2.2.3 MotionFX library operation

The MotionFX library integrates 6- and 9-axis sensor fusion algorithms in one library; they can even run

simultaneously to provide both rotation vector (9X) and game rotation vector (6X).

Cortex-M3, Cortex-M4 and Cortex-M7

The library implements the following critical internal functions associated with sensor fusion computation:

1. the MotionFX_propagate is a prediction function used to estimate the orientation in 3D space; gyroscope

data is given more weight in this phase.

2. the MotionFX_update is the corrective function which adjusts the predicted value when necessary;

accelerometer and magnetometer data are given more weight in this phase.

The MotionFX_update function can be called whenever the MotionFX_propagate is invoked, or less often in

systems that have less computation power.

The MotionFX_update function takes approximately three times more MCU computation time than the

MotionFX_propagate function.

Cortex-M0+

The sensor fusion computation is concentrated in only one function MotionFX_CM0P_update.

2.2.4 MotionFX library parameters

Cortex-M3, Cortex-M4 and Cortex-M7

The library is "parameterized" using an MFX_knobs_t structure.

The parameters for the structure are:

•ATime, MTime, FrTime represent the weighting stability of sensors for prediction (trust factor), from 0 to 1.

Default values are recommended.

–ATime: lowering the value will increase the accelerometer weight and sensitivity towards external

acceleration. If the application experiences low acceleration (<1g) most of time, it is recommended to

increase the value.

–MTime, FrTime: for 9X solution, the lower value will increase the weight of magnetometer reading. If

the application experiences low magnetic interference (<50 μT) most of time, it is recommended to

increase the value.

•LMode represents the gyroscope bias learning mode; the library automatically tracks and calibrates gyro

zero-rate bias drift.

This possible parameter values are:

– LMode = 0 – learning off; use this mode if the gyro is already calibrated

– LMode = 1 – static learning; learning is performed only when the system is not moving

– LMode = 2 – dynamic learning; learning is also performed when the system is moving

•gbias_acc/gyro/mag_th_sc_6X, gbias_acc/gyro/mag_th_sc_9X represent the thresholds below

which the gbias algorithm automatically starts. These values should be established through testing (they are

different for different part numbers). The values in the example project are usually correct. The value can be

determined by enabling start_automatic_gbias_calculation, placing the device stationary for 10

seconds and reading the value of knobs.

–modx represents the decimation of MotionFX_update call frequency

–output_type represents the sensor fusion library output orientation: 0 = NED, 1 = ENU

–start_automatic_gbias_calculation: this flag allows computing gbias_acc/gyr/

mag_sens_th_sc_6X/9x for an application, by placing the device stationary for 10 seconds and

setting this flag to 1 by calling MotionFX_setKnobs API. After 10 seconds or more, call

MotionFX_getKnobs API to get the value of these thresholds.

–acc/gyro/mag_orientation is the acc/gyro/mag data orientation string of three characters

indicating the direction of each positive orientation of the reference frame used for the accelerometer

data output, in the sequence x, y, z. Valid values are: n (north) or s (south), w (west) or e (east), u (up)

or d (down).

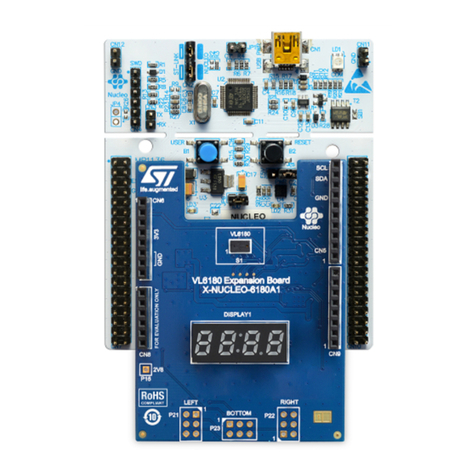

As shown in the figure below, the X-NUCLEO-IKS01A2 accelerometer sensor has an NWU orientation

(x - East, y - North, z - Up), so the string is: “nwu”.

UM2220

MotionFX library

UM2220 - Rev 7 page 4/24