10

Wireless Tag Reader Installation Guide

Standby Mode

In Standby Mode the WTR can be triggered by an opening or closing contact to generate

an LF Field for a 10 second interval. During this interval, tags in the LF Field are scanned

and the tag data transmitted to the RFID system.

•To select Standby Mode, sett the Options block Mode Switches OFF, ON, OFF

as shown in Figure 6 on page 8.

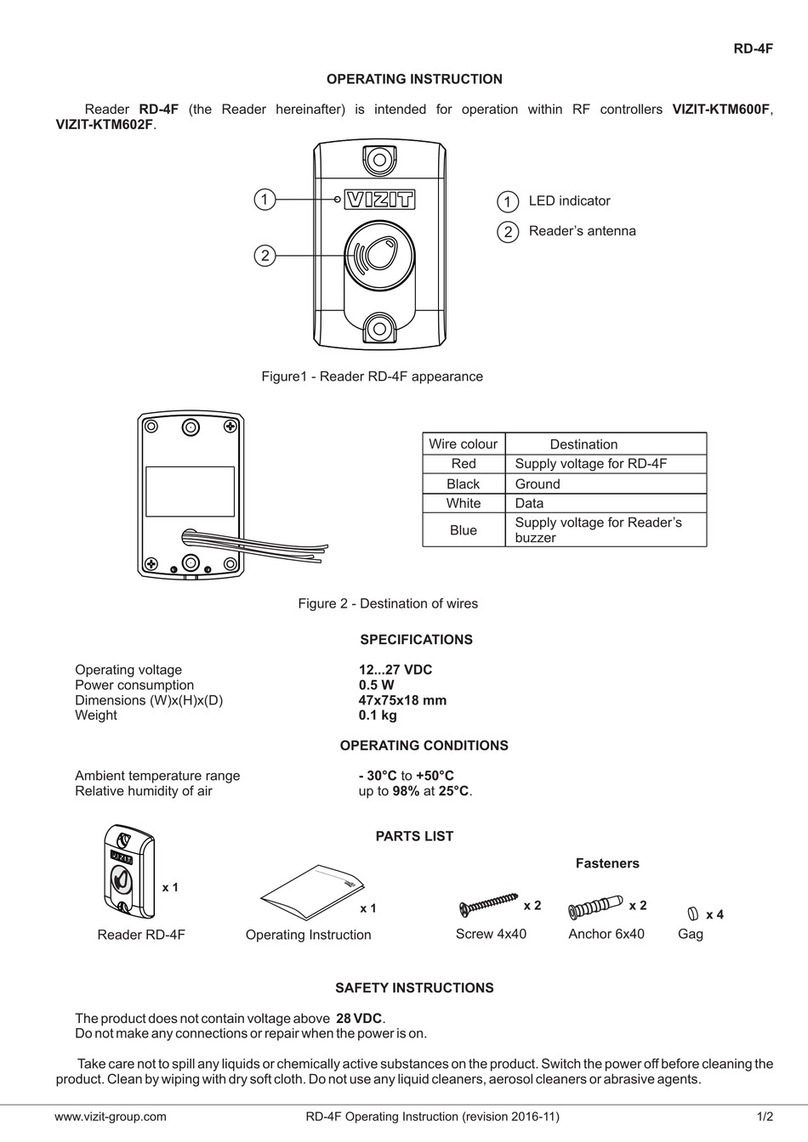

•To trigger Standby Mode, connect a switch across the input terminals of the

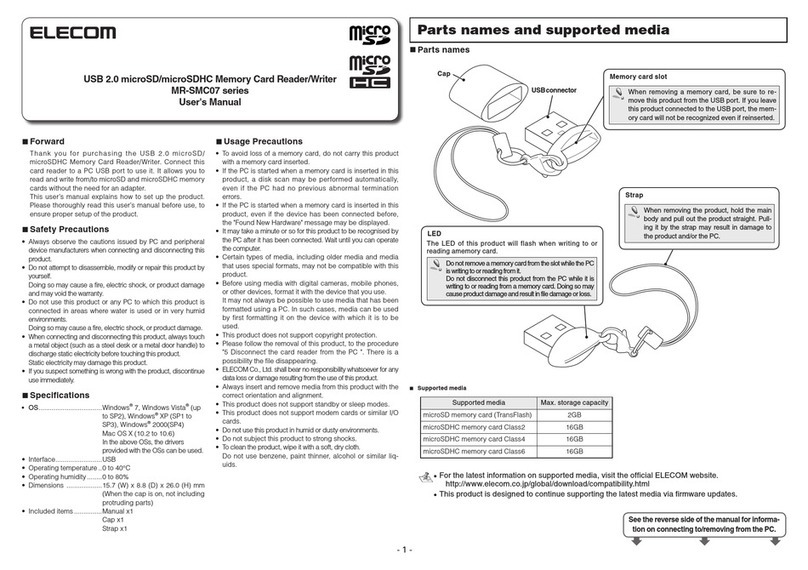

WTR 4 pin terminal block as shown in Figure 7 below.

Figure 7: Input Wiring

Using End Of Line Resistors in Standby Mode

In Standby Mode, the input can be configured to use EOL resistors. This configuration

provides input fault or tampering detection.

•To enable EOL resistor detection, move Switch 1 of the Options DIP switch to

the ON position. See Figure 6 on page 8.

An input with EOL resistors provides two fixed resistance values instead of open and

closed switch states. The WTR treats the transition from one resistance value to the other

as an opening, or as a closing switch. If EOL resistors are present and the WTR so config-

ured, the WTR remembers the input values resulting from the EOL resistors. If the

WTR detects an input value different from the EOL values, it transmits a unique mes-

sage. Please see “Troubleshooting” on page 12.

Input Edge Selection in Standby Mode

You can choose to trigger the LF Field on either a rising edge (opening switch) or a falling

edge (closing switch). See Figure 7 above for the switch wiring diagram.

Edge selection is controlled by switch 2 in the Options DIP Switch shown in Figure 6 on

page 8. See Step 2 below.

To configure Standby Mode options:

1 Connect the input wires as shown in Figure 7above.

2 Set switch 2 of the Options DIP switch block to the desired position.

2.a To trigger the LF Field on by a rising edge, or by an opening switch,

move Switch 2 (edge selection switch) to the ON position.

2.b To trigger the LF Field on by a falling edge, or by a closing switch,

move Switch 2 (edge selection switch) to the OFF position.