ST&G L1311A User manual

ST&G USA Corp. Phone: (714) 524-0663

2691 Saturn St. Fax: (714) 364-8113

Brea, CA 92821 www.stngco.com

Instructions for L1311A

Weight Activated Brake Knee

with Manual Lock

1 Description and purpose

Prosthetist instructions.

L1311A knee is for lower limb prosthesis.

Recommended for K1 up to K2.

Weight limit for a user is up to 125kg / 275lbs

Ability to lock knee in full extension as part of rehabilitation process.

Can progress from locking to full-time unlocked weight activated brake knee.

Contra-indications

Residual muscular weakness, contractures or proprioceptive dysfunction

including poor balance.

Inability to comprehend instructions

Contra lateral joint instabilities or pathology

Complicated conditions involving multiple disabilities

Product Code

L1311A

Mechanical Single Axis Knee Joint with Brake Function and Optional Manual Lock

125Kg

275lbs

Ensure the end user has understood any Instructions for use, especially to

the safety information.

2. Construction

Principal Parts

Frame Aluminum Alloy

Knee control Various materials principally Aluminum Alloy, Brass, Stainless

Steel, Poly Urethane

The Caution symbol highlights safety information which must be followed carefully.

Be aware of finger trap hazard at all times

Any changes in performance of the knee e.g. inability to engage manual

lock mechanism, instability or lag in transition from flexion moment to full

knee extension moment in the knee, or unusual noise should be

immediately reported to the Clinician / Practitioner

Any excessive changes in heel height may adversely affect the stability of

the knee.

The user should be advised to contact their Clinician / Practitioner if their

condition changes.

4 Safety Information

3 Function

Pyramid proximal mount

30mm distal tube clamp mount

Adjustable integrated spring extension assist

Adjustable weight activated brake sensitivity

Adjustable swing friction

Dual function manual lock lanyard handle

Manual lock can be disabled

Enables easy switching between locked knee and free weight activated brake knee

Overview

Due to unique construction, the L1311A knee joint can be used both as a locking

joint with manual release, and as a weight activated brake knee joint as the

user's mobility progresses. The L1311A is particularly suitable for above-knee

amputees with a high need for safety as the innovative brake mechanism

increases the safety of the knee which can help compensate for some reduced

muscle activity of the hip.

5 Maintenance

Maintenance must be carried out by qualified personnel.

Bi-Annual inspection is recommended.

Check for visual defects that may affect proper function.

A loaner system is available should servicing be required.

The wearer should be advised:

Any changes in performance of this device must be

reported to the Clinician / Practitioner.

Changes in performance may include:

Increase in knee stiffness

Inability to easily lock the knee with full extension

Knee instability

Any unusual noises

Cleaning:

Use a damp cloth and mild soap to clean the outside surfaces.

DO NOT use aggressive cleaning agents or lubricants.

If the limb/knee comes into contact with salt or chlorinated water,

or bodily fluids, it should be rinsed with fresh water and dried

6 Limitations on use

Intended Life:

Service life of the product is covered by the warranty period (2 years)

This product is recommended for use with other ST&G Products.

Lifting Loads:

Amputee weight and activity is governed by the stated limits.

Combined amputee, and carrying load, should not be at, or exceed stated weight limit.

Environment:

Avoid abrasive environments such as those containing dust or sand for

example as these may promote premature wear. Avoid contact with

talcum powder.

Operating and Storage Temperature Range:

Exclusively for use between temperatures of -10˚C to 50˚C [14˚F and 122˚F]

7 Alignment and Set-Up

Users be aware of potential finger trap hazard

Alignment for the L1311A should be adhered to so as to enable a stable and safe functioning

prosthesis for the wearer. The recommended alignment is 10mm anterior to the Knee Center

which will have the weight line on the centerline along the length of the pylon. Weight line

should also be along the centerline of the pylon in the sagittal plane so as to not promote

undue stress on the knee joint axis.

Important: If the weight line is too close to the knee center, there is possibility of inadvertent

knee instability. Adhere to allowance for safety factor of at least 3mm for initial fitting, and to

reassess knee alignment and function on a regular basis initially (especially for new

amputees) so as to gauge their progression and ability with the need for fine tuning knee

function!

Set the bench alignment taking into account the heel height of associated footwear plus

3mm safety factor!

It is not recommended to have alignment too close to the knee center, as it could

cause knee instability or inconsistent weight activation of brake!

Bench Alignment:

Weight line 10mm

Anterior to knee center

(centerline of pylon)

Do not insert any tube spacers into tube clamp section –This can lead to

potential failure. Only the intended pylon should be fully inserted to the tube

clamp bottom.

The L1311A is supplied by the factory in the basic setting.

Carefully assess the brake function with the wearer during the dynamic initial

fitting to see if the basic setting is optimal.

If adjustment is necessary, it is best to start with the Stance Phase adjustment and

then go to Swing Phase adjustments.

NOTE: There is a fine balance to adjusting this so as to ensure that the wearer will

have a smooth transition to swing. Overly adjusting will cause the knee to not

release during swing initiation!

8 Knee Adjustment

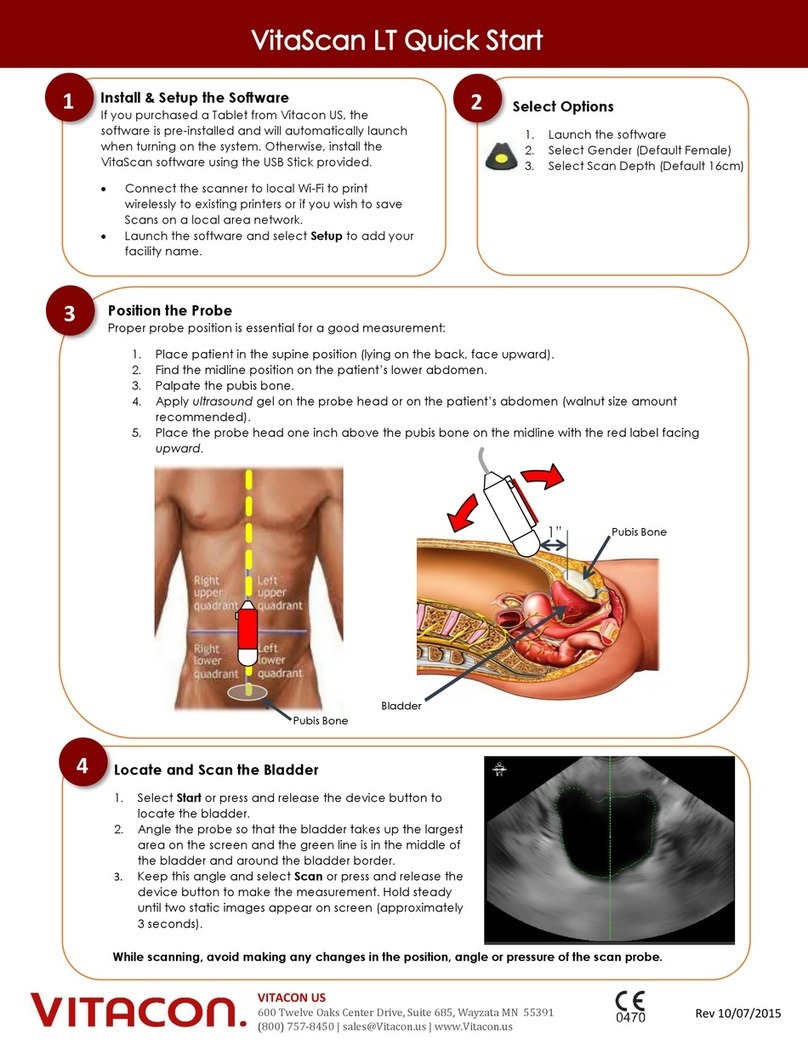

8.1 STANCE PHASE - Brake Sensitivity Stance Adjustment

The brake sensitivity adjustment is to fine tune the

amount of load required during stance phase to activate

the brake mechanism.

Brake sensitivity adjustment screw location on L1311A

To access the adjustment screw, be sure the knee is

unlocked and flex to fully expose the adjustment screw on

the brake mechanism face (fig. 1)

Using a 4 mm hex wrench turn adjustment screw:

Clockwise requires more weight needed to initiate the

brake function so the brake effect is induced later

(fig. 1)

Anti-Clockwise requires less weight needed to initiate

the brake function so the brake effect is induced earlier

(fig. 1)

NOTE: Adjustment as little as 5 degree turn makes a

notable difference!

Resetting Brake sensitivity to factory setting: Brake

sensitivity adjustment screw head should be flush with

the knee brake mechanism surface.

Fig. 1

Note that knee is flexed

to expose screw

Less More

weight needed

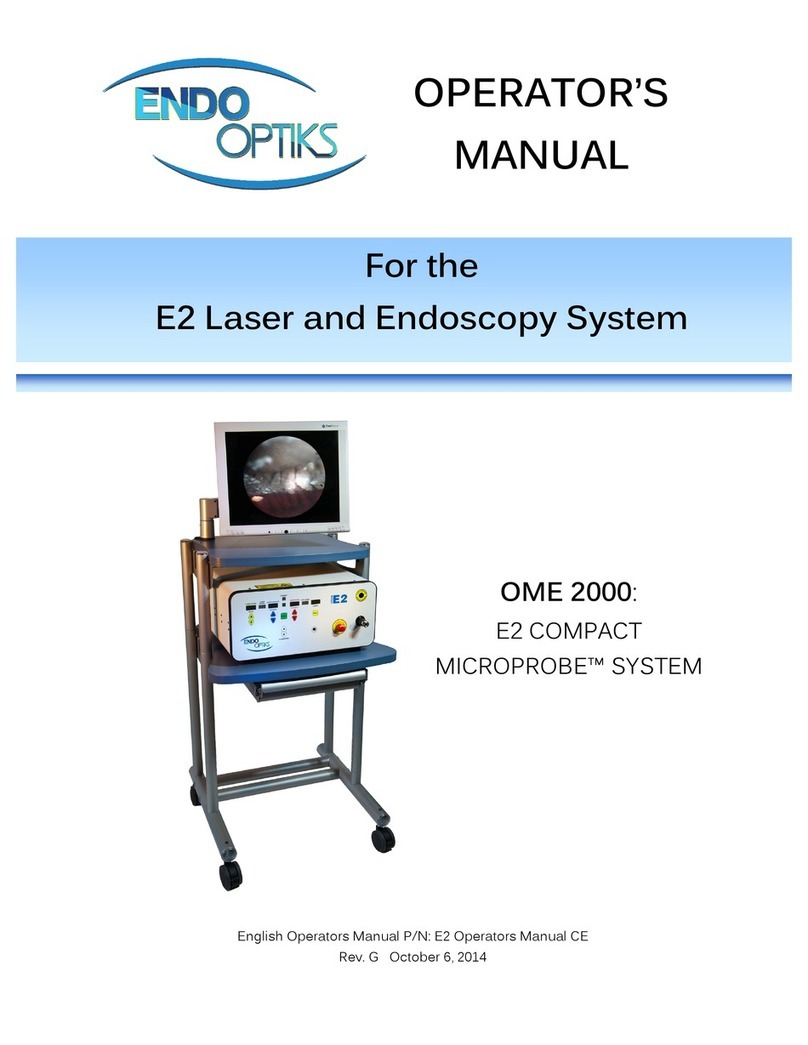

The Knee Friction Adjustment screw is located

towards the bottom of the knee joint on the

anterior and can be adjusted with a 3mm hex

wrench. (fig. 2)

Readjusting the knee friction setting.

NOTE: Minor adjustments of as little as 3 degree

turn will provide a notable difference!

The knee friction effect may occur anyway during

initial swing (prosthesis sticks) depending on the

user’s weight or walking habits which could

impair the safety and the user’s walking behavior.

In this case, the knee friction screw can be turned

using a 3mm hex wrench:

Anti-Clockwise to reduce friction/sticking during

initial swing. Reassess knee function during

walking and adjust accordingly.

Important: flexion and extension must be possible

at all settings!

8.2 SWING PHASE - Friction Adjustment

Less More

Friction

Fig. 2

Note that the screw is on the

bottom.

Clockwise = increased friction

Anti-Clockwise = reduced friction

(Screw accessed above it is knee

axis pin retainer screw)

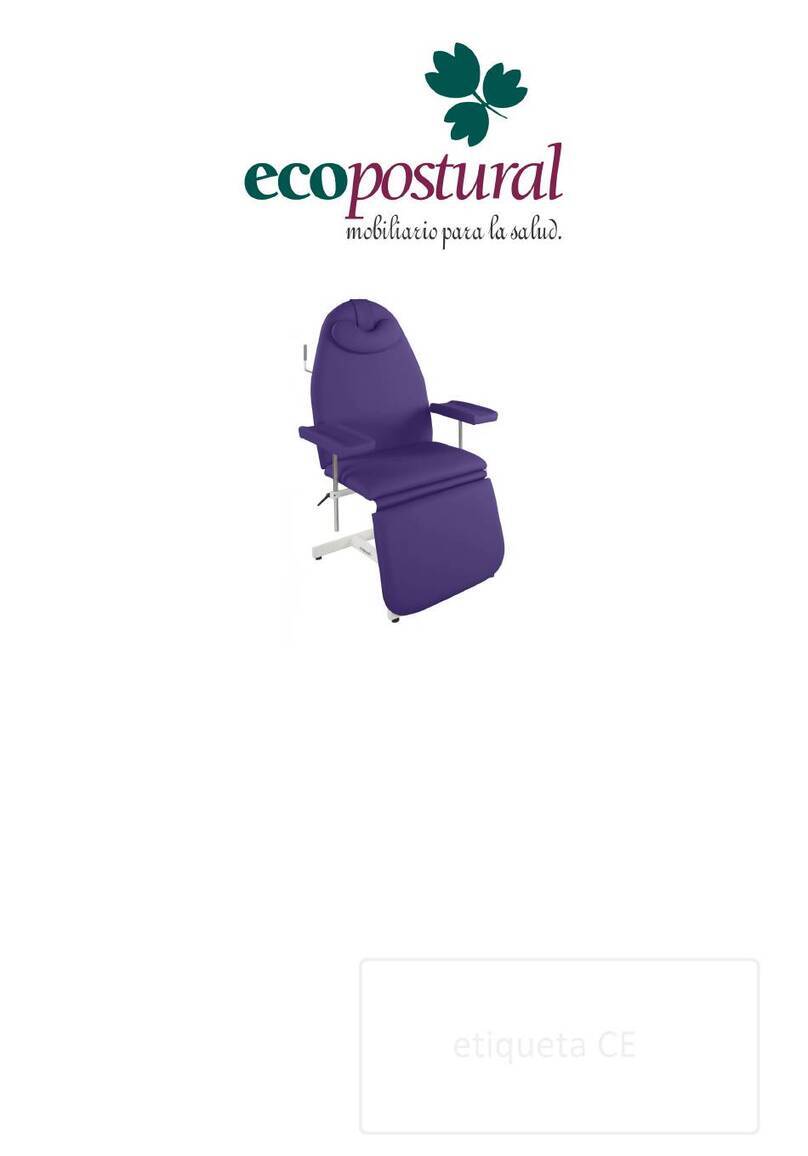

The Knee Spring Extension Adjustment screw is

located within the tube clamp portion of the knee

joint, and is adjusted with a flat blade screw

driver. (fig. 3)

Using a flat blade screw driver, the spring

extension assist adjustment screw can be turned:

Clockwise for increased extension assist.

Anti-Clockwise for reduced extension assist.

Important: Knee action should be smooth. This

knee is a low activity knee, so do not expect for

very rapid extension assist to occur. Excessive

spring tension could possibly affect knee friction

tension.

Be sure that the 5mm Hex Wrench Tube Clamp

Pinch Bolt torque is set to 16Nm.

8.3 SWING PHASE –Spring Extension Assist

Less More

Extension Assist

Fig. 3

Note that the screw is

inside the tube clamp.

(Screw accessed by

removing pylon from

knee unit tube clamp)

Resetting Friction to factory setting: Friction adjustment screw should be

reset to be flush with knee frame surface.

8 Knee Adjustment

8.4 Unlocked Knee Mode - Manual Lock Disable Procedure

Manual Lock Disable:

Lock mechanism-

• Push the locking lever (a) upwards and hold

it in this position (fig. 7)

• Lanyard can be removed by removing the

retainer screw with 2.5mm hex wrench.

• Secure locking lever (a) in this position by

turning the set screw (b) with a 2.5 mm hex

wrench clockwise. Apply thread locker!

a

b

Note: Lock should only be disabled by the prosthetist when patient

has been released to have the ability to control the prosthesis

without the need for the manual lock mechanism!

IMPORTANT: Set screw (b) should be tightened to a torque of 5 Nm

and secured with thread locker when finishing the prosthesis. Do not

over tighten! Use a torque wrench!

Note: Failure to adequately secure the set screw (b) when disabling

the locking lever (a), can result in loss of function of the knee and /

or makes it impossible to move the knee freely.

Note: If being used with the locking function, the disable set screw

(b) must not impede the function of the locking lever (a) and must

be secured with Loctite to rule out inadvertent loosening and

inadvertent function.

Setting the Dual Function Lanyard Handle on the Lanyard Cable:

Once the retainer screw is mounted with the star nut on the socket (refer to

“Attachment of Lanyard Handle Star Nut:” section).

Setting the Lanyard Cable length:

• Unlock knee and flex the prosthesis.

• set the length by pulling the slack out of the cable from the lock lever and

lanyard handle with the lanyard handle set in the “knee lock range” side of the

retainer tabs making sure that the lock is pushed down so it is not completely at

the maximum open range.

NOTE: We want to be sure that the lock will release by simply pulling up on the

lanyard handle till the retainer tabs are encountered, and that the knee will again

lock by releasing the lanyard handle.

• Set the lanyard handle cable retainer screw so it is snug, but not crushing the

cable as to make further adjustment easier.

• Confirm lock mechanism function by cycling the lanyard handle to assess that

the knee lock lever does lock in a completely extended position, and unlocks to

allow knee flexion in the “knee lock range” of the handle.

• Confirm lock mechanism stays temporarily unlocked by having prosthesis fully

extended/locked, and pull on the lanyard handle past the retainer tabs.

Prosthesis should be able to flex without holding lanyard handle.

• Readjust cable as needed.

• If used with the locking function, the locking lever or lanyard cable must not be

impeded by the cosmesis. The cable must run freely.

IMPORTANT! Secure the cable so that it cannot catch in grinding tools when

modifications are required to socket! Hazard potential!

The Dual Function Lanyard Handle

The Dual Function Lanyard Handle has the ability to keep the knee in either the

temporary unlocked or locked position.

Knee lock range

Knee unlock range

Retainer tabs

Cable retainer set

screw locations

Lanyard cable entry and

exit holes

The following is not the preferred method, but should the situation arise, this

technique could be utilized as a temporary method!

Attachment of Lanyard Handle Star Nut:

The Star Nut needs to be laminated into the socket. Depending on the nut supplied,

the hole should be burnished through, and then:

If the Star Nut is not threaded, drill out with 3mm drill bit and tap with 4mm tap.

If the Star Nut is threaded, chase threaded nut to clean thread with 4mm tap.

If for some reason, the Star Nut is not laminated into the socket, a relief can be

sanded into the interior of the socket so that the Star Nut sits completely into the

relief and does not protrude into the socket –The location and amount the Star

Nut needs to be flush is to be determined by the Prosthetist.

Drill a corresponding hole the same size as the star nut hole into the determined

location that the Lanyard Handle will be.

After relief is achieved, the Star Nut can be Bonded into position with Acrylic

Sealing Resin with fiber filler, or ST&G Glu-It Urethane Adhesive.

The Star Nut will need to be completely covered over, and the bonded area can

be covered with Masking Tape till the bond is totally cured.

Once cured, the hole should be burnished and chased with a tap, or drilled and

tapped –PLEASE REFER TO Attachment of Lanyard Handle Star Nut.

• Once the location is set, drill a corresponding

hole the same size as the Star Nut (3mm bit).

• Sand down the inside of the socket enough

to have the Star Nut lay flush with the socket

surface.

• You can locate the Star Nut with the

associated screw (if threaded, otherwise utilize

a rivet) that has petroleum jelly on the threads

and inserted through the hole and the Star Nut

very slightly screwed onto it (fig a).

• Use Urethane Adhesive, such as ST&G Glu-

It, or bonding resin with filler, and be sure to

cover the nut entirely with enough to have a

flush inner surface! (fig. b)

•Slightly tighten the screw to draw in the Star

Nut to the socket wall

Fig. a

Fig. b

Apply Masking tape over the whole area to enable a

smooth and relatively flat blended in surface –if the

screw sticks through the tape, that is ok. You want

to be sure that the Star Nut is completely covered

so it stays in place when the hole is either chased,

or drilled and tapped.

After Star Nut bonding has cured:

If Star Nut is threaded, burnish a through hole, and

chase the threads with a 4mm metric tap.

If not threaded, burnish a through hole, re-drill a

clean hole, and tap with a 4mm metric tap.

Apply thread locker to the stud threads, and screw

the stud into the hole and into the Star Nut.

After determining the length needed for the cable,

run through the lanyard handle.

NOTE: Cable can be run through a housing.

NOTE: Lanyard handle is a dual function type

that can hold knee unlocked when pulled past

the retainer screw.

After the length is established, insert the handle so

the pull tabs are on the distal aspect when inserted

onto the stud.

NOTE: Do not tighten set screw completely in

case length needs to be adjusted!

Once length is established, the set screw(s) can be

tightened down.

NOTE: Be sure to leave some extra cable in

case some length adjustment may need to be

done at a later time!

NOTE: Be sure knee lock can cycle adequately

before delivering to your patient.

Key Dimensions:

9 Technical Specification

Operating & Storage Temperature Range: -10˚C to 50˚C ( 14˚F to 122˚F)

Weight: 495g

Recommended Activity: K1, K2

Maximum User Weight: 125kg (275lbs)

Maximum flexion angle (without socket): 145 degrees

Proximal Alignment attachment: Pyramid

Distal Alignment attachment: 30mm Tube Clamp

Tube clamp torque setting: 16Nm

Build Height: 65mm

Swing Phase: Integrated Extension Spring

Stance Phase: Optional lock or weight activated

Brake Mechanism

Materials: Aluminum Alloy, Stainless Steel, Steel, Urethane

Build Height:

Component = 65mm

Knee Center to mid ball = 26mm

CE Conformity

This product meets the requirements of 93/42/EEC guidelines for medical products.

This product has been classified as a class I product according to the classification

criteria outlined in appendix IX of the guidelines. Please keep this manual in safe place

for future use.

10 Warranty

Warranted for 2 years from the date of invoice by ST&G.

The user should be aware that changes or modifications not approved will void the

warranty.

11 Liability

The manufacturer recommends using the device only under the specified conditions

and for the intended purposes. The device must be maintained according to the

instructions for use supplied with the device. The manufacturer is not liable for

damage caused by the component combinations that were not authorized by the

manufacturer.

ST&G USA Corporation

2691 Saturn Street, Brea, CA 92821, USA

Tel: 1-714-524-0663 Fax: 1-714-364-8113

L1324IFU Rev. A (05-09-18)

Table of contents

Other ST&G Medical Equipment manuals