2

in the apparatus. SPERIAN cannot be responsible for

damage to property, personal injury, or death in which

environmental exposure is a contributing factor.

• Do not use this respirator in environments where the

concentrations of contaminants are unknown, or where

the atmosphere is immediately dangerous to life or

health (IDLH). IDLH atmospheres are dened as:

1. Those which the wearer could not breathe for short

periods.

2. Those from which the wearer could not escape

without the aide of the respirator.

3. Those which have an immediate or delayed adverse

effect on health.

• Never use this respirator without appropriate SPERIAN

cartridges/lters identied on the NIOSH approval label

securely threaded onto the face piece.

• This respirator does not supply oxygen and must not be

used in the atmospheres containing less than 19.5%

oxygen by volume.

• Our engineers cannot predict what will happen to this

equipment in every potential environment. Materials

can be chemically attacked if exposed to the wrong

environment and may exhibit excessive corrosion or

other forms of damage. Permeation of gases and liquids

through the materials could be excessive. Extreme of

temperature might cause thermal degradation. Each of

these things, or a combination of them, could crated

conditioning with this SPERIAN equipment would be

dangerous to use.

• All persons using this SPERIAN breathing apparatus

must be amde aware of its limitations.

We cannot be responsible for any damage to property,

personal injury, or dath in which environmental

exposure is a contributing factor.

• Always read cartridge labels prior to use to be certain

that you have cartridges and/or lters that will provide

the required protection. Cartridges/lters labeled for

protection against particulate only shall not be used

for gases/vapors, and cartridges/lters labeled for

protection against gases/vapor only shall not be used

for particulates:

• Immediately return to a non-contaminated area if:

a. You taste or smell contaminates , or if your eyes,

nose, or throat become irritated. blasting, underwater

diving, or interior structural re ghting.

b. Breathing becomes difcult.

c. The air you are breathing becomes uncomfortably

warm.

d. You feel nauseous or dizzy.

• This respirator does not protect exposed areas of the

body. Some contaminates can be absorbed directly

through the skin while other may irritate exposed area.

• This respirator must not be used for abrasive blasting,

underwater diving, or interior structural re ghting.

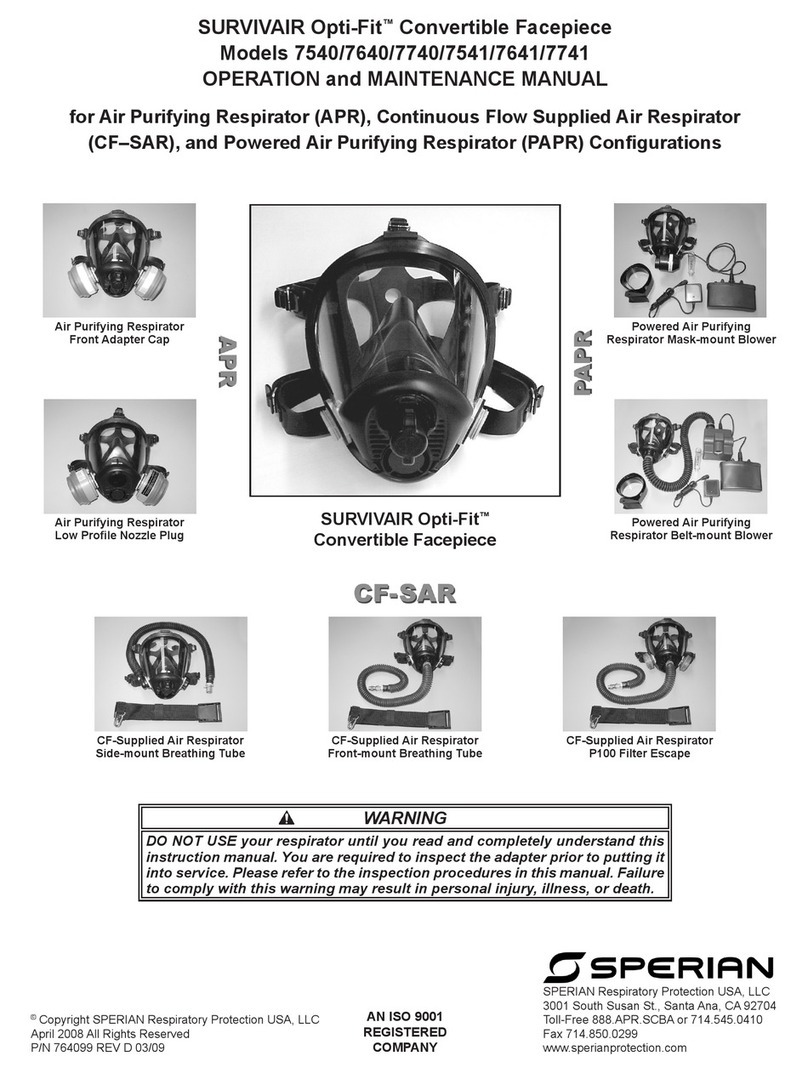

WARNING

• Do not use this respirator at temperatures below -30°F

(-1°C) or above 130°F (71°C). Do not wear this respirator

if a satisfactory t, as determined by a qualitative or

quantitative t test, cannot be obtained. See ANSI

Z88.2 1992 and OSHA Standards for Asbestos and

Lead. Beards, stubble, or sideburns will prevent a good

facepiece seal. Do not use this respirator unless you

are clean shaven. Absence of one or both dentures can

seriously affect the t of the facepiece.

• No respirator can provide complete protection from all

conditions. Use extreme care for emergency operations.

Do not use this respirator for applications involving

exposure to high heat or direct ame.

• Accessories not offered by SPERIAN may degrade

performance, and will void NIOSH certication.

• NEVER use this respirator without SPERIAN cartridges

or lters securely threaded onto the facepiece. This

respirator must be used in conjunction with a written

respirator program meeting the requirements of the

OSHA Standard for Respiratory Protection, 29 CFR

1910.134, available from the U.S. Department of Labor,

Occupational Safety and Health Administration. The

program must include procedures for evaluating air

contaminants and selecting appropriate respirators,

procedures for proper use of respirators, procedures

for testing the facepiece-to-face t of respirators,

procedures for cleaning, disinfecting, inspecting,

maintaining, and storing respirators, procedures for

determining if workers are physically and medically

capable of wearing respirators, and procedures for

training employees in the use of respirators and in

recognizing the hazards associated with contaminants

in the work place. When used with a written respirator

program, this respirator will reduce, but not eliminate

the inhalation of contaminants.

• SPERIAN respirators, accessories, and associated

equipment should not be used in atmospheres which

may contain contaminant concentrations above the

lower explosive level (LEL). Intrinsic safety certication

of electronic components does not eliminate potential

danger from ignition in these atmospheres.

• FAILURE TO OBSERVE ALL WARNINGS MAY RESULT IN

PERSONAL INJURY, SERIOUS ILLNESS, OR DEATH.