Contents

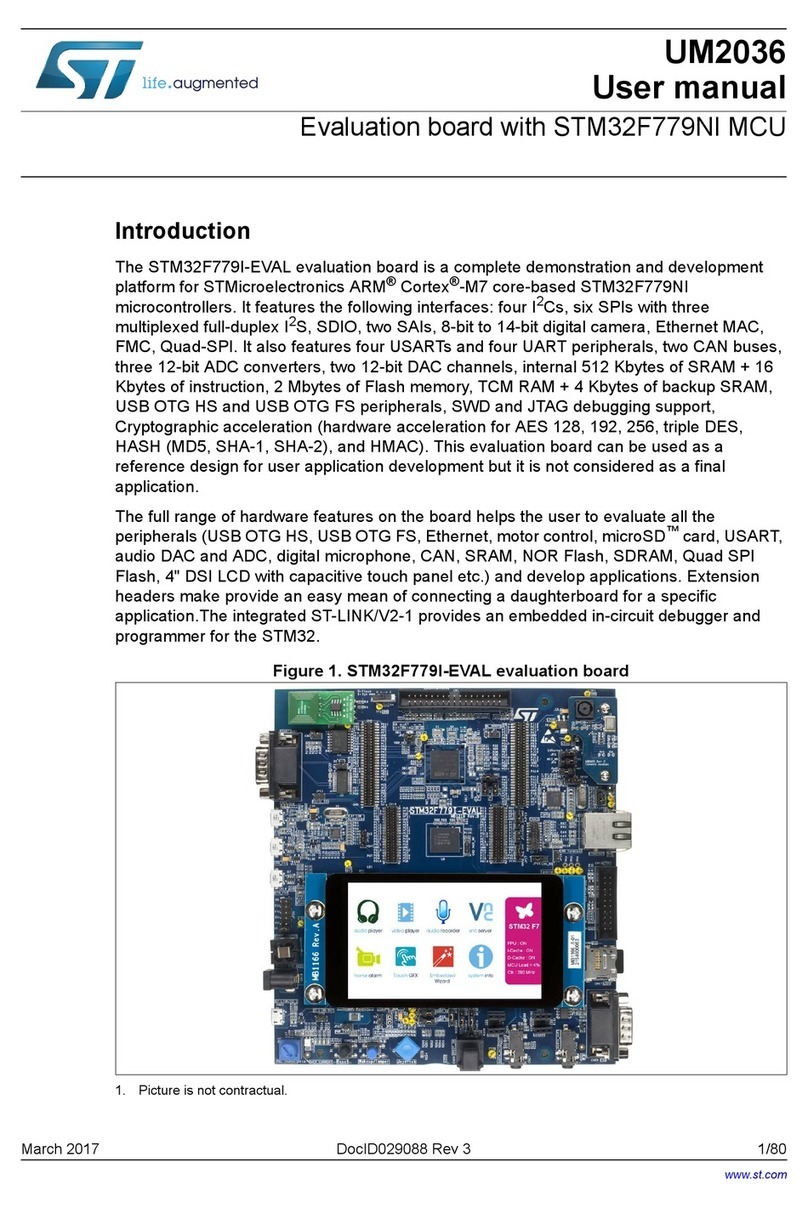

1Demonstration board overview......................................................6

1.1 What does this demoboard aim to demonstrate?..............................6

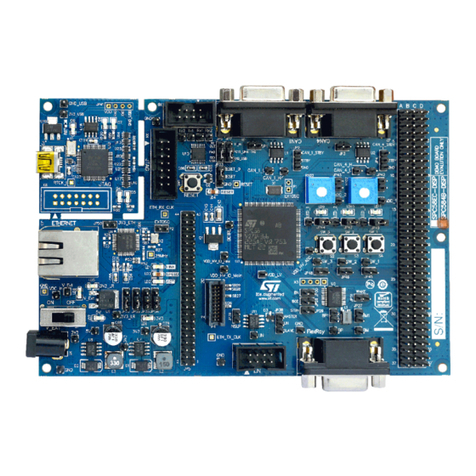

1.2 STEVAL-ISF003V1 functional blocks................................................6

1.3 Target applications............................................................................7

1.4 Main part numbers............................................................................7

1.5 Operating range................................................................................7

1.6 Performance characteristics..............................................................8

1.7 Standby consumption........................................................................9

2Getting started...............................................................................11

2.1 Safety instructions...........................................................................11

2.2 Board connection and start-up........................................................11

2.3 DC bus capacitor discharge for demonstration purposes................13

2.4 LED indications...............................................................................13

2.5 Possible board variations................................................................14

2.5.1 EMI filter and DC bus capacitor alteration........................................ 14

2.5.2Power factor circuit connection ........................................................ 14

2.5.3 Motor inverter connection................................................................. 15

2.5.4 Control with an external microcontroller........................................... 15

3Schematic diagrams......................................................................17

4STEVAL-ISF003V1 power supplies and typical consumption....20

5Inrush-current limitation...............................................................22

5.1 IEC 61000-3-3 overview..................................................................22

5.2 STEVAL-ISF003V1 compliance with the IEC 61000-3-3 limit.........22

6Mains voltage dips and interruptions ..........................................26

7AC voltage monitoring and zero-voltage synchronization.........30

7.1 Zero voltage and AC line voltage sensor circuits ............................30

7.2 Zero AC line voltage detection........................................................31

8SCR switch insulated control.......................................................32

9EN55014 test results .....................................................................34

10 STEVAL-IHT008V1 silk-screen .....................................................35

11 Bill of materials..............................................................................36

12 Test points.....................................................................................40