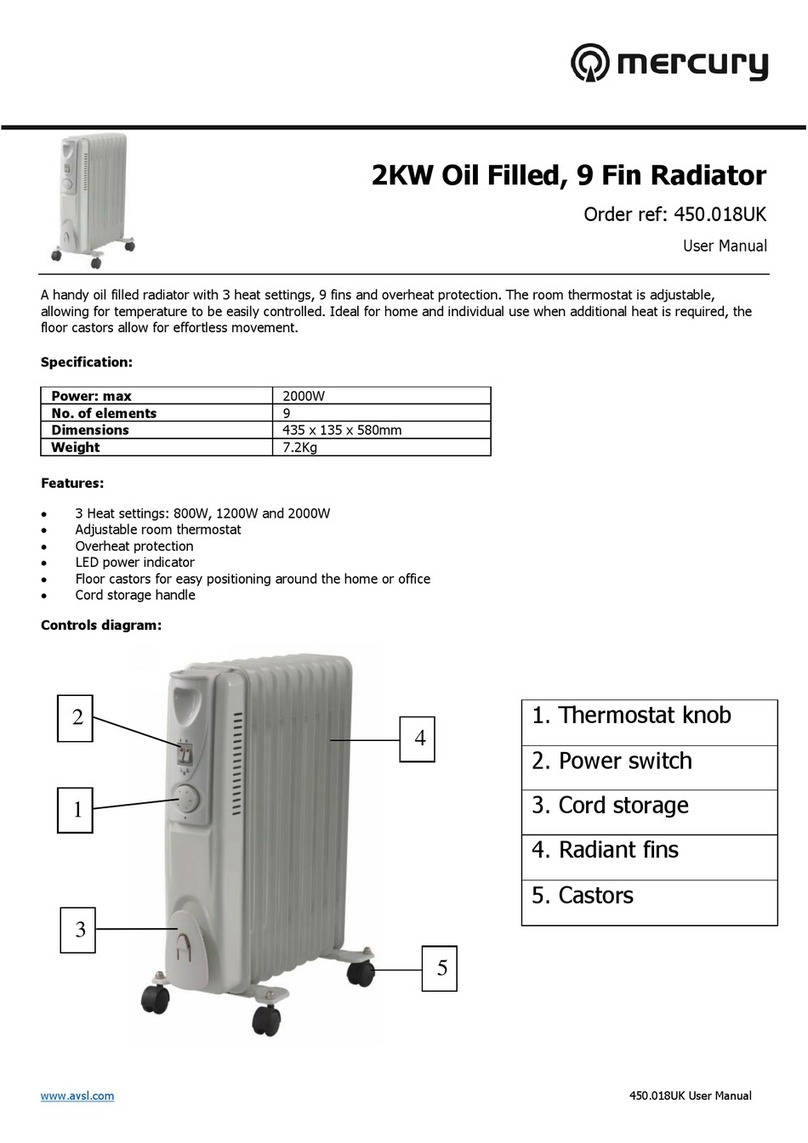

Table 14

Flue

Type Max

Combustion

Air 100mm Ø

Max Flue

Length

100mm Ø

Max flue length

Concentric

150/100mm Ø

Max length

combined

combustion air

and flue

Reduce length

for 90° bends

100mm Ø

Reduce length

for 90° bends

concentric

A215m N/A N/A 15m -1.7m N/A

B22 13m 15m N/A 28m -1.7m N/A

C12 1 8m + 1m 8m + 1m 1m + 8m + terminal 9m -1.7m -2.5m

C32 18m + 1m 8m + 1m 1m + 8m + terminal 9m -1.7m -2.5m

C52 13m 15m N/A 28m -1.7m N/A