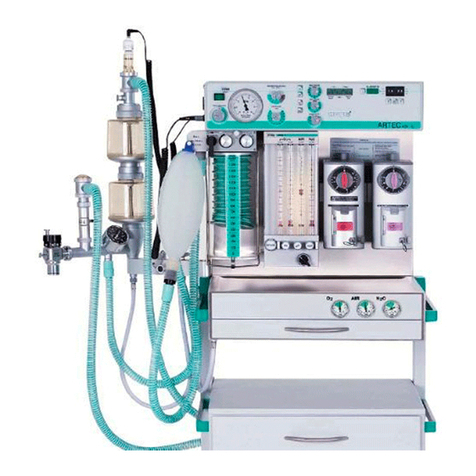

Operating Instructions Artec

5

1 General Information

The Medical Equipment Regulations (MedGV), and the law on technical medical working

materials (MPBetreibV) stipulate that the attention of the operator must be drawn to the

following:

The operation of the Unit must be carried out only by qualified personnel. Exact knowledge

and understanding of the Operating Instructions is a pre-conditioned for operation.

Use of the equipment is solely for that as stipulated in the Operating Instructions.

Inspections and servicing must be duly entered in the Logbook of the Unit. The Equipment

must be inspected at regular intervals by qualified personnel only.

F.Stephan GmbH stipulates a half-yearly inspection and maintenance by one of its

authorized Service Technicians.

Before each use of the unit, a complete function test of the unit must be carried out.

In the case on medico.technical devices with electrical connection, the standards of

particular VDE 0751 and IEC 601 must be closely complied with. According to these

standards, such devices may only be set up and put into operation by the manufacturer or

his expressedly authorized technician or dealership.

Unit equipped with a pressure reducer should undergo a basic overhaul at least every 5

years for reasons of safety.

An emergency ventilation system (e.g. Ambu-Bag) must always be in close proximity of

the unit.

F. Stephan shall assume no responsibility or liability for any damage or defects arising

from non-observance of the above-mentioned information.