Spray Master Technologies POWER CLEAN C Series User manual

FOR COMMERCIAL USE ONLY

www.spraymastertech.com

MANUFACTURED DATE SHIPPED SERIAL NUMBER

POWER CLEAN CENTRAL SYSTEMS

2.0 C / 5.0 C / INTERNATIONAL C SERIES

OWNER’S MANUAL

IMPORTANT DOCUMENT - DO NOT DISCARD

2

Congratulations!

You have just purchased the best

spray washer on the market today.

It incorporates the very latest

in technological advances. To

assure you the best and safest

performance as well as longest

equipment life, please read the

enclosed information.

After reading the material in

this manual, should you need

assistance, please call customer

service at our toll free number

(800) 548-3373 or (479) 636-5776.

SPRAY MASTER SERVICE

Mon-Fri, 8:00 am - 5:00 am CST

(800) 548-3373

techservice@assembledproducts.com

Spray Master Technologies will repair or replace any originally

installed parts on the Power Clean series which are found

to be defective in material or workmanship for a period of

two (2) years and on the Power Clean Go series for a period

of one (1) year from the date of shipment to the original

purchaser, excluding items listed below. The defect must

occur during normal use of the product and within the length

of warranty coverage. The repair or replacement of that part

will be provided according to the time limits of the warranty

policy. Repairs must be completed using only Spray Master

Technologies approved parts.

EXCLUDED ITEMS

The following items are covered by the above warranty for

ninety (90) days from date of shipment:

Wear Items* - Spray guns, wands, hoses, nozzles, quick

couplers, Hummer Jet Sr. and Hummer Jet Jr. casters and

handles, check valves and chemical injectors.

The following items are covered by the above warranty for

1 year from the date of shipment:

Unloaders, Chemical Valves†

Electrical Components - float switch, temperature

switch, Solid-State Relay, Master Control Panel,

electronic injectors, wiring harnesses and flow

switch.

LABOR AND TRAVEL

Labor and travel to repair or replace defective parts shall be

covered for a period of 1 year from date of shipment. Labor and

travel for warranty wear items shall be covered for a period of

90 days.

ITEMS VOIDING WARRANTY

The following voids all warranty claims: Accidental breakage;

abuse; misuse; failures caused by incorrect installation if

not installed by authorized factory representative; failure

to correctly wire the system at the electrical source;

foreign items, chemical or mineral buildup in the pumps

and water lines caused by untreated or unfiltered tap, hard

or recaptured water; excessive hot water temperatures

exceeding 160˚ Fahrenheit; failures due to injecting bleach or

harsh or corrosive chemicals; not following Owners Operation

instructions; damage due to freezing temperatures; natural

disasters, electrical surges; and, tampering, aempted

repair by unauthorized service personnel, and not following

prescribed Preventive Maintenance Program.

*Wear Items Not Covered – O-rings, gaskets, filters. †O-rings,

gaskets, pulse pump diaphragm, check valves or failures due to

chemical damage are not covered by this Limited Warranty.

LIMITED WARRANTY

Spray Master Technologies®

Effective May 20, 2020

3

LIMITED WARRANTY >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

OWNER / USER RESPONSIBILITY >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

FIRST STEPS

Receiving Your Pressure Washer >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Returning Your Pressure Washer >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Pressure Washer Utility Requirements >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

What To Do For Service >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Model Identification >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

IMPORTANT SAFETY WARNING INSTRUCTIONS

Safety Warnings >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Ground Fault Circuit Interrupter (GFCI) Protection >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Grounding >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Extension Cords >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

OPERATING THE PRESSURE WASHER

User Operated Controls >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Pre-Operation Check >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Daily Maintenance >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Preparation for Use >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Operation >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Accessories >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

MAINTENANCE

General Maintenance >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Moving & Storage >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

CHEMICAL METERING

Chemical Metering Instructions >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Manufacturer’s Recommended Dilution Chart >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

MASTER CONTROL PANEL CODES >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

OWNER / USER RESPONSIBILITY

The owner and/or user must understand the operating instructions and warnings before using this pressure

washer. Warning information should be emphasized and understood. Owner and operator must study this manual

and keep handy for future reference. The operator must know how to stop the machine quickly and understand

the operation of all controls. Never allow anyone to operate the machine without proper instructions.

TABLE OF CONTENTS

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

2

3

4

4

4

4

4

5

7

7

7

8

9

9

9

10

10

11

11

12

12

13

FIRST STEPS

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

4

RECEIVING YOUR PRESSURE

WASHER

Damage: Check for damage in shipping. Report any

damage to the shipping carton or contents to the

freight carrier. File a claim with the carrier within ten

(10) days. Spray Master Technologies is not responsible

for damage to the equipment caused by the freight

carrier.

Package Contents: Carefully check the contents of

the shipping cartons to ensure the contents match

with the packing list. Please call our Customer Service

Department if items are missing at 1-800-548-3373 or

1-479-636-5776.

SAVE THESE INSTRUCTIONS!

This manual should be considered a permanent part of the machine and should remain with it. When

ordering parts, please specify model and serial number. Use only identical replacement parts. This

machine is to be used only by trained operators.

PRESSURE WASHER

UTILITY REQUIREMENTS

WATER

Flow Rate:

Minimum 5 GPM

Pressure:

30 PSI min. to 80 PSI max.

Temperature:

160° F max, 70.1° C

ELECTRICAL

Power Clean 2.0 C:

120V, 60Hz, 20 AMP

Power Clean 5.0 C:

240V, 60Hz, 30 AMP

Power Clean International C:

230V, 50Hz, 20 AMP

RETURNING YOUR PRESSURE

WASHER

Any item returned for warranty or for credit must have

a Returned Authorization Number. Call our Customer

Service Department to discuss your return request.

Please note that all items returned must be F.O.B.

Rogers, Arkansas. No collect or C.O.D. shipments will

be accepted unless prior arrangements have been made

with Customer Service. A restocking fee may be applied

to the items returned for credit that are not under

warranty.

WHAT TO DO FOR SERVICE

If a problem occurs, first refer to the Power Clean

Central System Series Service Manual in the “Trouble

Shooting and Diagnostics” section starting on page 38.

MODEL IDENTIFICATION

The model and serial numbers will be found on a decal on

the pressure washer. Please record these along with date

of purchase for future reference.

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

SERVICE PHONE 1-800-548-3373

IMPORTANT SAFETY

WARNING INSTRUCTIONS

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

5

Indicates a hazardous

situation which, if not

avoided, could result in

death or serious injury.

Indicates a hazardous

situation which, if not

avoided, could result in

minor or moderate injury.

THIS IS THE SAFETY ALERT SYMBOL.

THIS SYMBOL ALERTS YOU TO

POTENTIAL HAZARDS THAT CAN

KILL YOU OR HURT YOU AND

OTHERS. ALL SAFETY MESSAGES

WILL FOLLOW THE SAFETY ALERT

SYMBOL AND THE WORD “DANGER”,

“WARNING”, OR “CAUTION”.

THESE WORDS ARE DEFINED AS:

Indicates a hazardous

situation which, if not

avoided, will result in death

or serious injury.

READ OPERATOR’S MANUAL

THOROUGHLY PRIOR TO USE.

Read the owner’s manual thoroughly. Failure to

follow instructions could cause malfunction of the

machine and result in death, serious bodily injury

and/or property damage.

1. Read these instructions before using the product.

2. To reduce the risk of injury, close supervision is

necessary when a product is used near children.

3. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

4. Stay alert – Watch what you are doing.

5. Do not operate the product when fatigued or under

the influence of alcohol or drugs.

6. Keep operating area clear of all persons.

7. Do not overreach or stand on unstable support.

Keep good footing and balance at all times.

8. Follow the maintenance instructions specified in

the manual.

9. All installations must comply with local codes.

Contact your electrician, plumber, utility company

for specific details.

SAVE THESE INSTRUCTIONS!

6

IMPORTANT SAFETY

WARNING INSTRUCTIONS

(Continued...)

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

KEEP WATER SPRAY AWAY FROM

ELECTICAL WIRING.

Keep wand, hose, and water spray away from

electric wiring or fatal electric shock may result.

To protect the operator from electrical shock, the

machine must be electrically grounded. It is the

responsibility of the owner to connect this machine to a

UL grounded receptable of proper voltage and amperage

ratings. Do not spray water on or near electrical

components. Do not touch machine with wet hands

or while standing in water. Always disconnect power

before servicing.

TRIGGER GUN KICKS BACK – HOLD WITH

BOTH HANDS.

Grip cleaning wand securely with both hands before

starting. Failure to do this could result in injury from a

whipping wand.

DO NOT SPRAY MACHINE, PEOPLE, ANIMALS

OR ELECTRICAL PARTS.

RISK OF EXPLOSION. DO NOT SPRAY

FLAMMABLE LIQUIDS.

»Do not allow acids, caustic or abrasive fluids to pass

through the pump.

»Never run pump dry or leave spray gun closed longer

than 1-2 minutes.

»Keep operating area clear of all persons.

RISK OF INJECTION OR SEVERE INJURY TO

PERSONS. KEEP CLEAR OF NOZZLE.

»To reduce the risk of injury, close supervision is

necessary when a machine is used near children. Do

not allow children to operate the pressure washer.

This machine must be attended during operation.

»Never make adjustments on machine while in

operation.

»Be certain all quick coupler fittings are secured

before using pressure washer.

PROTECTIVE EYE WEAR AND CLOTHING

MUST BE WORN.

High pressure spray can cause paint chips or other

particles to become airborne and fly at high speeds. To

avoid personal injury, eye, hand, and foot protection

must be worn when using this equipment.

Always wear properly-rated eye protection, such as

safety goggles or face shield, while spraying. (Safety

glasses do not provide full protections.)

RISK OF EXPLOSION – OPERATE ONLY

WHERE OPEN FLAME OR TORCH IS

PERMITTED.

Flammable liquids can create fumes which can ignite,

causing property damage or severe injury.

7

IF CONNECTED TO A POTABLE WATER

SUPPLY, PROTECT AGAINST BACKFLOW.

PROTECT FROM FREEZING.

»To keep machine in best operating conditions, it

is important you protect machine from freezing.

Failure to protect machine from freezing could cause

malfunction of the machine and result in death,

serious bodily injury, and/or property damage. Follow

storage instructions specified in this manual.

»Inlet water must be clean fresh water and no hotter

than 160˚F.

»Manufacturer will not be liable for any changes made

to our machines or any components not purchased

from us.

»The best insurance against an accident is precaution

and knowledge of the machine.

RISK OF INJURY FROM FALLS WHEN USING

LADDER.

Be extremely careful when using a ladder, scaffolding

or any other relatively unstable location. The cleaning

area should have adequate slopes and drainage to

reduce the possibility of a fall due to slippery surfaces.

»Do not overreach or stand on unstable support. Keep

good footing and balance at all times.

»Do not operate this machine when fatigued or under

the influence of alcohol, prescription medications, or

drugs.

SOME DETERGENTS MAY BE HARMFUL IF

INHALED OR INGESTED.

Some detergents may be harmful if inhaled or ingested,

causing servere nausea, fainting or poisoning. The

harmful elements may cause property damage or

severe injury.

GROUNDING

This product must be grounded. If it should

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the

risk of electric shock. This product must be attached

to an electrical supply of appropriate voltage and

sufficient amperage that is properly installed and

grounded in accordance with all local codes and

ordinances.

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-pole cord connectors that

accept the plug from the products. Use only extension

cords that are intended for outdoor use. These

extension cords are identified by a marking “Acceptable

for use with outdoor appliances, store indoors while

not in use.” Use only extension cords having an

electrical rating not less than the rating of the product.

Do not use damaged extension cords. Examine

extension cord before using and replace if damaged.

Do not abuse extension cords and do not yank on any

cord to disconnect. Keep cord away from heat and

sharp edges. Always disconnect the extension cord

from the receptacle before disconnecting the product

from the extension cord.

Improper connection of the equipment grounding

conductor can result in a risk of electrocution.

Check with qualified electrician or service

personnel if you are in doubt as to whether the

power supply is properly grounded. Have a

proper outlet, and appropriate cord set, installed

by a qualified electrician. Do not use any type of

adapter with this product.

TO REDUCE THE RISK OF ELECTROCUTION,

KEEP ALL CONNECTIONS DRY AND OFF THE

GROUND. DO NOT TOUCH THE PLUG WITH

WET HANDS.

8

OPERATING THE

PRESSURE WASHER

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

USER OPERATED CONTROLS

Master OFF/ON Switch:The power switch for Spray

Master Central Systems should remain in the “ON” position

at all times, unless being serviced.

»This unit comes with a lockout tag that will be placed

on the unit after its first start up. The lockout tag will

prevent the unit from accidentally being turned off.

Lockout tag must be replaced on unit when system is

powered back up after service.

Spray Gun: The spray gun assembly provides the

operator control of the flow, pressure, and pattern of the

high-pressure spray. Squeezing the gun trigger while

directing the spray nozzle toward the surface to be

cleaned operates the spray gun. Your spray gun may be

equipped with a dual nozzle or vari-nozzle.

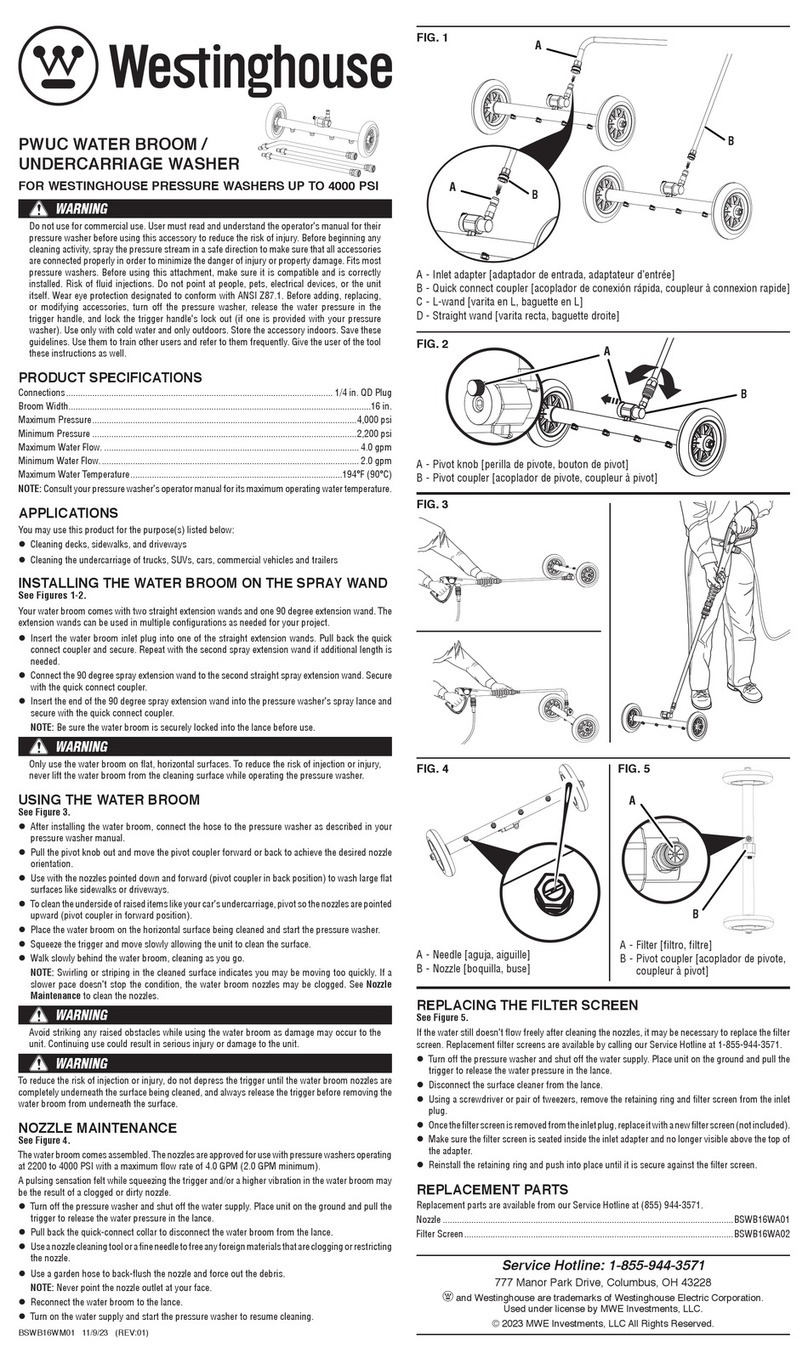

»Dual Nozzle: The dual nozzle selector is used to select

either the low-pressure “soap” nozzle or the high

pressure “rinse” nozzle. Selection of the desired nozzle

must be made while the spray gun trigger is released.

To select the low-pressure nozzle, rotate the spray gun

90˚ counterclockwise so that the spray gun handle

is parallel to the ground with the hose connection

extending to the operators right, then squeeze the

trigger. To select the high-pressure nozzle, rotate the

spray gun 90˚ clockwise so that the spray gun handle

is parallel to the ground with the hose extending to

the operator’s left, then squeeze the spray gun trigger.

Once the nozzle has been selected and the spray gun

trigger held open, the spray gun may be rotated and

aimed at the surface.

»Vari-Nozzle: The vari-nozzle is used to select either

low-pressure “soap” or high-pressure “rinse”, and to

adjust the spray-pattern from a wide-angle spray to

a zero-degree stream. For high-pressure, pull the

nozzle-body firmly toward the spray-gun handle. To

select low-pressure, push the black nozzle body firmly

away from the spray gun handle. To vary the spray

pattern of the nozzle, twist the black nozzle body

clock ways to narrow pattern and counter clock ways

to widen the spray pattern.

Electronic Chemical Metering:This unit comes with

two electronic chemical injectors. These are located to

the left of the pump and motor assembly on the main

frame. Chemical pickup lines feed Chem 1 and Chem

2 feed into the system. A 1/16” size Allen Key is used

to adjust chemical dilution. Part number 300-0405.

Please refer to the Chemical Dilution Chart at back of

this Owner’s Manual to set desired rate of chemical

delivery.

Master Control Panel:The Master Control Panel

(MCP) will provide you with information on hours of

operation, error codes and LED lighting that provide

quick visual status checks of the system. Please refer

to Technical Manual for specific information on error

codes and LED lighting signals.

When the system power is on a green LED light located

in the center of the MCP will indicate that the system is

receiving power. If the green LED light is off, check to

see that power to the unit is present. Check to ensure

that power supply is on, properly connected and that

GFCI plug (if equipped) and/or GFCI circuit breaker are

not tripped. If all of these are confirmed and the green

light is still off, call Spray Master service for assistance.

If the green light is off and you see a red light glowing

in the lower portion of the MCP then the system fuse is

blown. There is a spare specialized fuse provided with

your system. It is taped to the inside of the MCP clear

lid behind the front label. Contact your maintenance

department or Spray Master service to have replaced.

Remote Control Panel(s):To use the system the

activation of Rinse, Chem 1, and Chem 2 are turned

on at each Remote Control Panel at the desired wash

down area. Users will roll out the pressure washer

hose, connect to the discharge nipple at remote panel

and select desired rinse or chemical. Activation of

trigger on spray wand will begin the pressure wash.

9

PRE-OPERATION CHECK

»Perform the pre-operation daily maintenance check

prior to operating the unit to ensure safe operation

and prolonged equipment life.

»Read safety, operation, and maintenance instructions

before starting machine.

DAILY MAINTENANCE

»Check oil level. Fill to center of sight glass. See “Oil” in

General Maintenance Section.

»If equipped, check to see that the GFCI power cord,

or GFCI Outlet, is in good condition. Have a qualified

electrician replace any damaged power cord, plug, or

faulty outlet. Test the GFCI circuit weekly by pressing

the TEST button on the GFCI. Reset the GFCI after

test by pressing the RESET button on the GFCI.

»Hoses – Check hoses for breaks and damaged fittings.

Replace as needed.

»Spray Gun – Check spray gun for damaged fittings,

nozzle, and trigger. Replace as needed.

PREPARATION FOR USE

»Verify that the surface or equipment to be cleaned can

withstand the high-pressure spray.

»Confirm that power switch is lockout in the ON

position.

»Wear safety googles or other approved eye protection

when cleaning with high-pressure spray washers.

»Check with your Safety Representative for other

Personnel Protective Equipment (PPE) that may be

required for the job being performed.

»Clear area of slip or trip hazards. Keep area clear while

cleaning.

»Attach high-pressure hose to discharge nipple

with quick coupler. Lock quick coupler in place

by pulling back coupler collar and inserting it

into the discharge nipple then pulling back on

coupler collar to lock into place.

»Attach spray gun to hose.

»Check that unit is plugged in, and confirm water

supply.

»This machine will siphon chemical and mix with

water at the chemical injector. Check the main

unit to confirm there is enough chemical for

cleaning operation.

RUNNING PUMP ON CHEM 1 OR CHEM 2

WITHOUT CHEMICAL CAN INTRODUCE AIR

INTO SYSTEM AND CAN DAMAGE PUMP AND

RESULT IN PRESSURE LOSS.

10

OPERATING THE

PRESSURE WASHER

(Continued...)

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

OPERATION

»Firmly grasp spray gun.

»Point the spray gun in safe direction.

»Direct the spray gun nozzle toward the surface or

equipment to be cleaned and squeeze the spray gun

trigger. (Note: Use low-pressure for SOAP application

and high-pressure for RINSE.)

»Apply chemical solution on low-pressure to the

surface or equipment to be cleaned and let soak

according to the instructions for the chemical you are

using.

»Use high-pressure spray to rinse the surface or

equipment being cleaned. Rinse thoroughly.

»Turn remote panel to “OFF” position.

»Squeeze the spray gun trigger to release system

pressure. Hose and spray guns cannot be

disconnected while the system is pressurized.

»Disconnect and store all equipment.

ACCESSORIES

The accessories listed below are available for use with your

Spray Master Technologies high-pressure cleaning system.

»Hummer Jet™ Jr. – Indoor floor surface cleaner.

Focuses high-pressure spray in centralized area for

thorough cleaning. Reduces misting and overspray.

»Dual-Nozzle Spray Gun – Single spray gun unit

designed to quickly change from low pressure soap to

high pressure rinse with the flip of a wrist.

»Vari-Nozzle Spray Gun – Single spray gun unit

designed to quickly change from low pressure soap to

high pressure rinse by a simple push/pull on the nozzle

head.

»Tornado Spray Gun – High impact spray gun used to

focus on small trouble areas.

»Foamer Gun – Specialized low-pressure spray gun that

foams cleaning chemicals. Ideal for soak operations.

»6” Shorty Spray Gun – Specialized spray gun for tight

spots.

»Wall and Tile Brush – 10” scrub brush hooks up to

pressure hose and enables soap and rinse features.

»Trap Shooter – Specialized spray gun for cleaning

drains and interior of containers.

11

MAINTENANCE

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

MOVING & STORAGE

Moving:Spray Master Central System series units are

stationary units that are installed to walls or racks. Once

installed, it is impractical to move the pump for use in

various locations.

Storage:Store Spray Master equipment and accessories

indoors and so that they do not present a trip or fall hazard.

When storing Spray Master units for extended periods or in

freezing conditions, drain all water and winterize the system

with potable water antifreeze.

WINTERIZE YOUR SPRAY MASTER

SYSTEM AS FOLLOWS:

»Turn off the water supply and disconnect the water

supply hose from the unit.

»Run the unit with the spray gun open at each remote

location until antifreeze is detected. Continue at each

station until the tank is empty.

»Fill the tank with a suitable potable anti-freeze

solution.

»Run the unit with the spray gun open until the tank

is empty. Refill tank with additional antifreeze until

all remote locations have been winterized. A small

amount of liquid will remain in the bottom of the tank.

»Disconnect unit from power.

GENERAL MAINTENANCE

Oil: Add oil to the pump reservoir as needed to keep the oil

level at the center of the oil-level sight glass between the

arrows. Check oil level with the machine “OFF”.

»First oil change must be done at 50 hours of operation.

»Follow-on oil changes must be done every 3 months or

after 50 hours of operation.

»Use ISO-68 non-detergent hydraulic oil only.

Use of any other type of oil will VOID warranty and may

damage the pump. Oil may be purchased from Spray Master

by calling 800-548-3373 or 479-636-5776.

Water Supply Filter:A quality water supply filter is

essential to pump life longevity. Do not operate your pump

without a water supply filter.

»Replace with 5-micron water supply filter every 3

months or as needed to ensure an adequate supply of

clean water to the pump.

»A dirty water filter can restrict water flow and cause

intermittent shutdown of the pump.

Chemical Foot Screen: Flush the chemical foot screens

and injector with warm water to remove chemical buildup

that can restrict water flow. Perform flush every 90 days or

sooner depending upon strength and thicker viscosity of

strong cleaning agents.

»Remove the chemical pickup tube with foot screen

from the chemical supply and submerse in warm

water.

»Operate the system on low-pressure for 2 minutes

with the chemical control set to maximum.

Hard Water Deposit: Flush the pump with a de-liming

agent such as Lime-A-Way as often as necessary to keep

the system free of mineral buildup that can adversely affect

operation.

»Pour 8 ounces of de-liming agent into a full float tank.

»Turn pump “ON” and allow recirculation for 5 minutes.

»Direct the spray gun to a drain and run spray gun for

several minutes to purge the de-liming agent from the

system

TO PREVENT DAMAGE TO THE PUMP, DO

NOT RUN THE PUMP AFTER THE UNIT HAS

BEEN EMPTIED.

IF YOUR SYSTEM IS USED TO CLEAN FOOD-

PROCESSING EQUIPMENT, CONSULT YOUR

CHEMICAL SUPPLIER FOR ANTI-FREEZE

THAT IS SUITABLE FOR THAT APPLICATION.

CHEMICAL METERING

POWER CLEAN CENTRAL SYSTEM SERIES OWNER’S MANUAL

CHEMICAL METERING

INSTRUCTIONS

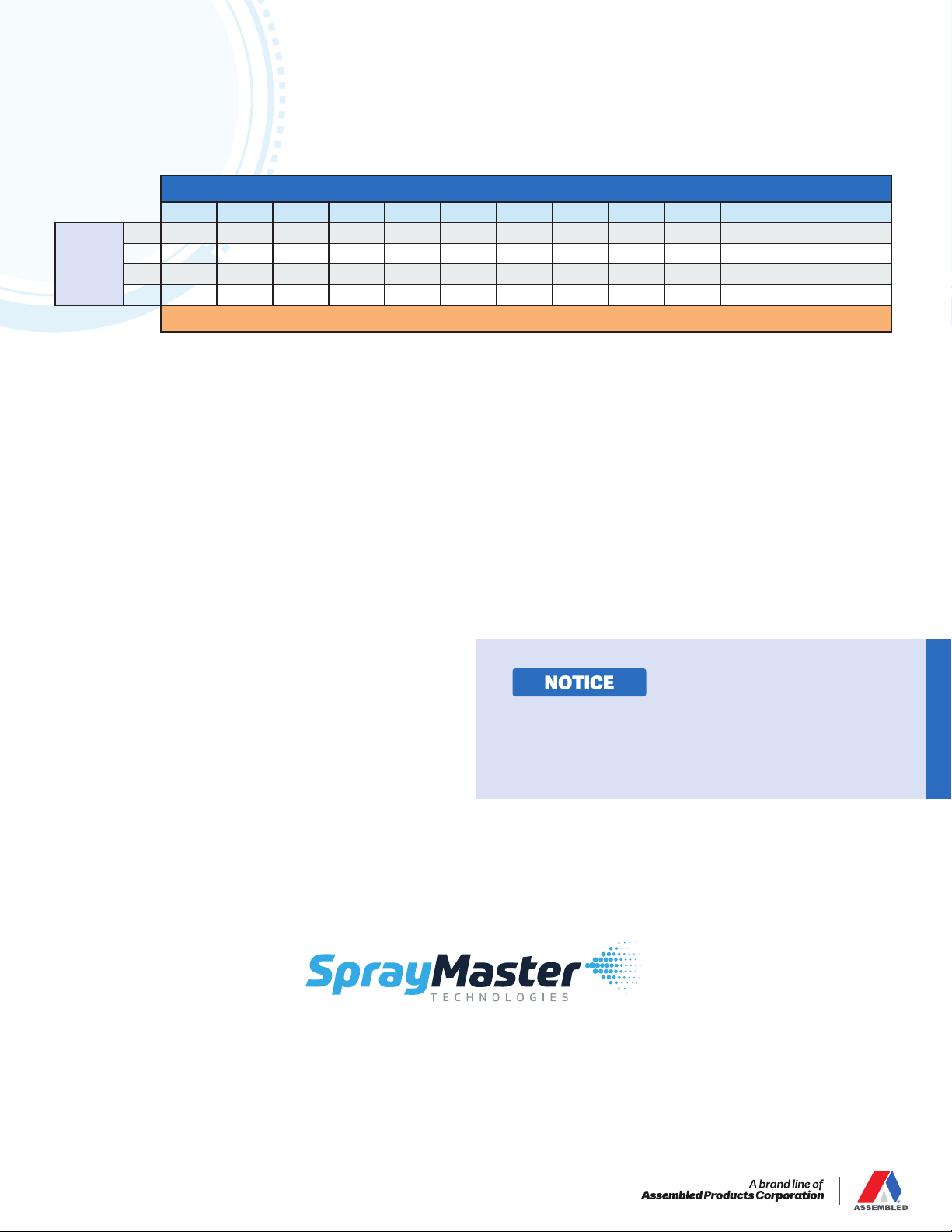

The chemical dilution chart below display’s ounces of

chemical per gallon of water.

Follow the steps below to calculate and adjust the chemical

dilution for a Spray Master cleaning system.

»Find your pump GPM rating on the left side of the chart.

»Follow the row identified in Step 1 to the right until

you find the column heading with the chemical

manufactures ounces per gallon to be injected into the

water.

»The value at the point where the row, Step 1, and the

column, Step 2, intersect is the duration of time, in

seconds, it should take for the Spray Master system to

draw 5 ounces of chemical.

»Example: The 2.1 gallon per minute (GPM) pump used to

apply a chemical requiring a mix ration of 4 ounces per

gallon will need to inject 5 ounces of chemical over a 36

second period.

Failures due to bleach or injecting harsh or

corrosive chemicals in non-compatible equipment

will void the warranty.

CHEMICAL MANUFACTURERS RECOMMENDED OUNCES PER GALLON (OZ/GAL.)

1/4 1/2 1 2 3 4 5 6 7 8 OTHER DILUTIONS USE

PUMP

FLOW

(GPM)

2.1 571 286 143 71 48 36 29 24 20 18 143 / (Oz per Gal.)

2.6 462 231 115 58 38 29 23 19 16 14 115 / (Oz per Gal.)

3.0 400 200 100 50 33 25 20 17 14 13 100 / (Oz per Gal.)

3.6 333 167 83 42 28 21 17 14 12 10 83 / (Oz per Gal.)

Time in Seconds to Draw Five (5) Ounces of Chemical

»Fill a measuring cup, graduated in ounces, with the

chemical to be injected and submerge the chemical pick-

up tube with the foot screen into the chemical.

»Turn the pump ON and set it to inject chemical.

»Adjust the chemical metering device so that 5 ounces of

chemical is injected in the duration of time identified in

Step 3.

NOTE: Check the chemical metering regularly to ensure

accurate chemical dispensing.

© 2020 Assembled Products Corp, Inc. | 200723_SMT_Momentum2.0c_5.0c_IntC-OM_EN Rev 00 | AXXXXXX-XX

115 Linden St. • Rogers, AR 72756 USA • (800) 548-3373

This manual suits for next models

6

Table of contents

Other Spray Master Technologies Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

COMAC

COMAC INNOVA 60 B 2013 Use and maintenance manual

SmaK

SmaK Neptune 500H Information & operating instructions

Vaportek

Vaportek Restorator 90-5000 Use and Operating Instructions

My Clean Buddy

My Clean Buddy Jr. product manual

Nilfisk-Advance

Nilfisk-Advance Griff user guide

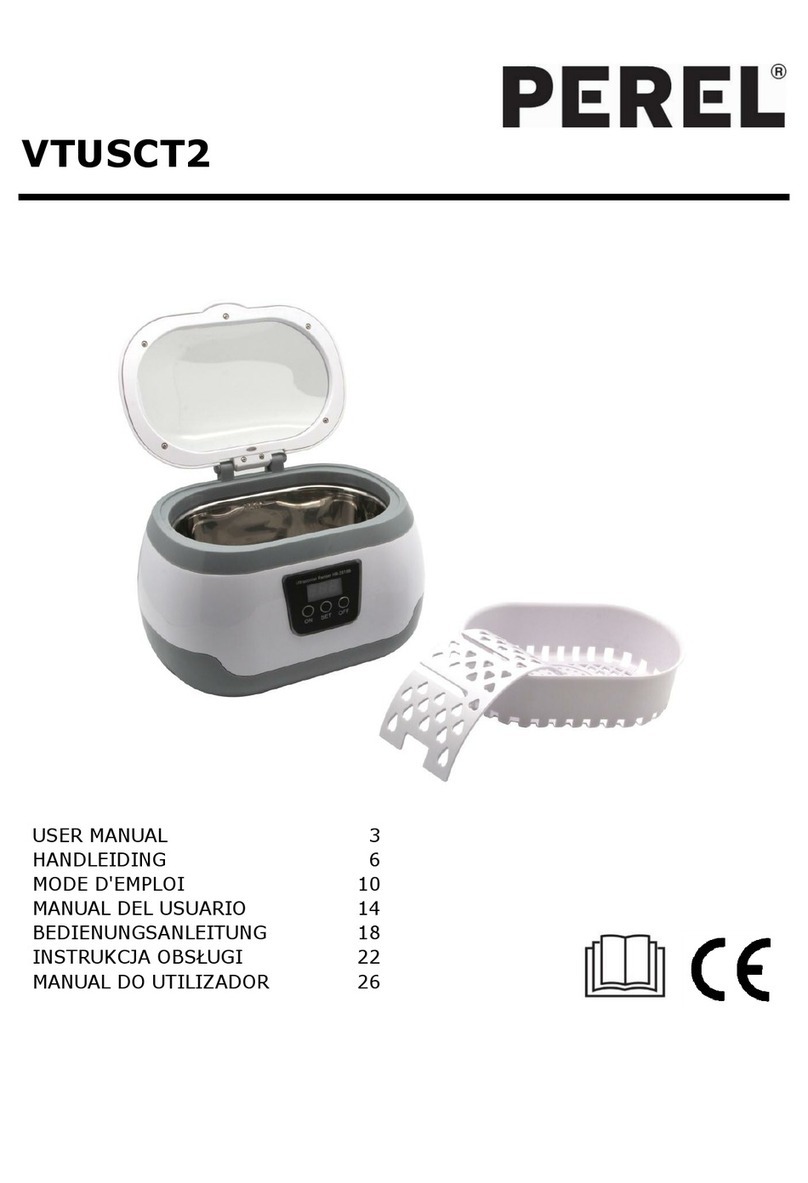

Perel

Perel VTUSCT2 user manual