KE-2070/2080 MS Parameter

[1] Overview..................................................................................................1-1

1-1. Definition ..................................................................................................................1-1

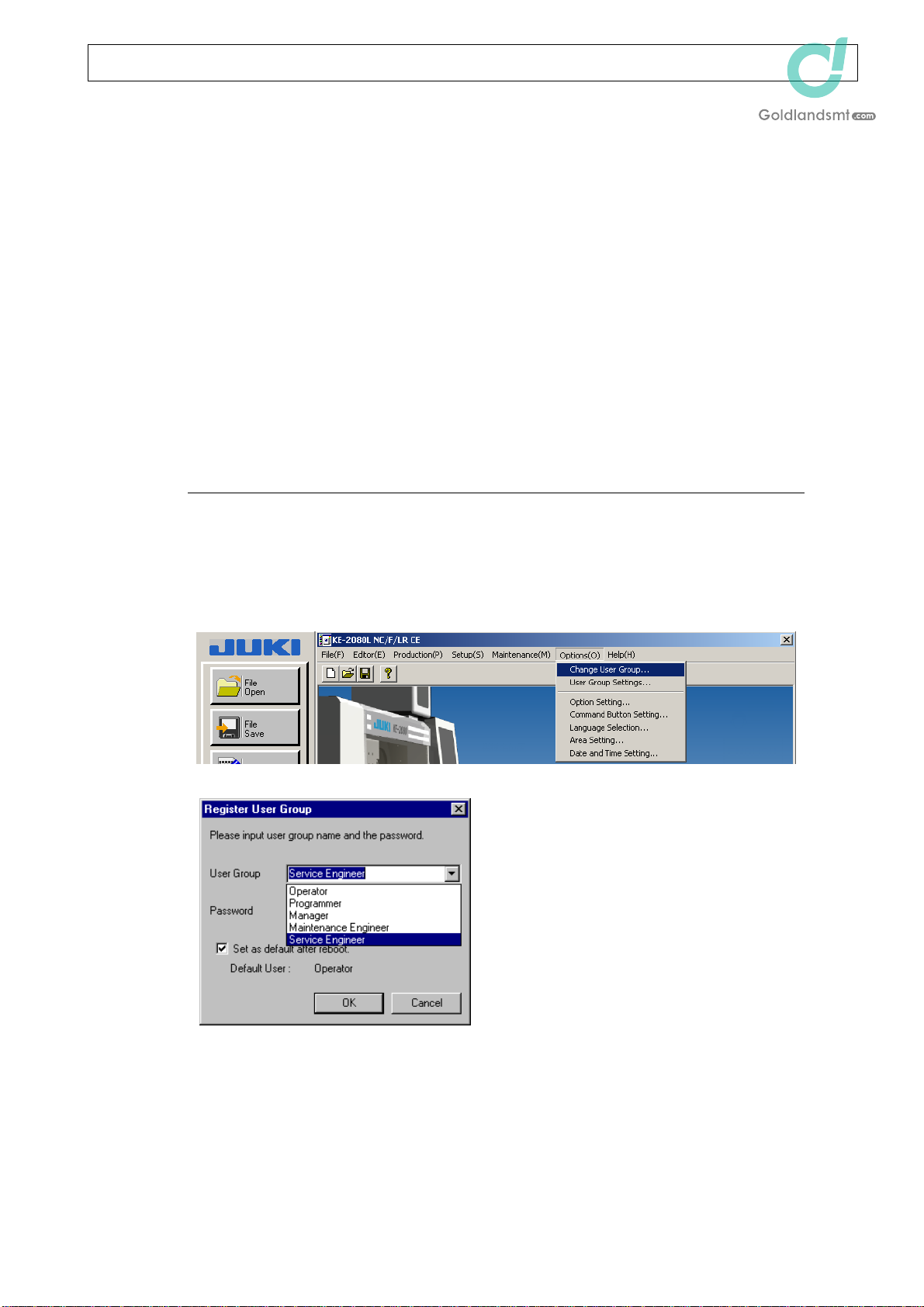

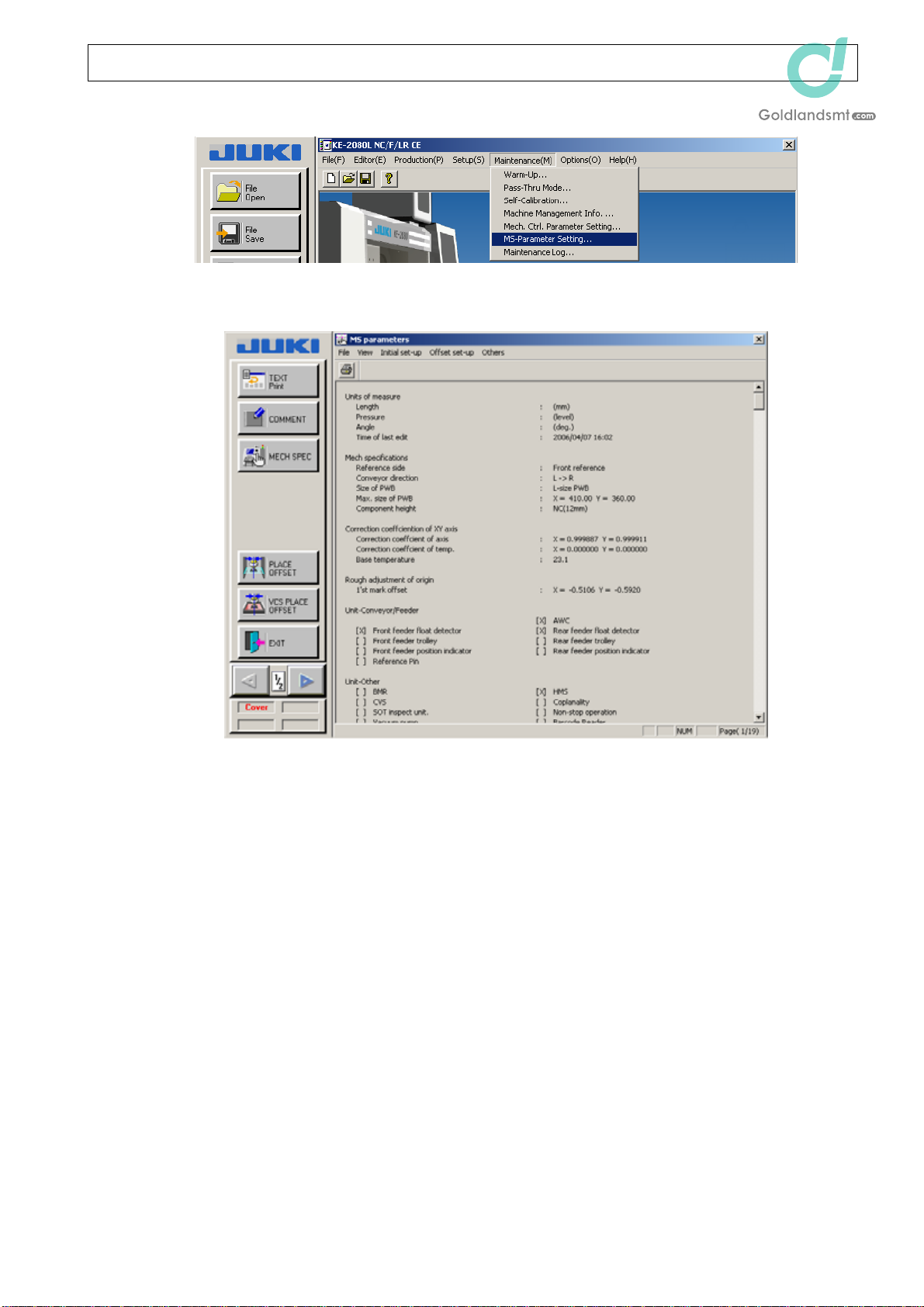

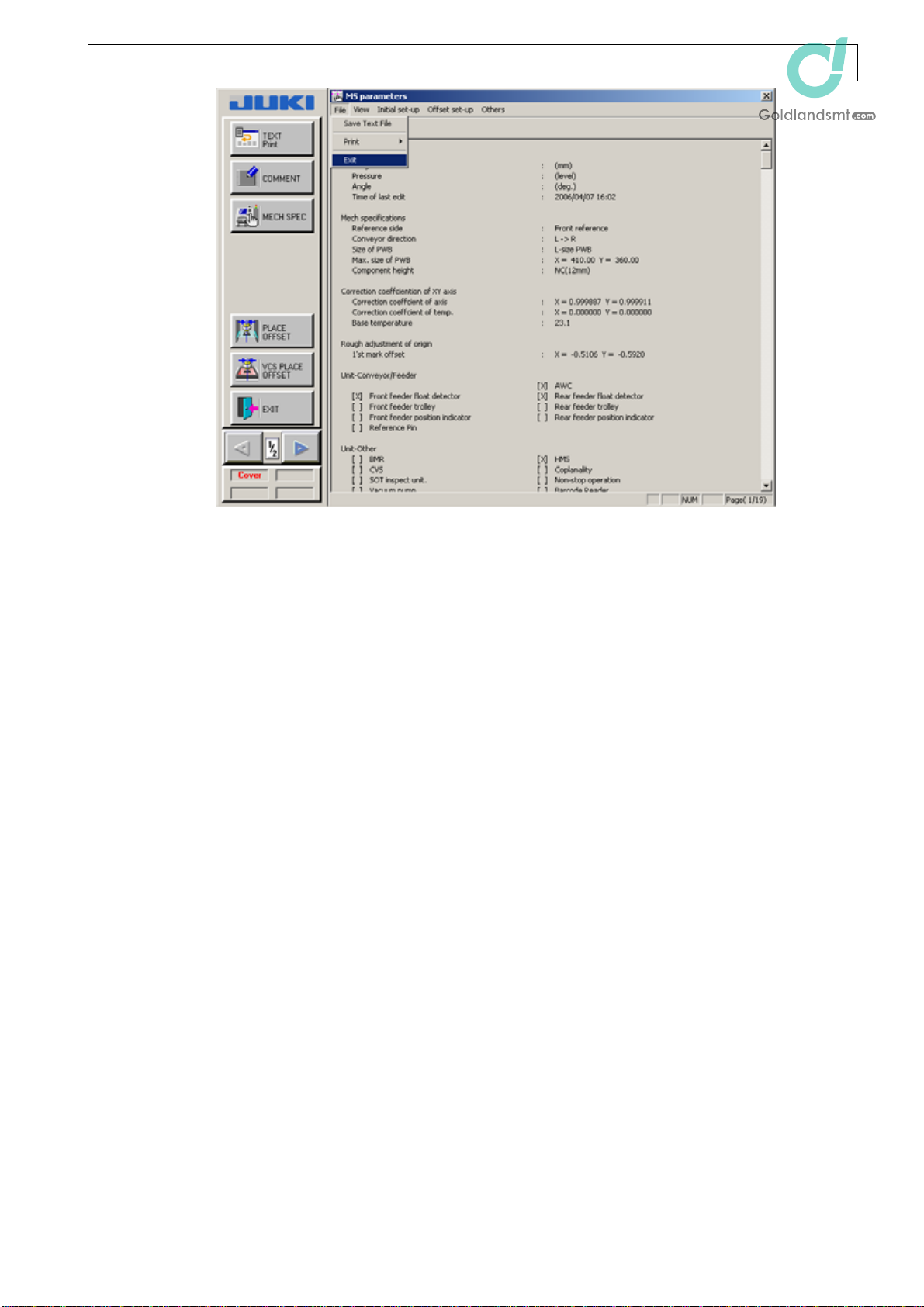

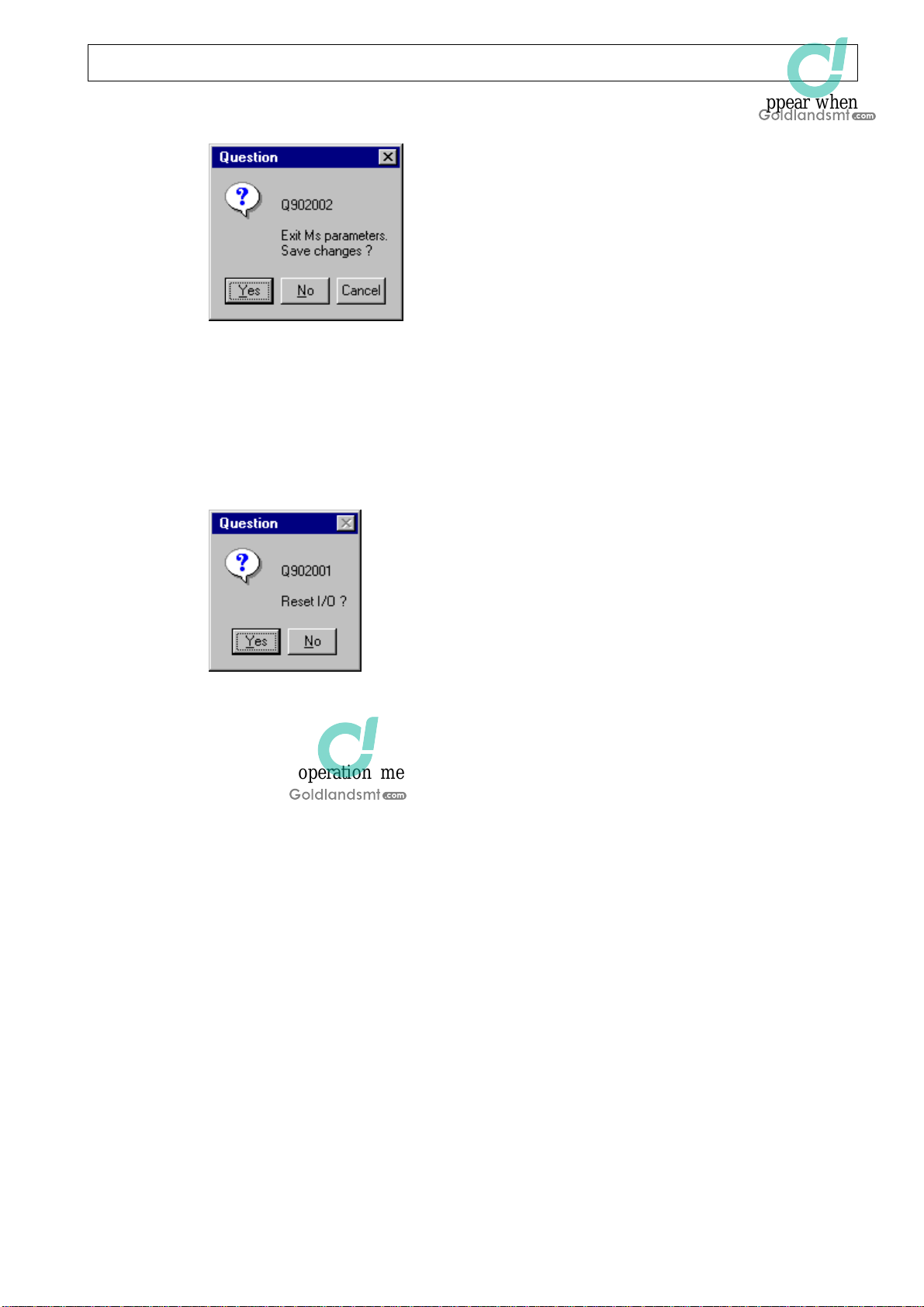

1-2. Starting up and exiting the MS parameter ................................................................1-1

1-3. Configuration............................................................................................................1-4

1-4. MS parameter storage locations...............................................................................1-5

1-5. Basic operation.......................................................................................................1-14

[2] Control menu ...........................................................................................2-1

2-1. Start up.....................................................................................................................2-1

2-2. Menu contents..........................................................................................................2-1

2-3. XY move...................................................................................................................2-2

2-4. Z move .....................................................................................................................2-3

2-5. Conveyor control ......................................................................................................2-4

2-6. Light map .................................................................................................................2-4

2-7. Light setting..............................................................................................................2-5

2-8. Nozzle up cylinder ....................................................................................................2-5

[3] Initial set-up..............................................................................................3-1

3-1. Machine specifications .............................................................................................3-1

3-2 Square adjustment ...................................................................................................3-2

3-3. Origin rough adjustment ...........................................................................................3-5

3-4. XY axis correction coefficient ...................................................................................3-6

3-5. Options.....................................................................................................................3-7

3-6. Action specifications.................................................................................................3-9

3-7. X axis curve correction ...........................................................................................3-14

3-8. Comment................................................................................................................3-15

[4] Offset set-up ............................................................................................4-1

4-1. Laser/Sensor Offset .................................................................................................4-1

4-2. OCC offset................................................................................................................4-8

4-3. CAL block offset .....................................................................................................4-17

4-4. Head offset .............................................................................................................4-19

4-5. VCS offset ..............................................................................................................4-26

4-6. Coplanarity offset ...................................................................................................4-42

4-7. ATC offset...............................................................................................................4-45

4-8. CVS offset ..............................................................................................................4-49

4-9. Conveyor offset ......................................................................................................4-51

4-10. Pick-up reference position offset ............................................................................4-54

4-11. General placement offset .......................................................................................4-56

4-12. θ-axis offset ............................................................................................................4-60

4-13. PLCC offset ............................................................................................................4-61

4-14. SOT inspect unit offset ...........................................................................................4-62

4-15. VAC-CAL offset ......................................................................................................4-64

ii Rev. 1.00