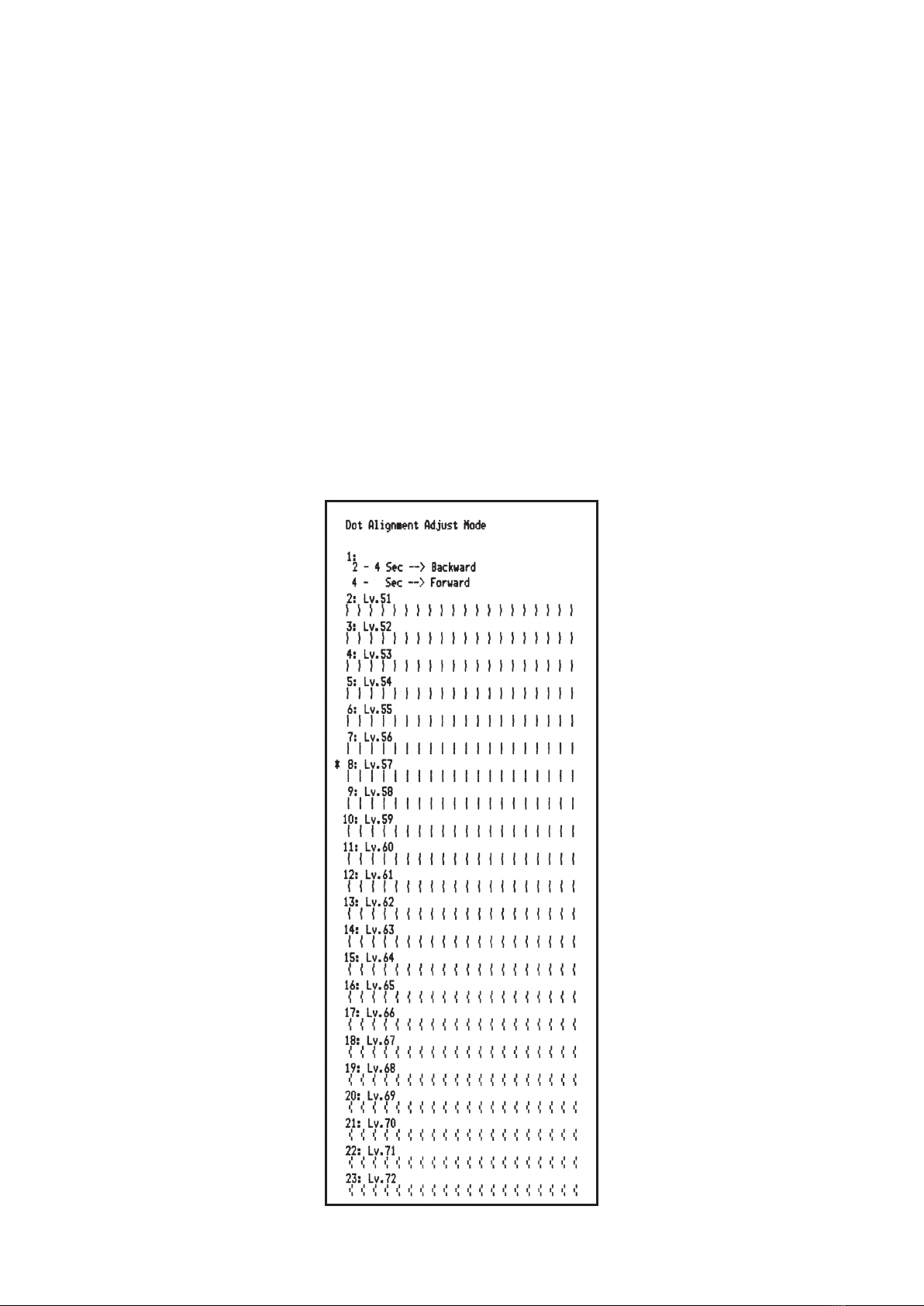

To adjust, select the adjustment pattern with the smallest amount of discrepancy in the dots in coming and going

directions by looking at the print results. To do so, count from the top line to the line of the desired pattern,

and press the FEED switch for that number of times. When doing so, when you get to the number of times that

corresponds to the desired line number, continue to press the FEED switch (approximately 2 seconds) until the

buzzer rings for a long time to set the new value.

< For example, to set the eighth line from the top, press the FEED switch seven times, and on the eighth time,

hold down the FEED switch (for approx. 2 seconds) until the switch buzzer rings. >

If you press the FEED switch up to 23 times, which is the switch setting range, the buzzer will ring once. If you

go beyond that the buzzer will issue a warning by repeatedly ringing.

If you do not see a pattern in the adjustment patterns that you can use, you can use the Backward or Forward

operations below to change the settings of the dot correction and reprint the pattern, then retry the operations

from #3. above.

Backward:

Hold down the FEED switch for two to four seconds. e buzzer will ring and an adjustment pattern

corrected more to the le than the outward pass, and more to the right than return pass than the currently

printed pattern.

Forward:

Hold down the FEED switch for more than four seconds. e buzzer will ring twice and an adjustment

pattern corrected more to the right than the outward pass, and more to the le than return pass than the

currently printed pattern.

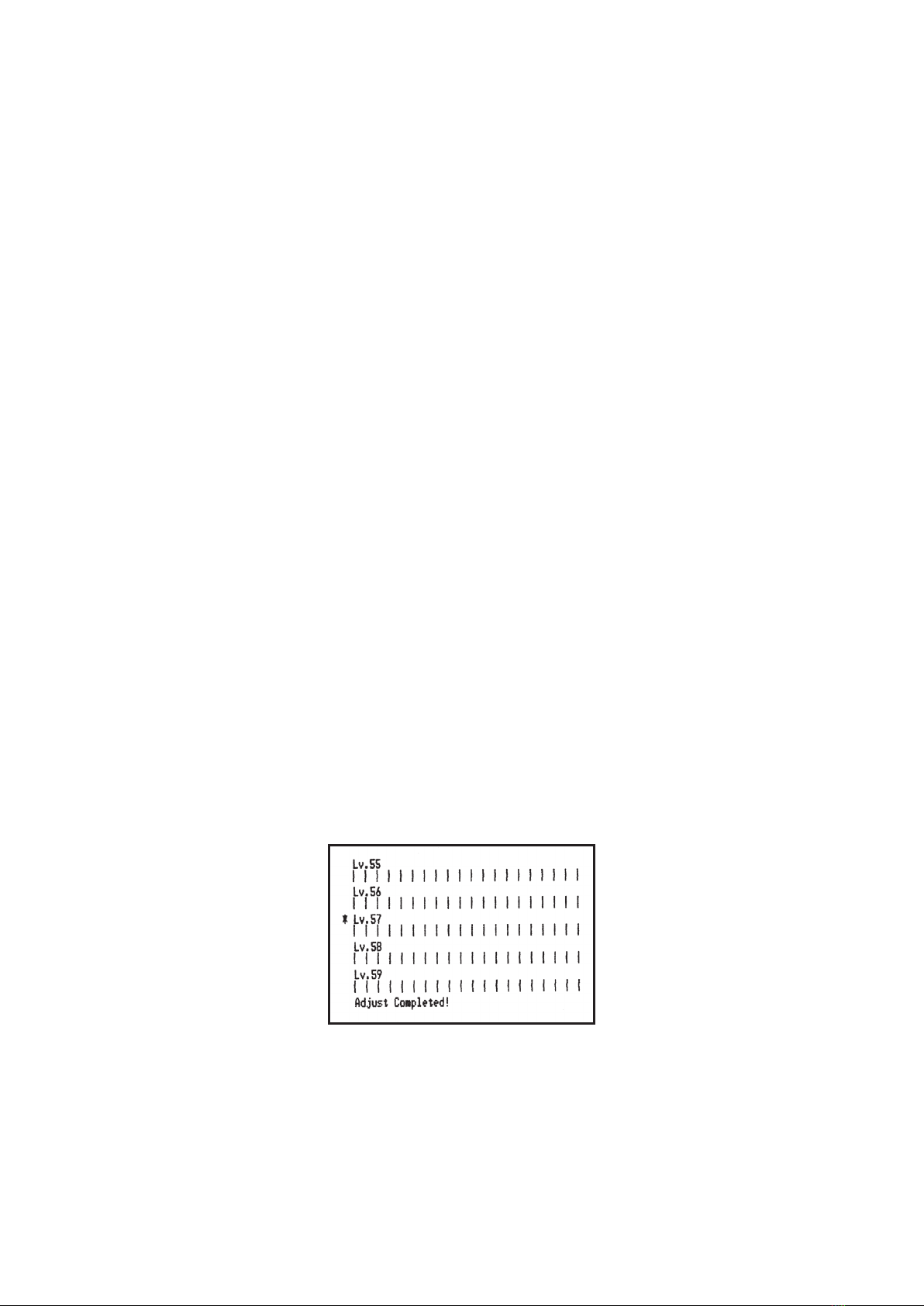

Aer making the setting, the printer will then write that new setting to the non-volatile memory.Below that, the

printer will print the set dot adjustment pattern and the message “Setting Completed.”

Note: e printer will write the setting to the non-volatile memory between the time the long buzzer has

rung when you have determined the setting and printing of the message has started. If you turn the

power o during that time, the dot adjustment setting and all memory switch settings will be initialized.

Absolutely do not turn the power o.

6.

7.

8.

e buzzer will ring once, for a long time, and the printer will automatically be reset.

is ends the printing position adjustment mode.

9.

- 7 -