ST STEVAL-WBC86TX User manual

Other ST Motherboard manuals

ST

ST STEVAL-MKI132V1 User manual

ST

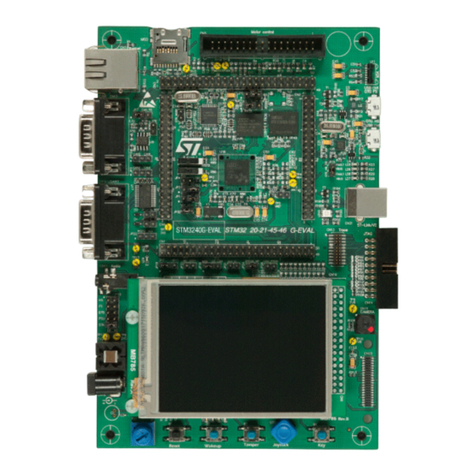

ST STM3240G-EVAL User manual

ST

ST STM32 Nucleo Installation and operating instructions

ST

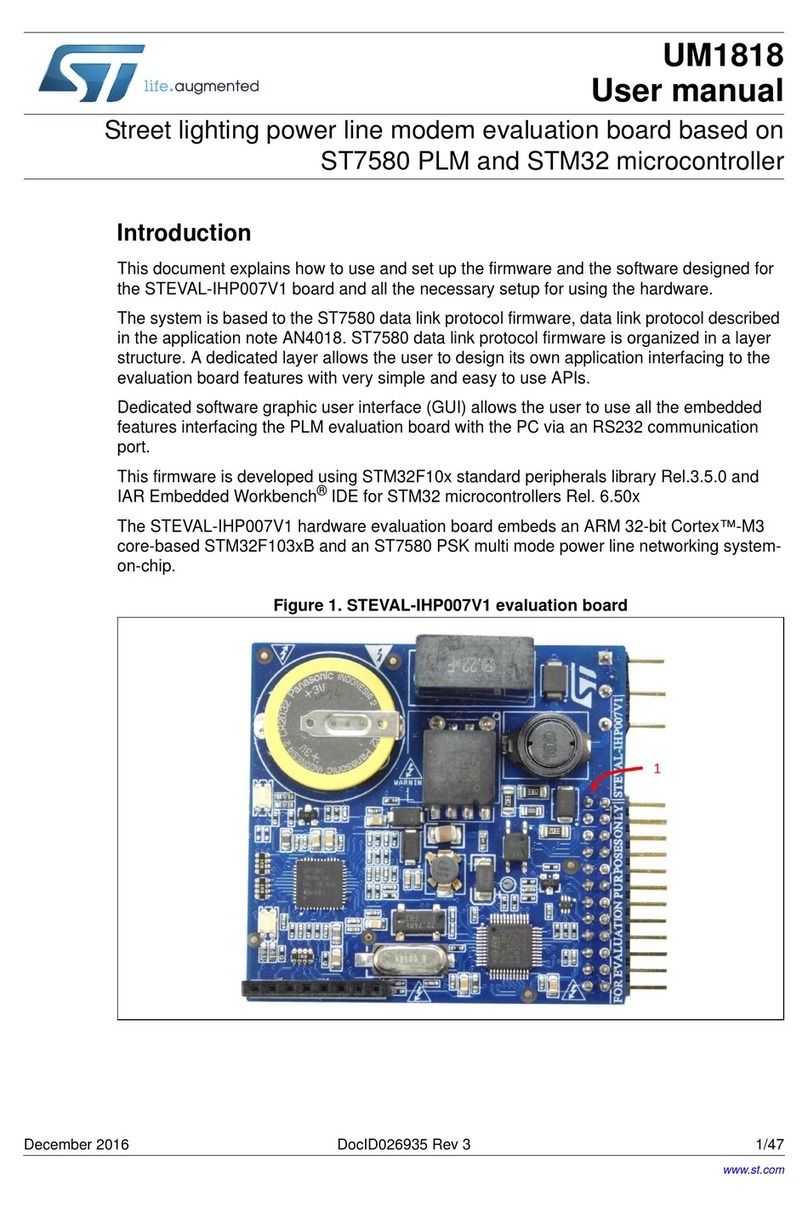

ST STEVAL-IHP007V1 User manual

ST

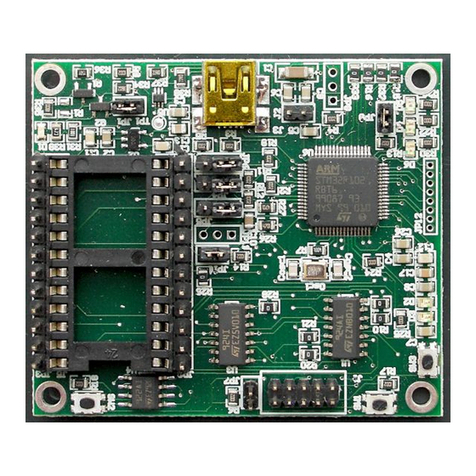

ST eMotion STEVAL-MKI109V1 User manual

ST

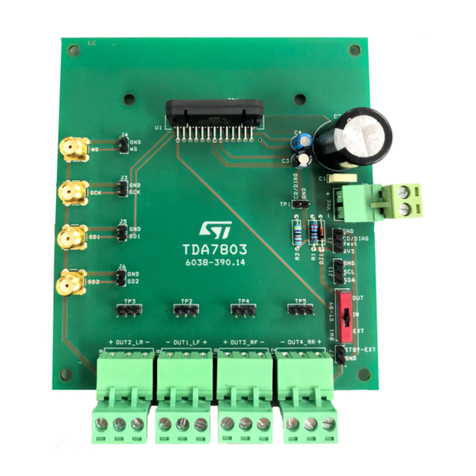

ST EVAL-TDA7803A User manual

ST

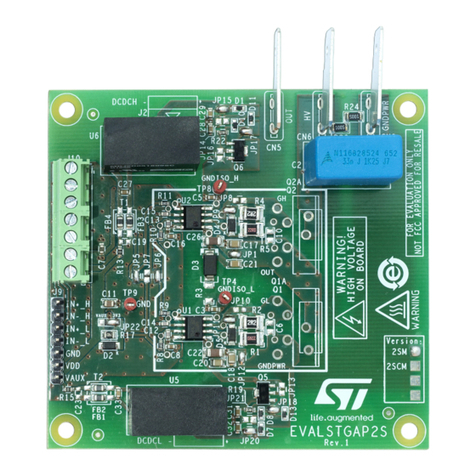

ST EVALSTGAP2S User manual

ST

ST UM2313 User manual

ST

ST SPC560D-DIS User manual

ST

ST EVAL-L9963-MCU Installation and operating instructions

ST

ST EVAL-L99H02XP User manual

ST

ST STEVAL-MKI019V1 User manual

ST

ST STLINK-V3SEGT User manual

ST

ST STM32F103RET6 User manual

ST

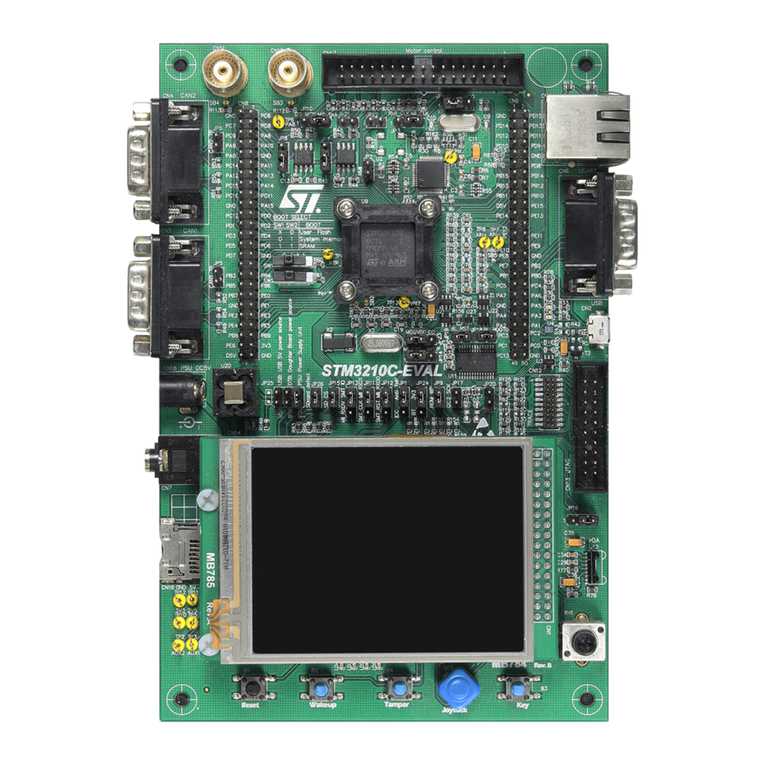

ST STM3210C-EVAL User manual

ST

ST SPC570S Series Installation and operating instructions

ST

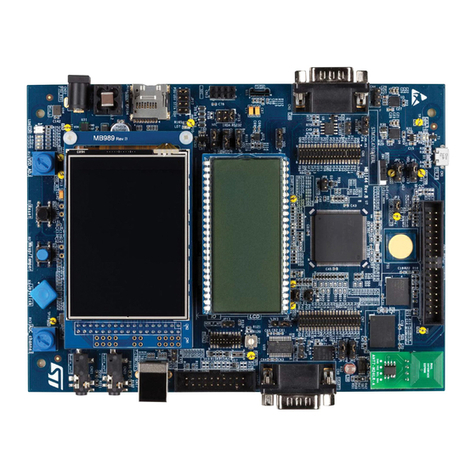

ST STM32L476G-EVAL User manual

ST

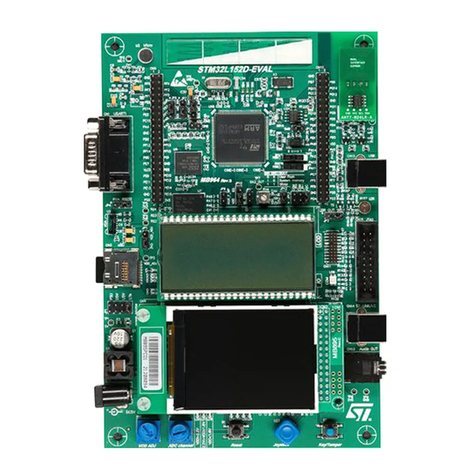

ST STM32L152-EVAL Installation and operating instructions

ST

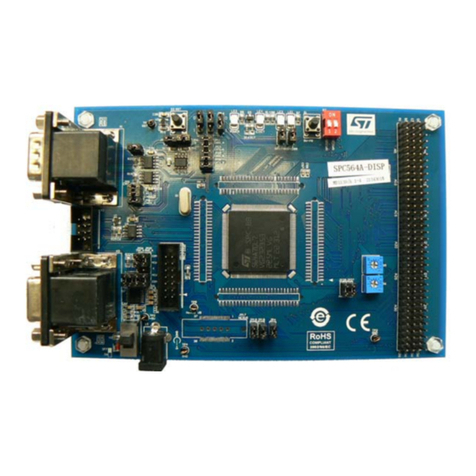

ST SPC564A-DISP Installation and operating instructions

ST

ST STEVAL-DIGAFEV1 User manual