2 Getting started

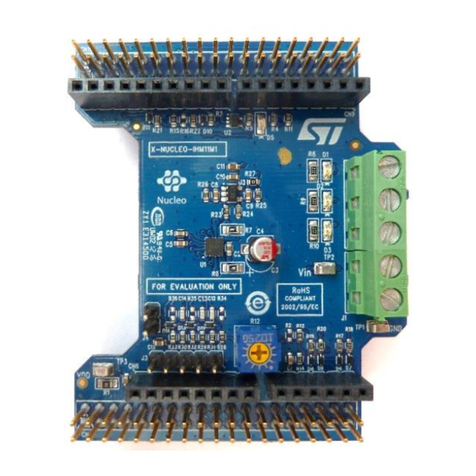

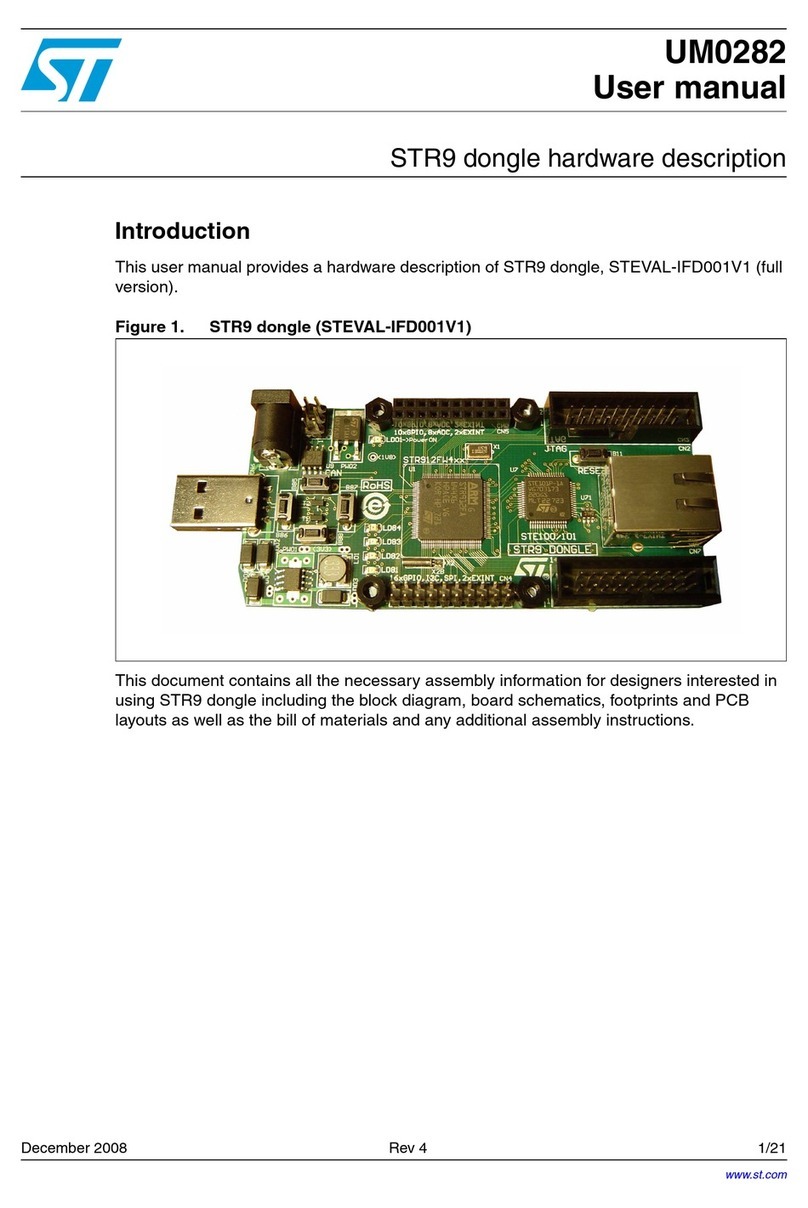

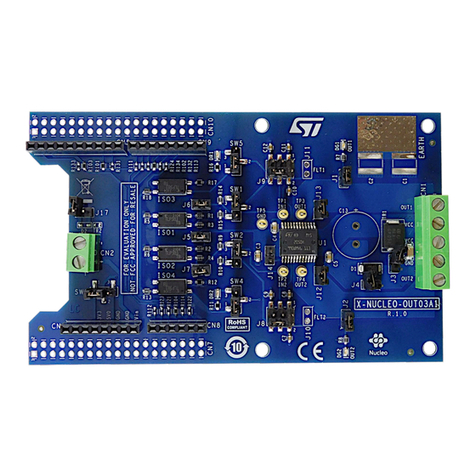

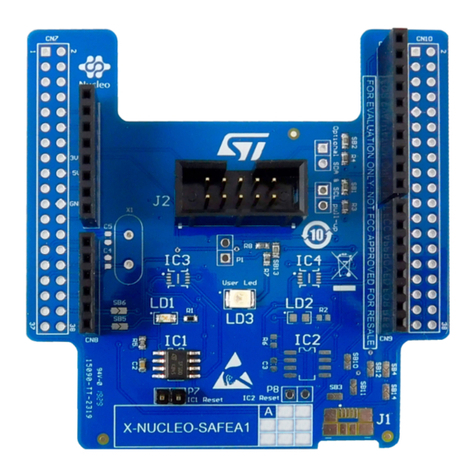

2.1 STEVAL-PCC020V1 interface board overview

The STEVAL-PCC020V1 interface board key features are:

• Bidirectional communication between PC (USB) and STNRG011

• Self-powered from the USB line

• On-board 19 V generation for STNRG011 programming

• Electric Isolation between USB and other board electronics

• I²C bus running at up to 1 MHz

• A UART bus running at 19200 bps

• UART and I²C bus muxed together on the same interface

• On-board firmware upgrade through USB port

• Display power metrics (AC voltage, PFC power)

• Access to STNRG M24C32 optional E²PROM (used to store patch, calibration and event history data)

• Program NVM settings

• RoHS compliant

2.2 GUI overview

The GUI key features are:

•Runs on Windows XP, Windows 7 (.NET 4.0 framework needed)

• Real-time monitoring of the digital controller status

• Access to STNRG011 NVM parameters

• Access to STNRG011 external E²PROM for patch upload, calibration and event history

• Embedded PFC calibration wizard

2.3 Package contents

The STEVAL-PCC020V1 package includes:

• Hardware

– the interface board

– a 1.8 m USB A to USB mini-B cable

– a 15 cm 6-wire flat cable for target connection to the STNRG011 device

• Software

– USB drivers

– PC GUI installation package

Note: The complete software package is available at www.st.com.

2.4 System requirements

To use the STEVAL-PCC020V1 interface board, you need a PC with Windows® operating system.

The graphical user interface (GUI) works with Microsoft Windows XP or later versions and .NET Framework 4.0.

Note: The .NET Framework 4.0 is not included in the Windows XP installation package.

UM2342

Getting started

UM2342 - Rev 1 page 4/57