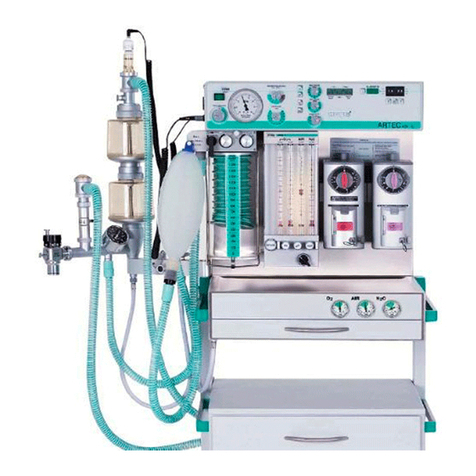

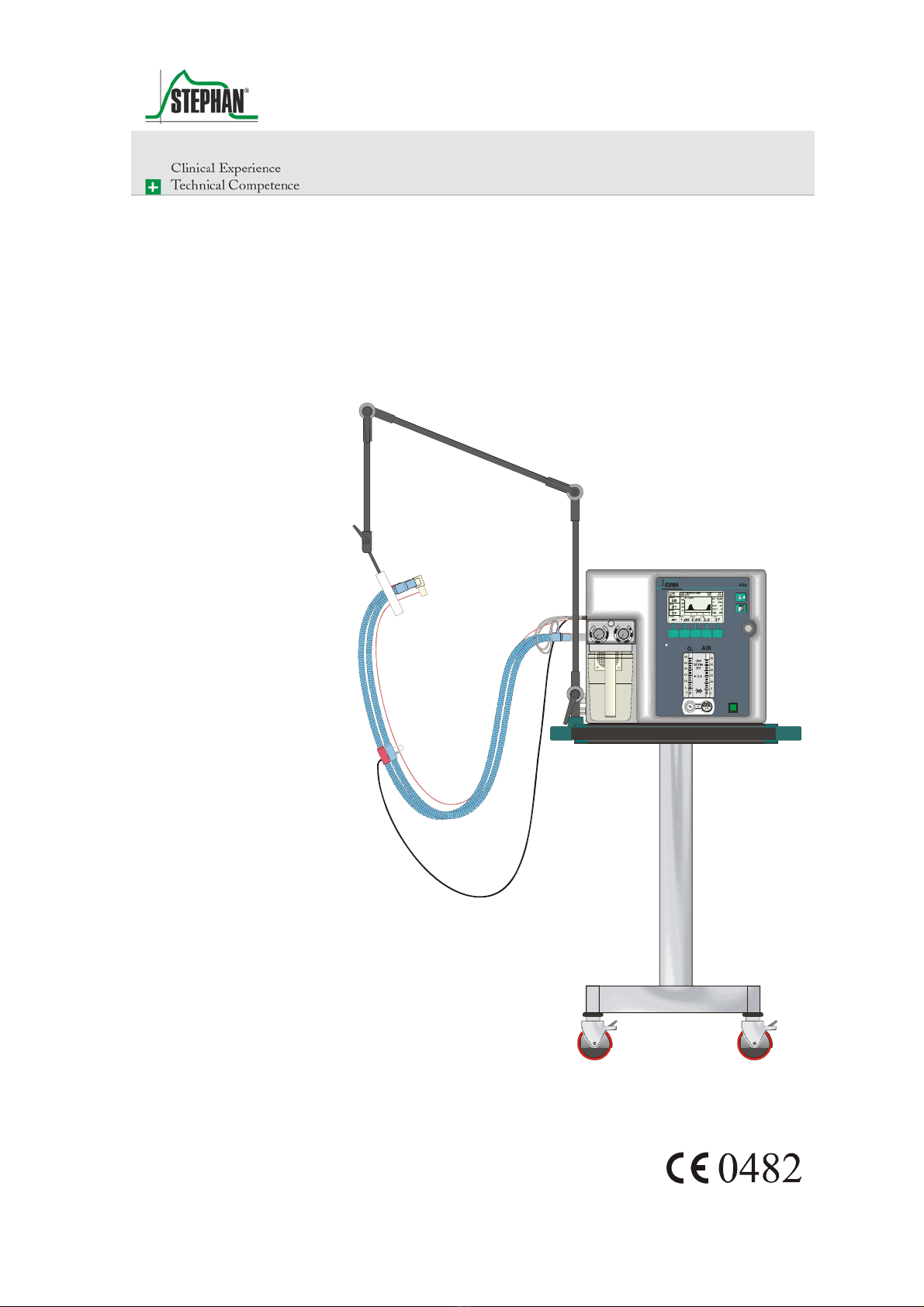

Stephan Alia Operating instructions

Alia

Ventilator

30

25

20

15

10

5

2

30

25

20

15

10

5

2

Med.

AIR

Alia

Steril es aqua dest.

max.

INSPI RATIONS- DRUCKEXPIRATIONS-DRUCK

mbar

PLATEAU

PEEP

40

1

20

15

50

5

60

10

30

0

AIR

O

2

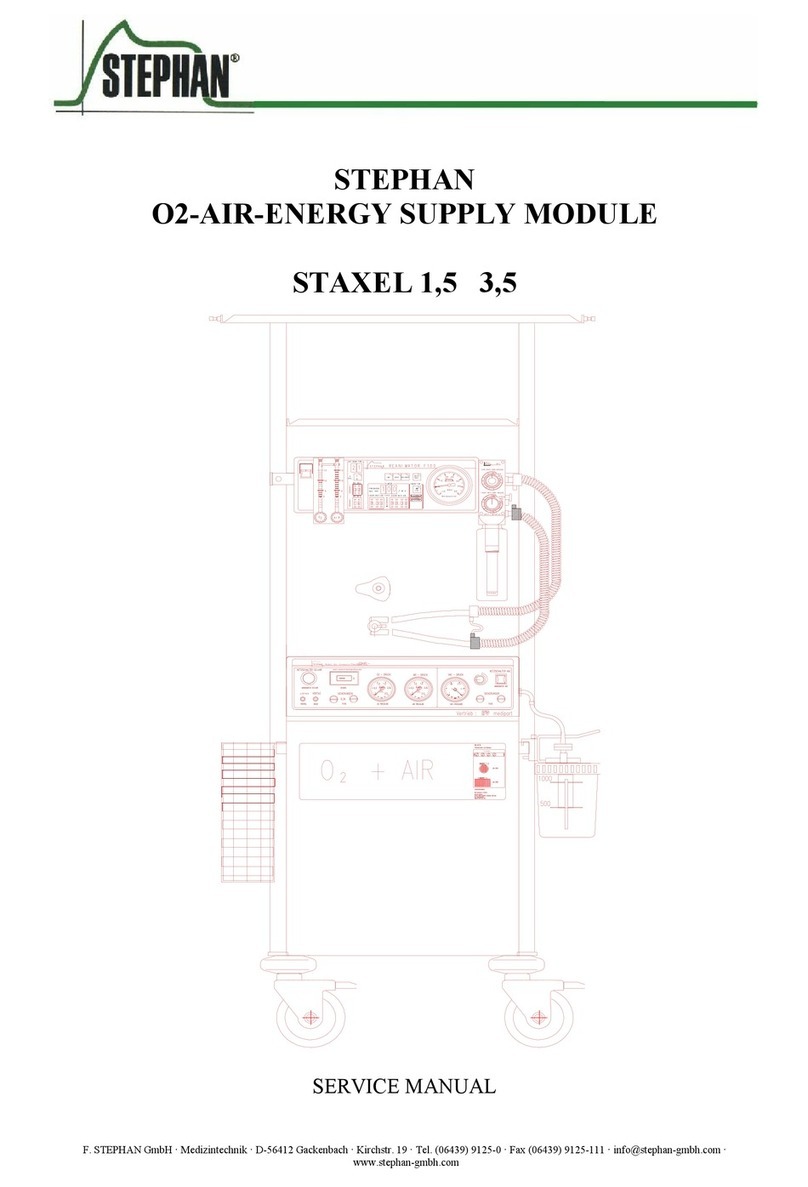

Service Instructions

Preface

2 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

These service instructions aim to provide assistance for troubleshooting

activities with the ALIA ventilator.

It contains drawings, circuit diagrams and parts lists for a better

understanding of how the ventilator works.

Service and maintenance work can be carried out to the peripheral

components of the ALIA ventilator. Repairs to the electronic control of

the ventilator can only be carried out by F. STEPHAN GMBH or authorized

service partners. Otherwise the entire electronic systems in the ALIA

ventilator require no maintenance.

Every step of a specific procedure should be read through carefully

before starting to service the unit. Always only use the correct tools and

the stated measuring equipment. Failure to follow the instructions and/or

recommendations in these service instructions can result in the device not

working properly or cause damage to the device.

Only use original spare parts by F. STEPHAN GMBH as contained in the

spare parts list (see chapter 10 p. 75).

These service instructions do not replace the operating instructions.

Handling the device in any way presumes an exact knowledge and

compliance with the operating instructions. The device is only intended

for the described purpose.

Service instructions

Note

F. Stephan GmbH

- Medizintechnik -

Kirchstrasse 19

56412 Gackenbach

Subject to technical alterations.

as of: Januar 2006

version: V1.0

®

Contents

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 3

Contents

Contents .....................................................................................................3

1General information...........................................................................5

1.1 Device name and manufacturer...............................................5

1.2 Maintenance and repairs..........................................................5

1.3 Abbreviations and definitions..................................................6

1.4 Safety instructions ...................................................................7

2Mechanical structure..........................................................................9

3Components and functions...............................................................15

3.1 Electronic controls.................................................................16

3.1.1 Sensor board..............................................................16

3.1.2 Controller board ........................................................20

3.1.3 Power Distribution Unit PDU ...................................22

3.2 Power supply .........................................................................25

3.2.1 Power supply unit......................................................26

3.2.2 Rechargeable battery.................................................27

3.2.3 Inverter......................................................................28

3.3 Gas supply .............................................................................29

3.3.1 Oxygen supply...........................................................30

3.3.2 Compressed air supply ..............................................31

3.4 Fresh gas reservoir.................................................................32

3.5 Patient part.............................................................................36

3.5.1 PEEP valve................................................................37

3.5.2 Plateau valve .............................................................38

3.5.3 Breathing gas humidifier...........................................38

3.6 Patient tube system................................................................40

3.6.1 Patient tube system for adults....................................40

3.6.2 Patient tube system for children................................42

3.6.3 Temperature sensor for patient tube system..............43

3.6.4 Pneumotachograph type D........................................44

3.6.5 Pneumotachograph Typ C.........................................44

4Serial interface.................................................................................45

4.1 Commands.............................................................................46

Contents

4 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

4.2 Setting and querying the date and time..................................47

4.3 Output of measured values ....................................................48

5Tools and aids..................................................................................51

6Checks and maintenance..................................................................53

6.1 Every time before starting the device....................................53

6.2 Weekly...................................................................................54

6.3 ½ yearly.................................................................................55

6.3.1 ½ yearly maintenance basic unit ...............................55

6.3.2 Maintenance of the patient part.................................59

6.4 Safety checks.........................................................................60

6.4.1 Test report .................................................................61

7Troubleshooting...............................................................................69

8Annex...............................................................................................71

9List of illustrations...........................................................................73

10 List of tables.....................................................................................75

11 Place for your Notes.........................................................................77

®

1 General information

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 5

1 General information

1.1 Device name and manufacturer

ALIA

F. STEPHAN GMBH

- MEDIZINTECHNIK -

KIRCHSTRASSE 19

56412 GACKENBACH

(+)49 (6439) 9125 – 0

(+)49 (6439) 9125 – 111

www.stephan-gmbh.com

1.2 Maintenance and repairs

In the interests of device safety, maintenance of the ALIA ventilator

should be carried out every six months.

Safety checks must be carried out every six months.

Maintenance must be carried out by the authorized customer service of F.

STEPHAN GMBH.

Only spare parts from F. STEPHAN GMBH must be used during

maintenance.

Clean and disinfect the device respectively device parts every time before

maintenance, even when returning the device for repairs.

Device name

Manufacturer

Caution!

1 General information

6 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

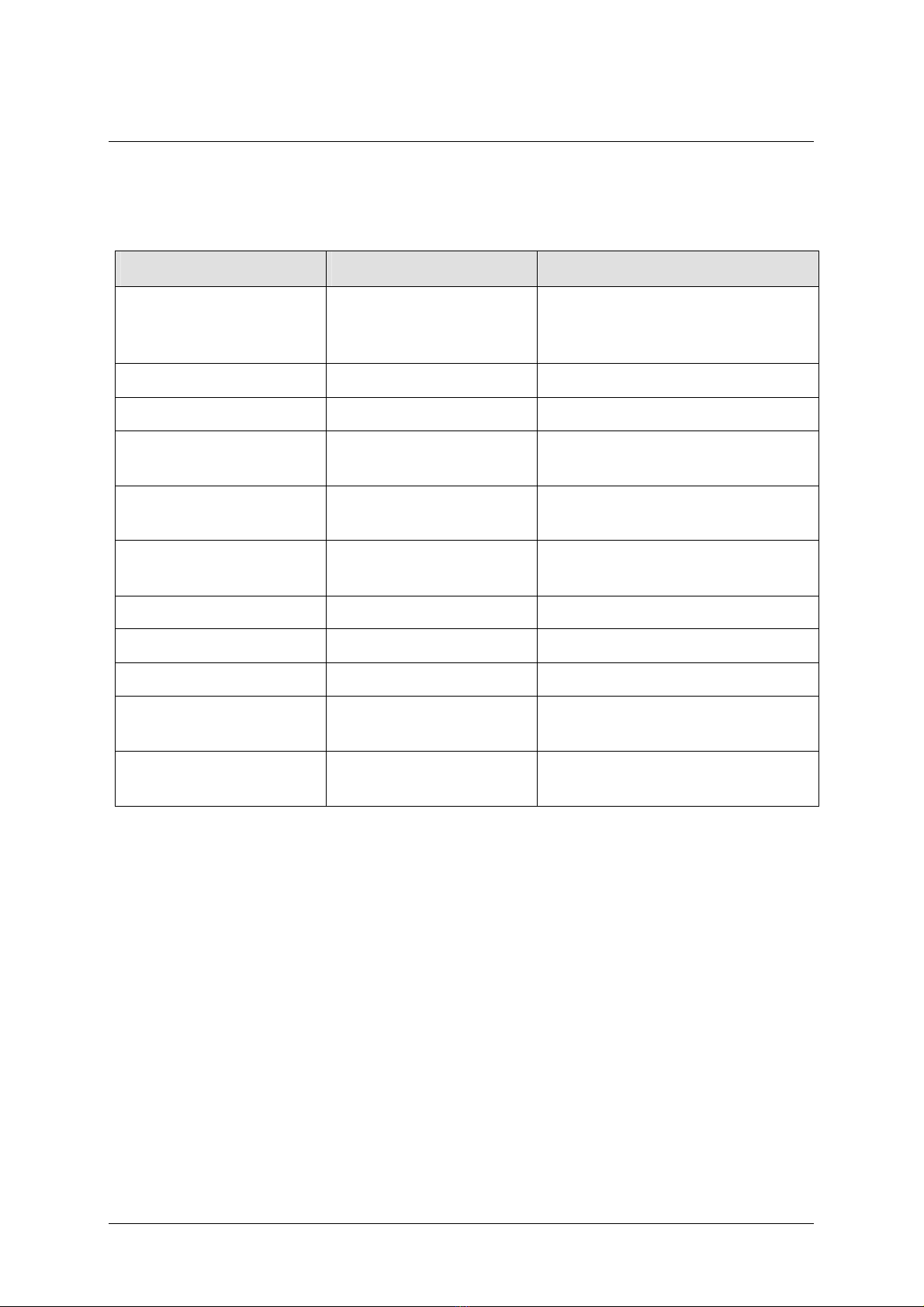

1.3 Abbreviations and definitions

Abbreviation Definition Meaning

%h Percentage hours Service life of the oxygen sensor in

hours depending on the oxygen

concentration

AIR Medical compressed air

aqua dest. Aqua destilata (lat.) Distilled, demineralized water

bar Unit of measurement for compressed

air

Batt Rechargeable battery Device for storing electrical energy in

the form of chemical energy

cmH2O Unit of measurement for compressed

air = mbar

FiO2Inspired oxygen concentration

IGR Incremental transducer Push button and knob

PDU Power distribution unit Power Distribution Unit

PEEP Positive end expiratory

pressure

V Volt Unit of measurement for electrical

voltage

Table 1: Abbreviations and definitions

®

1 General information

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 7

1.4 Safety instructions

Refers to instructions drawing attention to important facts.

The following safety instructions appear at relevant points in the service

instructions and must always be heeded.

Refers to warnings which, if not heeded, can result in malfunctions,

damage or defects in the device, which can possibly also put the patient at

danger.

Refers to precautions which, if not heeded, can result in damage to the

device and its accessories.

Warning

Caution

®

2 Mechanical structure

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 9

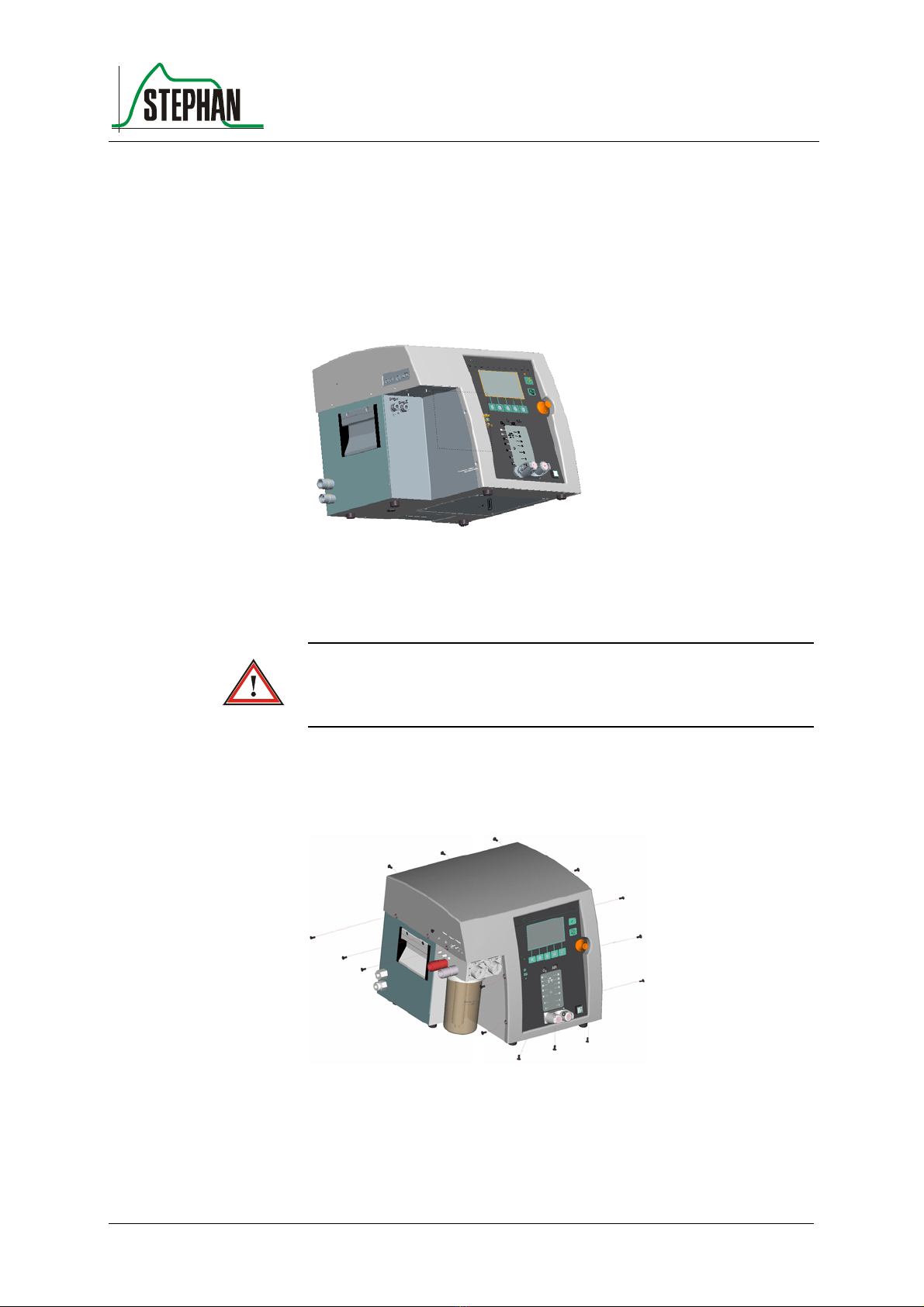

2 Mechanical structure

The ALIA ventilator consists of a basic housing and a front housing. The

front housing also acts as the device cover.

Fig. 1: Basic and front housing: general

Remove the front housing to open the ALIA ventilator.

Risk of an electric shock

Disconnect from the power source before opening the housing!

The front housing is screwed to the frame with 15 countersunk screws

M4x10. The 9 screws used on the side of the device are also fitted with

rosettes to prevent damage to the plastic front housing when tightening

the screws.

Fig. 1: Opening the housing

The front housing can now be hinged open to the front.

Front housing

Warning

2 Mechanical structure

10 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

Fig. 2: Hinging open the housing

Before hinging open the front housing, ensure that the connectors for the

tube heating, the temperature sensors and the pneumotachograph have

been disconnected.

The plastic front housing is coated with an EMC varnish on the inside. It

contains the input periphery of the ALIA ventilator.

This input periphery consists of touch buttons, the IGR (push/turn knob),

the LCD display, the controller board, the double flowmeter ON/OFF

switch on the front pane.

Fig. 3: Front housing with input periphery

1 double flow meter

2 FiO2and flow adjustment

1

2

®

2 Mechanical structure

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 11

The frame of the ALIA ventilator and its reinforcement bar, fastening

bracket and panels consist of 2 mm thick powder-coated aluminium. The

bottom of the housing has a cut-out for the rechargeable battery.

Fig. 4: Basic housing

1 Reinforcement bar

2 Cut-out for rechargeable battery

3 Rechargeable battery

The intake filter and oxygen sensor are located behind a service flap on

the back of the ventilator.

To open the service flap, loosen the knurled screws by turning counter-

clockwise.

The oxygen sensor is located on the left next to the intake filter. It is

screwed into the connection block.

It can be removed by turning counter-clockwise.

The electrical connection between the oxygen sensor and device consists

of a 2-pin AMP connector.

Basic housing

Service flap

2

3

1

2 Mechanical structure

12 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

Fig. 5: Service flap

1 Intake filter 3 Oxygen sensor

2 Service flap

On the left and right side wall there are recessed handles for carrying the

ALIA ventilator.

Some of the electronic controls and the power supply are accommodated

inside the ventilator.

Fig. 6: Electronic components

1 Power supply 3 Electronic controls

2 Cold device connector combination

2

1

3

1

2

3

®

2 Mechanical structure

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 13

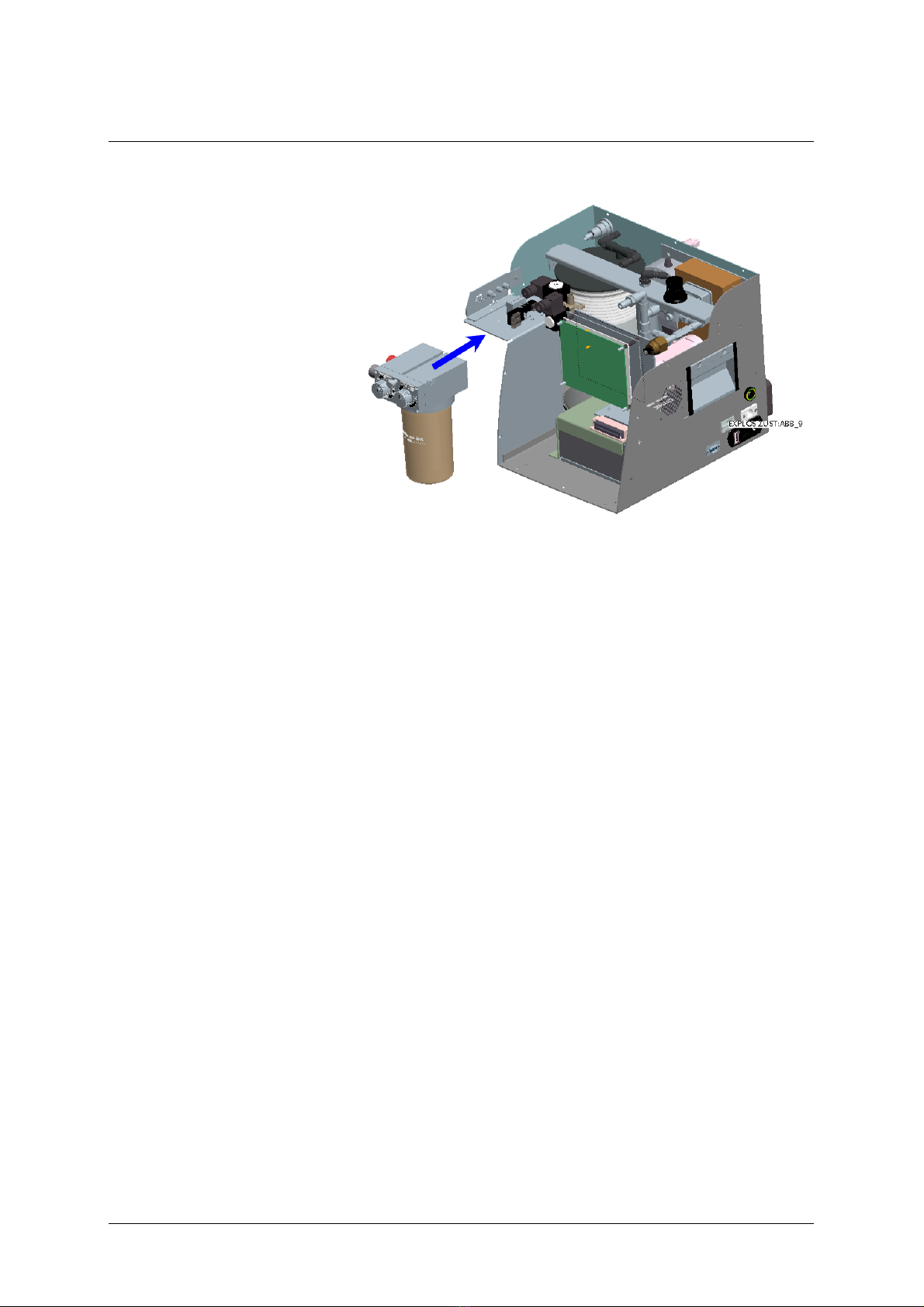

The entire pneumatic system is accommodated in the basic housing. Only

the double flowmeter is in the front housing.

The pneumatic system consists of the compressor, the fresh gas reservoir

and its control valves. The pressure switches for detecting the intake

pressure are firmly integrated in the pneumatic system

Fig. 7: pneumatic components

1 compressor 2 fresh gas reservoir

3 gas inlets 4 service flap

The patient part is connected to the basic device from the front.

The patient part is held in position by the guide rail.

2

3

4

1

2 Mechanical structure

14 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

Fig. 8: Inserting the patient part

3 Components and functions

16 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

3.1 Electronic controls

The ALIA ventilator uses an 8-bit micro controller. This controls the

sensors and actuators in the system.

In addition to these components, the unit also has electronic components

which provide the electrical power supply.

These consist of a power supply unit and a device for bridging any power

failure. In the event of a power failure, the device switches over to battery

operation and regulates the battery charging process.

The sensor board generates voltages of ±15V and -5V, and the controller

board generates + 5V.

3.1.1 Sensor board

The sensor board acts as interface for triggering the actuators (control of

the fresh gas reservoir and the expiration valve) and for registering the

measured data (pressure and differential pressure sensors, AD converter).

An SPI bus system provides the link to the micro controller. This

simplifies linking the various components in terms of both hardware and

software.

The following illustration shows the components on the sensor board.

Abb. 2: Sensor board

®

3 Components and functions

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 17

The main task of the sensor board is to convert the analog signals.

Rechargeable battery voltage

"DC_good"signal

On/off signal

Input voltage

12 V (for heating and valves)

Inspired pressure

Expired pressure

Flow sensor differential pressure

Oxygen sensor cell voltage

Heating

Valves

"Batt_enable"

The power supply for the electronic components is generated by a

DC/DC converter on the sensor board, generating +15V, -5V and -15V.

The input signals for On/Off, DC_good, input voltage and "Batt_enable"

are sent to the SPI bus by a slide register. The input signals for pressure,

flow, O2and battery voltage are sent to the SPI bus following

amplification and conversion via an 8-channel AD/12 bit converter.

The AD converter is equipped with protective diodes (max. 5V) on the

input side.

A serial chargeable slide register with power amplifier is used for

triggering the heating and the valves, via the SPI bus.

The respiratory pressure is measured at the inspiration fitting of the

patient part. The pressure present here is conveyed via a tube to the

pressure sensors (respiratory pressure).

For safety reasons, two pressure sensors are provided for measuring the

respiratory pressure.

The differential pressure developing over the resistance body of the PNT

head is used for measurement of the volume flow. This differential

pressure is conveyed via two tubes to the differential pressure sensor.

Main tas

k

Voltage signals (input):

Voltage signals

(output):

Pressure sensors

3 Components and functions

18 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

Fig. 10: PNT and pressure fitting

1 hose heating socket

2 temperature sensor socket

4 electrical connection magnetic

coil

3 pneumotachograph connector 5 pressure fittings

6 water bath connectors

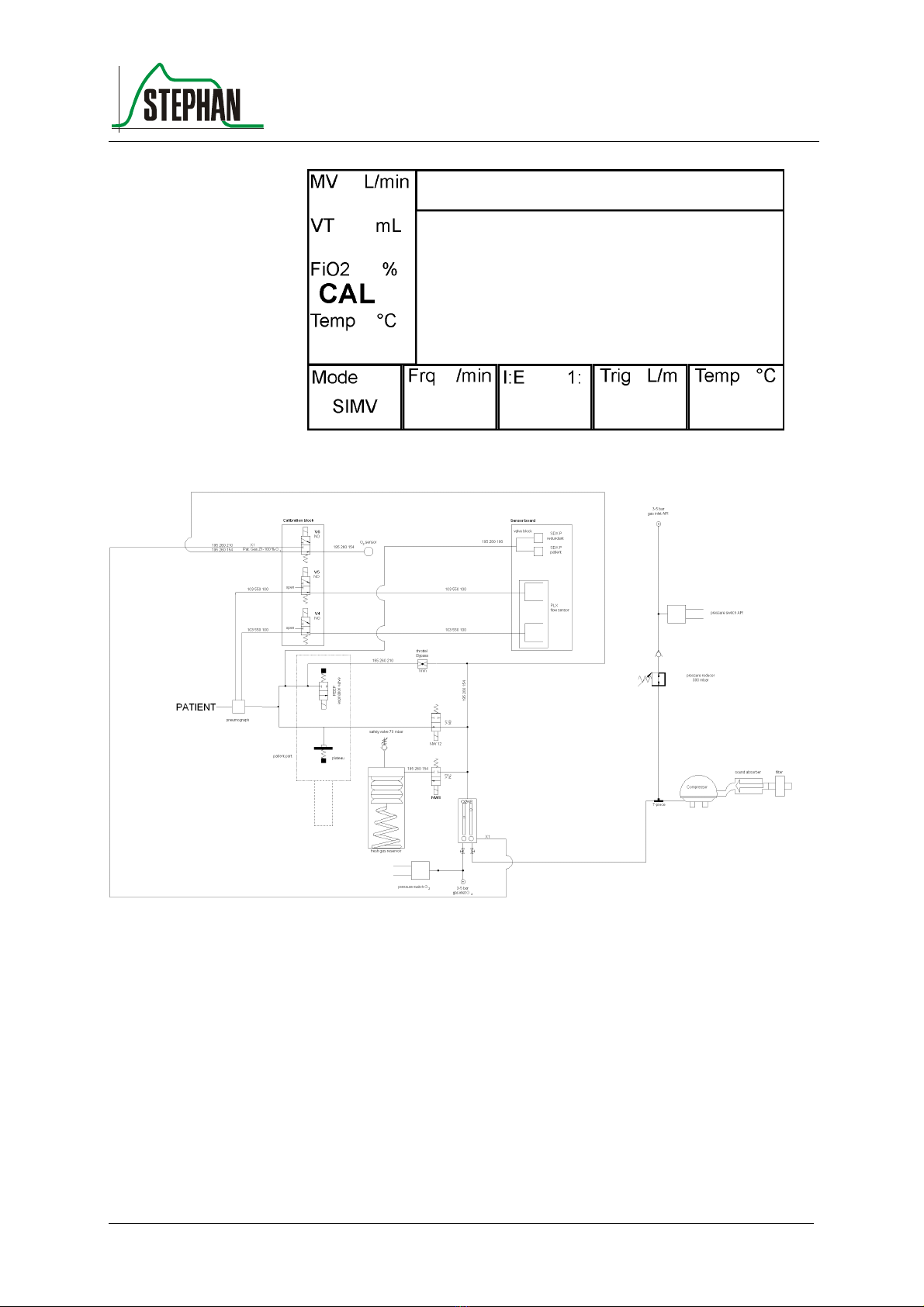

The calibration block allows for offset calibration of the differential

pressure sensor and the oxygen sensor.

The interposed solenoids V4 and V5 switch the measuring lines of the

differential pressure sensor against the atmosphere. The valves are

switched at exactly the same time. The value measured in this way

corresponds to a flow of 0 l/min.

FiO2measurement is carried out using an electrochemical cell (fuel cell).

This oxygen sensor generates a voltage depending on the prevailing

oxygen concentration. The voltage is then converted electronically into a

corresponding signal.

To calibrate the oxygen sensor, compressed air ( 21% O2) is blown

against it via solenoid V6. During this procedure, the display shows

"CAL" in the window of the FiO2value. After completing calibration, the

valve switches the oxygen sensor back to the output of the double

flowmeter.

Calibration bloc

k

FiO2 measurement

3

6

2

4

5

1

®

3 Components and functions

©F. Stephan GmbH SA-112-0106V1.0-WEM-GB 19

Fig. 11: Display showing 'CAL'

Fig. 12: Pneumatic function diagram

3 Components and functions

20 SA-112-0106V1.0-WEM-GB ©F. Stephan GmbH

3.1.2 Controller board

Fig. 13: Controller board

1 PDU board 2 controller board

Various functional groups are accommodated on the controller board.

The figure shows the functional groups for the user interface, CPU and

interfaces.

The user interface consists of the keyboard, display (LCD) and LEDs as

input and output units for regular handling of the system. The controller

board also contains the alarm system for indicating alarm statuses.

The digital interfaces for triggering the actuators and reading the sensors

(via the sensor board) are integrated on the controller board.

1

2

Table of contents

Other Stephan Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual