12 13

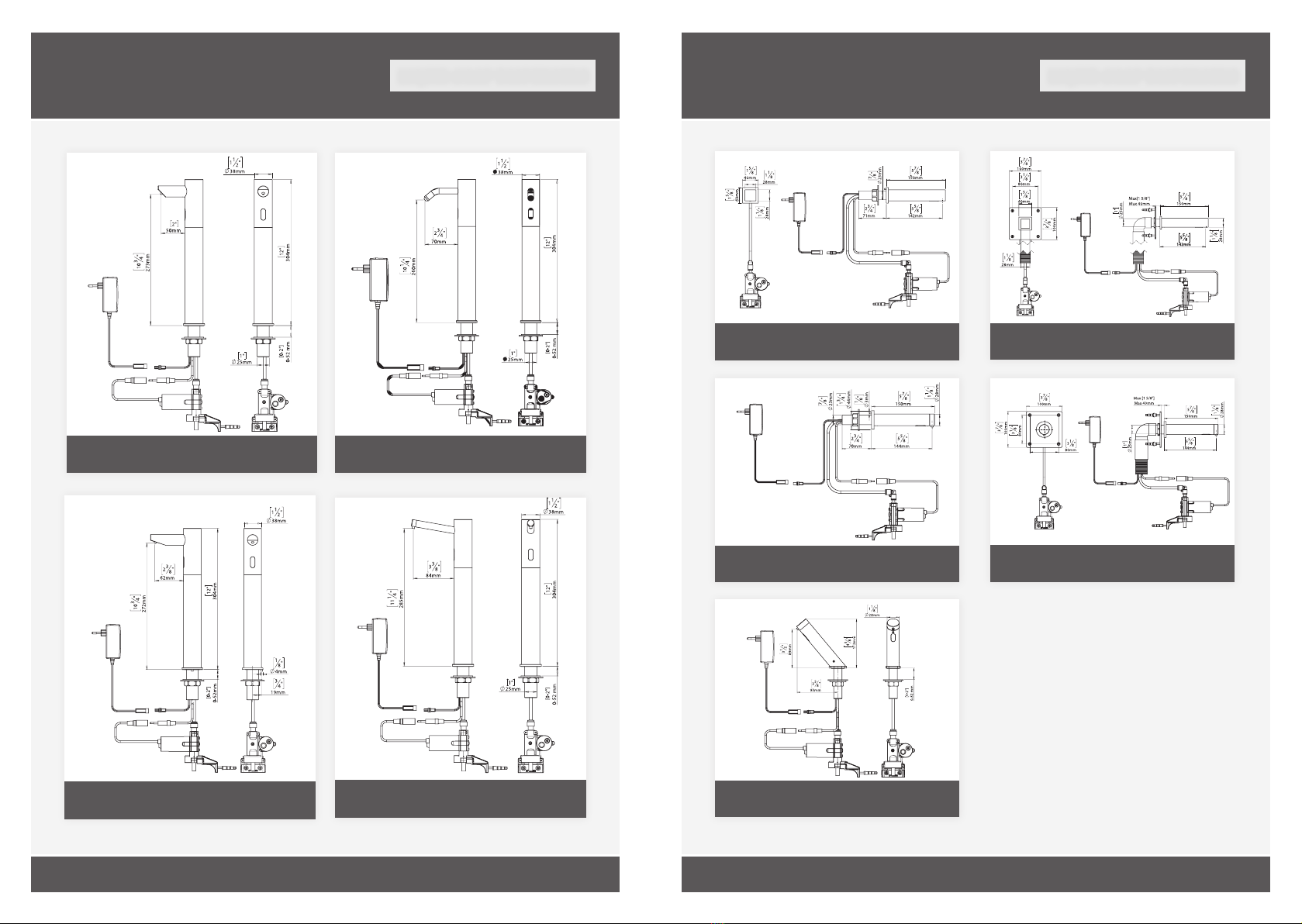

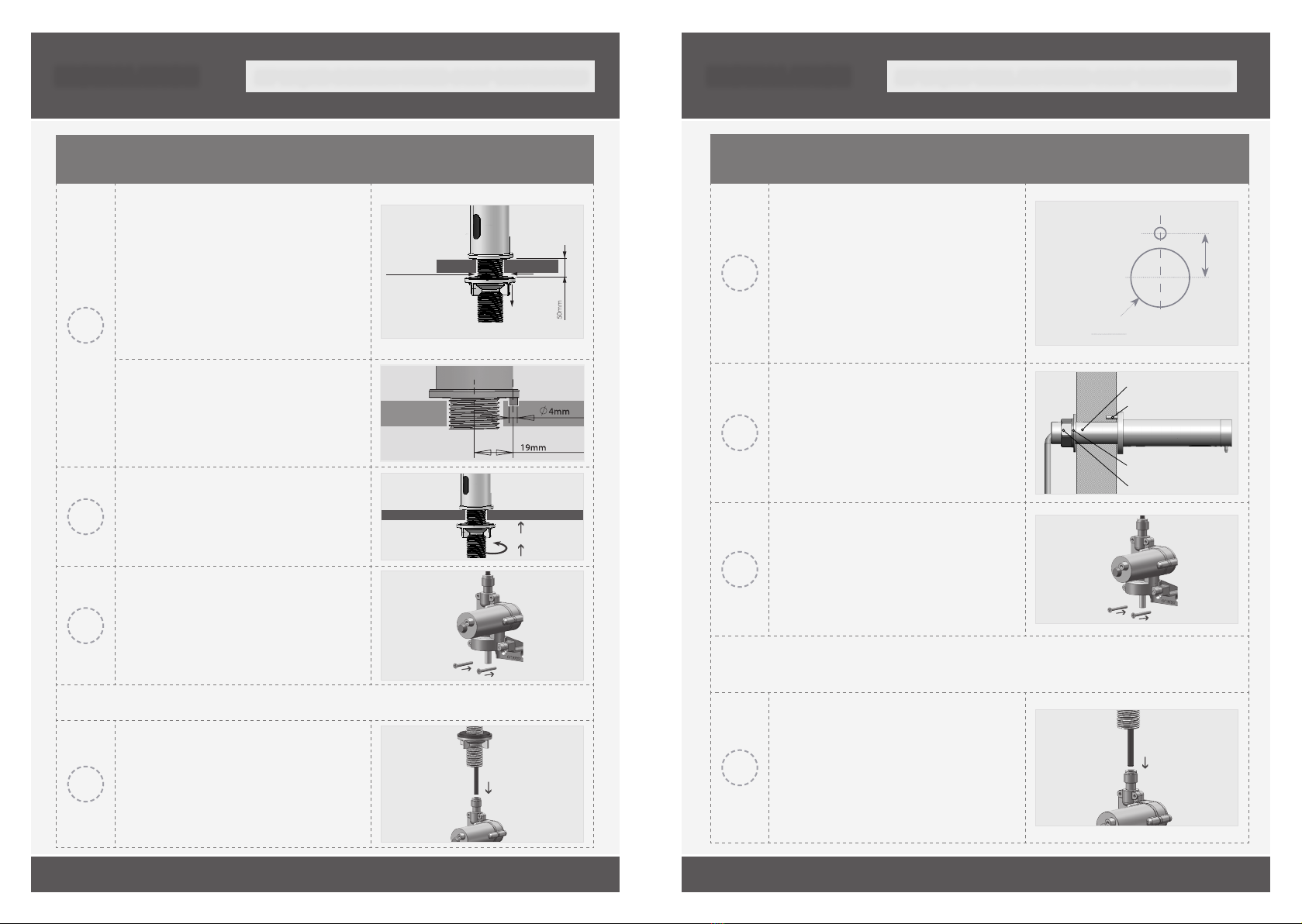

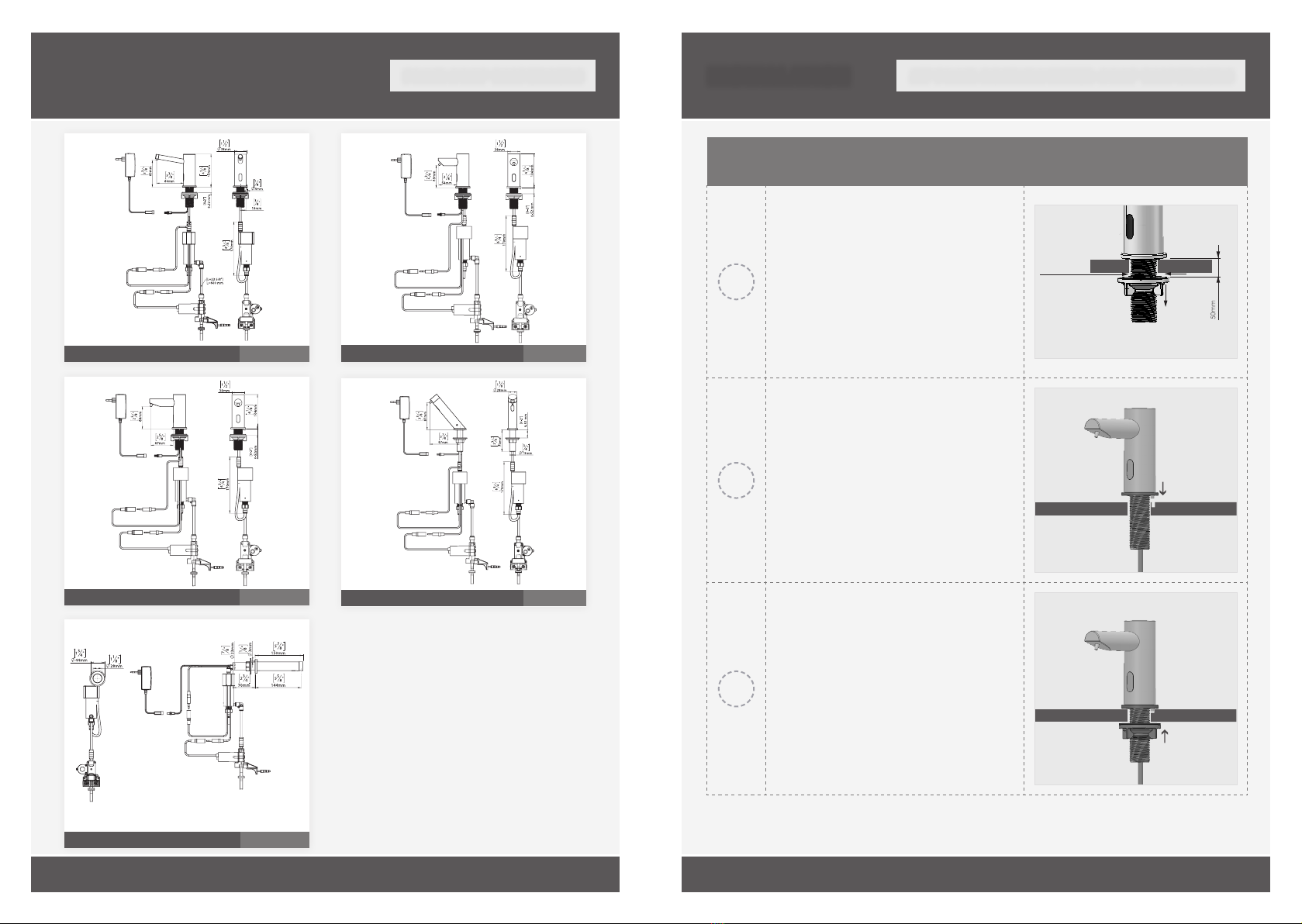

LIQUID SOAP DISPENSERS

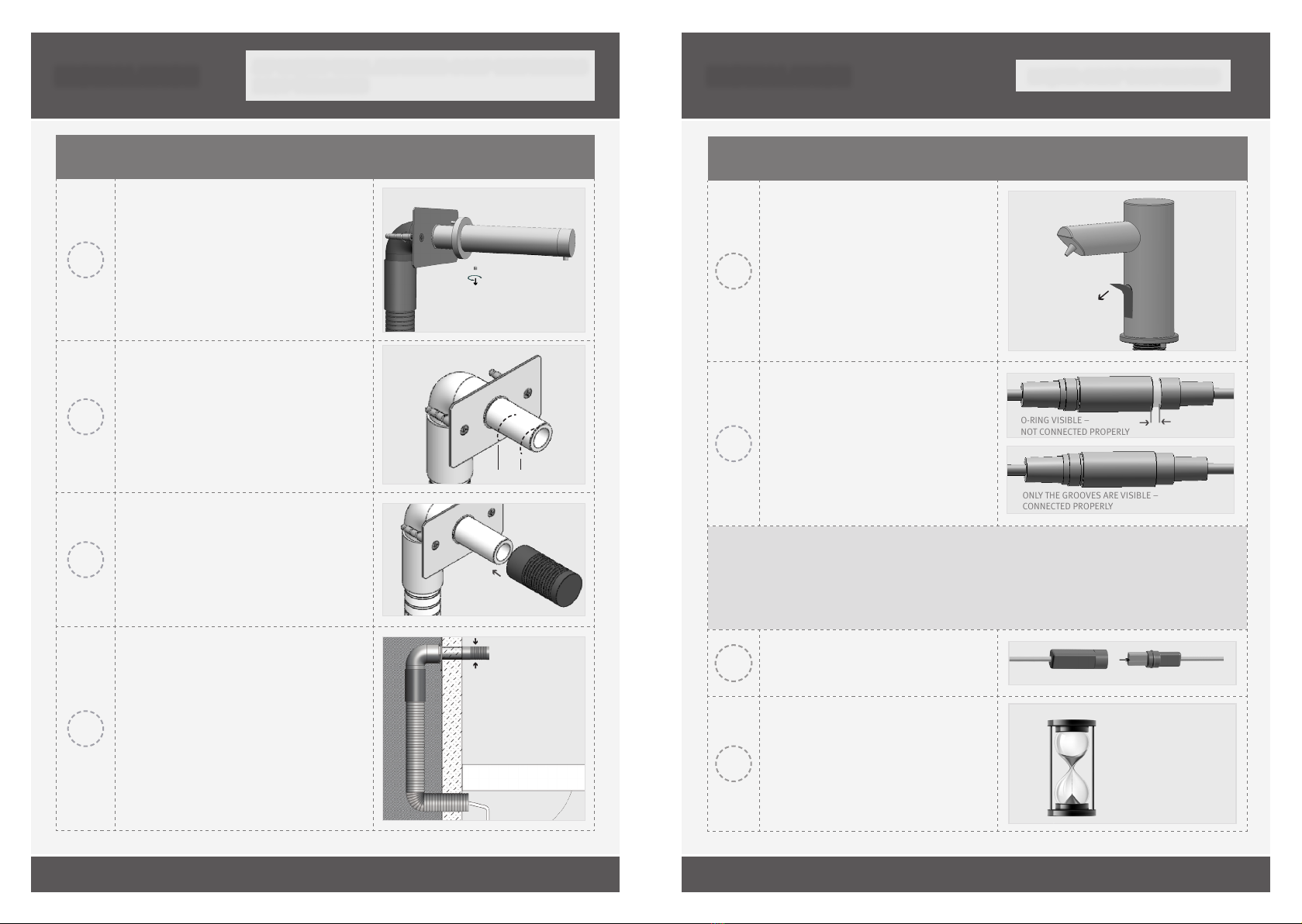

REMOTE cONTROL FUNcTIONS LIQUID SOAP DISPENSERS

Top Multifeed Cap Kit

Soap Filling Kit

Input Plug Kit

Coupling cap for 6 tubes and accessories

Soap Tank L

Soap Tank Support

V Transformer EU plug

V Transformer UK plug

V Transformer US plug

V Transformer AU plug

V Transformer Universal (EU/UK/US) plug

pack Sensor Kit MF Smart, Trendy, Elite, Extreme, Swan SD

pack Sensor Kit MF Green SD

pack Sensor Kit MF Green , Tubular, Tubular , Quadrat, Quadrat SD

pack Sensor Kit MF Smart, Trendy, Elite, Extreme Plus SD

Pump assembly MF Smart, Trendy, Elite, Extreme, Green, Green , Swan, Plus SD

Pump assembly MF Tubular, Tubular , Quadrat, Quadrat SD

Seals and Screws Kit MF Smart, Trendy, Elite, Extreme, Plus SD

Seals and Screws Kit MF Green SD

Seals and Screws Kit MF Green SD

Seals and Screws Kit MF Swan SD

Seals and Screws Kit MF Tubular SD

Seals and Screws Kit MF Tubular SD

Seals and Screws Kit MF Quadrat SD

Seals and Screws Kit MF Quadrat SD

Remote Control for Soap Dispenser

SPARE PARTS LIST

If you acquired the remote control together with your soap dispenser, you may adjust

the dispenser settings if required. To use the remote control hold it straight in front of

the sensor at a distance of about cm 6”).

Attention: The remote control held out of the recommended range (too close or too far)

will not operate.

The remote control can be used to adjust the following functions:

1-SOAP qUANTITY

The drop keys allow the user to choose the desired soap quantity.

. to . *

. to .

. to .

. to .

Indication: continuous blinking of the LED in the sensor eye.

*The exact dosage depends on soap viscosity.

2-ADJ

This function resets the sensor back to factory

settings.

Indication: blinks of the LED in the sensor eye.

3-TEMPORARY OFF FUNcTION

This function is ideal to perform any kind of activity

in front of the sensor without operating the system

(for example, cleaning). The soap dispenser will

remain shut for one minute when this button is

pressed once.

To cancel this function and to return to normal

operation press the On/O button again or wait for

one minute.

Indication: OFF – fast blinks, ON – fast blinks

4-FILL THE SOAP TANK

Once the soap tank has been lled / re-lled, press

the FILL button. The pump will run for one minute

for priming the soap to the soap dispenser spout.

To stop this activity press the FILL button again. If

the soap has not started coming out of the spout,

press the Fill button again.