EBV Series and EBVT Series (with Access Fitting) Installation Instructions

SD-227 / August 2009

n Welded body joint. Factory tested to ensure positive,

leak-free performance. Forged brass body construc-

tion with extended copper fittings and optional access

fittings.

nFull size ports for unrestricted flow on most sizes 1/4” (6

mm) through 2-1/8” (54 mm).

nDual Teflon seals surround the polished, brass ball to

prevent leakage. Stem seal and stem washer provide the

primary stem seal. Bottom load stem for safety.

nStainless steel stop plate ensures fully open to fully

closed with a 1/4 turn.

nBall internal relief port design ensures positive shut-off

in either flow direction, even during system evacuation.

nAll EBV(T) ball valves are bi-directional and may be in-

stalled in any position.

nFull refrigeration service temperature range: -40°F to

+325°F (-40°C to +149°C).

nDesign working pressure: 700 psig (49 bar).

nU.L. Listed File No. SA13413 (SFJQ)

nThe new EBV(T) ball valves are suitable for use with

R-12, R-22, R-123, R-125, R-134a, R-236fa, R-402A, R-

402B, R-404A, R-407A, R-407C, R-410A, R-422D, R-502,

and R-507.

nDate code stamped into valve bodyYr/Mo/Day

Valve Type

Valve Type

with

Access

Fitting

Connection

(ODF)

Overall

Length

D

Socket

Depth

B L

Overall

Height

M

Port

Size

C

Mounting

Holes

E

Mounting

Hole Size

H Cv

Weight

EBV

& EBVT

(lbs.)

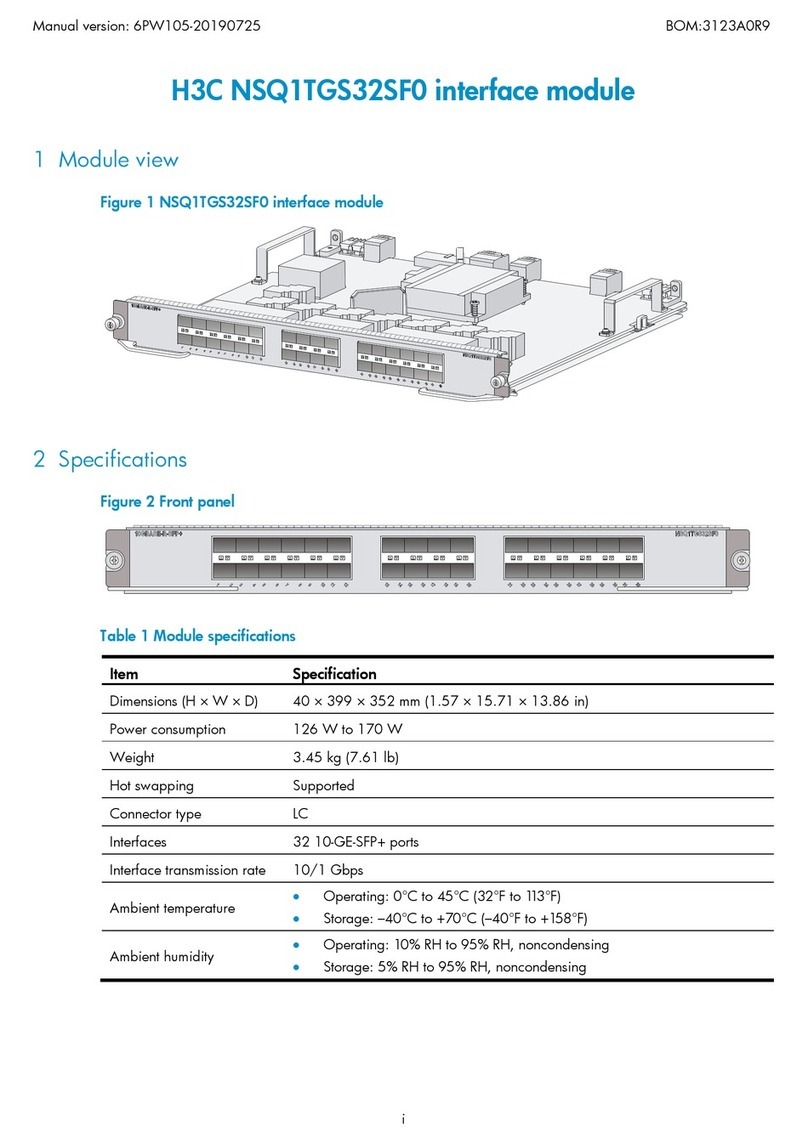

EBV-1020** EBVT-1020** 1/4 6.50 0.31 0.63 2.14 0.50 0.79 #8-36 UNF 2.1 0.725

EBV-1030 EBVT-1030 3/8 6.50 0.31 0.63 2.14 0.50 0.79 #8-36 UNF 4.3 0.725

EBV-1040 EBVT-1040 1/2 6.50 0.38 0.63 2.14 0.50 0.79 #8-36 UNF 7.0 0.725

EBV-1050 EBVT-1050 5/8 6.50 0.50 0.63 2.14 0.50 0.79 #8-36 UNF 13.9 0.725

EBV-1060 EBVT-1060 3/4 7.25 0.62 0.83 2.63 0.75 1.26 #8-36 UNF 21.0 1.375

EBV-1070 EBVT-1070 7/8 7.25 0.75 0.83 2.63 0.75 1.26 #8-36 UNF 30.3 1.405

EBV-1090 EBVT-1090 1-1/8 8.50 0.91 1.00 2.98 1.00 1.57 #10-32 UNF 61.3 2.10

EBV-1110 EBVT-1110 1-3/8 9.25 0.97 1.22 3.70 1.25 1.89 #10-32 UNF 85.2 3.36

EBV-1130 EBVT-1130 1-5/8 10.00 1.09 1.53 4.29 1.50 2.36 1/4-28 UNF 212 5.39

EBV-1170 EBVT-1170 2-1/8 11.38 1.34 1.87 5.18 2.00 2.95 1/4-28 UNF 285 10.09

EBV-1210 EBVT-1210 2-5/8 14.37 1.47 2.36 6.06 2.50 2.95 1/4-28 UNF 301 19.25

EBV-1250 EBVT-1250 3-1/8 16.54 1.66 2.81 7.01 3.15 4.10 5/16-24 UNF 420 40.13

EBV-2210* EBVT-2210* 2-5/8 12.88 1.47 1.87 5.18 2.00 2.95 1/4-28 UNF 238 11.11

EBV-2250* EBVT-2250* 3-1/8 14.37 1.66 2.36 6.06 2.50 2.95 1/4-28 UNF 324 19.25

Valve Type

Valve Type

with

Access

Fitting

Connection

(ODF)

mm

Overall

Length

D

mm

Socket

Depth

B

mm

L

mm

Overall

Height

M

mm

Port

Size

C

mm

Mounting

Holes

E

mm

Mounting

Hole Size

H Kv

Weight EBV

& EBVT

(lbs.)

EBV-6MM** EBVT-6MM** 6 165.10 8.00 16.00 54.36 12.70 20.07 #8-36 UNF 1.80 0.725

EBV-10MM EBVT-10MM 10 165.10 8.00 16.00 54.36 12.70 20.07 #8-36 UNF 3.67 0.725

EBV-12MM EBVT-12MM 12 165.10 10.00 16.00 54.36 12.70 20.07 #8-36 UNF 5.97 0.725

EBV-16MM EBVT-16MM 16 165.10 13.00 16.00 54.36 12.70 20.07 #8-36 UNF 11.86 0.725

EBV-18MM EBVT-18MM 18 184.15 17.00 21.08 66.80 19.05 32.00 #8-36 UNF 17.93 1.375

EBV-22MM EBVT-22MM 22 184.15 20.00 21.08 66.80 19.05 32.00 #8-36 UNF 25.86 1.405

EBV-28MM EBVT-28MM 28 215.90 24.00 25.40 75.69 25.40 39.88 #10-32 UNF 52.29 2.10

EBV-35MM EBVT-35MM 35 234.95 25.00 31.00 93.98 31.75 48.01 #10-32 UNF 72.68 3.36

EBV-42MM EBVT-42MM 42 254.00 28.00 38.86 108.97 38.10 59.94 1/4-28 UNF 181.18 5.39

EBV-54MM EBVT-54MM 54 289.50 35.00 47.50 131.57 50.80 74.93 1/4-28 UNF 242.85 10.09

EBV-64MM EBVT-64MM 64 365.00 35.00 60.00 153.92 63.50 74.93 1/4-28 UNF 256.16 19.25

EBV-76MM EBVT-76MM 76 420.00 38.00 72.00 178.30 80.00 104.00 5/16-24 UNF 359.23 40.13

EBV-64MM* EBVT-64MM* 64 327.15 35.00 47.50 131.57 50.80 74.93 1/4-28 UNF 202.59 11.11

EBV-76MM* EBVT-76MM* 76 365.00 38.00 60.00 153.92 63.50 74.93 1/4-28 UNF 276.71 19.25

* Reduced port and not a stock item. Minimum order quantity may be required.

** EBV-1020 and EBVT-1020 are not stock items. Minimum order quantity is required.

* Reduced port and not a stock item. Minimum order quantity may be required.

** EBV-6MM and EBVT-6MM are not stock items. Minimum order quantity is required.

EBV Series – Inches

EBV-MM Series – Millimeters