Operation Manual Total 26

page 2

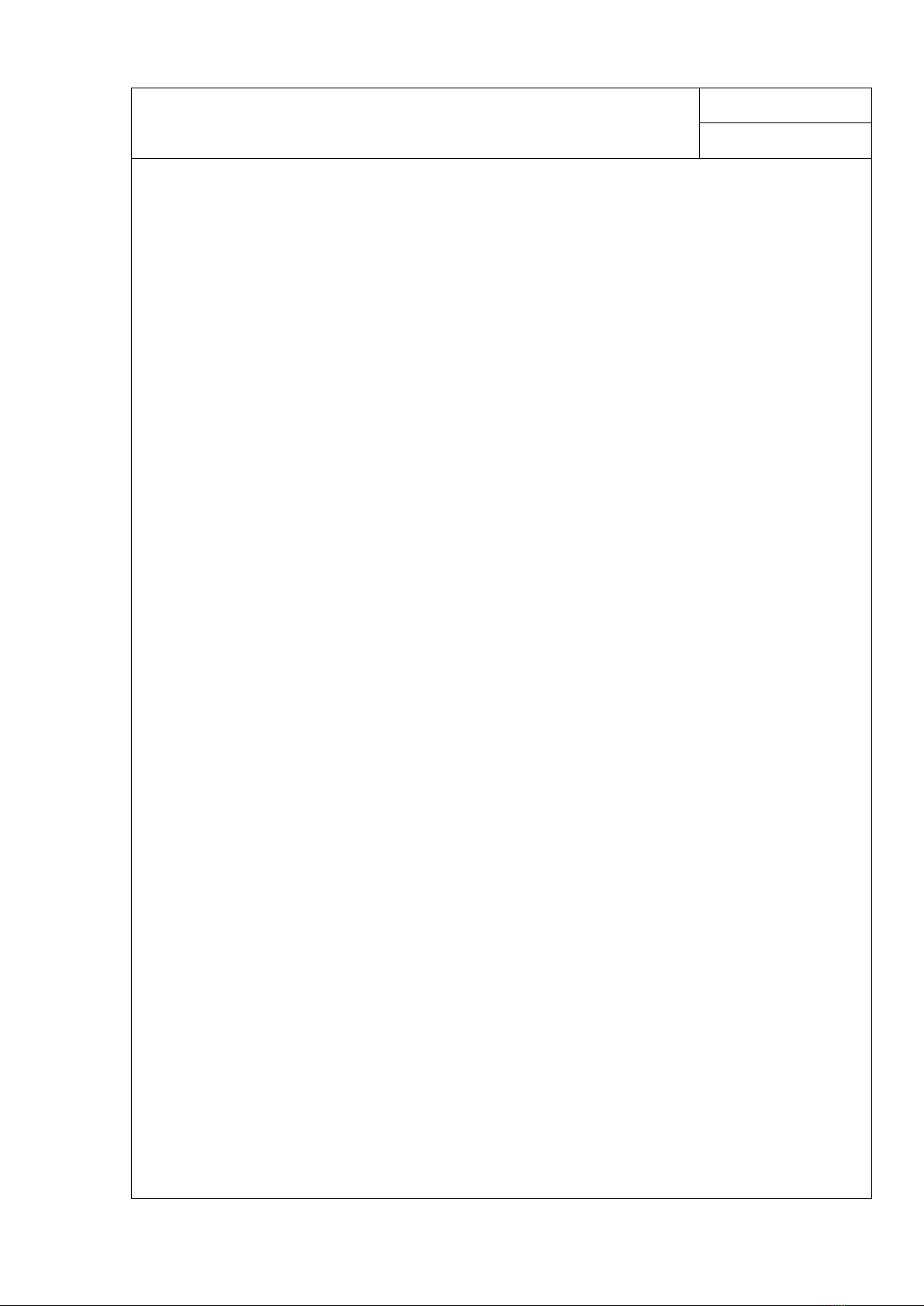

1.Main use and features of the machine:

JDT series vertical drilling machines are our new products designed and developed by our-self

based on our accumulated experience in so many years in this field. It is really a

multi-function universal machine which could be widely used for small and middle sizes of

work pieces for drilling, spot facing, reaming, tapping, Milling Plane, slot-milling, angular

mill etc. Besides, some machine tool accessories could also be used on this machine. The

machines are suitable for the machining workshop, maintenance workshop and production

line etc.

Features:

1.1 Good in appearance, easy in operation, convenience in maintenance and well

consideration in safety protection

1.2 Double speed motor is to be used for the main drive system with sufficient driving

power but saving energy. Wide spindle speed range is adopted driven by gears.

1.3 Oil lubrication both for the main driving system and for the feed driving system could

be supplied automatically by a new type of trochoid pump when it is working in forward and

reverse revolution.

1.4 The spindle features good rigidity and good wear resisting and equipped with tool

disassembly and balancing device.

1.5 The worktable could be turned round the column center line or worktable center line itself

or horizontal shaft centerline by manual and could be moving up and down by

manual or automatically.

1.6 Main operation levers and push buttons could be reached easily that makes you

comfortable when you operate the machine.

1.7 Spindle feed both in mechanical and in electrical with micro feed structure is available

in this series machines.

1.8 A locking device for the spindle quill is available for the purpose of milling job. There is

a screw hole located at the end of the main spindle for the clamping of different kinds of

milling cutters

1.9 Spindle feed both in mechanical and in electrical with micro feed structure is available in

this series machines.

1.10 Superior quality material with special treatment for the wear-resisting purpose has been

used for transmission parts such as gears, worm and worm shaft, rack, lead screw etc as well

as for some key parts like spindle and spindle quill.

1.11 An adjustable safety protection clutch in the spindle feed device is available in order to

prevent the machine and tools from damage when overloaded.

1.12 A safety protection guard under the spindle box is available as it is not only prevent

coolant splash while cutting but also could observe the machining status.

The guard is interlocked with the spindle, so when the guard is opened, the spindle could not

be running until the protection guard keeps his position.