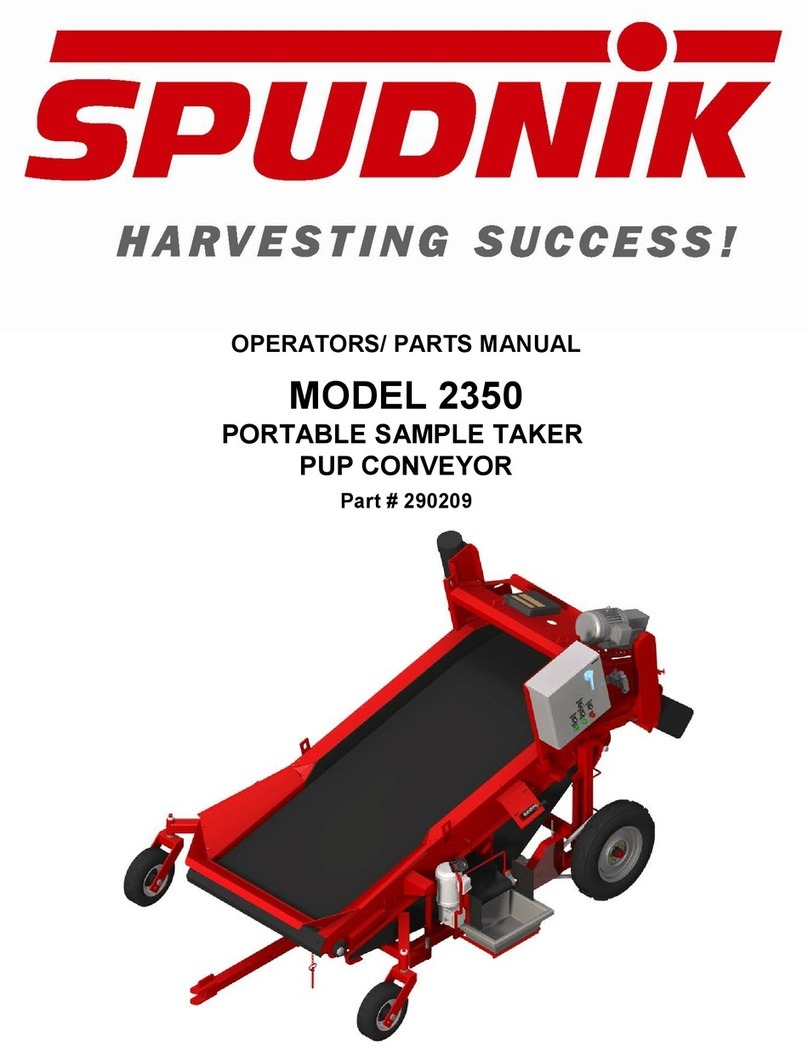

Limited Warranty Policy for New Spudnik Machinery

Spudnik Equipment Company LLC (“Spudnik”) warrants to the original purchaser each new Spudnik machine to be free from

defects in material and workmanship. Spudnik will repair or replace, at its option, any part covered by this warranty that is

found to be defective during the warranty period outlined below. Warranty service must be performed by an authorized dealer

or representative of Spudnik. This warranty is applicable only for the normal service life expectancy of the product or compo-

nents, as noted in the following table. Once the warranty period has begun, it cannot be stopped or interrupted.

What is included in the Spudnik Warranty:

Those items that are excluded from this warranty are as follows:

(1) any merchandise or components thereof, which, in the opinion of the company have been subject to: (a) Rock chip dam-

age and other abuse to painted surfaces, (b) damage caused by weather (to include UV damage), accident, or acts of God,

(c) any product that has been altered or modified in ways not approved by Spudnik Equipment Company LLC., (d) deprecia-

tion or damage caused by normal wear, lack of reasonable and proper maintenance, misuse, failure to follow the product’s

Operator Manual recommendations, (e) Using machine for other than normal moving of agricultural products during planting,

harvest, and processing seasons. Agricultural products to include: Potatoes, beets, onions, carrots, grains, etc., (2) Used

products, (3) Repairs made by unauthorized dealers.

To Obtain Warranty Service

To be eligible for the Spudnik warranty, purchaser must: (a) Have already remitted payment in full (b) have filled out and sub-

mitted the Spudnik Delivery Declaration form to a Spudnik representative (c) report the product defect to an authorized

dealer or Spudnik sales representative and request repair within 30 days of noticing the defect and (d) make the product

available to the dealer or service center within a reasonable period of time, transportation charges prepaid.

The selling dealer has no authority to make any representation or promise on behalf of Spudnik, or to modify the terms or limi-

tations of this warranty in any way.

Limited Warranty Statement

To the extent permitted by law, Spudnik does not make any warranty, representation, or promises express or implied as to the

quality, performance, or freedom from defect of any Spudnik New Machinery. NO IMPLIED WARRANTY OF MERCHANT-

ABILITY OR FITNESS IS MADE. IN NO EVENT WILL SPUDNIK, AN AUTHORIZED SPUDNIK DEALER, OR ANY COM-

PANY AFFILIATED WITH SPUDNIK BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. This warranty is

subject to any existing conditions of supply which may directly affect our ability to obtain materials or manufacture replacement

parts. Spudnik reserves the right to make improvements in design or changes in specifications at any time, without incurring

any obligation to owners of units previously sold. No one is authorized to alter, modify or enlarge this warranty nor the exclu-

sion, limitations and reservations.

To obtain more information, please contact your dealer or Spudnik at 1-208-785-0480.

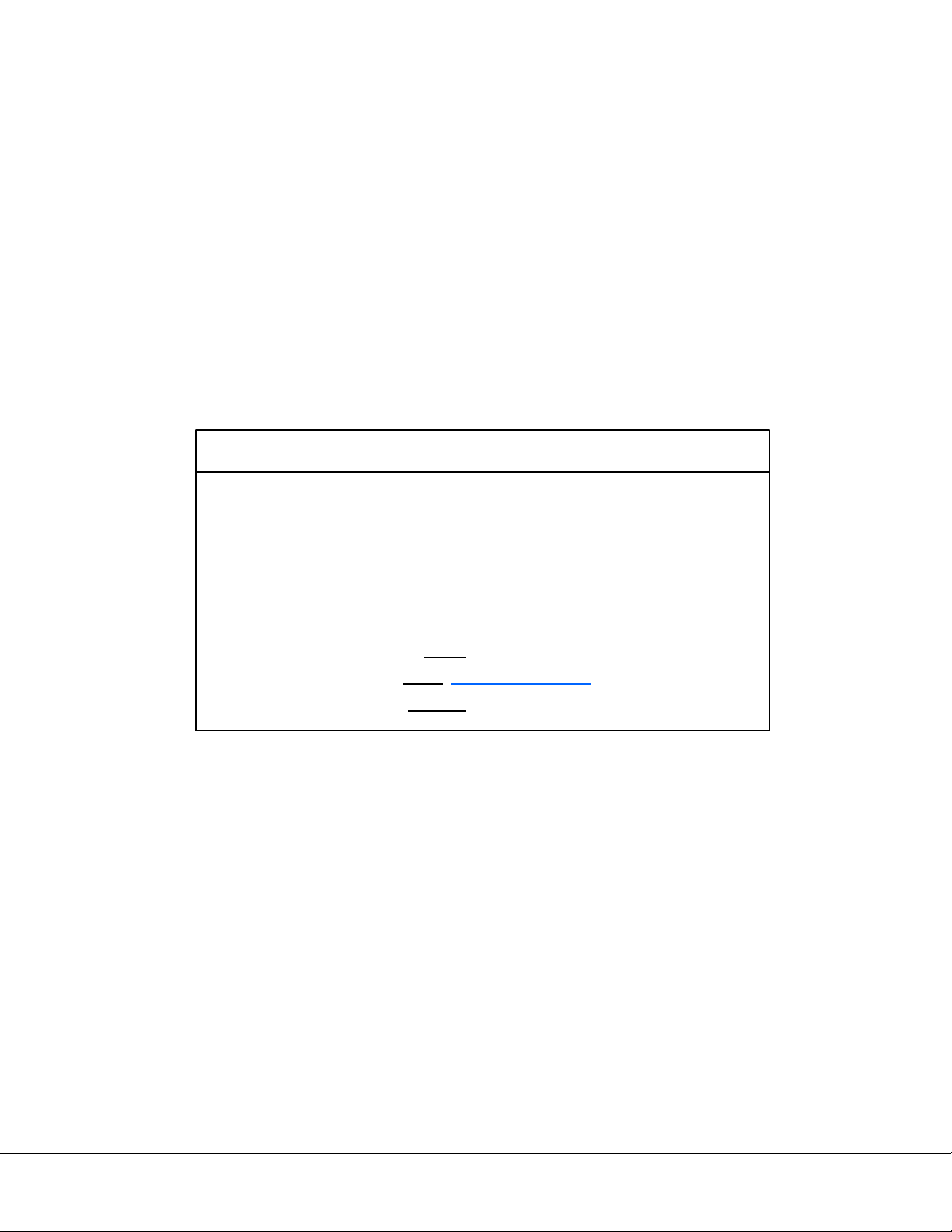

Product Warranty Term

Rollers, Sprockets, Roller Chain, Belt Lacing, and Bearings

180 Days from 1st day of operation or 720 Hours

of machine operation, whichever comes first

All paint to include: Insufficient coverage, failure of paint adherence,

and excessive runs. NOTE: Excessive runs not to exceed more than

15% of the painted surface on the machine.

12 Months from date of delivery of new Spudnik

product to the original retail customer

All other materials and workmanship (except as noted below)

12 Months from date of delivery of new Spudnik

product to the original retail customer

Genuine Spudnik replacement parts and components

30 days from date of purchase, or the remainder

of the original equipment warranty period,

whichever is longer

Operator's manual MODEL 4200