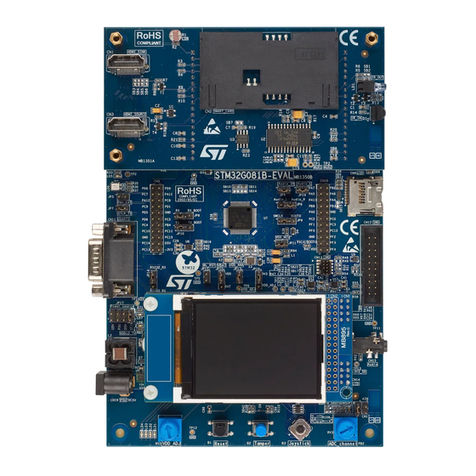

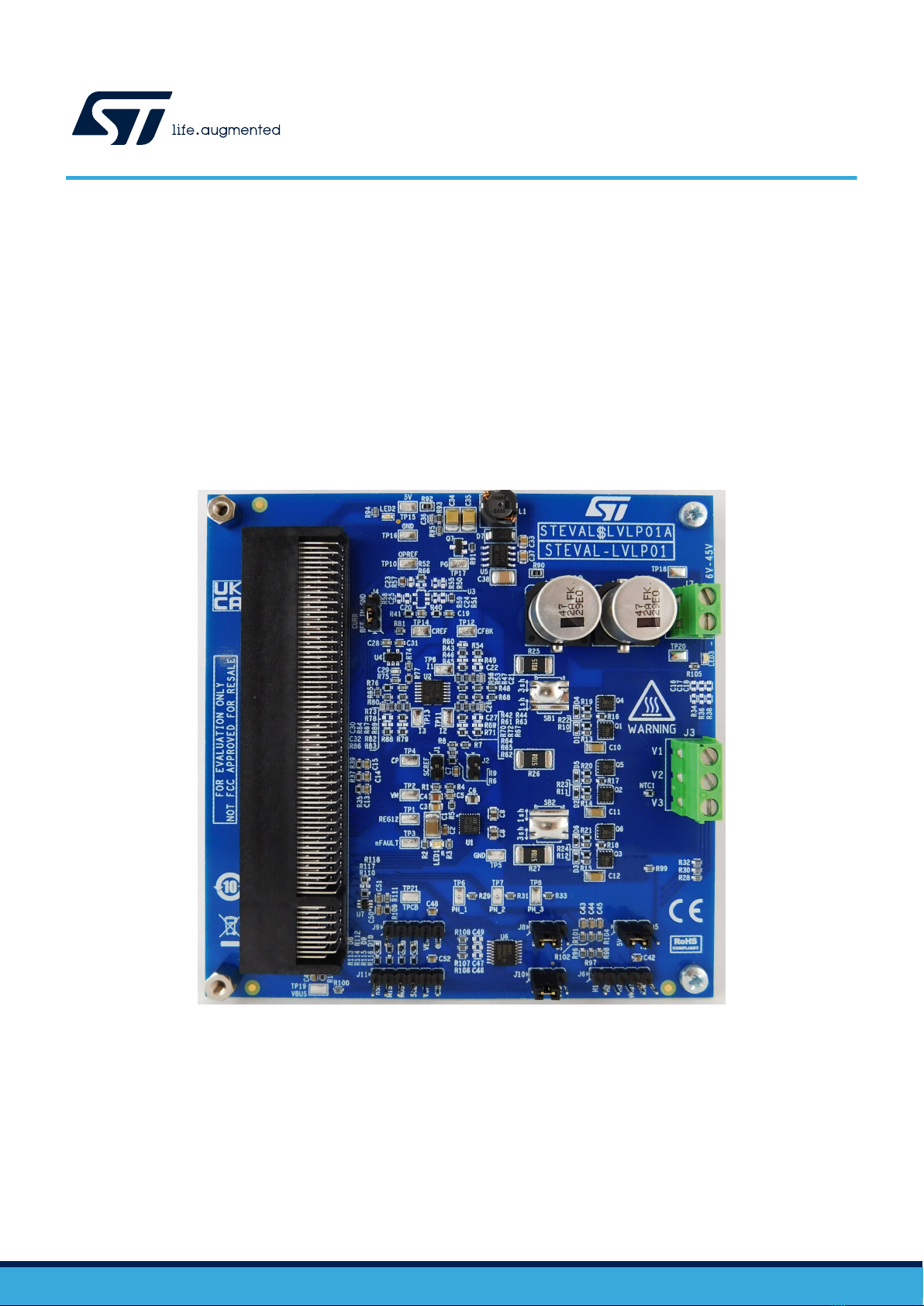

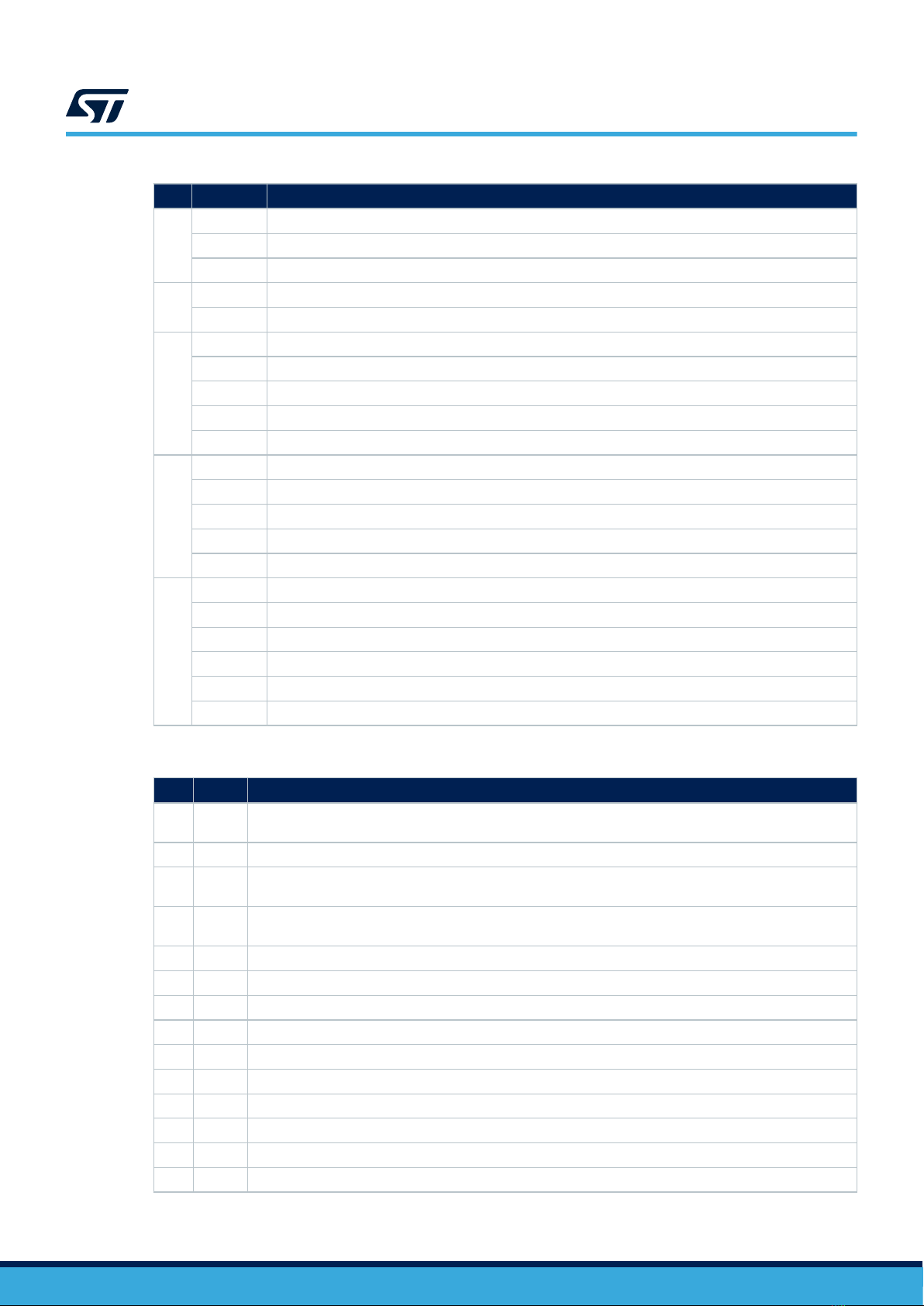

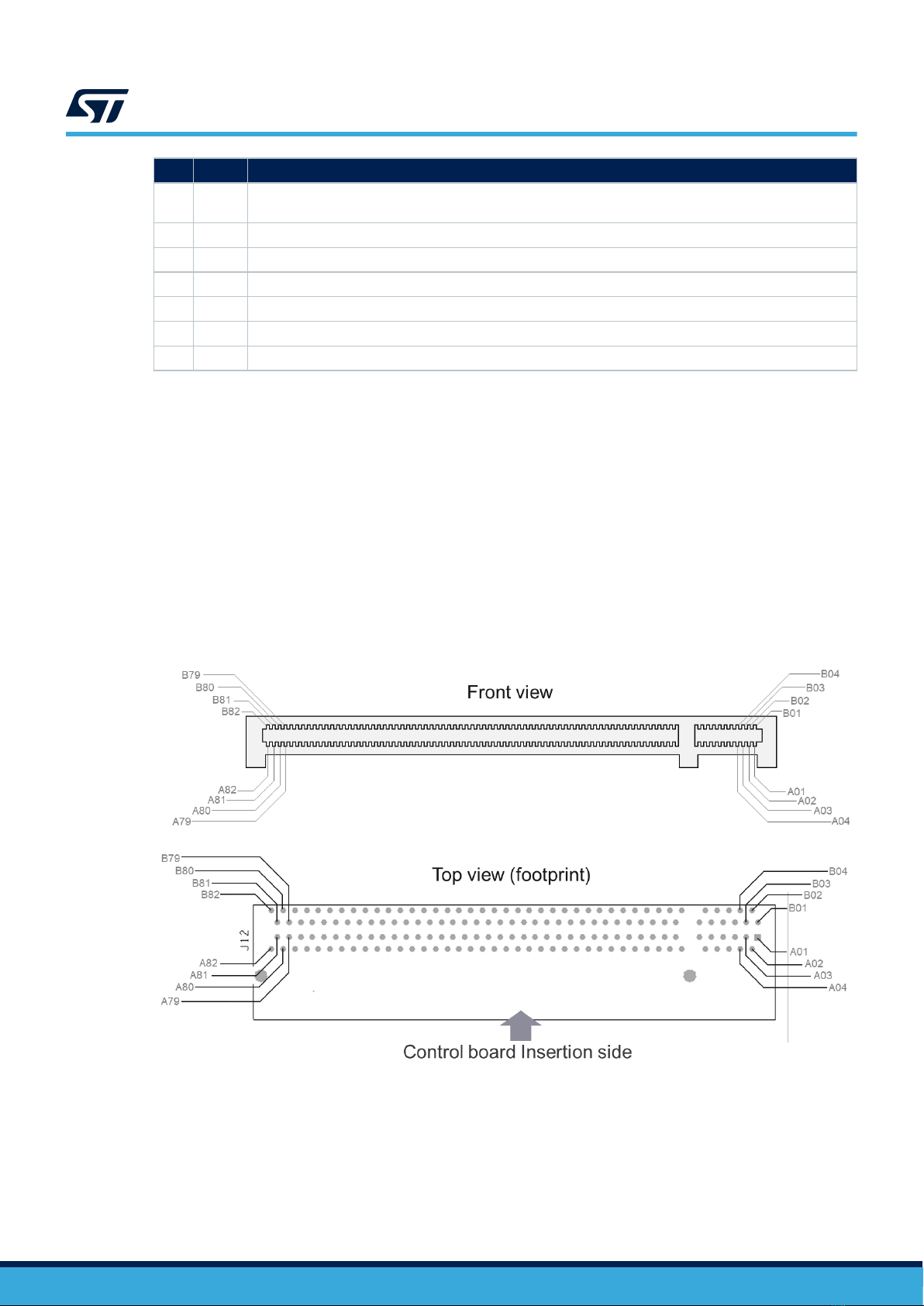

Table 2. STEVAL-LVLP01 connectors

Ref. Pin Label Description

J3

V1 Phase 1 (U) of the three-phase motor.

V2 Phase 2 (V) of the three-phase motor.

V3 Phase 3 (W) of the three-phase motor.

J7 + (VM) Main power supply of the power MOSFETs and the STDRIVE101. It ranges from 6V to 45V.

- (GND) Reference ground terminal (negative pole) of the main power supply.

J6

H1 Motor’s Hall sensor signal 1 (digital signal).

H2 Motor’s Hall sensor signal 2 (digital signal).

H3 Motor’s Hall sensor signal 3 (digital signal).

VHall Motor’s Hall sensors supply voltage (selectable by J5).

GND GND reference for the motor’s Hall sensors.

J9

A Motor’s encoder out A+ (digital signal).

B Motor’s encoder out B+ (digital signal).

Z Motor’s encoder zero feedback (digital signal).

Venc Motor’s encoder supply voltage (selectable by J8).

GND GND reference for the motor’s encoder.

J11

nSS SPI interface: Chip Select / Slave select (active low).

MISO SPI interface: Master Input Slave Output

MOSI SPI interface: Master Output Slave Input

SCLK SPI interface: Serial clock

VSPI SPI interface supply voltage (selectable by J10).

GND GND reference for the SPI interface.

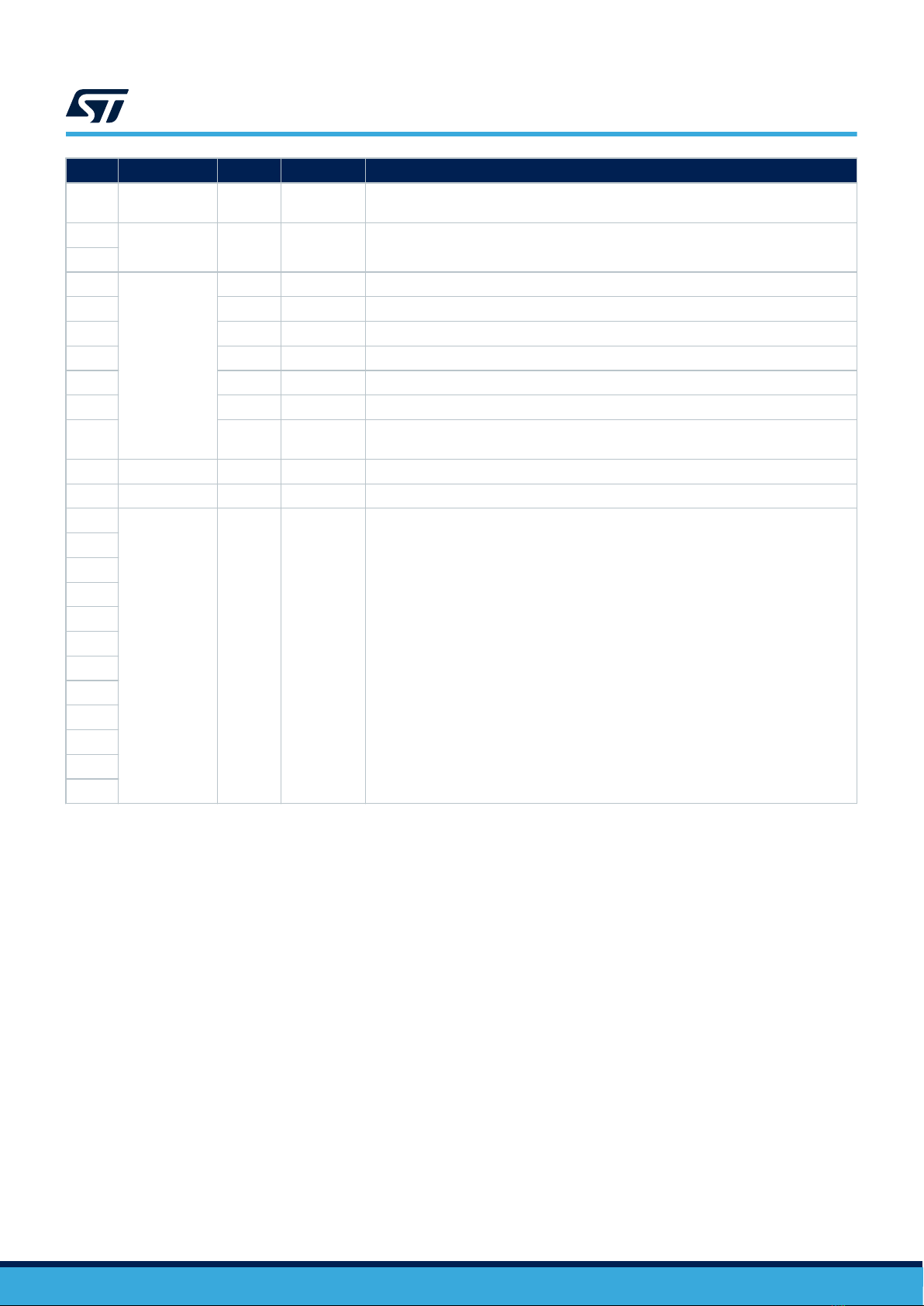

Table 3. STEVAL-LVLP01 test points

Ref. Label Description

TP1 REG12 Test point connected to the REG12 pin of the STDRIVE101; it is the output of the embedded linear regulator

and the supply of the gate drivers.

TP2 VM Voltage supply of the motor and the STDRIVE101. TP2 is placed next to the STDRIVE101.

TP3 nFAULT Test point connected to the nFAULT pin of the STDRIVE101. This pin indicates a failure condition detected by

the device.

TP4 CP Test point connected to the CP pin of the STDRIVE101. It is the input of the embedded comparator used for

overcurrent protection

TP5 GND Power GND. Close to the power stage.

TP6 PH_1 Voltage of the phase V1 (U) of the motor, rescaled and filtered.

TP7 PH_2 Voltage of the phase V2 (V) of the motor, rescaled and filtered.

TP8 PH_3 Voltage of the phase V3 (W) of the motor, rescaled and filtered.

TP9 I1 Amplified signal related to the current flowing in the phase V1 of the motor.

TP10 OPREF Reference voltage provided to the operational amplifiers.

TP11 I2 Amplified signal related to the current flowing in the phase V2 of the motor.

TP12 CFBK Amplified signal used by the comparator implementing the current control (Comparator for current control).

TP13 I3 Amplified signal related to the current flowing in the phase V3 of the motor.

TP14 CREF Reference signal used to set the current threshold of the current control (Comparator for current control).

UM3193

Hardware description and configuration

UM3193 - Rev 1 page 3/33