Sporlan ESX User manual

The model ESX step motor expansion valve is the newest

addition to Sporlan Valve Division’s complete line of high

quality refrigerant controls. The ESX expansion valve

provides precise flow control for virtually every refrig-

eration, air-conditioning, and heatpump ap-

plication, from basic to complex, and in a

wide range of environments. This step mo-

tor expansion valve is the ideal choice due

to its compatibility with most halocarbon refrigerant systems,

and most step motor controllers. Installation and operation of

the highly reliable ESX is simple and straightforward; enabling

any type system to be more efficient, more versatile, and more

reliable. The model ESX step motor expansion valve provides

maximum system value through precise, energy efficient flow

control.

Features & Benefits Summary

1. Highly reliable direct drive step motor

■ Compatible with bipolar and unipolar type controllers

■ Rugged design

■ No maintenance or re-calibration required

2. Precise 500 step flow resolution

3. Compact, fully hermetic design—no mechanical joints, no leaks

4. “ Dry” stator design

■ 10 position choices - movable and replaceable stator coil

5. Tight shutoff for high efficiency systems

■ Eliminates the need for a separate liquid line solenoid valve

■ Durable needle valve construction for reliable 10 year life

6. Efficient low power design; no holding current required

7. Rapid response; less than 6 seconds full stroke

8. Bi-flow capable for heatpump applications

9. Compatible with nearly all HCFC and HFC refrigerants

Step Motor Valve Function

Step motors accurately achieve and maintain a controlled position making them

ideal actuators for precision flow control valves. Like a conventional DC mo-

tor, the model ESX has a permanent magnet rotor and a stator; however, they

are specially designed for precise positioning, low power, and refrigerant

compatibility.

Bulletin 100-20-2

February 2006

STEP MOTOR EXPANSION VALVE

®

Page 2 / Bulletin 100-20-2

The “dry” stator is constructed with multiple magnetic

pole pairs created by energized wire windings. The term

“dry” is used because the windings of the stator are out-

side the refrigerant envelope. In the ESX stator there are 4

phases (windings) energized sequentially by a step motor

controller that creates a rotating magnetic field. The sta-

tor magnetically couples with the rotor and causes it to turn

in unison with the rotating field. The field rotates either

clockwise or counter-clockwise depending on the sequence

of electrical pulses to each of the 4 phases. The result is a

proportional valve actuator with the ability to achieve a pre-

cise, repeatable position using an electronic signal.

The “wet” rotor is directly linked to a low-friction threaded

“needle” which moves into and out of the valve’s metering

orifice. The term “wet” indicates that the permanent magnet

rotor is located in the hermetic refrigerant environment. As

the rotor rotates step by step, the needle’s distance from the

valve orifice changes incrementally, thus opening or closing

the expansion valve. Valve “steps” are incremental changes

of the rotor position; in the ESX valve, each step is equivalent

to a 3.75° rotation of the rotor. An internal torsion spring lim-

its clockwise and counter-clockwise motion to eliminate the

potential damage due to driving the valve past its full open or

full closed position. The torsion spring absorbs the torque at

the extreme rotational positions and causes the rotor to “slip”

in the magnetic field created by the stator. The ESX valve

incorporates a spring-loaded needle designed to “collapse”

as the valve approaches the full closed position. This novel

feature limits maximum seating force to reduce seat wear

and maximize valve life. The fine pitch thread design of the

needle prevents “back travel” when power is removed. This

specific feature increases efficiency by requiring power only

when a change in valve position is called for, the ESX does

not require continuous power to maintain position. The result

is a highly reliable step motor expansion valve which is pre-

dictable, durable, and energy efficient.

Open Loop Position Control

Step motors utilize open loop type feedback to achieve and

maintain a required valve position. Simply stated, the step

motor controller counts the number of pulses that are sent to

the valve in order to keep track of the valve’s position. In this

way, no direct feedback is required to monitor valve position

and design, function, and cost are greatly simplified. With an

appropriate controller and the ESX step motor valve, a wide

range of system diagnostics are possible.

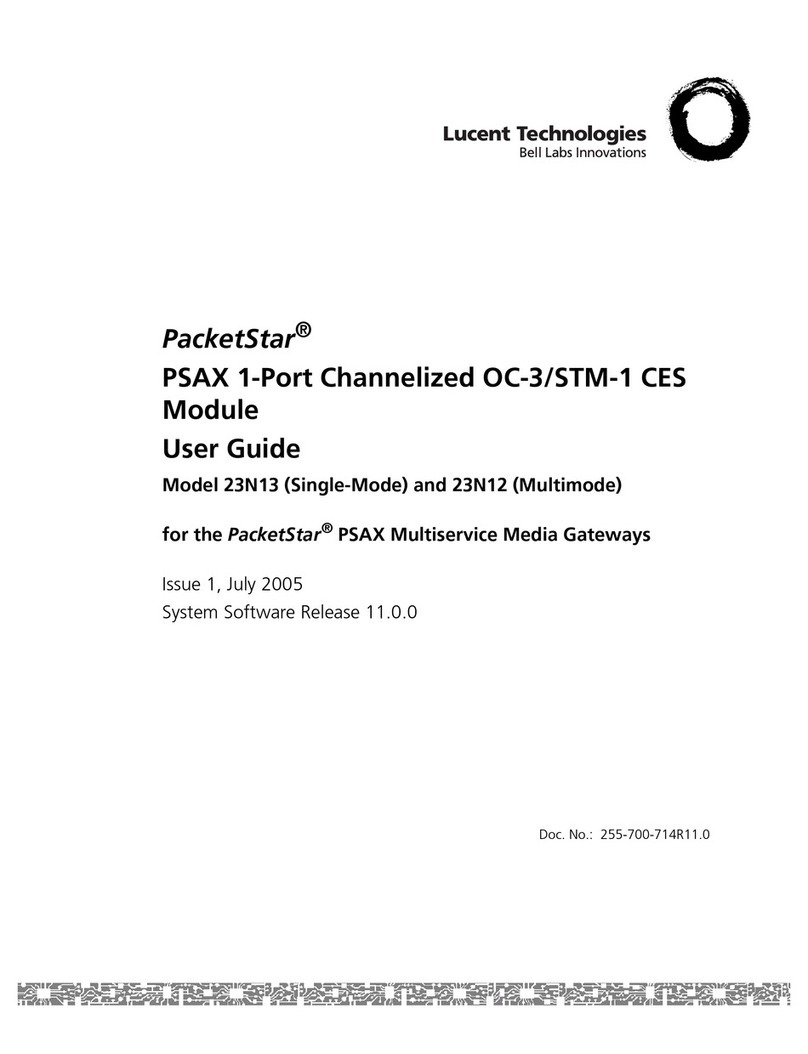

Valve Operation

Proper positioning of valve opening is achieved by sending

a series of electrical pulses to the ESX stator causing it to

rotate open or closed. There are 500 steps of rotation in the

most common single-phase stepping configuration. Of these

500 steps, 400 steps are in the linear control range as shown

in Figure 2. With 400 steps of resolution, incremental flow

changes of 0.25% of full flow are possible. As few as 40 steps

of resolution can achieve stable, efficient system operation

on many applications. This allows the ESX to be used at just

a fraction of its capacity. The wide range of control possible

with the model ESX allows it to be used down to 10% of its

capacity, or up to 110%. Refer to the capacity tables for proper

sizing for your application, refrigerant, and operating condi-

tions.

As shown in Figure 2, approximately 48 single-phase steps

from full closed are required before the valve orifice begins to

open. Beyond 448 steps, the flow rate does not significantly

change. The usable flow range of the valve is from 48 to 448

steps and is the recommended design range for flow control.

The step motor controller should be configured and scaled to

use 48 single phase steps (from step = 0 position) as the 0%

capacity point, and to use 448 steps (from step = 0 position) as

the 100% capacity point.

The initial opening steps (step = 0 to step = 48) position the

valve in its fully closed position but with varying levels of

seating force. This is due to the spring compression biasing the

needle (See figure 1) against the valve seat. Full seating force

is achieved at the home position (step = 0), which is the fully

overdriven position. It is suggested that in forward flow mode

(flow entering side fitting) driving to step 48 will achieve suf-

ficient seating force in most applications. It is not necessary to

overdrive the valve to step = 0 to achieve full valve closure in

forward flow mode, but it is necessary to achieve full closure

when the valve is flowed in the reverse direction.

Because the valve needle is spring biased, the MOPD (Maxi-

mum Operating Pressure Differential) of the valve in reverse

flow can be significantly lower than in forward flow mode.

The MOPD, in reverse flow mode only, varies with orifice

size and is shown in Table 1. Exceeding the MOPD in reverse

flow does not damage the valve; however, it will result in leak-

age through the valve seat until the pressure difference across

the valve decreases below the MOPD. Maximum MOPD will

always be achieved in forward flow mode.

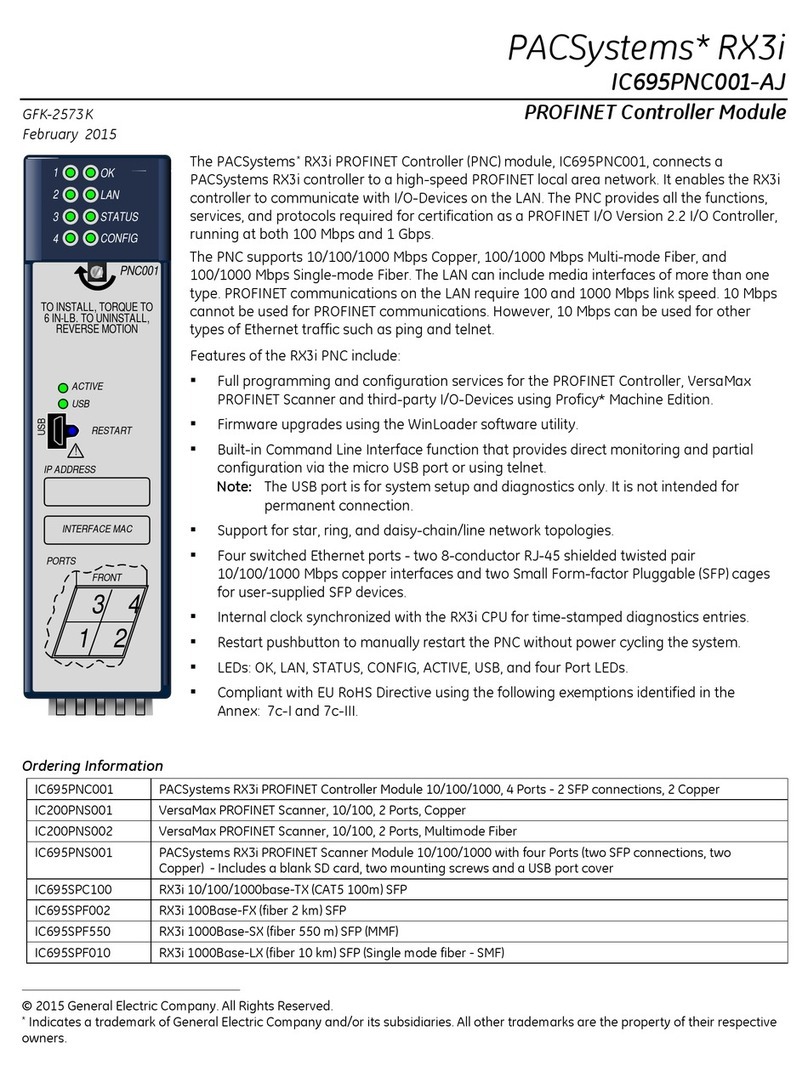

Stator

TabO-Ring

Washer

OUTLET

INLET

Torsion

Spring

Metering Orifice

Spring

Biased

Needle

“Dry” Stator

“Wet” Rotor

Figure 1 - ESX Internal View

Bulletin 100-20-2 / Page 3

Hysteresis and Power Up

Most thermostatic expansion valves have some level of hys-

teresis due to mechanical limitations in their design; this can

result in varying levels of over and underfeeding as the TEV

searches for the correct position. The ESX, however, does not

experience the same limitations due to its unique design. Con-

sequently, the ESX has almost no hysteresis when combined

with an appropriate controller. The controller maintains a step

count that is referenced to determine valve position. With

proper configuration of the step motor controller, extremely

accurate control can be achieved with flawless predictability

and repeatability.

When the controller sends pulses beyond the fully overdriven

(step = 0) position, the rotor will “slip” and the controller will

no longer control an accurate position. For this reason most

step motor valve controllers are configured with the usable

step range, and an initialization routine to establish “home”

(step = 0) position.

It is necessary for the controller to periodically overdrive the

valve for a minimum of 600 pulses to re-establish the step = 0

position; this routine is typically a pre-programmed controller

feature with some minor configuration necessary by the de-

signer. This will ensure that the controller always uses accu-

rate position information. Additionally, it is necessary, when

recovering from a controller or valve power failure, to over-

drive the valve in the exact same manner to re-establish the

step = 0 position. Failure to perform this reset operation after

a power loss or unexpected over/under drive condition can

result in incorrect valve position information and unpredict-

able valve operation.

Step Motor Valve Operation

Step motor expansion valves are available in two different

types, unipolar and bipolar. The ESX valve is a unipolar (5

wire) type; however, it can be utilized in either unipolar or

bipolar configurations.

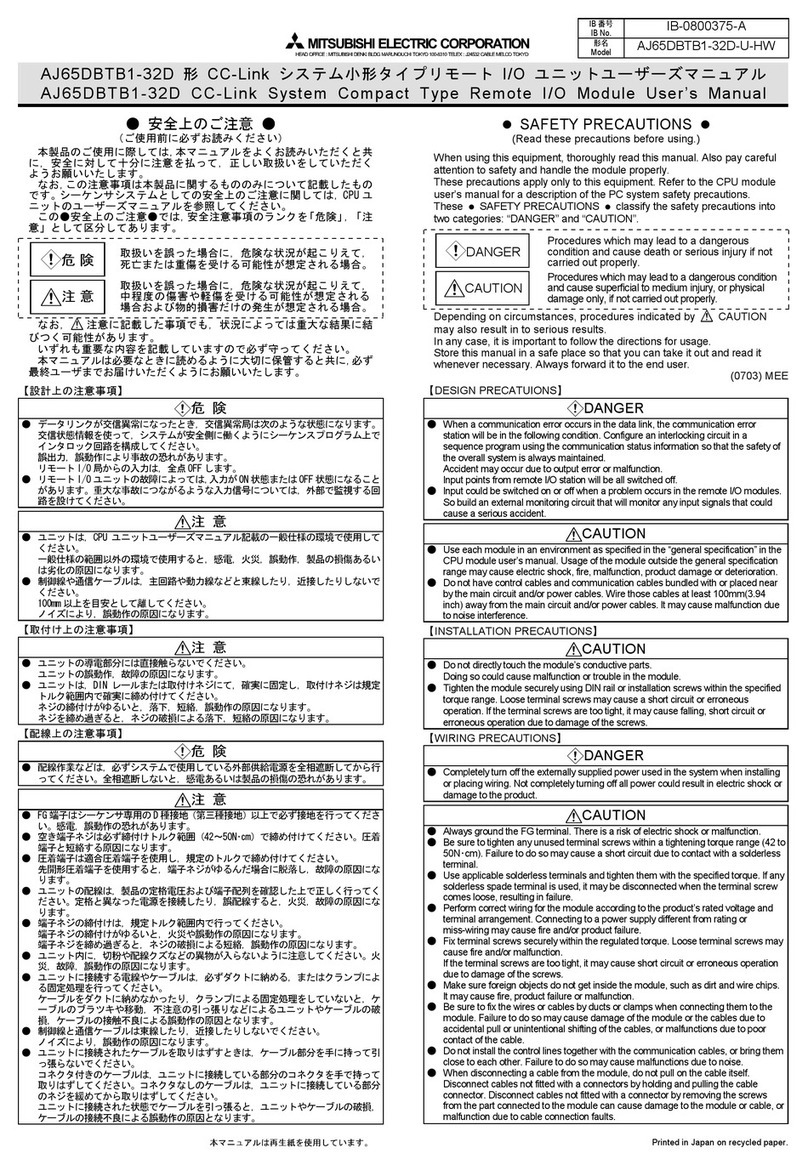

ESX Configured as a Unipolar

Step Motor Valve

The ESX unipolar motor utilizes two windings, each with

a center tap (Figure 3). The two windings, plus a common

center tap from each, form the five wire connection common

to unipolar step motors (Orange, Red, Yellow, Black, Gray)

The center tap (Gray) creates four independent phases, there

are four regions with which a magnetic field is produced. The

arrangement and sequence of energizing each of these four

phases causes the field rotation to move the permanent mag-

net rotor (Figure 3). By selectively and sequentially energizing

each stator phase, a magnetic pole (S) is created in the stator

which attracts the opposite permanent magnet pole (N) on the

rotor. To maximize resolution, two adjacent windings can be

energized simultaneously, called half-stepping, to move the

rotor to a region halfway between phases. An electrical logic

diagram is shown in Table 2 to clarify single-phase stepping

and the required selection and sequence for energizing the sta-

tor phases.

The drive circuit for a unipolar step motor is typically the least

complex of step motor controllers. The unipolar control cir-

cuit sequentially energizes each phase, and adjacent phase in

alternating sequence (Table 2).

Half-stepping is used to increase the resolution of the step

motor by doubling the number of regions where the rotor can

be positioned. The diagram below includes both single and

half-step (*) operations required to operate the ESX valve in

a unipolar configuration.

Note: For unipolar operation, only “pull” type stepping is re-

quired (no polarity change) for proper operation. Do not use

“push/pull” stepping (polarity switching) with the ESX valve

in a unipolar configuration.

Phase

Pulse Steps

Rotated O

(Orange) R

(Red) Y

(Yellow) B

(Black)

1 1 Zero HI HI HI

2 *2 Zero Zero HI HI

3 3 HI Zero HI HI

4 *4 HI Zero Zero HI

5 5 HI HI Zero HI

6 *6 HI HI Zero Zero

7 7 HI HI HI Zero

8 *8 Zero HI HI Zero

Note: Center taps at +12V at all times; “Zero” indicates Zero

V. “HI” indicates high impedance of phase. Reverse the se-

quence to rotate in the opposite direction. Only 8 steps shown;

for further rotation, sequence repeats.

Recommended Control Range

Single Phase Step Position

R-22 Mass Flow (lb/hr)

(100 psi ∆P, 100°F liquid)

0

0

100

200

300

400

500

600

700

800

900

50 100 150 200 250 300 350 400 450 500

48

448

ESX-24

ESX-18

ESX-14

Figure 2 - ESX Capacity Chart

Table 1 - ESX MOPD Limits

Table 2 - Unipolar Step Logic

MOPD Forward MOPD Reverse

ESX-14 500 psi 400 psi

ESX-18 500 psi 300 psi

ESX-24 500 psi 125 psi

Page 4 / Bulletin 100-20-2

O

B

–+

1

G

Y

R

G

s

N

Step

Position

O

B

–+

–+

2

G

Y

R

G

s

N

Step

Position

Wiring color code

O: Orange

R: Red

Y: Yellow

B: Black

G: Gray (common center tap)

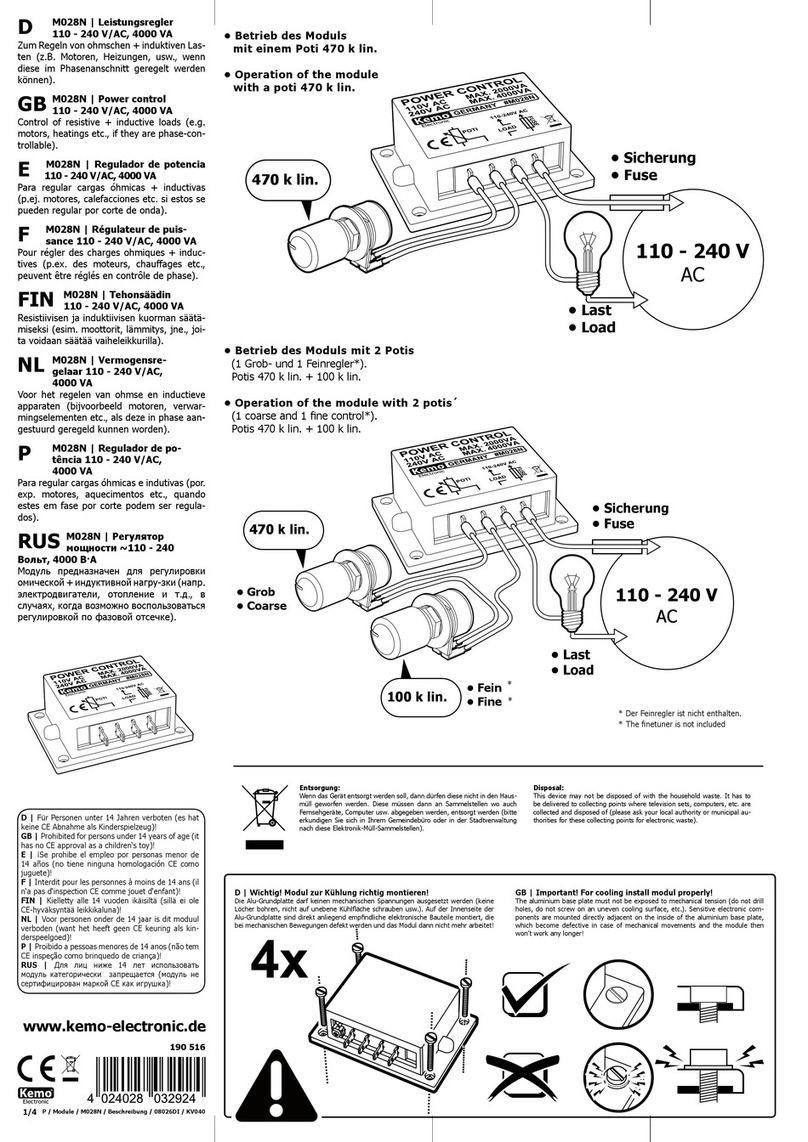

ESX Configured as a Bipolar

Step Motor Valve

Although strongly suggested that the ESX not be

powered in the bipolar mode, control with bipolar

drives is possible with suitable design.

Bipolar step motor valves utilize a different stator wind-

ing configuration by elimination of the center taps and con-

necting all phases together to form a bridge arrangement.

Connections to the windings are made at the junctions between

the windings, therefore only 4 wires and no separate ground

wire are required. There remain four regions with which a

magnetic field is produced. The polarity of each winding can

be reversed requiring a more complex control circuit than

the unipolar arrangement. Selectively energizing each stator

winding, while also switching polarity during the sequence,

creates the same step motion as the unipolar arrangement.

When using the ESX valve with a bipolar controller, the center

ground tap is not used (must be capped) and the stator is used

as a 24-volt bipolar stator. Resolution is decreased by half be-

cause each controller pulse in a bipolar arrangement moves

two single-phase steps (one two-phase step); a minimum of 2

phases are always energized. When using the model ESX in a

bipolar arrangement, valve capacity is the same, but resolution

is decreased from 500 single-phase steps to 250 two-phase

steps. In this arrangement the center tap is not used; each full

winding serves as two phases operating together with oppos-

ing polarity. Sequence and polarity of each phase winding

connection is shown in the table for 8 two-phase steps.

Phase

Pulse Step

Position

O

(Orange)

R

(Red)

Y

(Yellow)

B

(Black)

1 2 + - HI HI

2 4 - + + -

3 6 HI HI + -

4 8 + - - +

Note: “+” indicates +24V; “-” indicates –24V; “HI” indi-

cates high impedance. Reverse the sequence to rotate in the

opposite direction. Only 8 steps shown; for further rotation,

sequence repeats.

O

B

2

G

Y

R

G

s

N

Step

Position

+ –

O

B

–+

3

G

Y

R

G

N

Step

Position

s

O

B

–+

5

G

Y

R

G

N

Step

Position

s

O

B

–+

–+

4

G

Y

R

G

s

N

Step

Position

O

B

–+

–+

6

G

Y

R

G

N

Step

Position

s

O

B

–+

7

G

Y

R

G

N

Step

Position

s

O

B

–+

–+

8

G

Y

R

G

N

Step

Position

s

Figure 3 - ESX Unipolar Step Sequence

Table 3 - Bipolar Step Logic

O

B

4

G

Y

R

G

s

N

Step

Position

+–

+ –

O

B

6

G

Y

R

G

s

N

Step

Position

+ –

O

B

8

G

Y

R

G

s

N

Step

Position

+ –

+–

Figure 4 - ESX Bipolar Step Sequence

Bulletin 100-20-2 / Page 5

Application

Sporlan Valve Division is not responsible for system design,

any damage arising from faulty system design, or for misap-

plication of its products. If these valves are applied in any

manner other than as described in this bulletin, the Sporlan

warranty is void. Please contact your Sporlan Sales Engineer

for assistance with your specific application. It is the responsi-

bility of the controller manufacturer to provide suitable drive

circuitry and power supply. Sporlan will assist where neces-

sary, but accepts no liability for improper control of the valve.

It is strongly suggested that power be disabled to the valve

when not actively stepping. Conventional initialization rou-

tines, which include overdriving the motor to ascertain the

zero step position are acceptable. Contact Sporlan for more

information.

Selection Procedure

Electric Expansion Valves (EEVs) are one part of a system

used for refrigerant flow control in air conditioning or refrig-

eration applications. The other parts of the system are sensors

and an electronic controller.

The EEV controls the flow of refrigerant entering the direct

expansion (DX) evaporator in response to signals sent by the

controller.

These signals are calculated by the controller from sensor in-

puts. A set of sensors, either two temperature sensors or a pres-

sure transducer and a temperature sensor, are used to measure

superheat. Typical control is based on superheat setpoint but

an additional temperature sensor may be used to measure dis-

charge water or air temperature. This air or water temperature

is controlled directly, as long as superheat remains at a level

to prevent floodback.

The ability of the EEV to control the amount of refrigerant in

the evaporator to allow reaching discharge setpoint while pre-

venting floodback makes the EEV the ideal expansion device

for most air conditioning, chiller, environmental chamber

and refrigeration applications. Some EEV controllers can be

programmed to follow unique control algorithms making the

EEV especially useful for many diverse applications.

The actual selection of ESX valves should be based on infor-

mation generally required for any expansion valve. The fol-

lowing procedure should be used when selecting a Sporlan

EEV.

1. Determine refrigerant to be used. The ESX valves

may be used on most common refrigerants. See selection

tables.

2. Determine capacity required for the valve. This

is normally the evaporator capacity at the desired condi-

tions.

3. Determine pressure drop across valve. Subtract the

evaporating pressure from the condensing pressure. The

condensing pressure used in this calculation should be

the minimum operating condensing pressure of the sys-

tem. From this value, subtract all other pressure losses to

obtain the net pressure drop across the valve. Be sure to

consider all of the following possible sources of pressure

drop: (1) friction losses through refrigeration lines includ-

ing the evaporator and condenser; (2) pressure drop across

liquid line accessories such as a solenoid valve and filter-

drier; (3) static pressure loss (gain) due to the vertical lift

(drop) of the liquid line; (see Table 4) and (4) pressure drop

across a refrigerant distributor, if used. Refer to Bulletin

20-10 for further information on refrigerant distributors.

4. Determine the liquid temperature of the refriger-

ant entering the valve. The EEV capacity tables are

based on a liquid temperature of 100°F (38°C) for R-22,

R-134a, R-404A/R-507 and R-407C. For other liquid tem-

peratures, apply the correction factor given in the tables

for each refrigerant.

5. Select valve from the capacity tables. Select a valve

based on the design evaporating temperature and the avail-

able pressure drop across the valve. Due to improved abil-

ity to follow load, Sporlan EEVs provide 10% to 110% of

nominal capacity listed in the capacity tables. Be sure to

apply the appropriate liquid temperature correction factor

to the valve ratings shown in the tables. Once the desired

valve capacity has been located, determine the valve mod-

el from the first column of the tables. On multiple evapo-

rator systems, select each valve on the basis of individual

evaporator capacity.

Selection Example:

Refer to Figure 5

Refrigerant: R-134a

Condensing Temperature: 133°F

Liquid Temperature: 80°F

Evaporator Temperature: 40°F

Liquid Line Loss: 7 psi

∆P Distributor and Tubes: 35 psi

Evaporator Load: 2.5 tons

Condensing Pressure (psig): 211

Liquid Line Loss (Estimates): - 7

Distributor and Tubes: -35

Evaporator Pressure (psi): -69

∆P across EEV: 100

R-134a, 80°F Liquid Correction Factor

from Table: 1.19

ESX-18 2.1 tons x 1.19 = 2.5 tons

ESX-24 4.3 tons x 1.19 = 5.1 tons

Select an ESX 18 from capacity table.

*See Sporlan Bulletin 20-10 for pressure drop data as related

to percent loading.

Page 6 / Bulletin 100-20-2

Table 4 - Vertical Lift Pressure Drop

1.51 Ø1.92

0.87

0.5

0.20

0.18

0.96

2.54

2.63

1.00

4.44

0.97

1/2"

ODF

3/8"ODF

or

1/2"ODF

Standard

Flow

Pattern

R-134a

Valve

Type

Nominal

Capacity

(tons)

40°F

Pressure Drop Across Valve (psi)

40 60 80 100 120 140

ESX-14 1.5 0.8 1.0 1.1 1.2 1.4 1.5

ESX-18 2 1.3 1.6 1.9 2.1 2.3 2.5

ESX-24 3.5 2.7 3.4 3.9 4.3 4.8 5.1

B C

D

A

Figure 5 - Capacity Table Example

Liquid Temperature Correction Factors

°F (Liquid Line Temp) 40 50 60 70 80 90

R-134a (Multiplier) 1.44 1.37 1.31 1.25 1.19 1.13

E

Figure 6 - ESX External View

Refrigerant

Vertical Lift Pressure Drop

20 ft.

(psi)

6 m.

(Bar)

40 ft.

(psi)

12 m.

(Bar)

60 ft.

(psi)

18 m.

(Bar)

134a 10 0.7 20 1.4 30 2.0

22 9.9 0.7 20 1.3 30 2.0

407C 9.4 0.6 19 1.3 28 1.9

404A 8.5 0.6 17 1.2 25 1.7

507 8.5 0.6 17 1.2 25 1.7

410A 8.6 0.6 17 1.2 26 1.8

A: Evaporator Temperature/Pressure

B: Pressure Drop

C: Design System Capacity

D: Valve Selection

E: Liquid Temperature Correction Factor

Nomenclature (Example):

ESX -14 B

Valve Model Orifice Diameter Connections

Electronic 14 = 1.4 mm 5/16 x 5/16 ODF

Step Motor 18 = 1.8 mm A 3/8 x 3/8 ODF

eXpansion Valve 24 = 2.4 mm B 3/8 x 1/2 ODF

ESX Technical Specifications

Device Description

4 phase, 24 pole, unipolar, permanent magnet step

motor expansion valve for halocarbon refrigerants

Actuator Type

Dry stator: replaceable, rotatable, 10 position

Wet rotor: fully hermetic body

Valve Orifice Sizes

0.055” (1.4 mm): 1.5 tons R-22

0.071” (1.8 mm): 3.0 tons R-22

0.094” (2.4 mm): 5.0 tons R-22

Construction

Stator: Copper, nylon

Body: Brass, copper, stainless steel

Compatible Refrigerants

R-22, R-134a, R-404A, R-407C, R-507, R-410A

Compatible Oils

Mineral, polyolester, alkylbenzene

Resolution

500±20 steps; 0.104” (2.64 mm) travel

Step Rate

30 pulse/sec minimum to 83.5 pulse/sec maximum

Full Motion Transit Time

16.7 sec @ 30 pulse/sec

6 sec @ 83.5 pulse/sec

Valve Shutoff

140 cc/min @ 150 psid (10.3 Bar)

Metal/metal seating

Over/under drive protected

Stator Voltage

12 VDC ±10%

Power

4 watts nominal during transit

5.8 watts maximum

No holding power required

Stator Insulation

Class E; 500 V no dielectric breakdown

Flow Path/Connections

90° flow pattern; biflow capable

Extended copper connections

Installation orientation

Vertical to horizontal recommended

MOPD

500 psid (34.5 Bar) forward flow (side inlet)

See Table 1 for reverse flow (bottom inlet)

Max. Working Pressure

650 psig (44.8 Bar)

Burst Pressure

3250 psig (224 Bar)

Media Temperature

-40°F to 155°F (-40°C to 70°C)

Ambient / Storage Temperature

-25°F to 140°F (-30°C to 60°C)

Minimum Life

250,000 CYCLES

Corrosion Resistance

100 hr. ASTM B-117 salt spray

Weights

Body: 0.17 lb (77 g)

Stator: 0.34 lb (154 g); without cable

Phase Resistance

46± 4 Ohms each Phase to common (gray) wire

Bulletin 100-20-2 / Page 7

R-22

Valve

Type

Nominal

Capacity

(tons)

40°F 20°F 0°F

Pressure Drop Across Valve (psi)

50 75 100 125 150 175 200 50 75 100 125 150 175 200 75 100 125 150 175 200 225

ESX-14 1.5 0.6 1.1 1.3 1.5 1.6 1.8 1.9 0.9 1.1 1.3 1.4 1.6 1.7 1.8 1.1 1.3 1.4 1.5 1.7 1.8 1.9

ESX-18 2.5 1.0 1.9 2.3 2.5 2.8 3.0 3.2 1.6 1.9 2.2 2.4 2.7 2.9 3.1 1.8 2.1 2.4 2.6 2.8 3.0 3.2

ESX-24 5 2.14 4.0 4.6 5.2 5.7 6.1 6.5 3.2 3.9 4.5 5.0 5.5 5.9 6.4 3.8 4.4 4.9 5.3 5.8 6.2 6.5

Valve

Type

Nominal

Capacity

(tons)

-10°F -20°F -40°F

Pressure Drop Across Valve (psi)

100 125 150 175 200 225 250 125 150 175 175 200 225 250 100 125 150 175 200 225 250

ESX-14 1.5 1.4 1.5 1.6 1.7 1.9 2.0 2.0 1.4 1.5 1.6 1.7 1.8 1.9 1.9 1.2 1.3 1.4 1.5 1.7 1.8 1.9

ESX-18 2.5 2.3 2.6 2.8 3.0 3.1 3.3 3.3 2.3 2.5 2.7 2.9 3.1 3.3 3.3 2.0 2.2 2.4 2.6 2.8 3.0 3.1

ESX-24 5 4.8 5.3 5.7 6.1 6.4 6.8 6.8 4.7 5.2 5.6 6.0 6.3 6.7 6.7 4.1 4.6 5.0 5.4 5.8 6.1 6.4

R-134a

Valve

Type

Nominal

Capacity

(tons)

40°F 20°F 0°F

Pressure Drop Across Valve (psi)

40 60 80 100 120 140 160 60 80 100 120 140 160 180 60 80 100 120 140 160 180

ESX-14 1 0.8 1.0 1.1 1.2 1.4 1.5 1.6 0.9 1.1 1.2 1.3 1.4 1.5 1.6 0.9 1.0 1.1 1.2 1.3 1.4 1.5

ESX-18 2 1.3 1.6 1.9 2.1 2.3 2.5 2.7 1.6 1.8 2.0 2.2 2.4 2.6 2.7 1.5 1.7 1.9 2.1 2.3 2.4 2.6

ESX-24 3.5 2.7 3.4 3.9 4.3 4.8 5.1 5.5 3.2 3.7 4.1 4.5 4.9 5.3 5.6 3.1 3.5 4.0 4.3 4.7 5.0 5.3

R-404A

Valve

Type

Nominal

Capacity

(tons)

40°F 20°F 0°F

Pressure Drop Across Valve (psi)

50 75 100 125 150 175 200 50 75 100 125 150 175 200 75 100 125 150 175 200 225

ESX-14 1 0.6 0.8 0.9 1.0 1.1 1.2 1.2 0.6 0.7 0.8 0.9 1.0 1.1 1.2 0.7 0.8 0.9 1.0 1.0 1.1 1.2

ESX-18 1.5 1.1 1.3 1.5 1.7 1.8 2.0 2.1 1.0 1.2 1.4 1.6 1.7 1.9 2.0 1.2 1.3 1.5 1.6 1.8 1.9 2.0

ESX-24 3 2.2 2.6 3.1 3.4 3.7 4.0 4.3 2.1 2.5 2.9 3.2 3.6 3.8 4.1 2.4 2.7 3.1 3.3 3.6 3.9 4.1

Valve

Type

Nominal

Capacity

(tons)

-10°F -20°F -40°F

Pressure Drop Across Valve (psi)

100 125 150 175 200 225 250 125 150 175 175 200 225 250 100 125 150 175 200 225 250

ESX-14 1 0.9 0.9 1.0 1.1 1.1 1.2 1.2 0.8 0.9 1.0 1.0 1.1 1.2 1.2 0.7 0.8 0.8 0.9 1.0 1.0 1.1

ESX-18 1.5 1.4 1.6 1.7 1.8 1.9 2.0 2.0 1.4 1.5 1.7 1.8 1.9 2.0 2.0 1.8 1.3 1.4 1.5 1.6 1.7 1.8

ESX-24 3 3.0 3.2 3.5 3.7 4.0 4.2 4.2 2.9 3.1 3.4 3.6 3.8 4.1 4.1 2.4 2.6 2.9 3.1 3.3 3.5 3.7

Liquid Temperature Correction Factors

°F 40 50 60 70 80 90 100 110 120 130 140

R-22 1.32 1.27 1.22 1.16 1.11 1.06 1.00 0.94 0.90 0.84 0.78

R-134a 1.44 1.37 1.31 1.25 1.19 1.13 1.06 1.00 0.94 0.87 0.81

R-404A 1.53 1.45 1.36 1.27 1.18 1.09 1.00 0.93 0.84 0.74 0.63

°F Capacity Ratings R-22, R-134a, R-404A

Tons at Evaporator Temperature (Based on 100°F Liquid)

Model ESX valves are designed to cover an operating range from 10% of table capacity up to 110% of table capacity. Shaded areas are

standard rating conditions.

NOTE: Correction factor closest to actual system liquid temperatures may be

used, e.g. 48°F actual liquid use 50°F factor. Based on 0°F evaporator, variation

across evaporating range of -40°F to 40°F (-40°C to 5°C) is insignificant.

°F Capacity Ratings

Page 8 / Bulletin 100-20-2

R-410A

Valve

Type

Nominal

Capacity

(tons)

40°F 20°F 0°F

Pressure Drop Across Valve (psi)

100 120 160 200 240 280 320 100 120 160 200 240 280 320 100 120 160 200 240 280 320

ESX-14 1.5 1.3 1.4 1.6 1.8 2.0 2.1 2.3 1.2 2.1 2.3 1.4 1.6 1.7 1.9 1.2 1.3 1.5 1.7 1.9 2.0 2.1

ESX-18 2.5 2.1 2.3 2.7 3.0 3.3 3.6 3.9 2.1 2.3 2.6 3.0 3.2 3.5 3.8 2.0 2.2 2.6 2.9 3.1 3.4 3.6

ESX-24 5.5 4.4 4.8 5.6 6.2 6.8 7.4 7.9 4.3 7.4 7.9 4.7 5.4 6.1 6.6 4.2 4.6 5.3 5.9 6.5 7.0 7.5

R-407C

Valve

Type

Nominal

Capacity

(tons)

40°F 20°F 0°F

Pressure Drop Across Valve (psi)

50 75 100 125 150 175 200 50 75 100 125 150 175 200 75 100 125 150 175 200 225

ESX-14 2 0.8 1.5 2.0 2.2 2.4 2.6 2.8 0.8 1.0 1.1 1.3 1.4 1.5 1.6 0.9 1.1 1.2 1.3 1.4 1.5 1.6

ESX-18 3.5 2.1 2.6 3.3 3.7 4.1 4.4 4.7 1.4 1.7 1.9 2.2 2.4 2.6 2.7 1.6 1.8 2.1 2.3 2.4 2.6 2.8

ESX-24 7 3.0 5.3 6.9 7.7 8.4 9.1 9.7 2.8 3.4 4.0 4.4 4.9 5.2 5.6 3.3 3.8 4.2 4.6 5.0 5.4 5.7

R-507

Valve

Type

Nominal

Capacity

(tons)

40°F 20°F 0°F

Pressure Drop Across Valve (psi)

50 75 100 125 150 175 200 50 75 100 125 150 175 200 75 100 125 150 175 200 225

ESX-14 1 0.6 0.8 0.8 0.9 1.0 1.1 1.1 0.6 0.7 0.8 0.9 1.0 1.0 1.1 0.6 0.7 0.8 0.9 1.0 1.1 1.1

ESX-18 1.5 1.0 1.3 1.4 1.6 1.7 1.9 2.0 1.0 1.2 1.3 1.5 1.6 1.8 1.9 1.1 1.3 1.4 1.5 1.7 1.8 1.9

ESX-24 3 2.0 2.6 2.9 3.3 3.6 3.8 4.1 2.0 2.4 2.8 3.1 3.4 3.6 3.9 2.2 2.6 2.9 3.2 3.4 3.7 3.9

Valve

Type

Nominal

Capacity

(tons)

-10°F -20°F -40°F

Pressure Drop Across Valve (psi)

100 125 150 175 200 225 250 100 125 150 175 200 225 250 100 125 150 175 200 225 250

ESX-14 1 0.8 0.9 1.0 1.0 1.1 1.1 1.1 0.7 0.8 0.9 0.9 1.0 1.0 1.1 0.7 0.7 0.8 0.9 0.9 1.0 1.5

ESX-18 2 1.4 1.5 1.6 1.7 1.8 1.8 1.9 1.2 1.3 1.4 1.6 1.7 1.8 1.9 1.1 1.2 1.3 1.5 1.6 1.7 2.6

ESX-24 3.5 2.8 3.1 3.3 3.6 3.8 3.8 4.0 2.4 2.7 3.0 3.2 3.4 3.6 3.8 2.3 2.5 2.8 3.0 3.2 3.4 5.3

Liquid Temperature Correction Factors

°F 40 50 60 70 80 90 100 110 120 130 140

R-407C 1.42 1.35 1.28 1.21 1.14 1.07 1.00 0.93 0.85 0.77 0.69

R-410A 1.43 1.36 1.29 1.22 1.15 1.08 1.00 0.95 0.87 0.79 0.69

R-507 1.53 1.45 1.36 1.27 1.18 1.09 1.00 0.93 0.84 0.74 0.63

°F Capacity Ratings R-407C, R-410A, R-507

Tons at Evaporator Temperature (Based on 100°F Liquid)

Model ESX valves are designed to cover an operating range from 10% of table capacity up to 110% of table capacity. Shaded areas are

standard rating conditions.

NOTE: Correction factor closest to actual system liquid temperatures may be

used, e.g. 48°F actual liquid use 50°F factor. Based on 0°F evaporator, variation

across evaporating range of -40°F to 40°F (-40°C to 5°C) is insignificant.

°F Capacity Ratings

Bulletin 100-20-2 / Page 9

R-22

Valve

Type

Nominal

Capacity

(kW)

5°C -10°C -20°C

Pressure Drop Across Valve (psi)

4 6 8 10 12 14 16 4 6 8 10 12 14 16 6 8 10 12 14 16 18

ESX-14 4.5 3.4 4.1 4.8 5.3 5.8 6.3 6.7 3.2 4.0 4.6 5.1 5.6 6.1 6.5 3.9 4.5 5.0 5.5 5.9 6.3 6.7

ESX-18 7 5.7 7.0 8.1 9.0 9.9 10.7 11.4 5.5 6.7 7.8 8.7 9.5 10.3 11.0 6.5 7.5 8.4 9.2 10.0 10.7 11.3

ESX-24 15 11.7 14.3 16.5 18.5 20.3 21.9 23.4 11.3 13.8 15.9 17.8 19.5 21.1 22.5 13.4 15.5 17.3 19.0 20.5 21.9 23.2

Valve

Type

Nominal

Capacity

(kW)

-30°C -40°C

Pressure Drop Across Valve (psi)

8 10 12 14 16 18 20 8 10 12 14 16 18 20

ESX-14 4.5 4.3 4.8 5.3 5.7 6.1 6.5 6.9 4.2 4.7 5.1 5.6 5.9 6.3 6.6

ESX-18 7 7.3 8.2 9.0 9.7 10.4 11.0 11.6 7.1 8.0 8.7 9.4 10.1 10.7 11.3

ESX-24 15 15.1 16.9 18.5 19.9 21.3 22.6 23.8 14.6 16.3 17.9 19.3 20.7 21.9 23.1

R-134a

Valve

Type

Nominal

Capacity

(kW)

5°C -10°C -20°C

Pressure Drop Across Valve (psi)

4 6 8 10 12 14 16 4 6 8 10 12 14 16 6 8 10 12 14 16 18

ESX-14 4.5 3.1 3.8 4.4 5.0 5.4 5.9 6.3 2.9 3.6 4.2 4.7 5.1 5.5 5.9 3.4 4.0 4.4 4.9 5.3 5.6 6.0

ESX-18 7.5 5.3 6.5 7.5 8.4 9.2 9.9 10.6 5.0 6.1 7.1 7.9 8.6 9.3 10.0 5.8 6.7 7.5 8.3 8.9 9.5 10.1

ESX-24 15.5 10.9 13.4 15.4 17.2 18.9 20.4 21.8 10.2 12.5 14.5 16.2 17.7 19.1 20.5 12.0 13.8 15.5 16.9 18.3 19.6 20.7

R-404A

Valve

Type

Nominal

Capacity

(kW)

5°C -10°C -20°C

Pressure Drop Across Valve (psi)

4 6 8 10 12 14 16 4 6 8 10 12 14 16 6 8 10 12 14 16 18

ESX-14 3 2.2 2.7 3.1 3.5 3.9 4.2 4.4 2.0 2.5 2.9 3.2 3.5 3.8 4.1 2.8 3.1 3.4 3.7 3.9 4.1 2.6

ESX-18 5 3.8 4.6 5.3 6.0 6.5 7.1 7.5 3.5 4.3 4.9 5.5 6.0 6.5 6.9 4.7 5.2 5.7 6.2 6.6 7.0 4.4

ESX-24 10 7.7 9.5 10.9 12.2 13.4 14.5 15.5 7.1 8.7 10.1 11.3 12.3 13.3 14.2 9.6 10.7 11.8 12.7 13.6 14.4 9.0

Valve

Type

Nominal

Capacity

(kW)

-30°C -40°C

Pressure Drop Across Valve (psi)

8 10 12 14 16 18 20 8 10 12 14 16 18 20

ESX-14 3 2.6 2.9 3.2 3.4 3.7 3.9 4.1 2.4 2.7 3.0 3.2 3.4 3.6 3.8

ESX-18 5 4.4 4.9 5.4 5.8 6.2 6.6 7.0 4.1 4.6 5.0 5.4 5.8 6.2 6.5

ESX-24 10 9.0 10.1 11.1 11.9 12.8 13.5 14.3 8.4 9.4 10.3 11.1 11.9 12.6 13.3

Liquid Temperature Correction Factors

°C 4 10 16 21 27 32 38 43 49 54 60

R-22 1.32 1.27 1.22 1.16 1.11 1.06 1.00 0.94 0.90 0.84 0.78

R-134a 1.44 1.37 1.31 1.25 1.19 1.13 1.06 1.00 0.94 0.87 0.81

R-404A 1.53 1.45 1.36 1.27 1.18 1.09 1.00 0.93 0.84 0.74 0.63

°C Capacity Ratings R-22, R-134a, R-404A

kW at Evaporator Temperature (Based on 38°C Liquid)

Model ESX valves are designed to cover an operating range from 10% of table capacity up to 110% of table capacity.

NOTE: Correction factor closest to actual system liquid temperatures may be

used, e.g. 5°C actual liquid use 4°C factor. Based on 0°C evaporator, variation

across evaporating range of -40°C to 5°C (-40°F to 40°F) is insignificant.

°C Capacity Ratings

Page 10 / Bulletin 100-20-2

R-410A

Valve

Type

Nominal

Capacity

(kW)

5°C -10°C -20°C

Pressure Drop Across Valve (psi)

10 12 14 16 18 20 22 10 12 14 16 18 20 22 10 12 14 16 18 20 22

ESX-14 5 5.0 5.5 6.0 6.4 6.7 7.1 7.6 4.9 5.3 5.8 6.1 6.5 6.9 7.3 4.7 5.2 5.6 6.0 6.3 6.7 7.1

ESX-18 9 8.5 9.3 10.1 10.8 11.4 12.1 12.8 8.2 9.0 9.8 10.4 11.1 11.7 12.4 8.0 8.8 9.5 10.1 10.8 11.3 12.1

ESX-24 18 17.5 19.2 20.7 22.1 23.5 24.7 26.4 16.9 18.5 20.0 21.4 22.7 23.9 25.5 16.5 18.0 19.5 20.8 22.1 23.3 24.8

R-407C

Valve

Type

Nominal

Capacity

(kW)

5°C -10°C -20°C

Pressure Drop Across Valve (psi)

4 6 8 10 12 14 16 4 6 8 10 12 14 16 6 8 10 12 14 16 18

ESX-14 4 3.1 3.8 4.4 4.9 5.4 5.8 6.2 2.9 3.6 4.1 4.6 5.0 5.4 5.8 3.4 4.0 4.4 4.9 5.2 5.6 5.9

ESX-18 7 5.2 6.4 7.4 8.3 9.1 9.8 10.5 4.9 6.0 7.0 7.8 8.5 9.2 9.8 5.8 6.7 7.5 8.2 8.9 9.5 10.1

ESX-24 14 10.7 13.2 15.2 17.0 18.6 20.1 21.5 10.1 12.4 14.3 16.0 17.5 18.9 20.2 11.9 13.8 15.4 16.9 18.2 19.5 20.7

R-507

Valve

Type

Nominal

Capacity

(kW)

5°C -10°C -20°C

Pressure Drop Across Valve (psi)

4 6 8 10 12 14 16 4 6 8 10 12 14 16 6 8 10 12 14 16 18

ESX-14 3 2.2 2.7 3.1 3.5 3.8 4.1 4.4 2.0 2.5 2.8 3.2 3.5 3.8 4.0 2.4 2.7 3.0 3.3 3.6 3.8 4.1

ESX-18 5 3.7 4.5 5.2 5.9 6.4 6.9 7.4 3.4 4.2 4.8 5.4 5.9 6.4 6.8 4.0 4.6 5.2 5.6 6.1 6.5 6.9

ESX-24 10 7.6 9.3 10.7 12.0 13.2 14.2 15.2 7.0 8.6 9.9 11.1 12.1 13.1 14.0 8.2 9.5 10.6 11.6 12.5 13.4 14.2

Valve

Type

Nominal

Capacity

(kW)

-30°C -40°C

Pressure Drop Across Valve (psi)

8 10 12 14 16 18 20 8 10 12 14 16 18 20

ESX-14 3 2.5 2.8 3.1 3.4 3.6 3.8 4.0 2.4 2.7 2.9 3.2 3.4 3.6 3.8

ESX-18 5 4.3 4.8 5.3 5.7 6.1 6.5 6.8 4.0 4.5 5.0 5.3 5.7 6.1 6.4

ESX-24 10 8.8 9.9 10.8 11.7 12.5 13.3 14.0 8.3 9.3 10.2 11.0 11.7 12.4 13.1

Liquid Temperature Correction Factors

°C 4 10 16 21 27 32 38 43 49 54 60

R-407C 1.42 1.35 1.28 1.21 1.14 1.07 1.00 0.93 0.85 0.77 0.69

R-410A 1.43 1.36 1.29 1.22 1.15 1.08 1.00 0.95 0.87 0.79 0.69

R-507 1.53 1.45 1.36 1.27 1.18 1.09 1.00 0.93 0.84 0.74 0.63

°C Capacity Ratings R-407C, R-410A, R-507

kW at Evaporator Temperature (Based on 38°C Liquid)

Model ESX valves are designed to cover an operating range from 10% of table capacity up to 110% of table capacity.

NOTE: Correction factor closest to actual system liquid temperatures may be

used, e.g. 5°C actual liquid use 4°C factor. Based on 0°C evaporator, variation

across evaporating range of -40°C to 5°C (-40°F to 40°F) is insignificant.

°C Capacity Ratings

Bulletin 100-20-2 / Page 11

*Gray wire for ESX only.

DI1

1-

1S

1+

R = Red

G = Green

W = White

B = Black

TS2 - Temp. Sensor 2

TS1 - Temp. Sensor 1

PB1 PB2

8.8.

Temperature

Sensor

SER, ESX,

SEI, SEH

TS2TS1 B W G R 1+ 1S 1- DI1

24 VAC

24 VAC

40 VA

Transformer

Pumpdown

Relay

(optional)

Pressure

Transducer

*

Evaporator

DI1

1-

1S

1+

R = Red

G = Green

W = White

B = Black

TS2 - Temp. Sensor 2

TS1 - Temp. Sensor 1

PB1 PB2

8.8.

Temperature

Sensor

Temperature

Sensor

Outlet - Liquid or Air

ESX, SER,

SEI, SEH

TS2TS1 B W G R 1+ 1S 1- DI1

24 VAC

24 VAC

40 VA

Transformer

Pumpdown

Relay

(optional)

Pressure

Transducer

*Gray wire for ESX only.

*

Superheat Controller Wiring Schematic

Refrigeration P/T or Subcooler Controller Wiring Schematic

Page 12 / Bulletin 100-20-2

Printed in U.S. of A. © Copyright 2006 by Parker Hannifin Corporation, Washington, MO 206

Chiller Controller Wiring Schematic

Evaporator

Temperature

Sensor

ESX, SER,

SEI, SEH

TS4TS3 R G W B 2- 2S 2+ DI2

Pressure

Transducer

Evaporator

Valve 1

Valve 2

DI1

1-

1S

1+

R = Red

G = Green

W = White

B = Black

TS2 - Temp. Sensor 2

TS1 - Temp. Sensor 1

TS4 - Temp. Sensor 4

TS3 - Temp. Sensor 3

PB1 PB2

8.8.

Temperature

Sensor

SER, ESX,

SEI, SEH

TS2TS1 B W G R 1+ 1S 1- DI1

24 VAC

24 VAC

40 VA

Transformer

Pumpdown

Relay

(optional)

Pressure

Transducer

Valve 2 connections on

left block when used

*Gray wire for ESX only.

*

*

Table of contents

Other Sporlan Control Unit manuals

Sporlan

Sporlan SDR-4 Quick guide

Sporlan

Sporlan Secondary Fluid Control User manual

Sporlan

Sporlan OROA-5 Installation and maintenance instructions

Sporlan

Sporlan EBV Series User manual

Sporlan

Sporlan ORIT-10 Installation and maintenance instructions

Sporlan

Sporlan B5D User guide

Sporlan

Sporlan Parker S3C User guide

Sporlan

Sporlan ORIT-12 Installation and maintenance instructions

Popular Control Unit manuals by other brands

RF-Star

RF-Star RF-BM-ND04 manual

Pliant

Pliant CREWCOM operating manual

Crow

Crow CRRSI01 Installation & user guide

Mitsubishi Electric

Mitsubishi Electric FX-USB-AW user manual

Pentair

Pentair Anderson Greenwood 93 Series Installation and maintenance instructions

RAYLASE

RAYLASE SP-ICE-1 PCI/e PRO Hardware manual