Sporlan SDR-4 Quick guide

ELECTRIC

DISCHARGE

BYPASS

VALVES

®

Installation and Service Instructions

SDR-3 and SDR-4

SYSTEM CONSIDERATIONS

The discharge bypass valve is applied in a branch line off

the discharge line as close to the compressor as possible.

The bypassed vapor can enter the low side at one of the fol-

lowing locations:

1. Evaporator inlet with distributor.

2. Evaporator inlet without distributor.

3. Suction line.

Each is illustrated and discussed below.

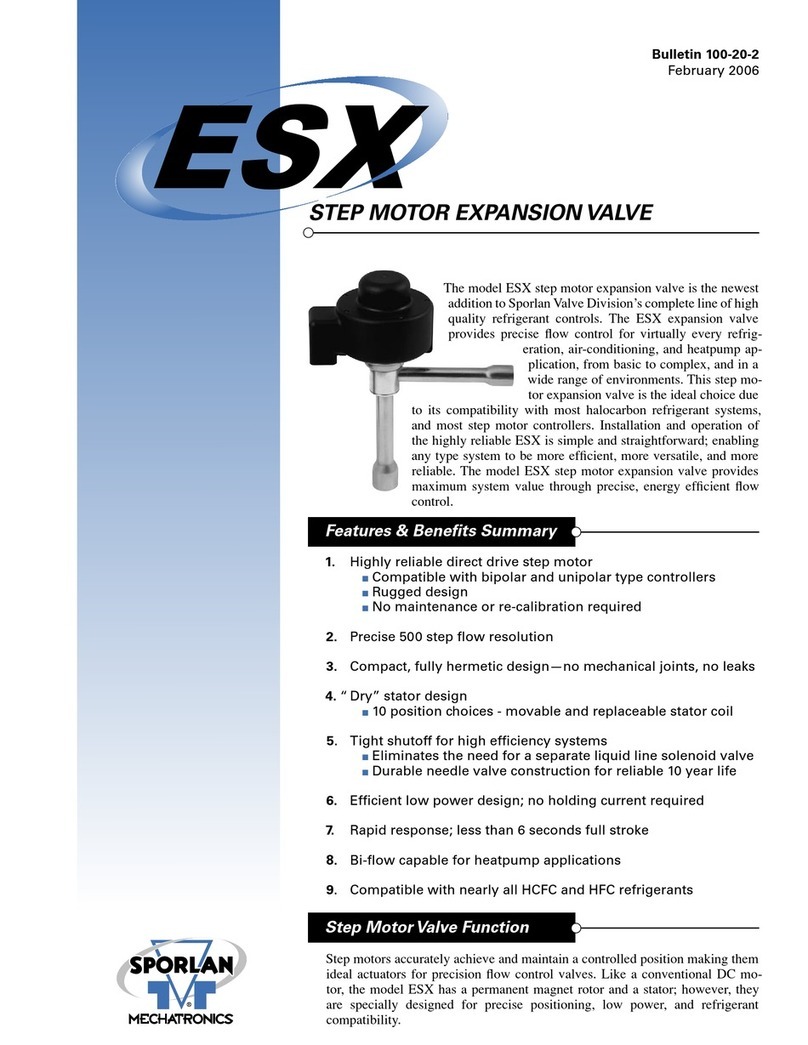

BYPASS TO EVAPORATOR INLET

WITH DISTRIBUTOR

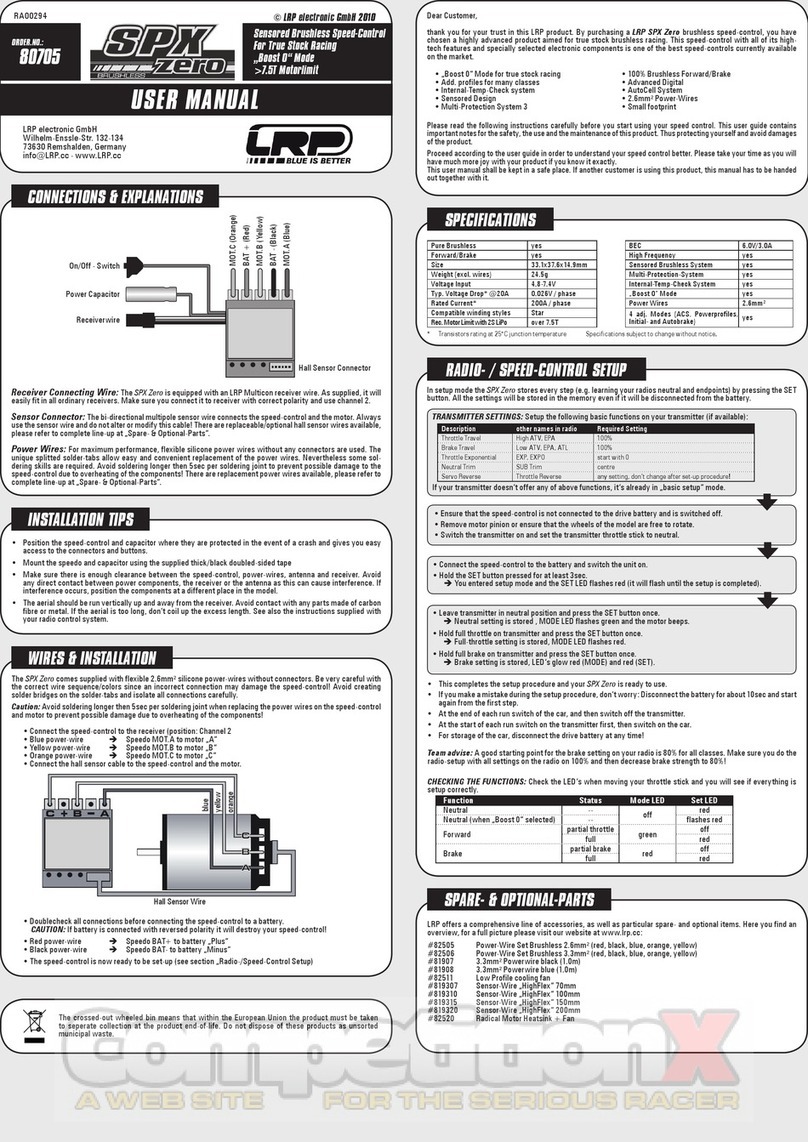

This method of application, illustrated in Figure 1, offers

distinct advantages over the other methods, especially for

unitary or field built-up units where the high and low side

are close coupled. The primary advantage of this method is

that The EDBV can directly control the temperature of the

cooled fluid. A sensor placed in the air off the evaporator or

on the chilled water line of a chiller can cause the EDBV to

modulate to maintain the desired temperature. In addition,

the system thermostatic expansion valve will respond to the

increased superheat of the vapor leaving the evaporator and

will provide the liquid required for desuperheating. The

evaporator serves as an excellent mixing chamber for the

bypassed hot gas and the liquid-vapor mixture from the

expansion valve. This ensures a dry vapor reaching the

compressor. Oil return from the evaporator is also improved

since the velocity in the evaporator is kept high by the hot

gas. Piping for this method of application can be accom-

plished by the use of a Sporlan 1650R series distributor on

a new application, or a Sporlan Auxiliary Side Connector

(ASC) when adding the valve to a system with distributor.

NOTE: If the distributor circuits are sized properly

for normal cooling duty, the flow of hot gas

through the circuits may cause excessive pressure

drop and/or noise. Therefore, it is recommended

that the distributor circuits be selected one size

larger than for straight cooling duty. For complete

technical details on the 1650R series distributor

and the ASC series Auxiliary Side Connector, refer

to Bulletin 20-10.

VALVE / EQUIPMENT LOCATION

AND PIPING

When the evaporator is located below the compressor on a

remote system, bypass to the evaporator inlet is still the

best method of hot gas bypass to insure good oil return to

the compressor. When this is done, the bypass valve must

be located at the compressor rather than at the evaporator

section. This will insure obtaining rated capacity from

the bypass valve at the conditions for which it was

selected. If the evaporator is above or on the

same level as the compressor, this valve

location will also eliminate the possibility

of hot gas condensing in the long

bypass line and running back into

the compressor during the off

cycle. Whenever hot gas

bypass to the evaporator

inlet is necessary for a

system with two or

more evaporator

External Equalizer

Compressor

Solenoid

Valve

TEV

Catch-All

Condenser

Receiver

Distributor

Evaporator

SDR 4

See•All

Return Air

TCB

Figure 1

SD-244 3/19/01 1:03 PM Page 3

sections each with its own TEV (no liquid line solenoid

valves) but handling the same load, two methods may be used

to avoid operating interference between sections:

1. Use a separate discharge bypass valve for each evaporator

section.

2. Use one discharge bypass valve to feed two bypass lines

each with a check valve between the bypass valve and the

evaporator section inlet. The check valves will prevent

interaction between the expansion valves when the bypass

valve is closed.

CAUTION - Introduction of the bypassed gas

between the thermostatic expansion valve and

the distributor is not generally recommended.

Hot gas flowing through the distributor nozzle

and circuit tubes, that were sized for normal cool-

ing flow rates, causes excessive pressure drop.

Careful evaluation and testing should precede

any application where hot gas is bypassed

between the TEV and the distributor.

BYPASS TO EVAPORATOR INLET

WITHOUT DISTRIBUTOR

Many refrigeration systems and water chillers do not use

refrigerant distributors, but may require some method of com-

pressor capacity control. This type of application provides the

same advantages as bypassing hot gas to the evaporator inlet

with a distributor. All information relating to bypassing hot

gas to the evaporator inlet with a distributor, except that con-

cerning distributors or ASC’s, also applies to bypassing to the

evaporator inlet without a distributor.

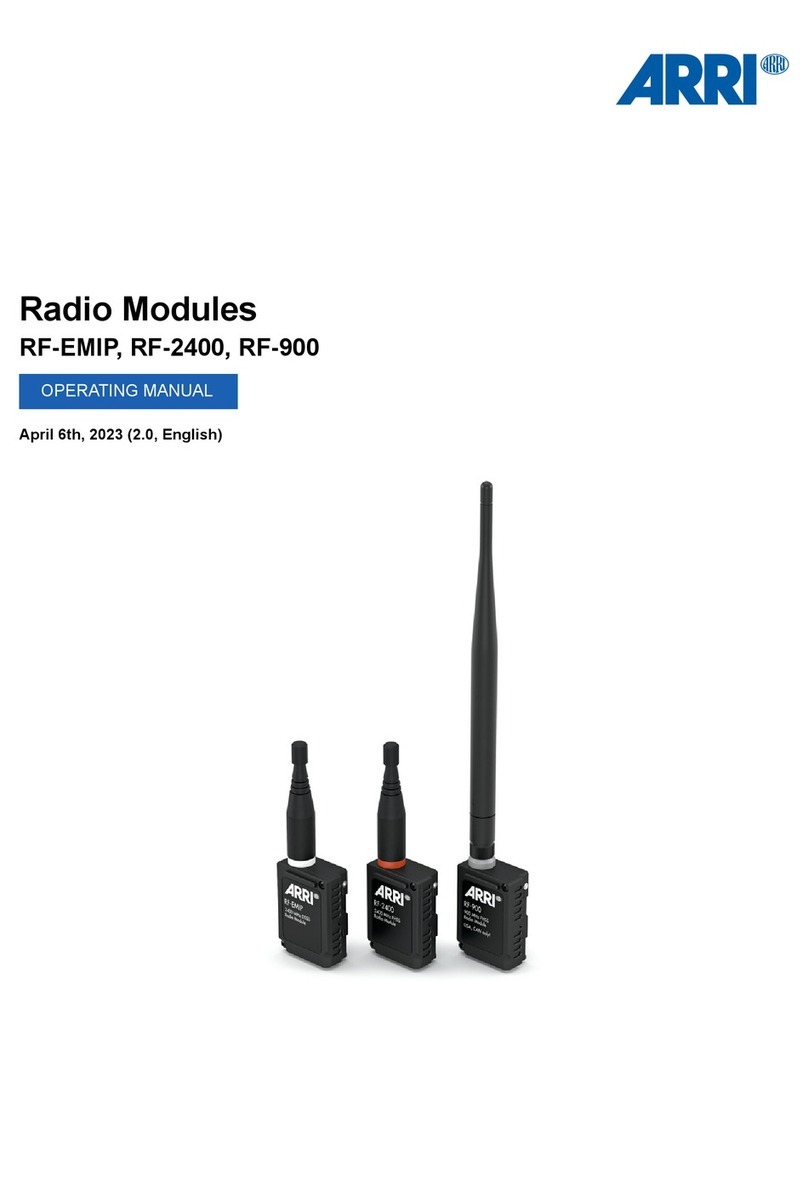

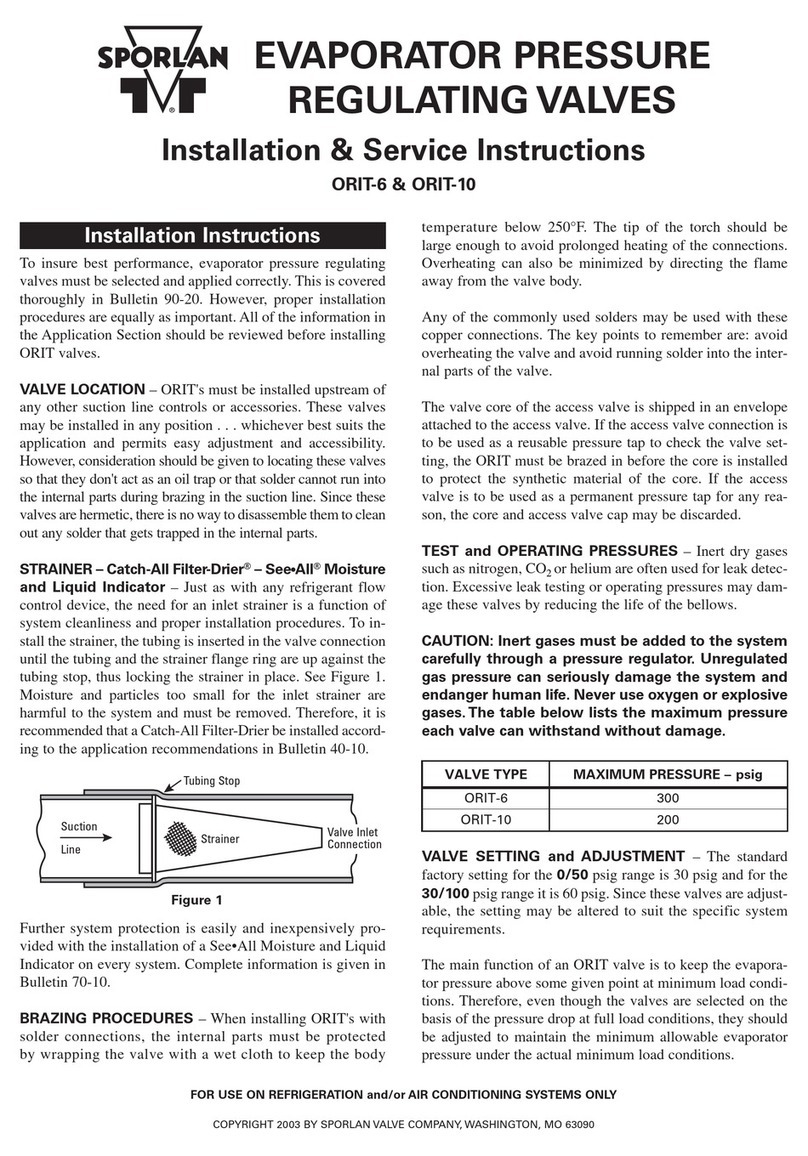

BYPASS TO SUCTION LINE

On many applications, it may be necessary to bypass directly

into the suction line (fig. 2). This is generally true of systems

with multi-evaporators or remote condensing units, as well as

on existing systems where it is easier to connect to the suction

line than the evaporator inlet. When hot gas is introduced

directly into the suction line, the danger of overheating the

compressor and trapping the oil in the evaporator exists. As

the suction temperatures rise, the discharge temperature like-

wise starts to increase. This can cause breakdown of the oil

and refrigerant with the possible result being a compressor

burnout. This method offers added flexibility for multi-evap-

orator systems or remote systems because the hot gas bypass

components can be located at the condensing unit. However,

to insure oil return, special care must be taken in the system

piping.

DESUPERHEATING THERMOSTATIC

EXPANSION VALVE

On those applications where the hot gas must be bypassed

directly into the suction line downstream of the main expan-

sion valve’s bulb, an auxiliary thermostatic expansion valve

(commonly called a desuperheating TEV or a liquid injection

valve) is required. The purpose of this valve is to supply

enough liquid refrigerant to cool the hot discharge gas to the

recommended suction temperature. Most compressor manu-

facturers specify a maximum suction gas temperature of 65°F.

For these requirements, special desuperheating thermostatic

charges are available which will control at the proper super-

heat to maintain the suction gas at or below 65°F. For appli-

cations requiring suction gas temperatures appreciably below

65°F, contact Sporlan Valve Company or the compressor man-

ufacturer for assistance. In all cases the maximum per-

missible suction gas temperature published by the

compressor manufacturer must be followed.

INSTALLATION INSTRUCTIONS

External Equalizer

Compressor

Solenoid

Valve

TEV

Catch-All

Condenser

Receiver

Distributor

Evaporator

SDR 4

DesuperheatingTEV

See•All

Return Air

TCB

Figure 3

External Equalizer

Compressor

Solenoid

Valve

TEV

Catch-All

Condenser

Receiver

Distributor

Evaporator

SDR 4

See•All

Return Air

TCB

Figure 2

Page 2

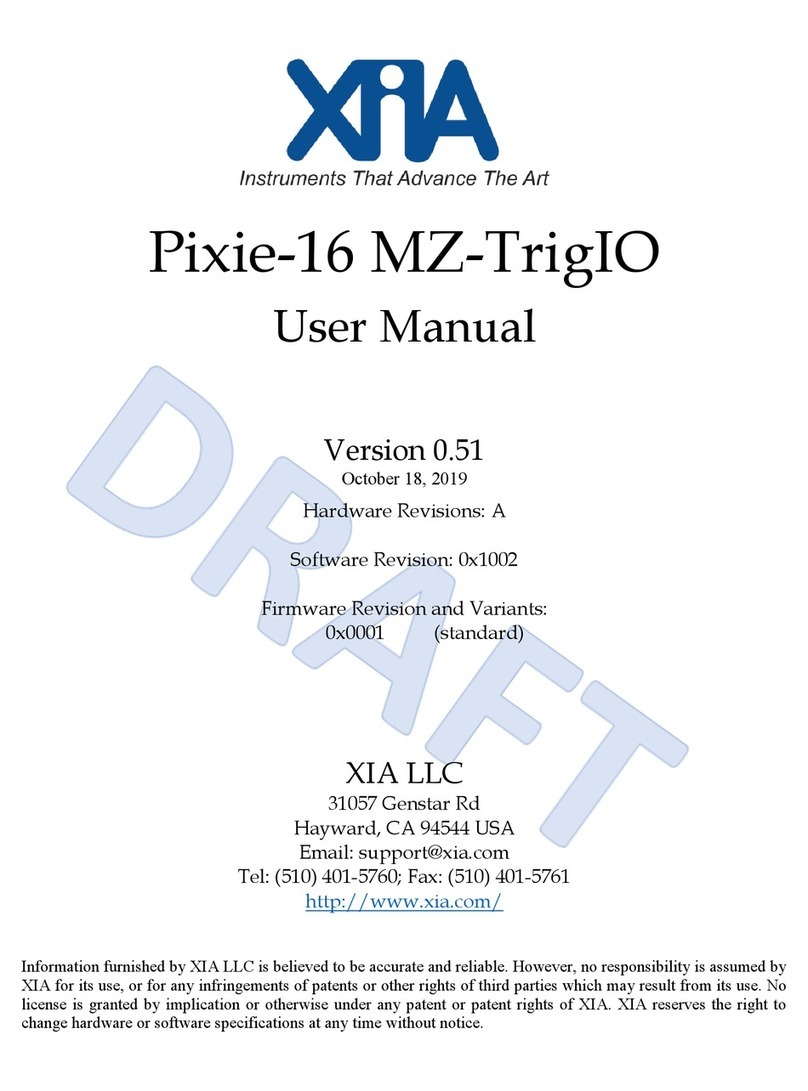

SDR-3 Figure 4

SD-244 3/19/01 1:03 PM Page 4

The valves have copper connections and any solder or brazing

alloy may be used to install the valve. There is no need to dis-

assemble the valve for installation, however, the torch flame

should be directed away from the motor housing and cable.

Care must be taken to assure that the cable is not damaged

either directly from the flame, or indirectly from contact with

hot piping. The valve is shipped in the open position to pre-

vent heat being conducted into the motor, but it is strongly

suggested that the valve body be wrapped with a wet cloth

during the soldering operation. The valve should be com-

pletely installed before connecting to the controller and apply-

ing power. The wiring is color-coded and the controller

manufacturer should be consulted for the proper attachment to

the controller.

FIELD SERVICING INSTRUCTIONS

The following steps are necessary for the proper disassembly,

inspection, cleaning and reassembly of the SDR valves

(whether in or out of the refrigerant piping).

1. Before disassembling the valve, be sure the refrigerant

pressure in the system has been reduced to a safe level

(0 PSIG).

2. Disconnect the line voltage to the valve controller.

3. Refer to the exploded view of the SDR valves (Figures

4 and 5) for the remaining instructions. Using the appro-

priate wrenches or a vice to properly support the valve

body, remove the motor assembly from the valve body by

loosening the lock nut. To prevent permanent

damage to the motor, DO NOT attempt to disas-

semble the motor housing.

CAUTION - Regardless of whether the valve is in

the system or in a vise, care must be take to pre-

vent distorting the valve parts when tightening.

4. The motor assembly may be removed for inspection and

cleaning.

5. If the motor fails to operate properly, check the resistance

of each motor phase. Resistance between the black and

white leads or between the red and green leads should be

approximately 75 ohms. Differences of more than 10%

between phases indicate a defective motor. Resistance

between black and red, or any lead and housing should be

infinite, any resistance reading will indicate a shorted

winding and the motor will need to be replaced.

6. If you have access to a SMA-12 test instrument, operation

of the valve may be proven. Connect the motor leads to the

proper color-coded connector on the SMA. Set the rate to

200 PPS and toggle in the "OPEN" direction. The piston or

pin should retract into the driver guide. After up to 30 sec-

onds, the driver should be fully retracted and a light click-

ing or "ratcheting" sound may be heard, this is normal to

the valves and proves operation of the motor. If the SMA

is toggled in the "CLOSE" position, after up to 30 seconds

the white polyester driver/pin should disengage the lead

screw, and can be removed. Inspect the driver for damage.

To replace the driver, toggle the SMA to the "OPEN" posi-

tion and carefully engage the driver to the lead screw.

CAUTION - Whenever the motor is powered while

not in place on the valve, the driver must be fully

retracted into the guide before the valve is

reassembled. Failure to do this will permanently

damage the valve.

7. If the motor responds to step 6 above, the valve body itself

should be checked for obstruction. Check for contaminants

in the port or strainer, if used.

8. If the valve body and strainer are clear and the motor oper-

ates as in step (6) above, the valve is considered opera-

tional and the problem lies in the controller or power

supply. The manufacturer of these components should be

contacted for further assistance.

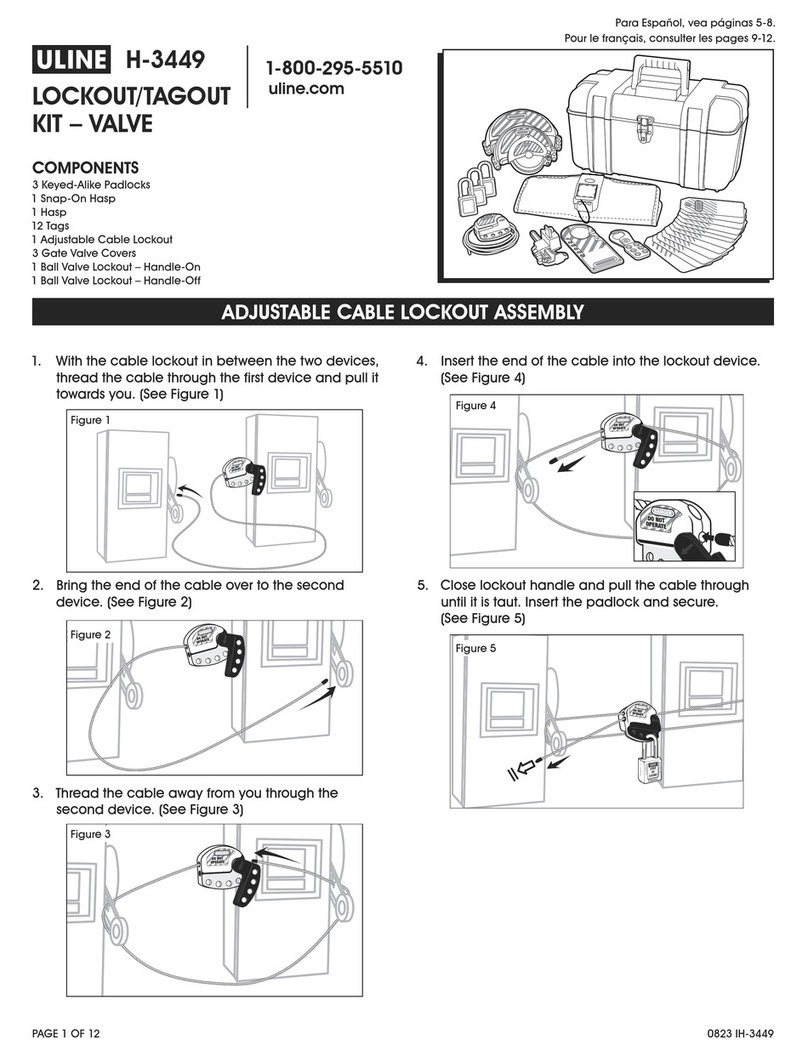

MOTOR ADAPTER ASSEMBLY

REPLACEMENT

If the motor is found to be defective in the above, the entire

motor assembly must be replaced.

1. Remove all power from the valve and controller.

2. Cut the existing valve cable at a convenient point at the

driest or most protected location.

3. Splice the new cable to the old cable using the waterproof

butt splices. COLOR CODING ON THE INDIVIDUAL

WIRES MUST BE MATCHED; FAILURE TO DO SO

WILL RENDER THE VALVE INOPERATIVE AND

MAY DAMAGE EITHER THE VALVE OR CON-

TROLLER.

Page 3

SDR-4 Figure 5

SD-244 3/19/01 1:03 PM Page 5

4. Waterproof the splice with shrink tube or electrical tape

suitable for use in cold and damp environments. Care

should be taken to prevent the splice from lying in a wet

location.

VALVE REPLACEMENT

The entire valve may be replaced if desired. The old valve

may be unsoldered or cut out of the piping. If cut out, use a

tubing or pipe cutter and not a saw. When installing the new

valve any convenient brazing alloy and method may be used.

The valve need not be disassembled, but the body and motor

assembly should be wrapped with a wet cloth to prevent dam-

age.

Extra care should be taken to prevent damage to the motor

cable, either directly from the torch, or indirectly from contact

with a hot surface.

Waterproof butt splices are not supplied with complete valves,

but must be used to prevent corrosion on the motor leads

unless the cable is replaced all the way to the controller. Refer

to the instructions for MOTOR REPLACEMENT above.

If the valve is disassembled for installation, refer to

REASSEMBLY instructions, below.

REASSEMBLY

1. Use the SMA-12 in the "OPEN" mode, or use the valve

controller to retract the white polyester driver/pin fully into

the driver guide. Remove power from the valve or con-

troller.

2. Lightly oil the threads on the new motor adapter as well as

the gasket or O-ring. Carefully seat the adapter and motor

assembly on the valve body.

3. Engage and tighten the lock nut. One eighth turn more than

hand tight is sufficient to achieve a leak proof seal.

4. Pressurize the system and check for leaks.

5. Reapply power to the controller. Each controller manufac-

turer has a slightly different initialization scheme and the

proper procedure must be followed. Since, during service,

valve position as calculated by the controller will be lost,

the controller should be initialized at least twice. In some

instances, cycling power to the controller will accomplish

this. However, the controller literature or the manufacturer

should be consulted.

SMA-12 VDC BIPOLAR STEP

MOTOR ACTUATOR

1. Connect any Sporlan step motor valve to the SMA-12 by

matching wire color to terminal color. Any 12 VDC bipo-

lar step motor may be tested with the SMA-12. Phase one

leads should be connected to the black and white termi-

nals. Phase two leads should be connected to the red and

green terminals.

2. Select a step rate with the selector knob.

3. Push the open/close toggle switch in the "CLOSE" direc-

tion to extend the driver or close the valve.

4. Push the open/close toggle switch in the "OPEN" direction

to retract the driver or open the valve.

5. Observe the terminal indicator lights. At rates other than 1,

indicator lights will flash quickly. Pushing the open/close

toggle in either direction at the 1 step rate will alternate the

phases energized.

The following sequence of indicator lights will light.

6. Check that the power indicator light is lit; if not, replace

the batteries.

7. If the terminal indicator lights do not light, one or both

motor phases are open and the motor must be replaced.

8. If the motor can be powered smoothly in both directions,

the motor assembly is functional and the controller must be

tested or replaced.

SPECIFICATIONS

Power input – (2) 9 volt Alkaline batteries

Power output – 10 Watts intermittent

Step rate – Selectable – 1, 50, 100, 200 steps per second

Drive type – Bipolar

Connector – Binding post with banana plug socket

An accessory pigtail item number 958112 is available at extra

charge to allow the SMA-12 to be directly connected to all

Sporlan Packard Weather-Pack™ equipped valves.

GNINEPO GNISOLC

deR&kcalBetihW&deR

etihW&deRkcalB&deR

neerG&etihWneerG&kcalB

kcalB&neerGetihW&neerG

dfdffdfdff

PRINTED IN THE U.S. OF A. SD-244-5-1000

Page 4

SD-244 3/19/01 1:03 PM Page 2

This manual suits for next models

1

Other Sporlan Control Unit manuals

Sporlan

Sporlan ORIT-10 Installation and maintenance instructions

Sporlan

Sporlan Parker S3C User guide

Sporlan

Sporlan ESX User manual

Sporlan

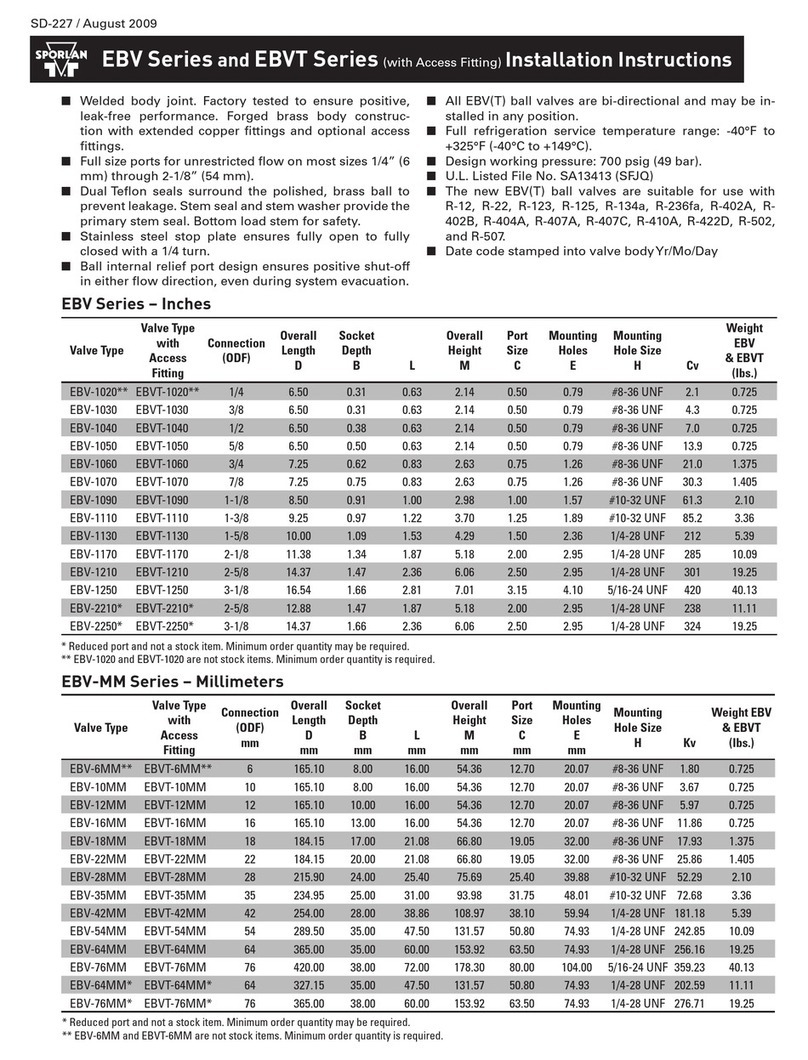

Sporlan B5D User guide

Sporlan

Sporlan EBV Series User manual

Sporlan

Sporlan OROA-5 Installation and maintenance instructions

Sporlan

Sporlan ORIT-12 Installation and maintenance instructions

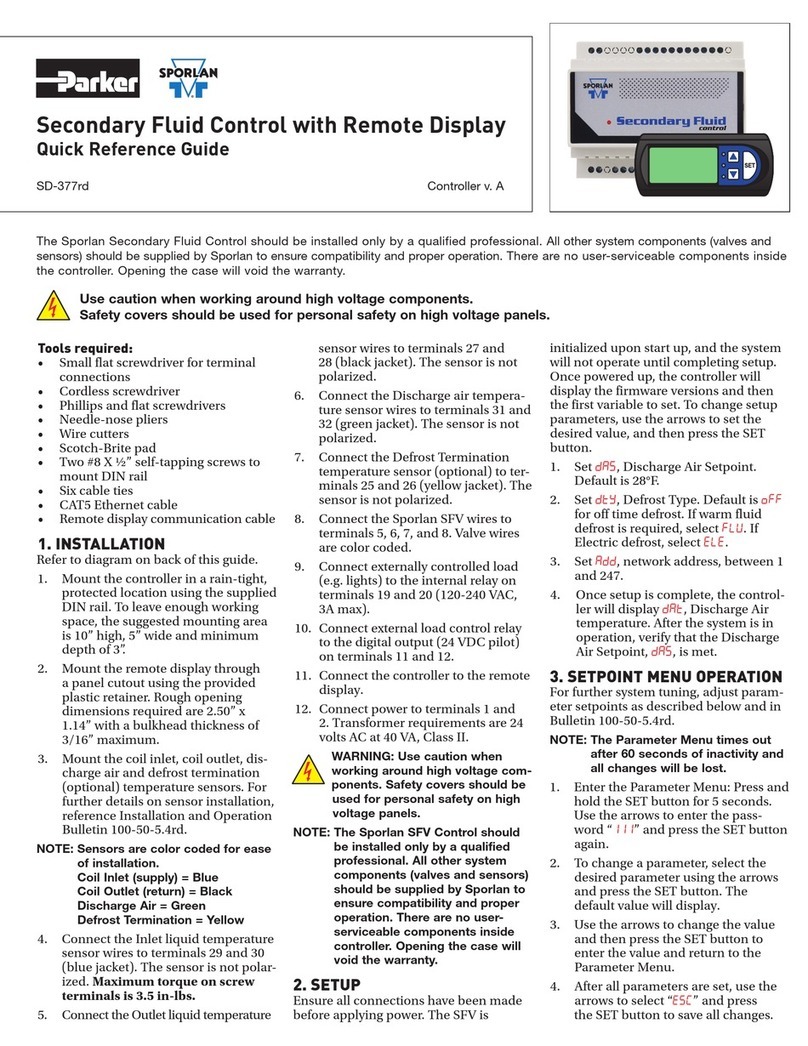

Sporlan

Sporlan Secondary Fluid Control User manual