Bulletin 30-21 / Page 9

Upon re-energizing the solenoid coil, the low pressure port of the

180 opens and allows instantaneous relief of pressure under the

thermostatic expansion valve diaphragm and normal operation of

the thermostatic expansion valve.

APPLICATION

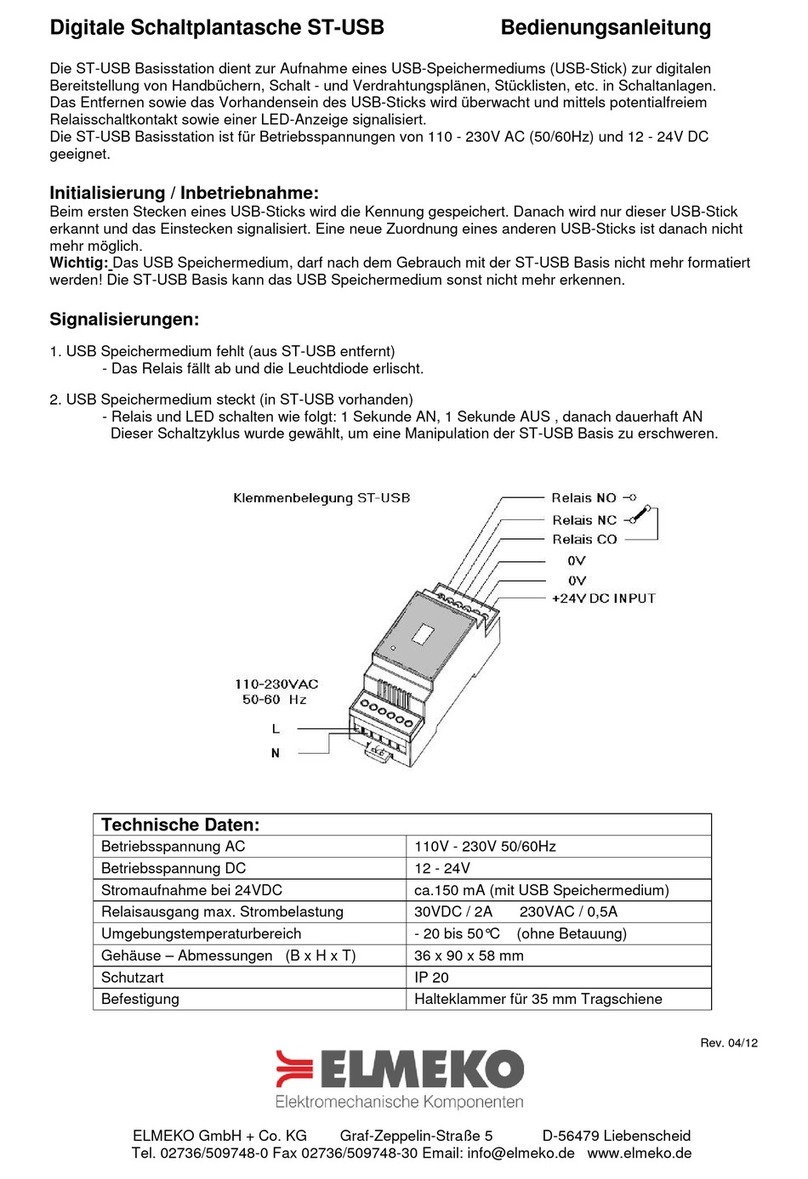

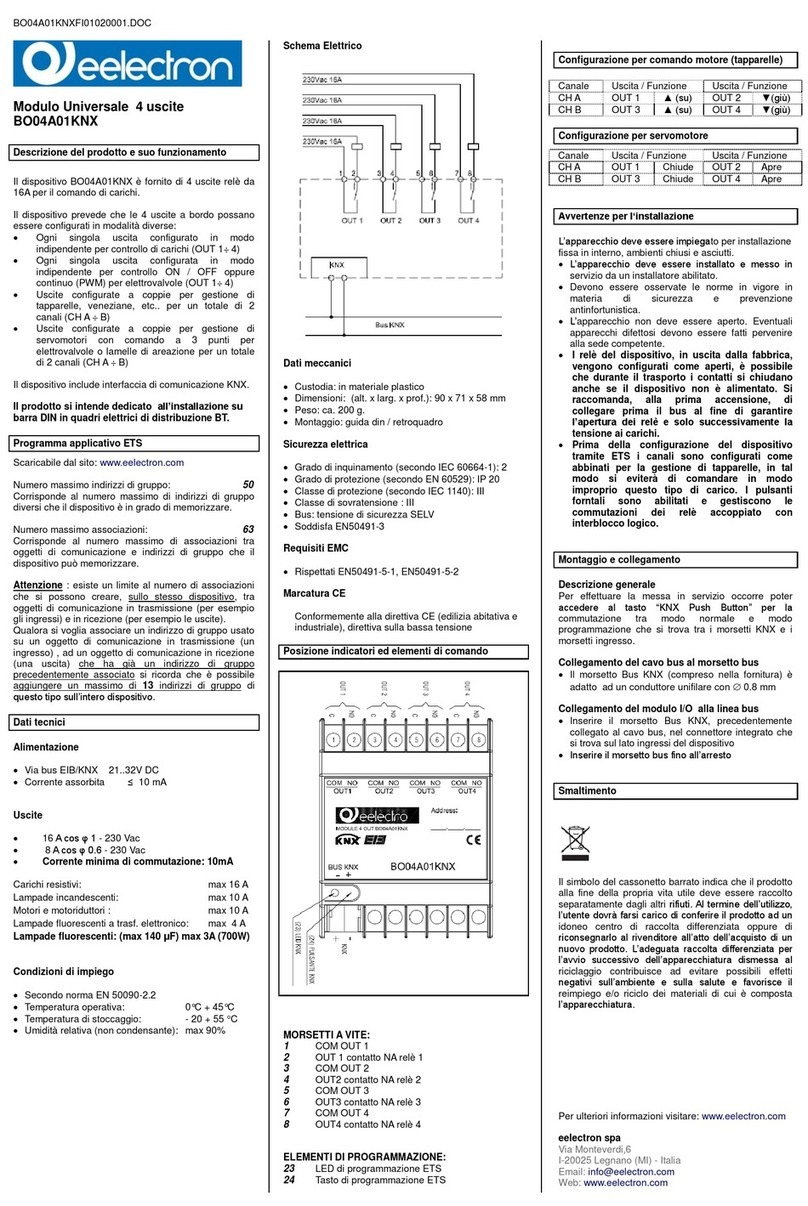

The Type 180 Solenoid Pilot Control may be connected to

any number of thermostatic expansion valves as large as those

nominally rated at 132 tons on Refrigerant 134a and 180 tons on

Refrigerant 22. Thus one Solenoid Pilot Control simultaneously

controls the action of all expansion valves on one evaporator or

system of evaporators. See Figure 11.

NOTE: Since the thermostatic expansion valve Types

V and W have an extended neck between the thermo-

static element and the valve body, a relatively large

quantity of liquid refrigerant resides at this point during

the off-cycle (Type 180 de-energized). Upon re-energiz-

ing the Type 180 control this liquid must boil off if the

TEV is installed so that the “neck” volume is NOT free

draining. The consequence of such an arrangement is

chilling of the thermostatic element and possible gas

charge condensation or migration.

Therefore, we recommend that Types V or W thermo-

static expansion valves (with gas or Type “P” ther-

mostatic charges), when installed with the Type 180

solenoid pilot control, be placed in an upright position

and at a point above the suction line so that the volume

under the diaphragm is free draining.

The Solenoid Pilot Control is actuated in the same manner as a liq-

uid line solenoid valve, e.g. with a thermostat, a pressure switch,

or by manual control. Since the Type-180 design requires that the

liquid line pressure during the off-cycle be slightly higher than

the expansion valve bulb pressure, certain types of applications

require special precautions.

COMFORT COOLING APPLICATIONS

Sporlan thermostatic expansion valves for comfort cooling

applications are generally supplied with Type P air condition-

ing charged thermostatic elements. These charges limit the

maximum operating or opening pressure during the off-cycle, as

well as during the running cycle. The table lists these standard

maximum operating pressures at an approximate 60°F saturated

evaporator temperature.

Therefore, during the off-cycle the receiver ambient temperature

needs to be only slightly higher, 65°F or more, to maintain a

higher liquid line pressure and to insure satisfactory Solenoid Pilot

Control operation.

COMMERCIAL OR LOW TEMPERATURE

REFRIGERATION APPLICATIONS

This type of application requires that the expansion valve and sen-

sor bulb be installed within the refrigerated space, so the bulb tem-

perature will be the same as the evaporator during the off-cycle.

Not only will this prevent compressor flood-back on start-up, but it

will help insure a liquid line pressure higher than the bulb pressure

to keep the expansion valve closed tight during the off-cycle.

COMFORT COOLING APPLICATION (Intermittent Operation)

In certain locales during mild weather, wide variations between

night and day temperatures can create unusual system pressure

conditions. This occurs when the receiver, hence the liquid line

pressure, falls below the maximum thermostatic expansion valve

operating pressures listed above. This is liable to occur when the

receiver is located on the outside of the building or is subjected to

unusually low ambient temperatures. Proper attention to receiver

location can minimize the possibility.

OTHER APPLICATIONS

On other applications where the Solenoid Pilot control may be

applied, care must be exercised to maintain the correct liquid line

– expansion bulb pressure relationship. If the expansion valve bulb

is located near heating coils or any other location warmer than the

receiver location, trouble may occur. During the off-cycle, the bulb

pressure for expansion valves with thermostatic charges other than

the Type P air conditioning charge will rise and open the valve.

This will tend to flood the evaporator; and, if the compressor is

on pressure control, cause it to run for a short period of time when

cooling is not required. Therefore, proper attention to component

location is important to insure correct operation of the Type 180

Solenoid Pilot Control.

RECOMMENDATIONS

Where the unusual conditions exist as previously described,

and where normal location precautions are not feasible, Sporlan

recommends that a conventional liquid line solenoid valve be

installed instead of the Type 180 Solenoid Pilot Control.

All refrigeration and air conditioning systems should be protected

from moisture and other system contaminants by the Sporlan

Catch-All®Filter Drier. When using the Type 180 Solenoid Pilot

Control, the expansion valve is used to shut off the liquid line

in place of a standard liquid line solenoid valve. Therefore, it is

essential that the system be free of these contaminants which might

prevent the thermostatic expansion valve from seating tight.

On double-ported thermostatic expansion valves, such as Sporlan’s

Types V and W, the chance of dirt causing leakage is increased

since either port could be partially blocked open. If this occurs,

the leakage would be even greater since both ports would leak

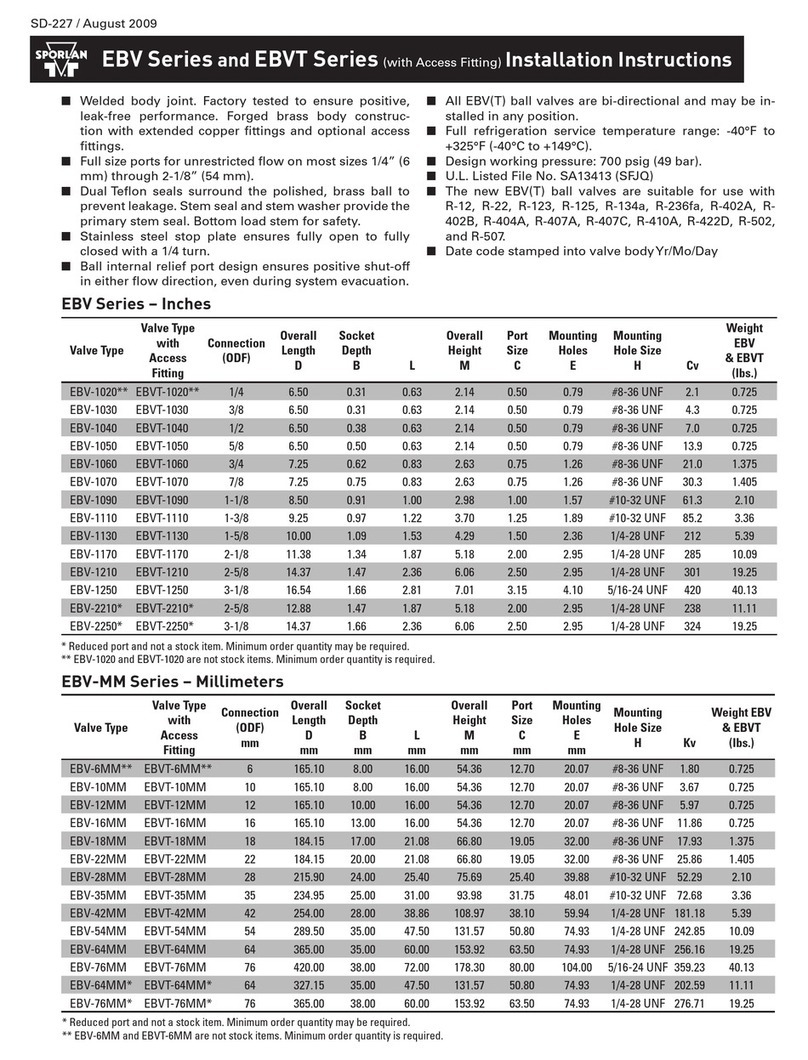

Figure 11

External Equalizer

Connection

Refrigerant Standard Maximum

Operating Pressure

12, 134a 50 psig

22 90 psig