© 2005, THE STANLEY WORKS. ALL RIGHTS RESERVED.

204027

Rev. C, 11/9/05

1 of 31

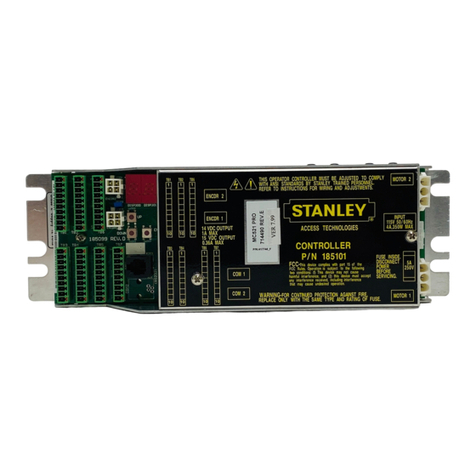

Stanley Access Technologies

TABLE OF CONTENTS

1. PURPOSE......................................................................................................................................................2

1.1 Discussion....................................................................................................................................................2

1.2 Applicability................................................................................................................................................2

1.3 Features and Functions................................................................................................................................2

2. PRECAUTIONS............................................................................................................................................3

3. WIRING INSTRUCTIONS ..........................................................................................................................3

3.1 Evaluating Power Requirements..................................................................................................................3

3.2 Connecting Main Power Wiring..................................................................................................................3

3.3 Connecting Breakout Status Signal Wiring (Magic-Swing Operators).......................................................4

3.4 Connecting Breakout Status Signal Wiring (Magic-Force Operators)........................................................6

3.5 Wiring the Operator Switch Module (Magic-Force Operators) ..................................................................8

3.6 Wiring the Operator for Required Handing (Magic-Force Operators)........................................................9

3.7 Wiring the “ON/OFF/HOLD OPEN” Switch and Power Switch................................................................9

3.8 Wiring the Door Activation or Safety Device.............................................................................................9

3.9 Wiring Sentrex

3

.........................................................................................................................................10

3.10 Wiring Bodyguard...................................................................................................................................10

3.11 Wiring Superscan ....................................................................................................................................10

3.12 Wiring Holding Beam .............................................................................................................................10

3.13 Wiring the Cycle Counter........................................................................................................................11

4. TUNE-IN INSTRUCTIONS.......................................................................................................................12

4.1 Initial Tune-In Settings..............................................................................................................................12

4.2 Tuning In the MC521 Controller Using the Palm Pilot.............................................................................12

4.3 Tuning In the MC521 Controller Using the Controller Pushbuttons.........................................................16

4.4 Final Tune-In Adjustments........................................................................................................................20

5. SPARE PARTS LIST..................................................................................................................................21

ATTACHMENTS

Attachment 1, Breakout Status Wiring on Magic-Swing Operators...................................................................22

Attachment 2, Magic-Force Wiring Diagram—MC521.....................................................................................23

Attachment 3, Magic-Force Wiring Diagram—MC521 With Power Close Option...........................................24

Attachment 4, Magic-Swing Wiring Diagram—MC521....................................................................................25

Attachment 5, Terminal Block Connections—TB1 Through TB5.....................................................................26

Attachment 6, MC521 Controller Controls and Indicators.................................................................................27

Attachment 7, ANSI/BHMA and UL Compliance Requirements for Swinging and Folding Doors.................29

Attachment 8, Palm Troubleshooting Aid—Swing/Bifold.................................................................................31