Symbols & Notes ............................................................................... 4

Scope of Delivery & Packaging ................................................................ 4

Important Security Information ............................................................... 4

Hook Up .......................................................................................... 5

Introduction ..................................................................................... 6

The Frontliner concept, Analog plug-ins ................................................... 6

Special technical features, Options ........................................................ 7

REAR PANEL ..................................................................................... 8

Standard wiring channel strip .............................................................. 8

Wiring examples: live and studio ............................................................ 9

Wiring examples: group of modules, Inserts ............................................. 1 0

Rear panel/sockets ........................................................................ 1 0

Signal connections, TRS socket, XLR sockets,

Balanced connections, Unbalanced connections ......................................... 11

Separate inputs and outputs, Preamplier: MIC IN,

Preamplier: LINE IN, Preamplier: OUT, De-Esser: IN and OUT ......................... 1 2

Compressor: IN and OUT, Equalizer/Tube Sat.: IN and OUT,

Main Outs OUT1 and OUT 2, AD Input 2, Power connection and fuses ................... 13

Rear Panel/Switches ....................................................................... 1 4

Voltage selector, Power switch, 48 V phantom power/rear switches, GND Lift .......... 14

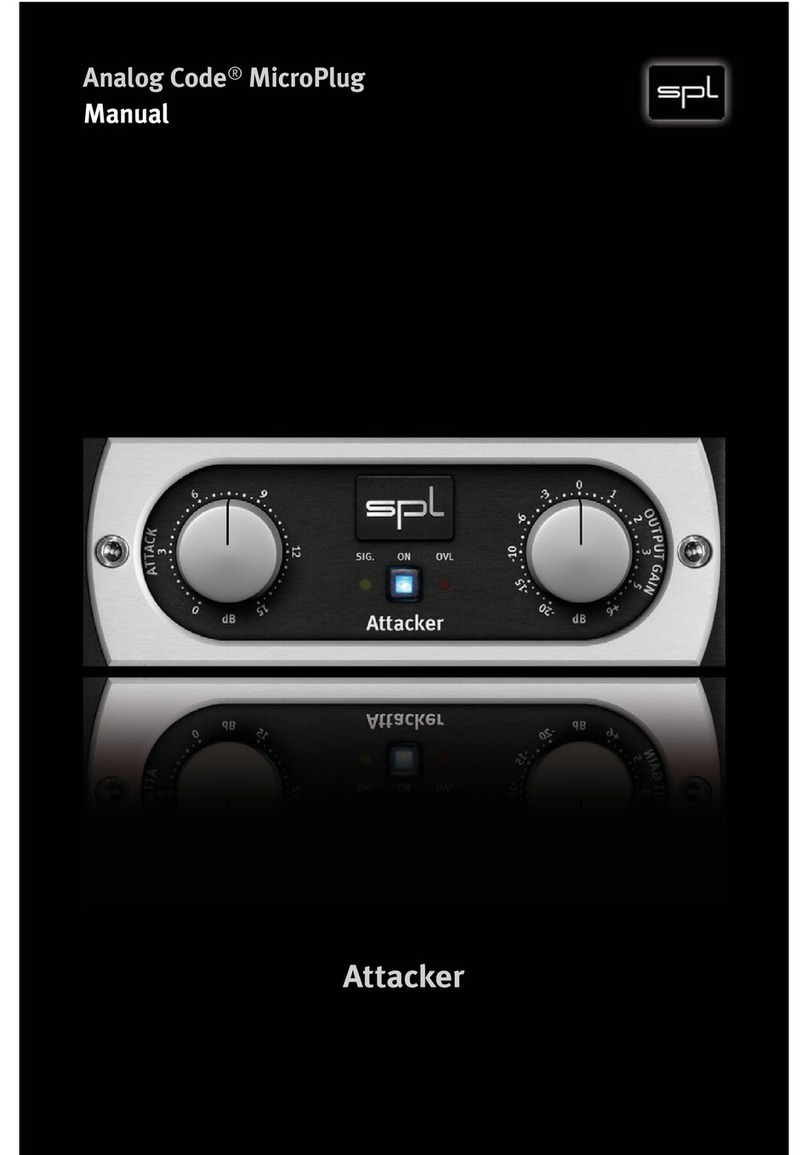

CONTROL ELEMENTS ........................................................................... 1 5

Preamplier ................................................................................. 1 5

MIC GAIN, MIC GAIN adjustments, 48 V, Activating phantom power ..................... 15

Phase reverse, High-pass lter, PAD, Instrument input ................................... 16

LINE GAIN/INSTR. GAIN, LINE GAIN and INSTR. GAIN adjustments,

INSTR. LINE IN, TUBE +15 dB ................................................................ 17

De-Esser .................................................................................... 1 8

ON, S-REDUCTION, SPL De-Esser technology ............................................. 18

Compressor/Limiter ........................................................................ 19

ON, THRESHOLD, RATIO, ATTACK .......................................................... 19

ATTACK with cruise control: Auto Mode, RELEASE,

RELEASE with cruise control: AUTO-Mode, MAKE UP ..................................... 20

Equalizer/Tube Saturation ................................................................. 21

ON, EQ PRE COMP., MHF (mid-/hi lter), MHF -/+ (cut/boost MHF)

2 1

LMF (low/Mid lter), LMF -/+ (cut/boost LMF),

AIR BAND, TUBE SATURATION .............................................................. 22

VU-Meter .................................................................................... 23

VU-Meter, VU/GR switch, 0 dB/-10 dB switch, VU/PPM switch ............................ 23

Output ....................................................................................... 24

OUTPUT, AD OVL-LED, MUTE switch ...................................................... 24

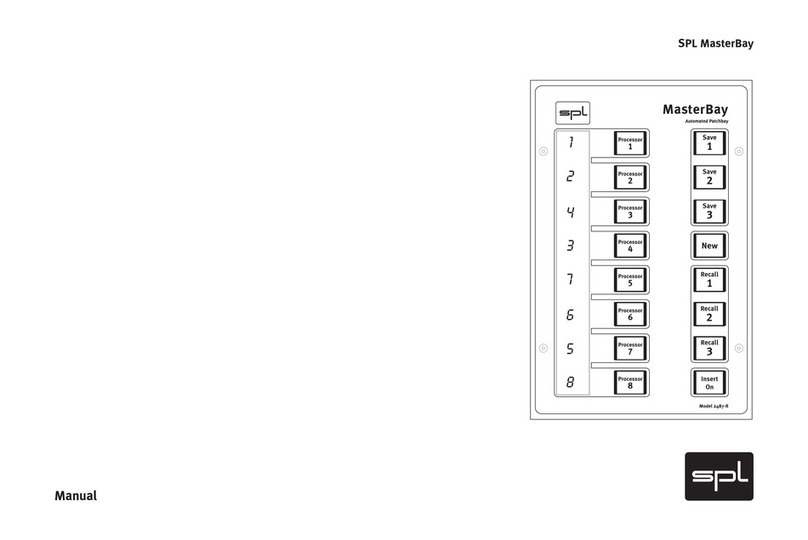

External Inputs ............................................................................. 25

Excluding a single module, Excluding a group of two or three modules, Ungroup ...... 25

Determining inserts, Key lock, Keys and switches ......................................... 26

Options .......................................................................................... 27

24/96 A/D converter model 2376, Information on I/O transformers .. . . . . ......... . . . ... 27

Specications ................................................................................... 28

Copy master: recall settings ................................................................... 30

Block diagrams .................................................................................. 31

Table Switch Logic .............................................................................. 33

Content