Microcentrifuge 24 · Manual · 5

Original instruction _____________________________________________________________________________5 – 33

Originalbetriebsanleitung ______________________________________________________________________35 – 63

Instruction initiale _____________________________________________________________________________65 – 93

Instruczione originale _________________________________________________________________________95 – 123

Certicates _______________________________________________________________________________________3 – 4

1 Operating instructions _________________________________________________________________________ 7

1.1 Usingthismanual ________________________________________________________________________________ 7

1.2 Dangersymbolsanddangerlevels ____________________________________________________________________ 7

1.2.1 Dangersymbols _____________________________________________________________________________ 7

1.2.2 Dangerlevels_______________________________________________________________________________ 7

1.3 Symbolsused ___________________________________________________________________________________ 7

1.4 Abbreviationsused _______________________________________________________________________________ 7

2 Safety ________________________________________________________________________________________ 8

2.1 Intendeduse ____________________________________________________________________________________ 8

2.2 Userprole _____________________________________________________________________________________ 8

2.3 Informationonproductliability _______________________________________________________________________ 8

2.4 Applicationlimits_________________________________________________________________________________ 8

2.4.1 DeclarationconcerningtheATEXdirective(2014/34/EU) ________________________________________________ 8

2.5 Warningsforintendeduse __________________________________________________________________________ 9

2.5.1 Personalinjuryordamagetodevice_______________________________________________________________ 9

2.5.2 Incorrecthandlingofthecentrifuge ______________________________________________________________ 10

2.5.3 Incorrecthandlingoftherotors _________________________________________________________________ 10

2.5.4 Extremestrainonthecentrifugationtubes _________________________________________________________ 11

2.6 Safetyinstructionsondeviceandaccessories ____________________________________________________________ 11

3 Product description ____________________________________________________________________________ 12

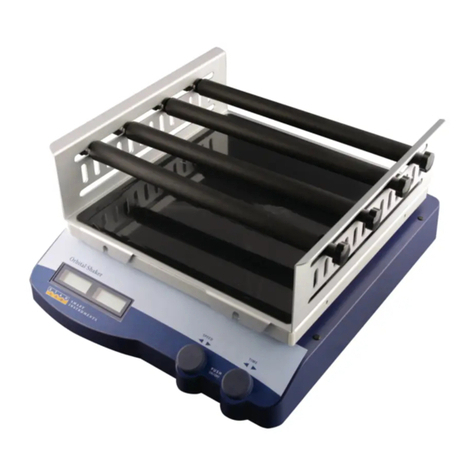

3.1 Productoverview ________________________________________________________________________________ 12

3.2 Deliverypackage ________________________________________________________________________________ 12

3.3 Features ______________________________________________________________________________________ 13

3.4 Nameplate ____________________________________________________________________________________ 13

4 Installation ___________________________________________________________________________________ 14

4.1 Selectingthelocation_____________________________________________________________________________ 14

4.2 Preparinginstallation _____________________________________________________________________________ 15

4.3 Installingtheinstrument___________________________________________________________________________ 15

5 Operation ____________________________________________________________________________________ 16

5.1 Operatingcontrols _______________________________________________________________________________ 16

5.2 Switchingonthecentrifuge ________________________________________________________________________ 17

5.3 Replacingtherotor ______________________________________________________________________________ 17

5.3.1 Insertingtherotor __________________________________________________________________________ 17

5.3.2 Removingtherotor _________________________________________________________________________ 17

5.4 Closingthecentrifugelid __________________________________________________________________________ 17

5.5 Preparingforcentrifugation ________________________________________________________________________ 18

5.5.1 Loadingtherotor ___________________________________________________________________________ 18

5.5.2 Closingtherotorlid _________________________________________________________________________ 18

5.5.3 Closingtherotorlid(aerosol-tightcentrifugation)____________________________________________________ 19

5.6 Centrifugation __________________________________________________________________________________ 19

5.6.1 Centrifugationwithtimesetting ________________________________________________________________ 19

5.6.2 Endofcentrifugation ________________________________________________________________________ 20

5.6.3 Centrifugingincontinuousoperation_____________________________________________________________ 20

5.6.4 Shortruncentrifugation ______________________________________________________________________ 20

5.6.5 Settingthealarmvolume _____________________________________________________________________ 20

5.7 Aerosol-tightcentrifugation ________________________________________________________________________ 21

5.8 Switchingoffthecentrifuge ________________________________________________________________________ 21

Table of contents

English