Spar SP-B80HI User manual

SPAR FOOD MACHINERY MFG. CO., LTD.

SP-B80HI PLANETARY MIXER

(Include Model SP-B80H, SP-B80I, SP-B80)

Installation, Operation and

Maintenance Instructions

SPAR FOOD MACHINERY MFG. CO., LTD.

NO.145, 11th Industry Rd. Ta Li City, Taichung Hsien, Taiwan, 412 R.O.C.

Tel:(886)4-2491-7585

Fax:(886)4-2491-7565

http://www.sparmixers.com

e-mail:[email protected]

2008.March

S

PAR

SPAR

MIXER

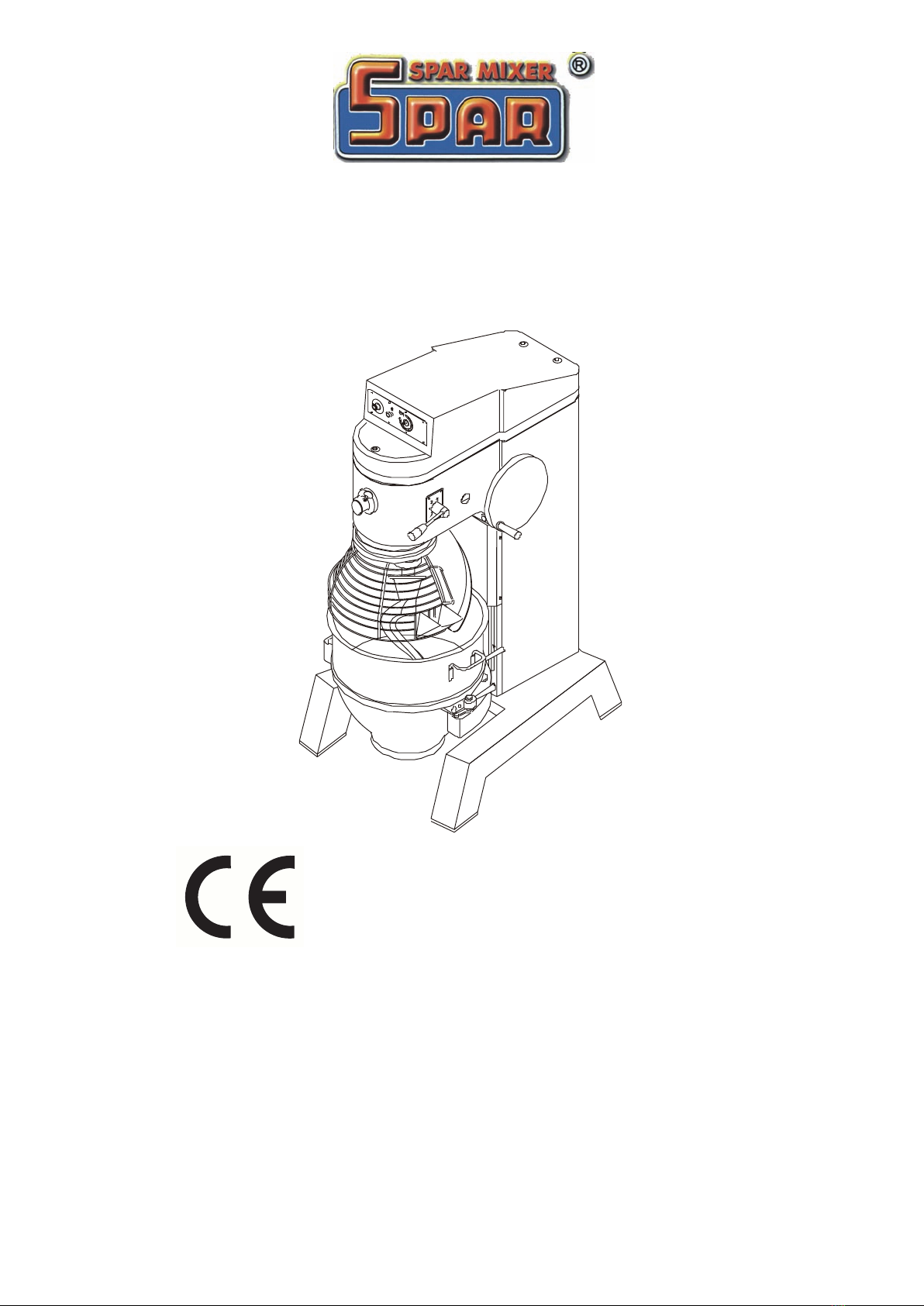

SP-B80HI / SP-B80I Planetary Mixer

1

SP- B80HI / SP-B80I PLANETARY MIXER

SPECIFICATION

Model SP-B80HI / SP-B80I

Bowl Size 80 Quarts

(I.D. 50 x H. 46.8 x TH. 2 cm)

Motor 3 H.P.

Electrics 220V/380V/415V

50/60HZ 3PH

Speeds - Agitator

(1) 1

st

Speed 60 rpm

(2) 2nd Speed 105 rpm

(3) 3rd Speed 176 rpm

(4) 4th Speed 310 rpm

Speeds –

Attachment Hub*

(1) 1

st

Speed 67 rpm

(2) 2nd Speed 118 rpm

(3) 3rd Speed 198 rpm

(4) 4th Speed 349 rpm

Dimensions (cm)

(LxWxH) 105 x 77 x 152

125 x 90 x 180 carton

Weight Gross 455 kg

Net 550 kg

Standard

Accessories*

Stainless Steel Bowl

with Beater, Whisk,

Spiral Hook, and Bowl

Truck

Optional

Accessories*

Attachment Hub, Bowl

Guard, Meat Mincer,

Vegetable Slicer…

Unitcm

Because of continual improvements, strict

accuracy of description cannot be guaranteed.

* Attachment Hub and Bowl Guards are

standard accessories for Model SP-B80HI

Note: Parts could be different subject

to different models.

CONTENTS

Specification……………………………….1

Installation…………………………………3

Electrical Connection……………………...3

Safety………………………………….……4

Correct Use of the Mixer………………….4

Gear Oil Meter……………………………...4

Annual Maintenance and Gear Oil Renewal….4

Fitting the Bowl…………………………..5

Bowl Lift & Bowl Guard………………...5

Tool Selection………………………………5

Fitting Mixing Tools………………………5

Speed Selection………………………..6

Controls and Operation…………………..6

Attachments………………………………...7

Care of the Mixer……………………….7

Mixing Capacities……………………..8

Maintenance………………………………...9

Fault Finding chart………………………..9

Electrical Wiring Diagram……….…...11~14

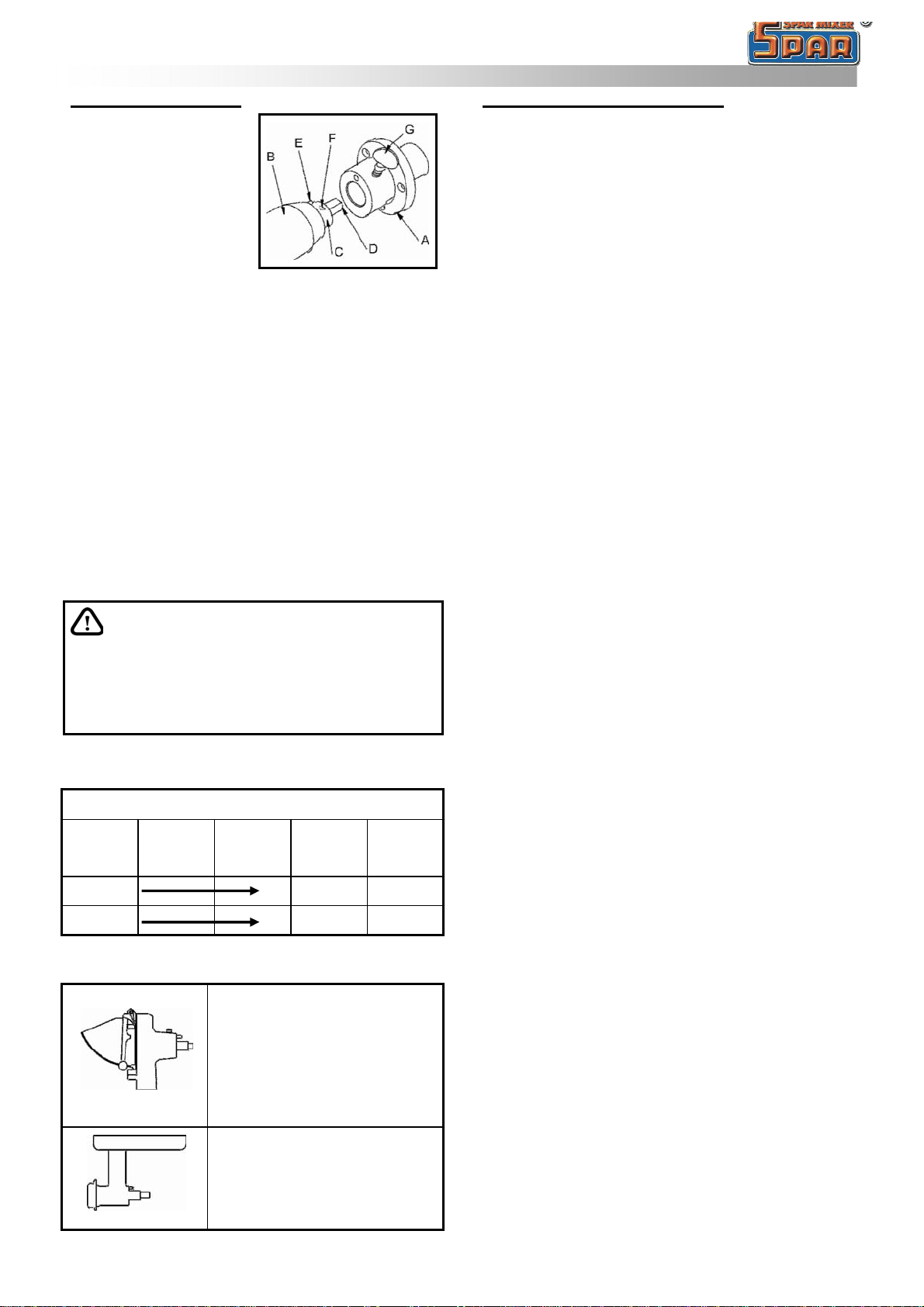

(A) Emergency Stop Button (G) Bowl

(B) Start Button (H) Oil Gauge

(C) Timer (I)

Bowl Handle Wheel

(D) Attachment Hub (J) Safety Guard

(E) Gear Arm (K) Feeder

(F) Planetary Shaft (L) Bowl Weld Clip

2

SP-B80HI / SP-B80I Planetary Mixer

SP-B80HI / SP-B80I Planetary Mixer

3

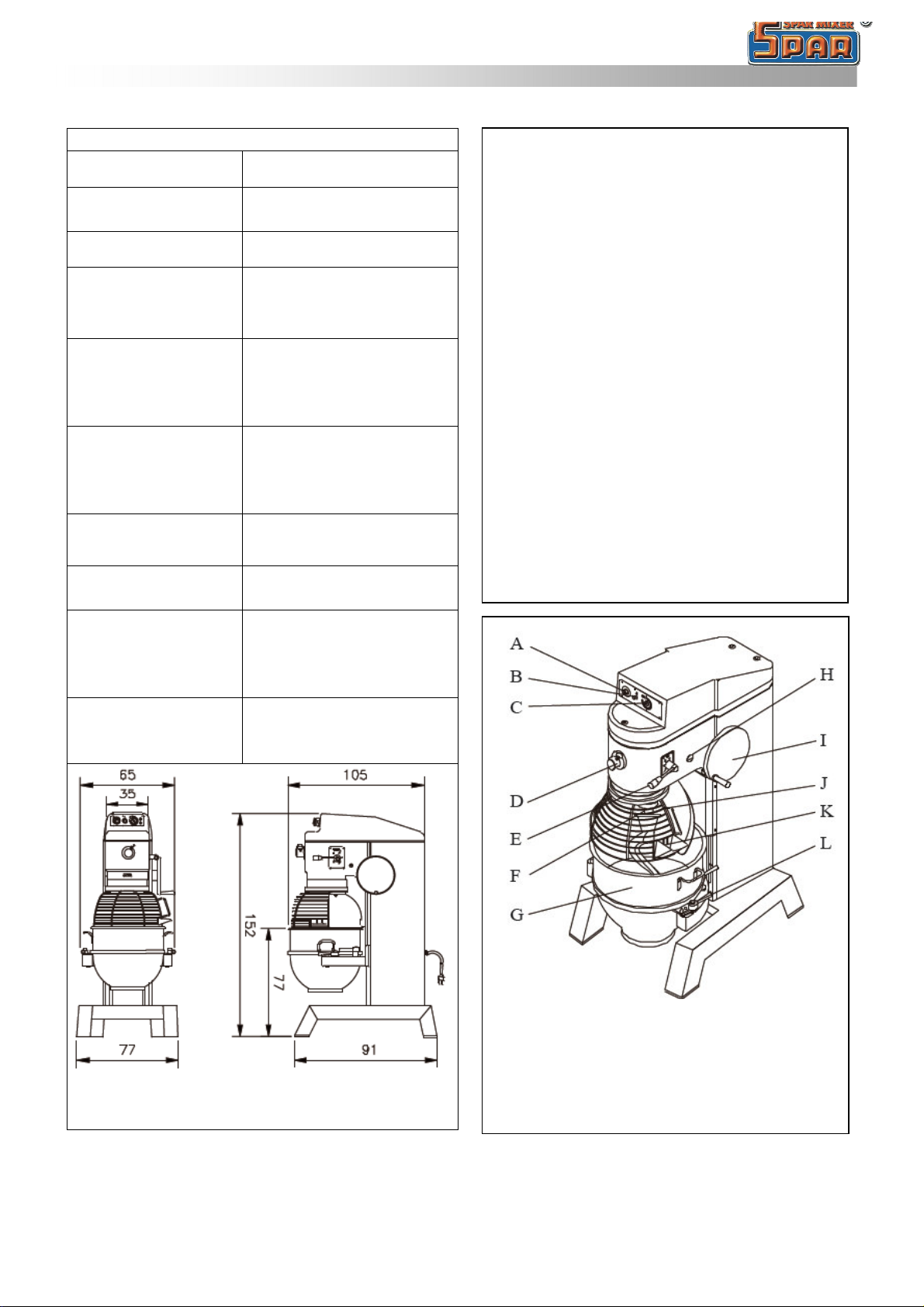

Figure 1

GUARANTEE

SPAR provides one year guarantee,

either the date of dispatch from our factory, or

the date of purchase from one of our

approved distributors. We will replace any

defected parts resulted from faulty design,

material or workmanship. In addition to this,

any repair must be carried out by our

authorized Service Agent. All defective parts

without no alteration or repair can be returned

to SPAR or the nearest authorized

representative, postage paid within one year

warranty.

SP-B80HI / B80I is a floor type planetary

mixer designed for commercial use by the

professional caterer. It has a total bowl

capacity of 80 Quart, combined with 4-speed

gearbox to ensure that all mixing

requirements can be met.

The intended use of the mixer is the food

processing industry, which not including the

pharmaceutical industry, chemical industry,

printing, etc.

INSTALLATION

The installation of mixer should comply

with a technician.

The mixer is lubricated and ready to run,

when it leaves the factory. During the

transportation or fitting, please do not lean

over 35 degree to avoid the gear oil leaking

from the gear oil container. Please use forklift

to transporting. Please see Figure 1.

ELECTRICAL CONNECTION

Before connecting the mixer to the

electrical supply, please check that the details

on the rating plate (located on the rear of the

mixer) correspond to the details of your

electrical connection.

The mixer is supplied with a trailing lead

fitted with a trailing lead fitted with a molded

plug. If the style of plug is unsuitable for the

socket you plan to use, the plug must be cut

off and replaced with an appropriate plug. In

terms of the 3-phase, when the mixer is

located and connected with the plug, please

make sure that the shaft goes clockwise. If

the shaft goes counterclockwise, please

replace the wires: R.S.T. (USA) L1, L2, L3,

(Europe). To replace the wires each other

until the shaft goes clockwise.

The mixer should be plugged into a

switched socket which isolates all poles and

has a minimum contact clearance of 3mm

and locates close to the mixer for use in an

emergency and to facilitate servicing (max.2

meters of cable). The machine must be

incorporated into a potential equalization

system.

The leakage current for this appliance is

no greater than 1 mA/KW. If the electrical

supply cable to the machine becomes

damaged, it must be replaced by a qualified

electrician using cable which is 3.0

specification or higher and suitable for a 3HP

motor load. The ground wire is fixed to the

machine and this connection must be kept

intact.

Note: The mixer MUST be grounded.

-The minimum requirement for all electrical

equipment is correct operation between aire

temperature of +5and +40.

-Electrical equipment is capable of operating

correctly when the relative humidity does not

exceeding 95% at a maximum temperature of

+40.

-Electrical equipment is capable of operating

correctly at altitude up to 1000m.

-Electrical equipment is designed to withstand

to protected against the effects of

transportation, and storage temperature

within a range of -25to +55and for

short periods not exceeding 24h at up to +70

.

4

SP-B80HI / SP-B80I Planetary Mixer

Figure 2

BEFORE USING THE MIXER

Before using the mixer, please ensure

that all users are familiar with the correct

operation of the mixer. In particular, care

should be taken to ensure that the bowl and

mixing tools are correctly fitted.

SAFETY AT WORK

Never place your hand or any kitchen

utensil in the bowl when the mixer is in

operation. Isolate the machine from the

electrical supply by removing the plug from

the socket before cleaning or dismantling.

Do not use the machine with any cover or

guard removed.

Certain operator notice advising about the

safe use of this mixer is attached to the

machine.

OFFICE, SHOPS AND RAILWAY

PREMISES ACT, 1963

The above Act requires that this machine

and attachments shall be operated only by a

properly instructed person or by an employee

who is under the supervision of a properly

instructed person. The instruction shall

include indication of the possible dangers

arising and the precautions to be observed.

The Act also requires that no person under

the age of 18 shall clean a machine if this

exposes him to risk of injury from a moving

part of that machine or any adjacent machine.

CORRECT USE OF THE MIXER

It is the responsibility of the operators to

use the mixer correctly within the

recommended limitations. Always follow the

instructions on the side of the machine when

changing speed. If the motor labors or the belt

slips, stop the machine and reduce the size of

the mix immediately. Damage resulting from

improper use is not covered by the SPAR

warranty.

In terms of operator safety, the mixer is

fitted with a bowl guard which is electrically

interlocker to ensure that the mixer cannot

operate unless the guard is correctly

positioned and the bowl is raised.*

* Note: Only SP-B80HI and SP-B80I are

equipped with bowl guard.

For additional safety, the mixer has a no

volt release feature which means that in the

event of a power failure, the machine will only

restart after the control button has been

pressed again. This arrangement ensures that

when the power is restored, the machine

cannot restart by its own.

-Careful handling of bagged products by

minimizing the height above the bowl base

from which they are poured.

-Careful slitting of bags in the lower part of the

bowl to allow dust free discharge of flour as

flour as possible.

-Use temporary bowl covers to minimize

openings through which flour many escape.

GEAR OIL METER

Use the gear oil to lubricate the mixer and

to prolong the life of the mixer. Before using

the mixer, please check the gear oil meter.

Please see Figure 2. When the indicator of

gear oil meter is above the half of the red circle,

the gear oil is full. Please fill the gear oil when

the indicator is below the red circle.

ANNUAL MAINTENANCE AND

GEAR OIL RENEWAL

Please unscrew and leak the oil from the

indicated oil-leaking hole. After finishing the

leaking, re-screw back tightly with the

anti-leaking coat on the screw. Fill the gear oil

to the indicated re-fill oil hole. We

recommended that any servicing or

maintenance work must be carried out by

trained technicians from a SPAR appointed

distributor.

SP-B80HI / SP-B80I Planetary Mixer

5

FITTING THE BOWL

1. Please use the

hand wheel to

lower bowl cradle

to the lowest

position.

2. Lift the bowl by

side handles and

(a) slowly position

locking pin

(located at the

rear side of the

bowl) into the

hole at the middle rear side of the cradle.

Then (b) fit two “side” holes (each hole is

located under each side handles) onto

pins on the opposite sides of the cradle.

3. Once the bowl is seated correctly on the

cradle, please secure the bowl by folding

both steady hooks (locking latches) inward

until locked tight.

Note: Please use bowl truck to load

and unload bowl containing more than

50lbs per batch.

BOWL LIFT & BOWL GUARD

The bowl cradle and bowl guard are

electrically interlocked so that the machine

will only operate with the bowl cradle in the

raised position. In addition to this, the bowl

guard must be locked into place by sliding it

into position across the top of the bowl to the

point where it will slide no further.

Only once the bowl is raised and the bowl

guard locked, the machine can operate. Thus

this ensures complete user safety at all times.

Once the guard has been opened or the

bowl lowered, the mixer will stop. If this

happens, please close the bowl guard and

raise the bowl lift and then press the START

BUTTON.

During the mixing process, additional

ingredients can be added by the chute

located on the right hand side of the bowl

guard.*

* Note: Only SP-B80HI and SP-B80I are

equipped with bowl guard.

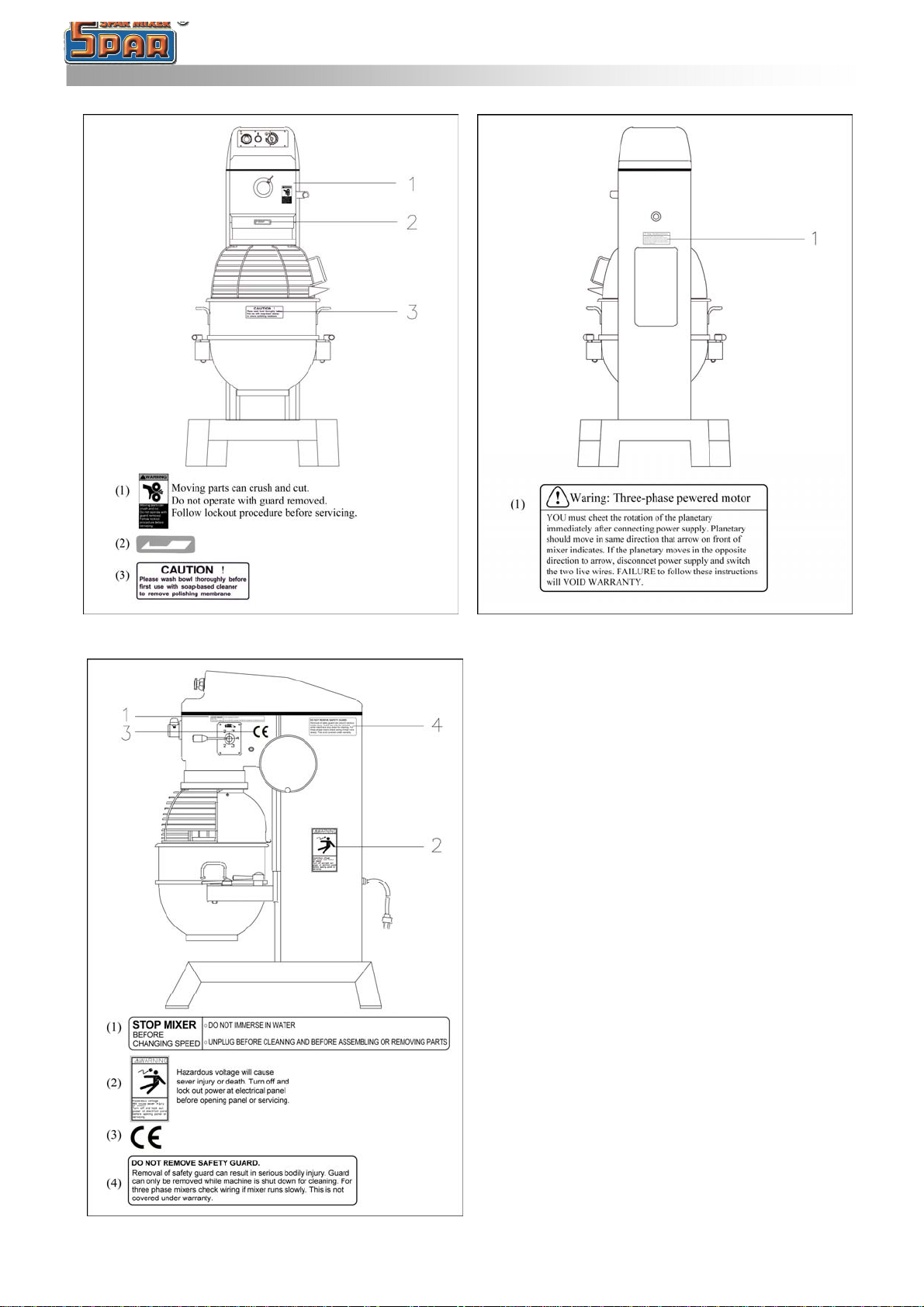

TOOL SELECTION

The beater, whisk and spiral dough hook

are meant for the work implied by their names.

Figure 3 shows the typical uses for each of

the tools.

Beater: Firm mixes such

as light pastry, cakes

biscuits, icings fillings and

mashed vegetables.

Spiral Dough Hook:

Heavy mixes such as

dough, pie pastry. .

Whisk: Light mixes such

as whipped cream,

mayonnaise, egg whites,

pancakes and soufflés.

Figure 3

FITTING THE MIXING TOOL

Note: Install the bowl BEFORE

inserting agitators.

Slide the bayonet

fitting of the tool onto the

drive shaft and twist

clockwise to secure it in

position. To remove the

mixing tool, slide the tool

up the shaft slightly and

twist counterclockwise.

Please see Figure 4.

Please refer to

Capacities &

Recommended Agitators

Chart for tool selection

and optimum

performance.

Note: Agitators should always rotate

in a clockwise direction around bowl. If

agitators move counterclockwise, please

contact licensed electrician immediately

to remedy incorrect wiring.

Note: Always wash agitator with mild

soap and apply light quantity of mineral

oil to planetary shaft after cleaning.

Figure 4

6

SP-B80HI / SP-B80I Planetary Mixer

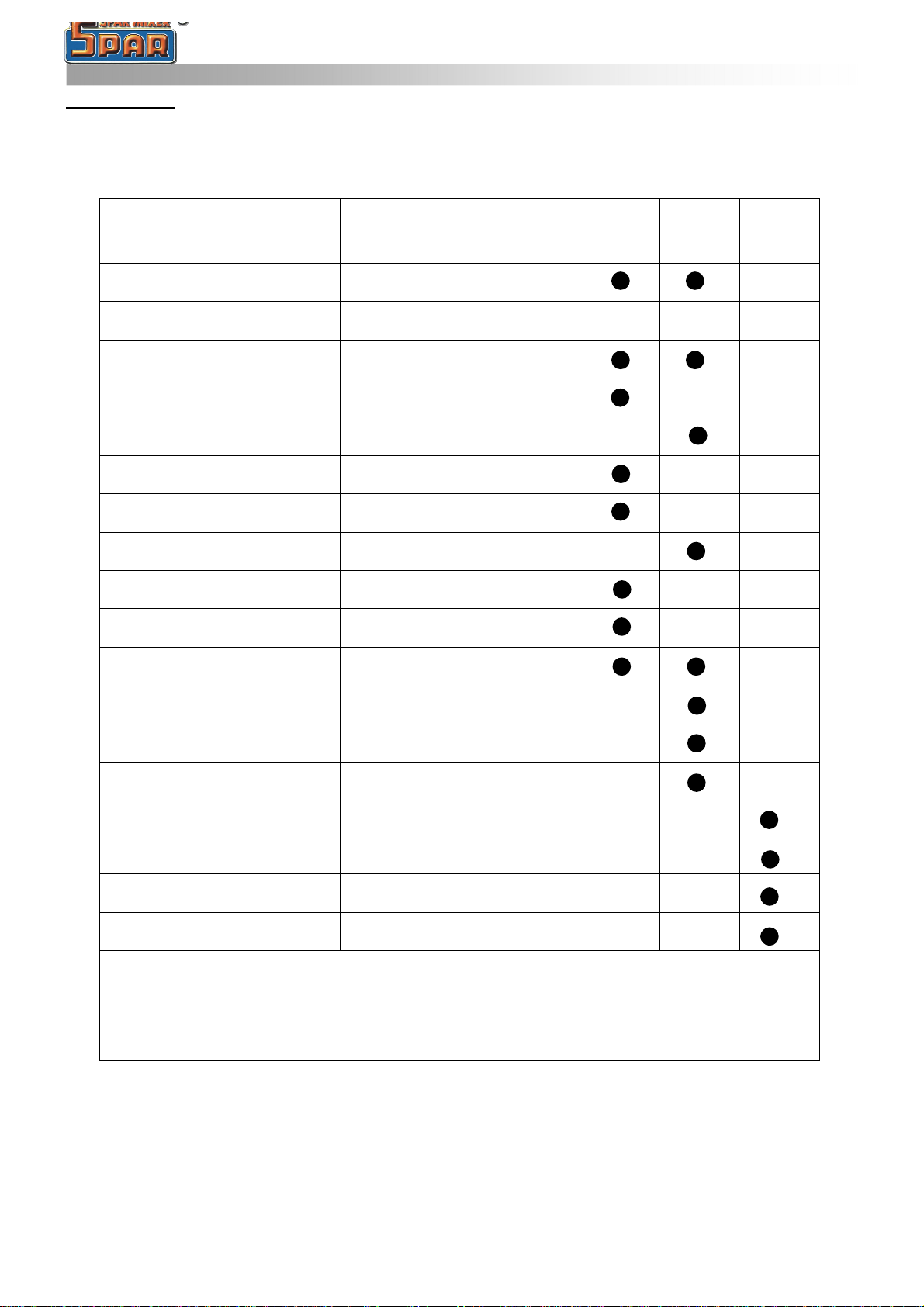

Table 1

SPEED SELECTION

Before changing speed, the mixer must

always be stopped by pressing the red button.

The necessary speed can then be selected

before restarting the machine by pressing the

green start button. The speed selected

depends largely on the quantity and

consistency of the product. It is

recommended that mixing is always started at

the lowest speed and progressively increased

to the desired setting. In an emergency

situation, always use the red emergency stop

button to stop the mixer. Table 1 shows the

recommended speeds for the range of tools.

Recommended Speed

1st

Speed 2nd

Speed 3rd

Speed 4th

Speed

Whisk

Beater

Hook

CONTROLS

A: Emergency Stop Button (Red Button)

To operate mixer, please check that the

Emergency Stop Button (Red Button) is

not pressed.

To stop mixer at anytime during

operation, please press the Emergency Stop

Button (Red Button) located at the left hand

side of the control panel.

B: Start Button (Green Button)

Press the Start Button (Green Button)

located at the middle of the control panel to

star mixing.

C: Timer

SP-B80HI/ SP-B80I are equipped with a

15 minutes timer. In terms of timing operation,

timer must be set at least more than 5

minutes. Mixer will automatically stop once

the set timing has expired.

a)Timing Operation: Turn timer knob in a

clockwise direction at least five minutes

past “0” to the desired time. Push start

button to start the mixer. If you want to set a

timing less than five minutes, please turn

timer knob clockwise to six and then turn it

counterclockwise back to desired time.

Push the start button to start the mixer.

b)Manual Operation: Turn timer knob in a

counter-clockwise direction until it stops.

Push start button to start the mixer. Mixer

will now run indefinitely. Push stop button to

stop the mixer.

Note: Mixer will not operate unless the

bowl cradle is raised in the uppermost

position. Please be sure to raise the bowl

support until it stops.

Note: For additional safety, the mixer

has a no volt release feature. So that in the

event of a power failure, the machine will

only restart by pressing the green start

button again after the power is restored.

Noise Test Report:

(1) Model No.: SP-B80HI

(2) Background noise:

Add Flour: background noise level is 59.8 dB(A)

Dry running: background noise level is 52.6 dB(A)

(3) Distance: 1m from the surface.

(4) Height: 1.6m from the floor.

Unit: dB(A)

A B C D E

Add Flour 69.6 70.1 69.9 70.6 69.1

Dry Running

59.1 60.9 60.8 61.0 60.5

SP-B80HI / SP-B80I Planetary Mixer

7

Figure 5

ATTACHMENTS*

The ranges of

attachments that can

be operated from the

attachment hub are

listed below. When

using an attachment,

please lubricate the

(D) Drive End by using a food

quality grease or oil. Please refer to Figure 5

to assemble an attachment.

Release the (G) Thumbscrew and slide

the shaft of the attachment into the hub.

Please ensure that the (D) Drive End

engages in the socket within the hub. Then

rotate the attachment to line up the (E)

Location Peg with its mating hole in the hub

and push firmly home. Finally, tighten the

thumbscrew to secure.

* Note: Only SP-B80HI and SP-B80H are

equipped with Attachment Hub.

Note: Only fit attachments when the

mixer is stationary. Never fit any

attachments when the mixer is under

operation. Do not use any attachments

when the mixer is mixing.

Table 2 shows the recommended speed

range for some of the available attachments.

Recommended speed

1st

gear 2nd

gear 3rd

gear 4th

gear

V99S

VH-12

Table 2

V99S Vegetable Slicer

Vegetable Preparation With

a range of 7 plates to slice,

grate or shred all types of

vegetable and fruit from nuts

and cabbage to carrots and

cheese.

VH-12 Meat Mincer

A no.12 mincing attachment

which works wonders with

meat, fish and vegetables

alike.

CARE OF YOUR MIXER

The mixer is designed for simple

maintenance carried out by operators. It may

be necessary from time to time to apply a little

Vaseline and oil to the rods on which the bowl

cradle slides. If so, use a little food quality

lubricant, ensuring that there is no excess oil

that could contaminate the food mix.

Water jet cleaning is not allowed.

Clean the mixer thoroughly after use. The

body should be wiped down with a damp

cloth after first isolating the machine from the

electricity supply. Do not spray the machine

with or immerse it in water. Do not forget to

clean the rear of the machine and do not

allow the rear vents to become blocked as

this may result in overheating. Pay particular

attention to the bowl pins and any

surrounding areas of the cradle to prevent the

accumulation of mix, as this could prevent

correct location of the bowl. For the same

reason ensure that the beater shaft and each

of the sockets on the tools are cleaned

thoroughly. The bowl and tools should be

washed in hot soapy water, rinsed and dried

before being put into storage. Do not wash

the tools in a dishwasher, as the polished

finish will be adversely affected by the

dishwashing chemicals.

- Steady state voltage: 0.9~1.1 of nominal

voltage.

- Frequency: 0.99~1.01 of nominal frequency

continuously.

- Avoid exposing to vibration environment.

- Avoid exposing to direct sunlight or heat

rays.

The overcurrent protection device should be

rated 13A in supply side by user at least.

8

SP-B80HI / SP-B80I Planetary Mixer

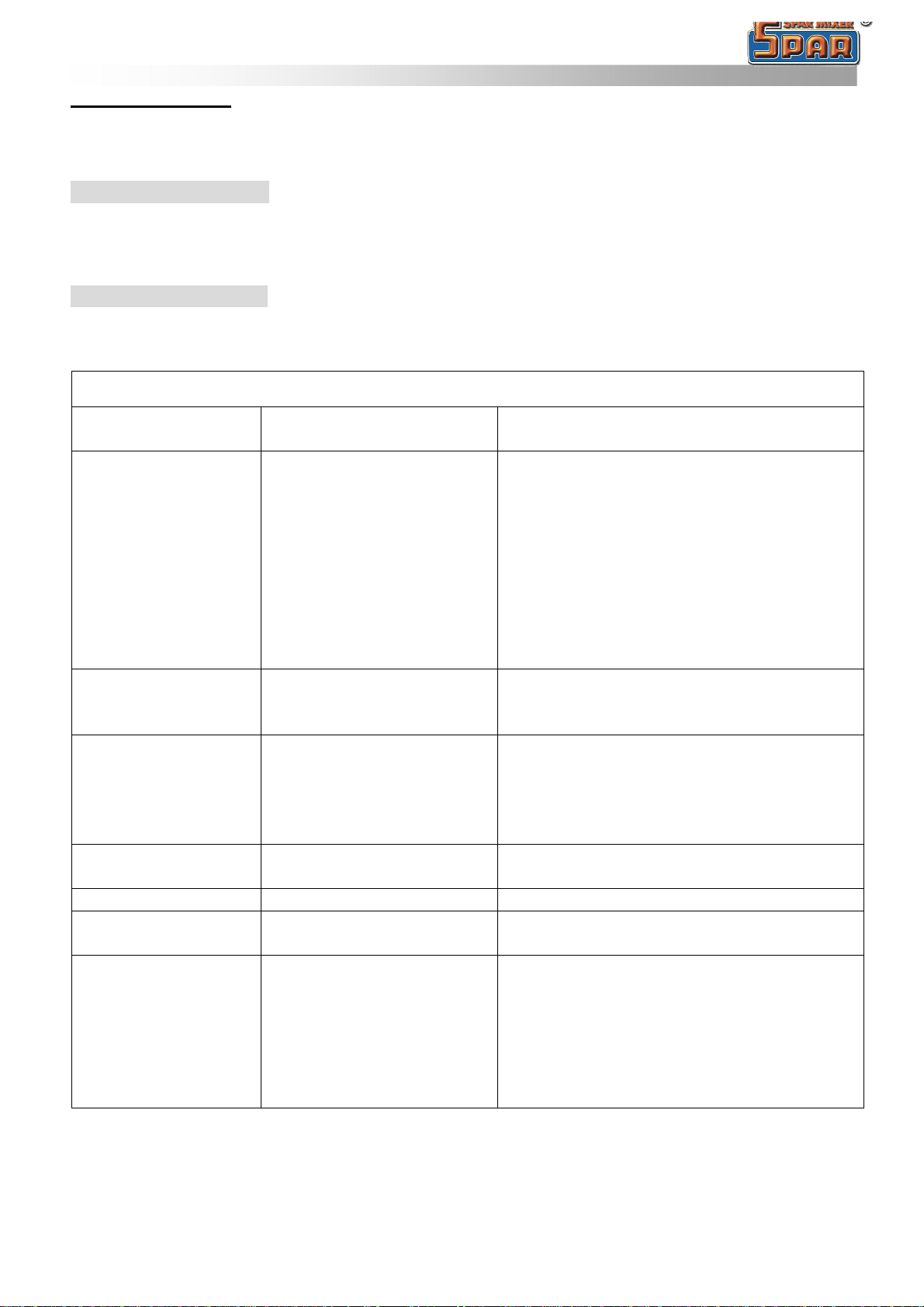

CAPACITY

Table 3 lists the recommended capacities of finished weights of regular mixes. Although the

machine may be capable of mixing larger quantities, it will lead to excessive and premature wear

and possible failure. Overloading also results in lengthy processes and unsatisfactory results.

Table 3

Product Maximum Regular Mix (kg) Whip Beater

Hook

Mashed Potatoes 40 lbs (18.2kg)

Frosting 3 lbs

Fruit Cake 80 lbs

Sponge Cake 54 lbs

Honey Cake 80 lbs

Angle Cake 60 lbs

Cookies 30 lbs

Brioche 115 dz.

Whipping Cream 16 qts

Mayonnaise 22 qts

Butter 32 qts

Egg White 2 qts (2.1L)

Muffin 90 dz.

Pie 60 lbs

Light Bread Dough

(65% moisture content)

86 lbs-2nd speed

Heavy Bread Dough

(60% moisture content)

73 pts-2nd speed

Pizza Dough

(50% moisture content)

70 pts-1st speed

Pizza Dough

(45% mois

ture content)

63 pts-1st speed

1. Recommended weight for a finished mix unless otherwise stated.

2. Water content e.g. 25# flour / 12.5# water = 50% moisture.

3. For pizza dough with lower moisture content, please consult SPAR

4. For higher gluten flour reduce dough batch by 25%.

SP-B80HI / SP-B80I Planetary Mixer

9

MAINTENANCE

Regular maintenance is necessary on all machines if they are to remain in good working

condition. It is strongly recommended that all maintenance must be carried out by trained

technicians from a SPAR appointed distributor.

ON A REGULAR BASIS

Clean the machine thoroughly after use and lubricate the rods with Vaseline or lubrication

oil which the bowl cradle slides. After clean the beater shaft, please wipe and lightly lubricate the

beater shaft with Vaseline to prevent rusting. (SEE CARE ON YOUR MIXER)

ON AN ANNUAL BASIS

Check that all bolts are tight and bowl guard secure. Please check the gear arm, bowl

handle wheel and replace these parts if it is necessary.

FAULT FINDING

FAULT CHECK POSSIBLE REASON AND ACTION

REQUIRED

No power to mixer Check plug socket

Check wiring in plug

Check fuse in plug

Check or change cable

Check microswitch

Check circuit breaker over

load or short

Mixer not plugged into a live socket or not

switched on

Plug incorrectly wired – rewire correctly

Possible faulty fuse – replace fuse

Cable damaged or split – replace cable

Limit switch damaged or faulty – replace

switch

Circuit breaker shut off or constantly

short – reset or replace the circuit breaker

(automatically reset).

Mixer fails to operate

Check transmission belt

Check gear change lever Belt damaged or broken – replace belt

Machine will not operate if out of gear –

put in gear

Mixer becomes

noisy Check bowl and tools

Check work surface

Check the wear of bearing

Ensure that bowl and tool are correctly

seated.

Uneven surfaces create excessive

resonance.

Worn bearings – replace bearings

Mixer loses power Check capacity

Check power Overloading of bowl – reduce load

Power failure – please restore the power

Motor overheating Check supply voltage Voltage should correspond to rating plate

Oil on planetary

shaft Check oil seal Worn oil seal – change oil seal

Mixing tools stuck on

planetary shaft Check planetary shaft

bent, unclean or rusted.

Planetary shaft twisted or bent – please

change planetary shaft.

Planetary shaft rusted – please use

descaler for derusting.

Turn planetary shaft anti-clockwise to meet

square groove, gently knock down mixing

tools.

It is recommended that any servicing or maintenance work must be carried out by a

trained technician or electrician.

Isolate the mixer from the electricity supply by removing the plug from the socket

before cleaning or servicing.

Isolate the mixer from the electricity supply by removing the plug from the socket after

long period of no use.

10

SP-B80HI / SP-B80I Planetary Mixer

Warning

We recommended that do not lean the mixer over 35 degree during the transportation to

avoid the gear leaking from the gear oil container

After replacing the parts by technicians, please screw back tightly with anti-leaking coat to

avoid the gear oil leaking after replacement.

We recommend that the all maintenance must be carried out by a trained technician.

Carry out on a more frequent basis if machine is arduously used.

Do not let the children using the mixer.

Do not using the mixer before fully reading this manual.

Do not let the cable near the hear, touch the rough object, press against he cable, or directly

pull the cable for unplug.

Do not insert any object into the air vent of motor or into the bowl.

Please unplug while not using the mixer.

The following warning is in the user instruction:

Through poor conditions of the electrical MAINS, shortly voltage drops can appear when

starting the EQUIPMENT. This can influence other equipment (such as blinking of a lamp). If the

MAINS-IMPEDANCE Zmax0.8 OHM, such disturbances are not expected. (In case of need,

you may contact your local supply authority for further information)

SP-B80HI / SP-B80I Planetary Mixer

11

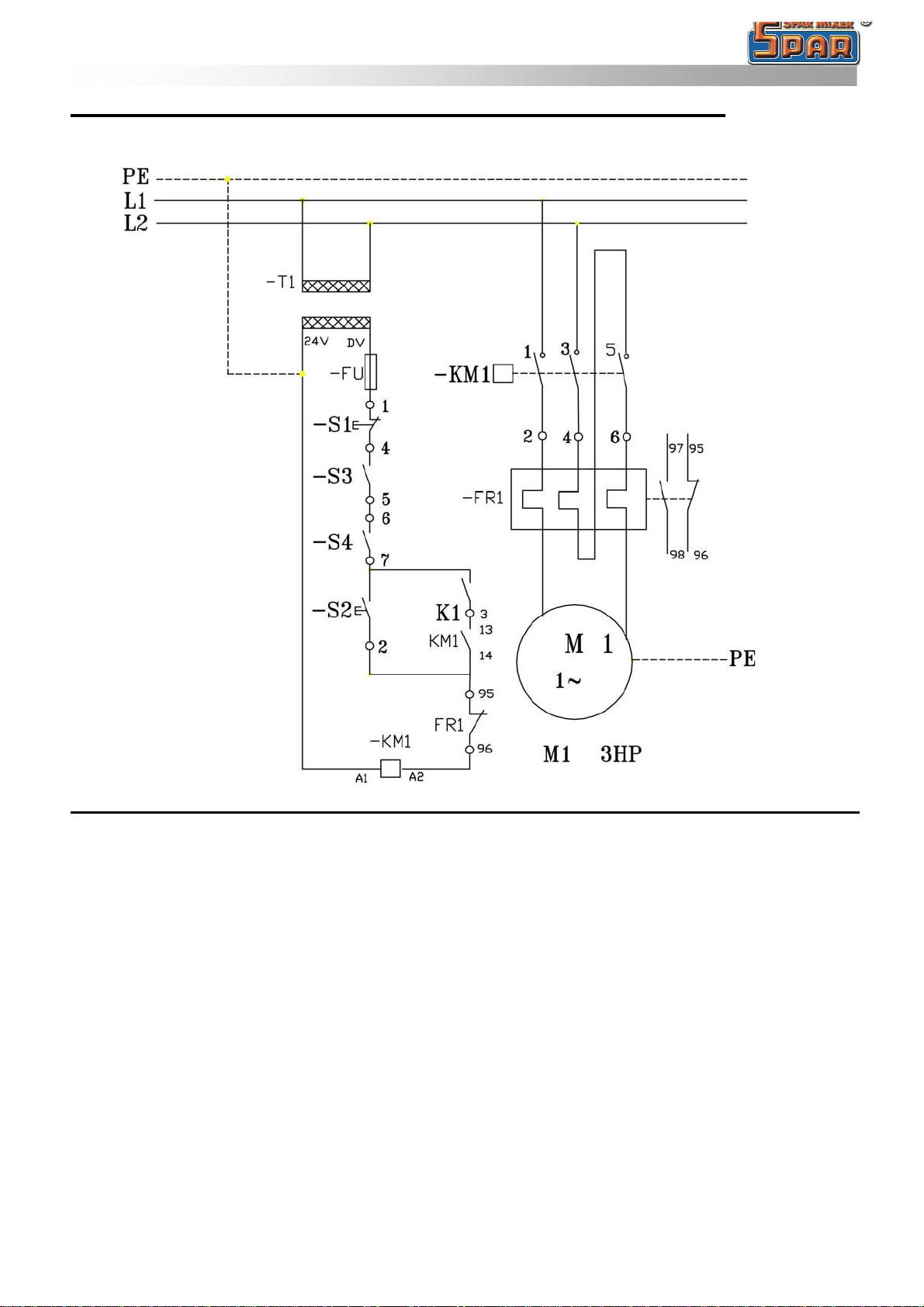

Electrical Diagram – SP-B80HI 220V Single Phase

(Include Model SP-B80I)

Item Description

S1 EMERGENCY STOP BUTTON

S2 START BUTTON

S3 MICROSWITCH (interlock guard)

MICROSWITCH (transmission gear)

S4 MICROSWITCH (height adjuster)

KM1 CONTACTOR COIL OF 220V 50Hz

24V

K1 TIMER

FR1 OVELOAD RELAY

M1 MOTOR 3 HP SINGLE PHASE 220V

T1 TRANSFORMER AC 24V

FU FUSE FIXTURE+FUSE 1A (5X20)

Manufature

Telemecanique

Telemecanique

Omron

Omron

Omron

Allen-Brodley

Ann yig

Allen-Brodley

Shiug jiann

Sung chuan

Conquer

Part number

XB2-BS542

XB2-BW3361B

D2VW-5-1M

Z-15GW22-B

Z-15GQ22-B

100-A24NJ3

AT-615

193-A4H1

HTB-32

Qty Rem.

1

1

1

1

1

1

1

1

1

1

1

1

12

SP-B80HI / SP-B80I Planetary Mixer

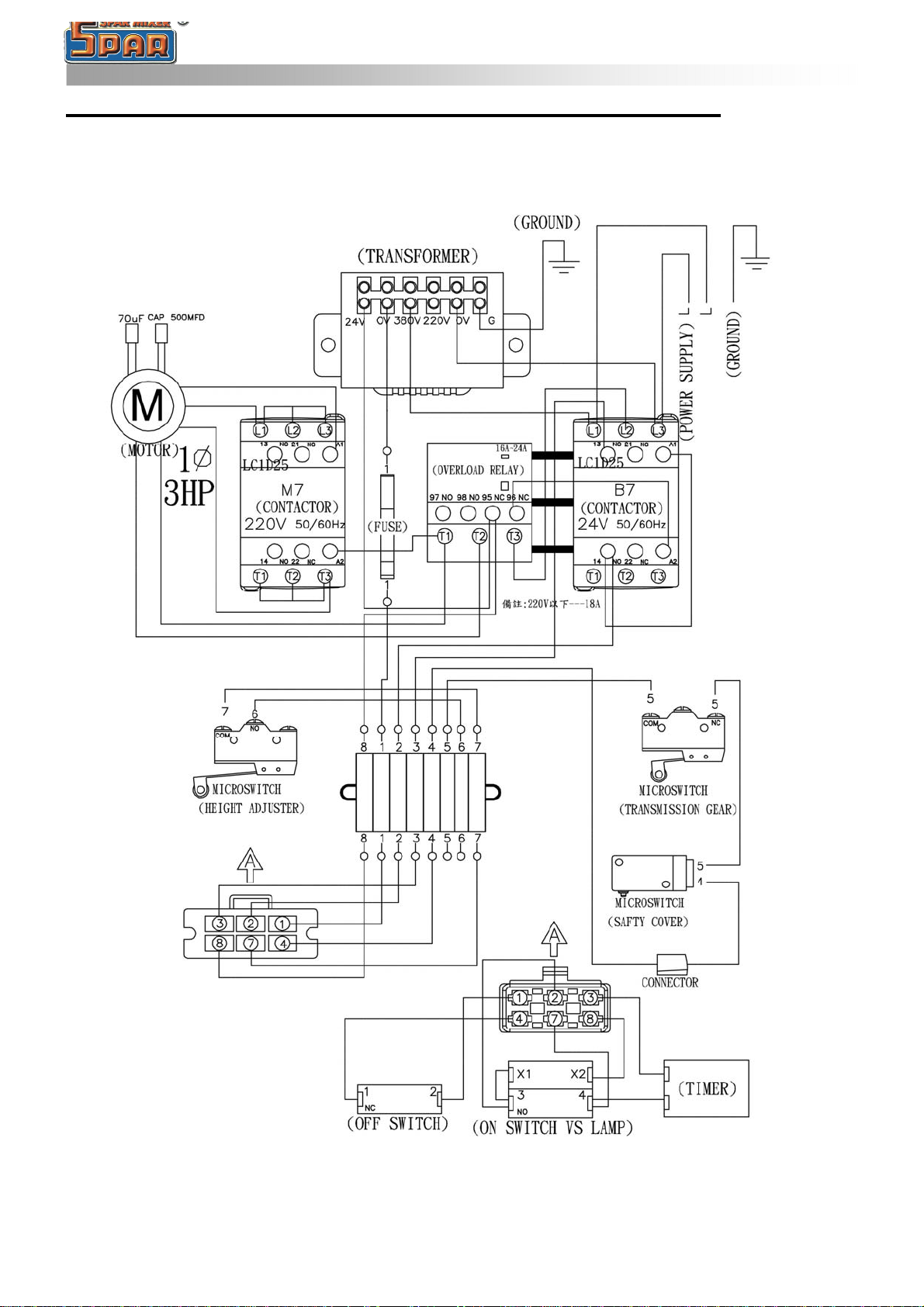

Electrical Diagram – SP-B80HI 220V Single Phase

(Include Model SP-B80I)

SP-B80HI / SP-B80I Planetary Mixer

13

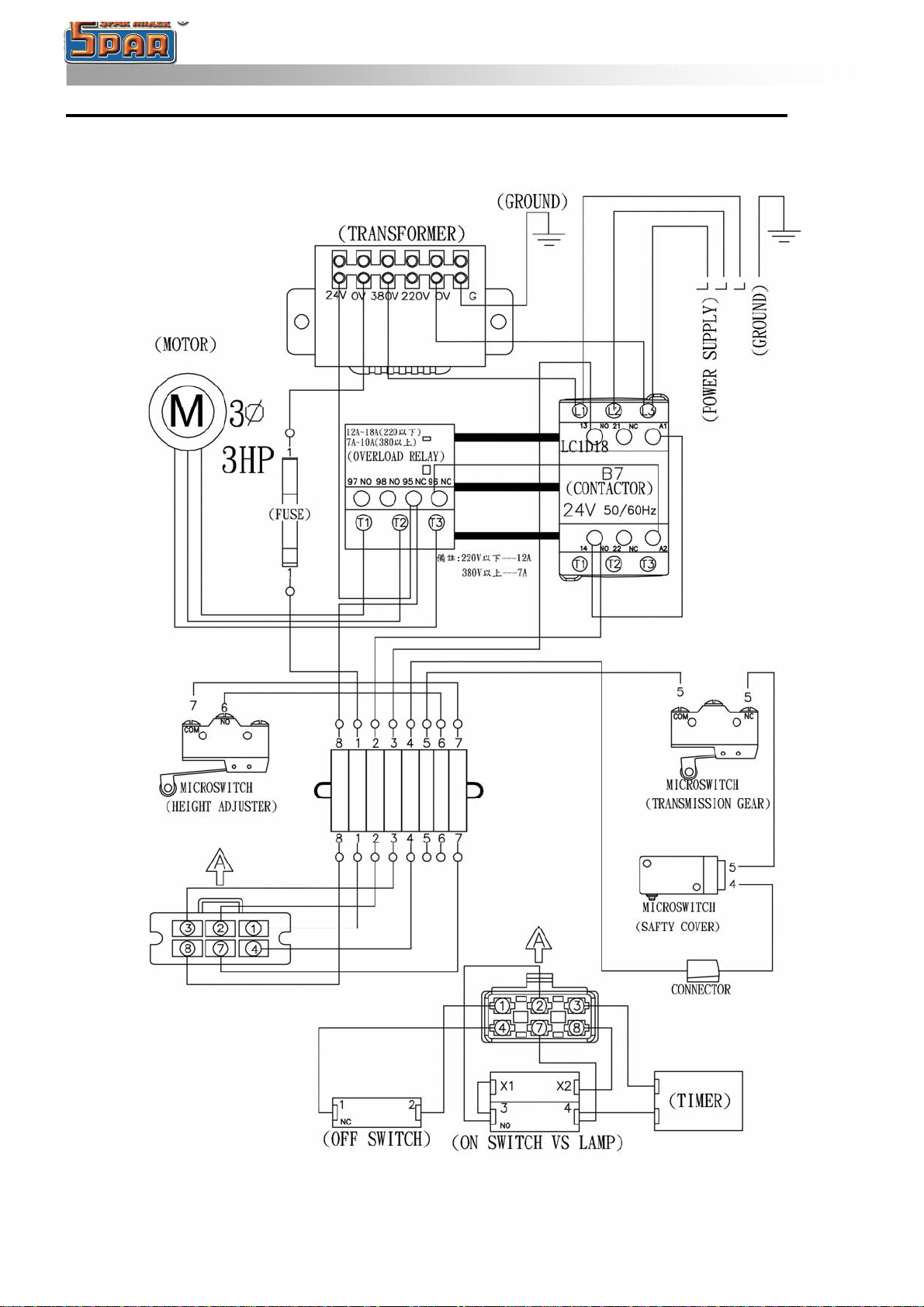

Electrical Diagram – SP-B80HI 230V/400V Three-Phase

(Include Model SP-B80I)

Item Description

S1 EMERGENCY STOP BUTTON

S2 START BUTTON

S3 MICROSWITCH (interlock guard)

MICROSWITCH (transmission gear)

S4 MICROSWITCH (height adjuster)

KM1 CONTACTOR COIL OF 220V 50Hz 24V

K1 TIMER

FR1 OVELOAD RELAY

M1 MOTOR 3 HP SINGLE PHASE 220V

T1 TRANSFORMER AC 24V

FU FUSE FIXTURE+FUSE 1A (5X20)

Manufature

Telemecanique

Telemecanique

G.G.T

Omron

Omron

SCHNEIDER

ANN YIH

SCHNEIDER

Shiug jiann

Sung chuan

Conquer

Part number

XB2-BS542

XB2-BW3361B

MFI MFR

Z-15GQ22-B

Z-15GW22-B

LR3D26/036

AT-615

193-A4H1

HTB-32

Qty Rem.

1

1

1

1

1

1

1

1

1

1

1

14

SP-B80HI / SP-B80I Planetary Mixer

Electrical Diagram – SP-B80HI 230V/400V Three-Phase

(Include Model SP-B80I)

SPAR MIXERS

HISTORY

FACILITIES

QUALITY CONTROL

FEATURES

SPAR Food Machinery Mfg. Co. Ltd. was established in 1980 with the goal of

producing top of the line multi-functional planetary mixers. SPAR began by

supplying the demands of the local bakery market in Taiwan. After establishing the

SPAR brand as the leading planetary mixer in Taiwan, SPAR began to expand into

other markets. Now SPAR supplies mixers to over 50 countries in six continents,

SPAR is a truly global competitor. SPAR has become such a success because it

has always remained true to its core principles, such as dependability, value,

innovation, and service.

SPAR has a new state of the art production facility. This facility has been designed

to optimize production schedules, thus cutting delivery times to customers. Also,

integrated into this production facility is a modern paint baking facility. This helps

SPAR achieve a high quality finish as well as meet today’s demanding sanitary

standards. SPAR is the only mixer manufacturer in Taiwan to have its own baked

paint facility. SPAR also has a second manufacturing plant which specializes in the

production of heavy duty mixers.

♠ heat treated hardened steel alloy gears, 25% thicker than industry’s leader

♠ abrasion resistant transmission design

♠ efficient, custom made, powerful motor

♠ high torque transmission for heavy loads

♠ long lasting lubricant quiet operation

♠ overload protection

♠ simple maintenance

♠ front mounted controls for easy access and operation

♠ unprecedented 3 year transmission warranty (available only in the US and

Canada) on most models, see warranty for details

♠ molded, heavy – duty, quick-release plastic safety guard with ingredient chute

and micro switch

SPAR uses state of the art CNC machines to cut all body castings and mill all gears

and shafts. Samples from each batch are evaluated to exacting standards by a

computerized Italian MPM 3-dimensional analyzer.

This manual suits for next models

3

Table of contents

Other Spar Mixer manuals