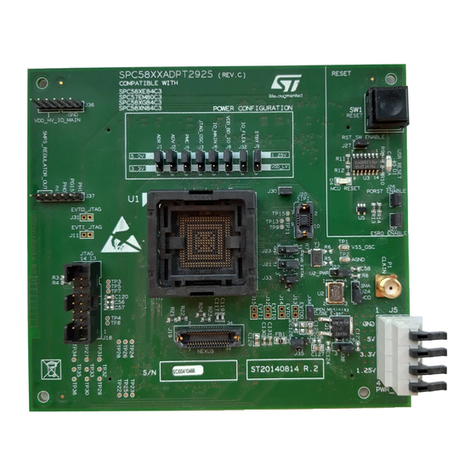

The main MCU features are:

•AEC-Q100 qualified

• High performance e200z2 single core:

– 32-bit Power Architecture technology CPU

– Core frequency up to 80 MHz

• 1088 KB (1024 KB code flash memory + 64 KB data flash) on-chip flash memory: supports reading during

program and erase operations, and multiple blocks allow performing the EEPROM emulation

• 96 KB on-chip general-purpose SRAM

• Comprehensive new generation ASIL-B safety concept:

– ASIL-B of ISO 26262

– FCCU for collection and reaction to failure notifications

– Memory error management unit (MEMU) for collection and reporting of error events in the memories

• One enhanced 12-bit SAR analog-to-digital converter unit:

– up to 27 channels (two channels for the power lift gate application to monitor the linear actuator

position)

– enhanced diagnostic features (such as current sensing current monitoring)

• Seven CAN interfaces

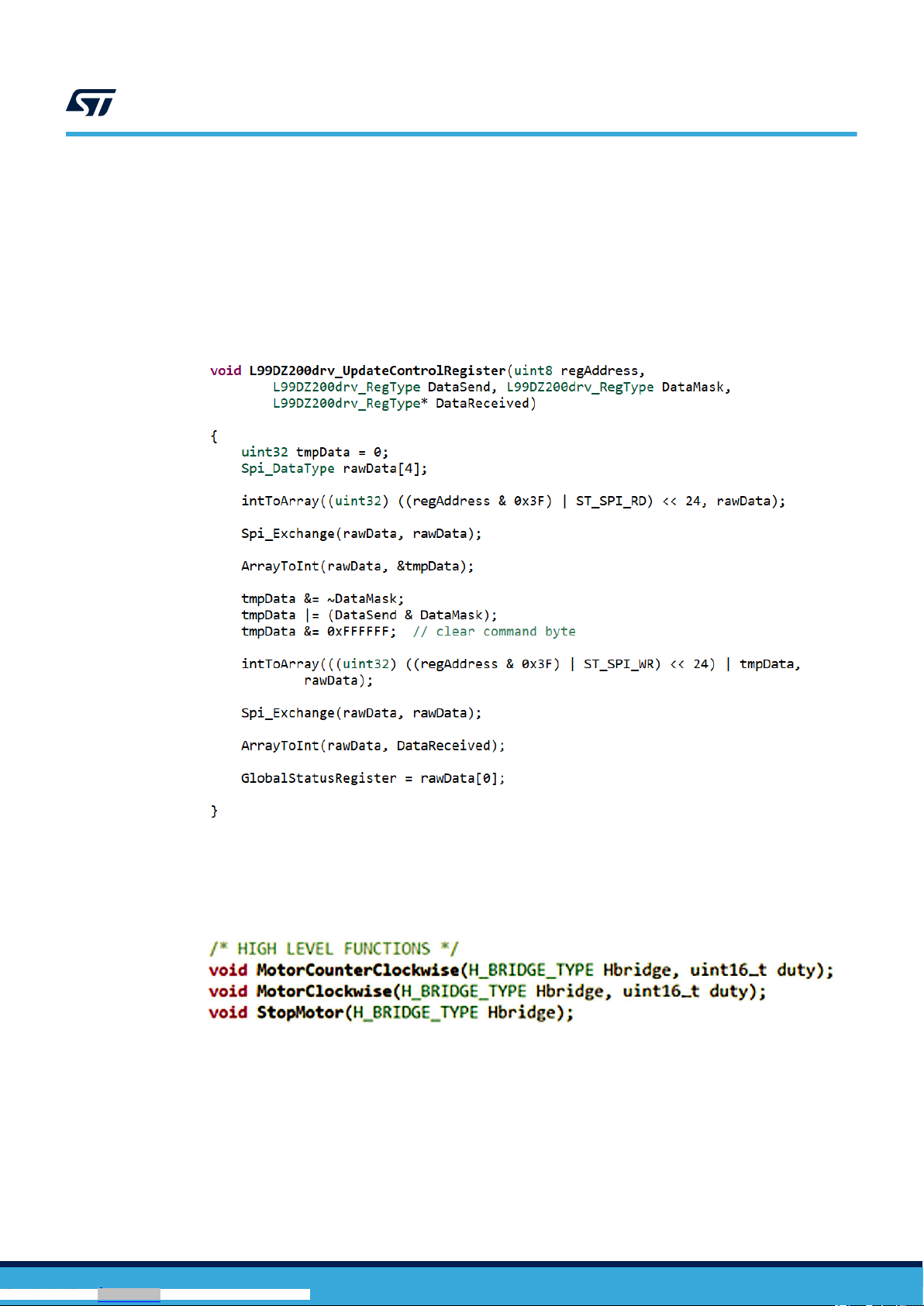

• Four serial peripheral interface (DSPI) modules (a DSPI is used for the communication between the MCU

and the L99DZ200G chip).

Note: For further information, refer to RM0403 or to the SPC582Bx datasheet.

1.1.2 L99DZ200G

The L99DZ200G chip belongs to the STMicroelectronics "Door-Zone" family. It consists of a range of system ICs

specifically designed to integrate in a single package all the main components and functions required to manage

advanced automotive door applications.

The L99DZ200G is a multifunctional actuator driver. It is programmed by a microcontroller. Its main features

include four half-bridges, seven high-side actuators, and two H-bridge drivers. Thanks to the H-bridge drivers

(configurable in single or dual mode), the L99DZ200G is able to manage the spindle motors used to raise and

lower the tailgate as well as the trunk lock. The L99DZ200G can also manage other typical loads located in the

power trunk (for example, buzzer, LED, and bulb supplies).

The device standby state reduces the battery power consumption.

The L99DZ200G features available in the AEK-MOT-TK200G1 are:

• Two H-bridge drivers for the spindle motors and lock motor. The on-board connector has eight outputs to

simplify the connection of the three motors. The outputs are doubled (that is, eight in total) as there are two

outputs for each half bridge of the two H-bridges. This duplication facilitates the connection of the third motor

in the middle of the two H-bridges

• Two high-side drivers for the LED modules

• One 5 V voltage regulator for the microcontroller supply

• One 5 V voltage tracker for the peripheral supply

• All the actuator outputs come with the following protection and supervisor features:

– Current monitoring (high-side only)

– Open-load and overcurrent

– Thermal warning and shutdown

• Configurable window watchdog

• A/D conversion of supply voltages and internal temperature sensors

Some of the L99DZ200G features are not implemented in the AEK-MOT-TK200G1:

• On the board, we disabled the MCU programming via the LIN and CAN transceiver by connecting the LIN

pin to Vsreg (12 V), while we left all the other pins related to CAN and LIN floating. To exit from a standby

condition, the L99DZ200G state machine requires at least one of the two interfaces to see a 12 V to 0 V

transition. We used the LIN one for this purpose. We also connected a wake-up button to the LIN pin to

wake up the device from the standby condition.

• All the other half-bridges and high-side outputs are not connected and left floating.

UM2995

Board main components

UM2995 - Rev 1 page 3/47

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.