FCB-KM

English

5

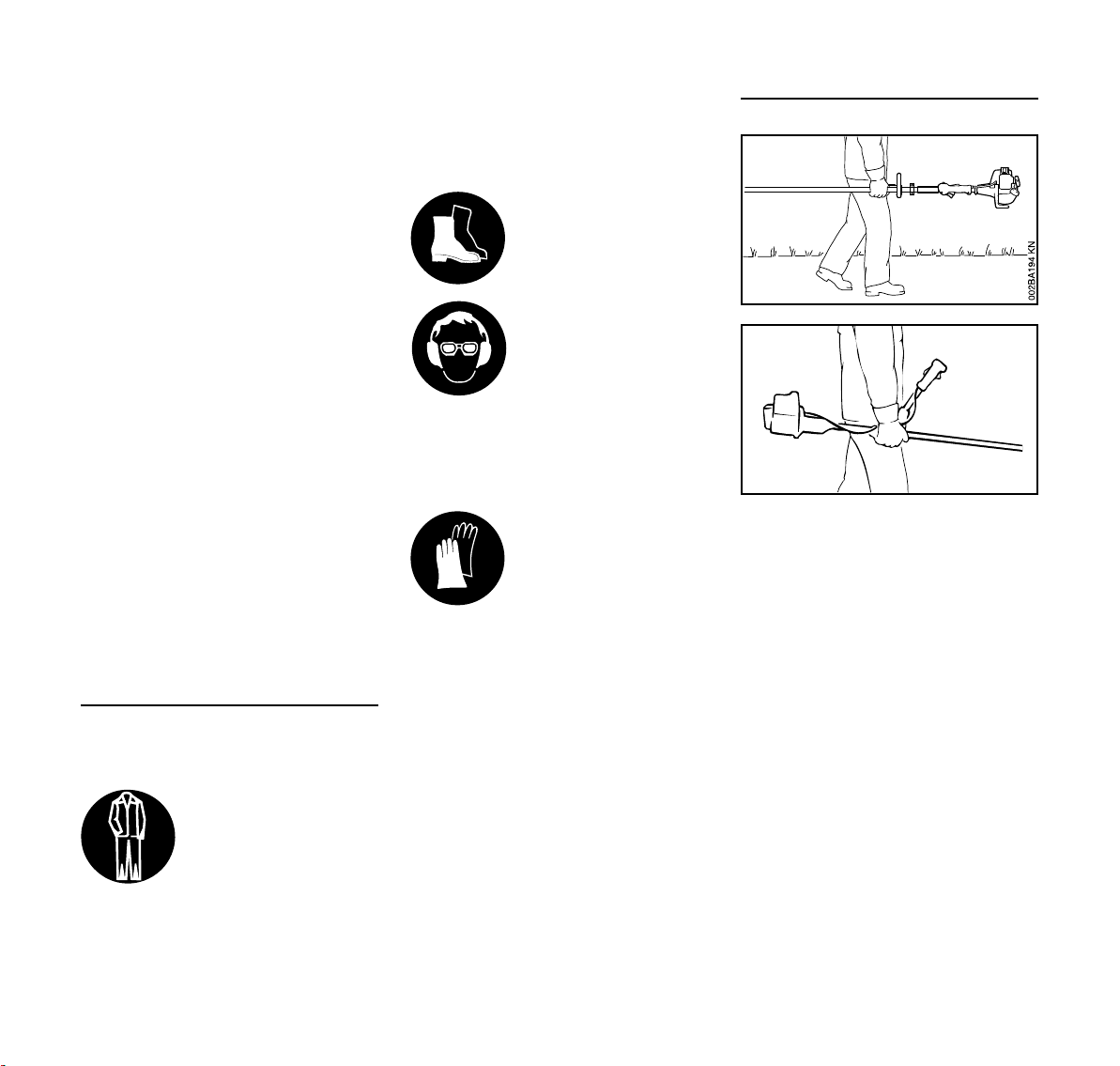

Take special care in slippery conditions

(ice, wet ground, snow), on slopes or

uneven ground.

Watch out for obstacles: Roots, tree

stumps or holes which could cause you

to trip or stumble.

Make sure you always have good

balance and secure footing.

Special care must be taken when

working in difficult, over-grown terrain.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

To reduce the risk of accidents, take a

break in good time to avoid tiredness or

exhaustion.

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Stay alert so as not to endanger

others.

Do not touch the cutting blade while the

engine is running. If the blade becomes

jammed by an obstruction, switch off the

engine immediately before attempting to

remove the obstruction – risk of injury.

Opening the throttle while the blade is

blocked increases the load and reduces

engine speed. The clutch then slips

continuously and this causes

overheating and damage to important

components (e.g. clutch, polymer

housing components) – and this can

increase the risk of injury from the

cutting attachment moving while the

engine is idling.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting". Make sure the safety

devices are working properly. Do not

continue operating your power tool if it is

damaged. In case of doubt, consult your

servicing dealer.

Check the cutting blade at regular short

intervals during operation or

immediately if there is a noticeable

change in cutting behavior:

–Turn off the engine. Hold the unit

firmly and press the blade into the

ground to bring it to a standstill.

–Check condition and tightness, look

for cracks.

–Replace a damaged blade

immediately, even if it has only

superficial cracks.

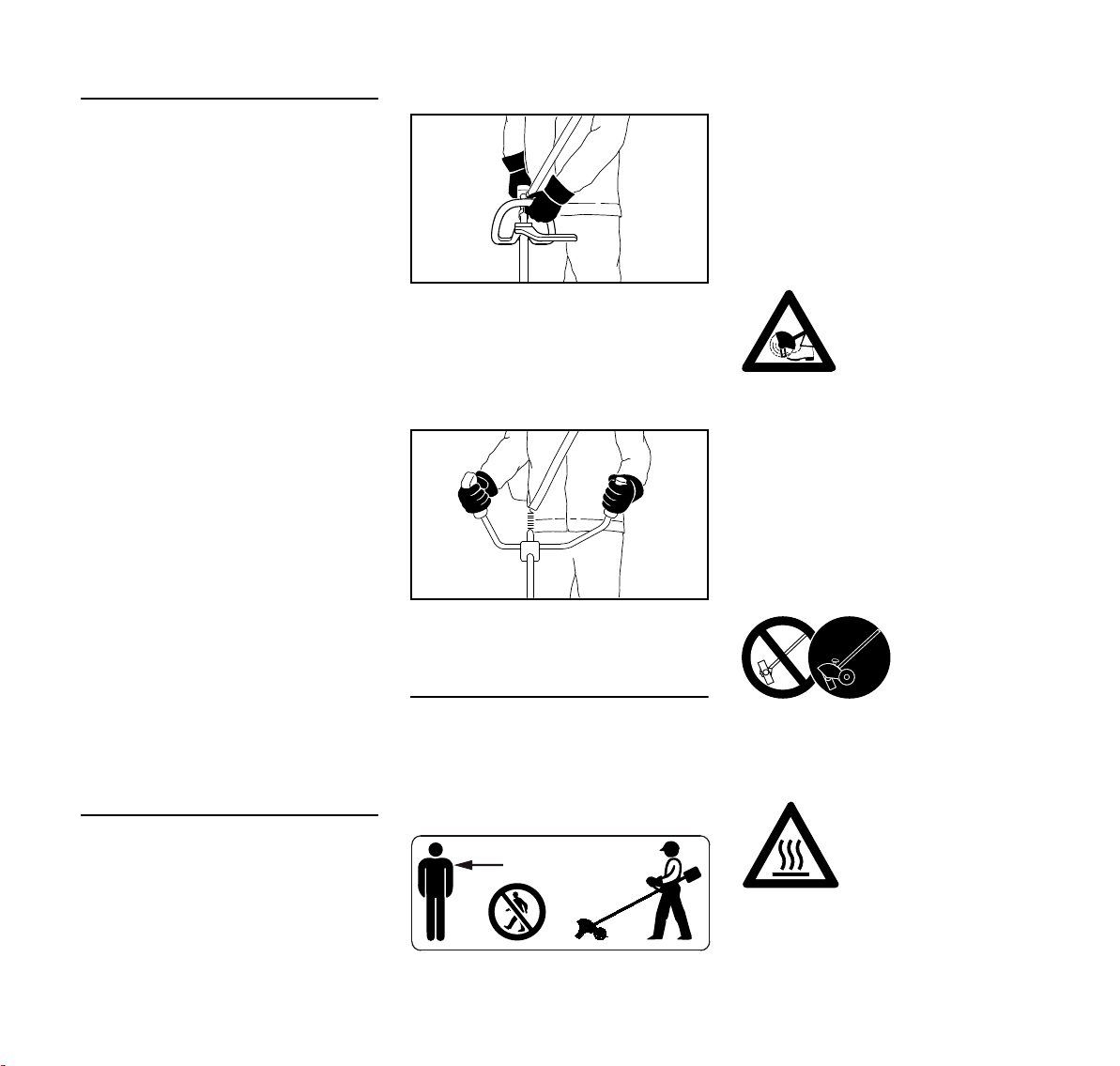

Clean the cutting attachment and

deflector at regular intervals during

operation.

–Shut off the engine.

–Wear gloves.

–Remove grass, weeds, clumps of

soil, etc.

To reduce the risk of injury, shut off the

engine before changing the cutting

attachment.

Do not continue using or attempt to

repair a damaged or cracked blade by

welding or straightening – risk of out of

balance.

This may cause parts of the cutting

attachment to come off and hit the

operator or bystanders at high speed

and result in serious or fatal injuries.

If a rotating metal cutting attachment

makes contact with a rock or other solid

object there is a risk of sparking which

may cause easily combustible material

to catch fire under certain

circumstances. Dry plants and scrub are

also easily combustible, especially in hot

and dry weather conditions. If there is a

risk of fire, do not use metal cutting

attachments near combustible

materials, dry plants or scrub. Always

contact your local forest authority for

information on a possible fire risk.

After Finishing Work

After finishing work or before leaving the

unit unattended: Shut off the engine.

After finishing work, clean dirt, soil and

plant residue off the cutting attachment –

wear gloves to reduce the risk of injury.

Inspect the work area:

Stones, pieces of metal

or other solid objects may

be thrown more than 15

meters and cause per-

sonal injury or damage

the cutting attachment

and property (e.g. parked

vehicles, windows).

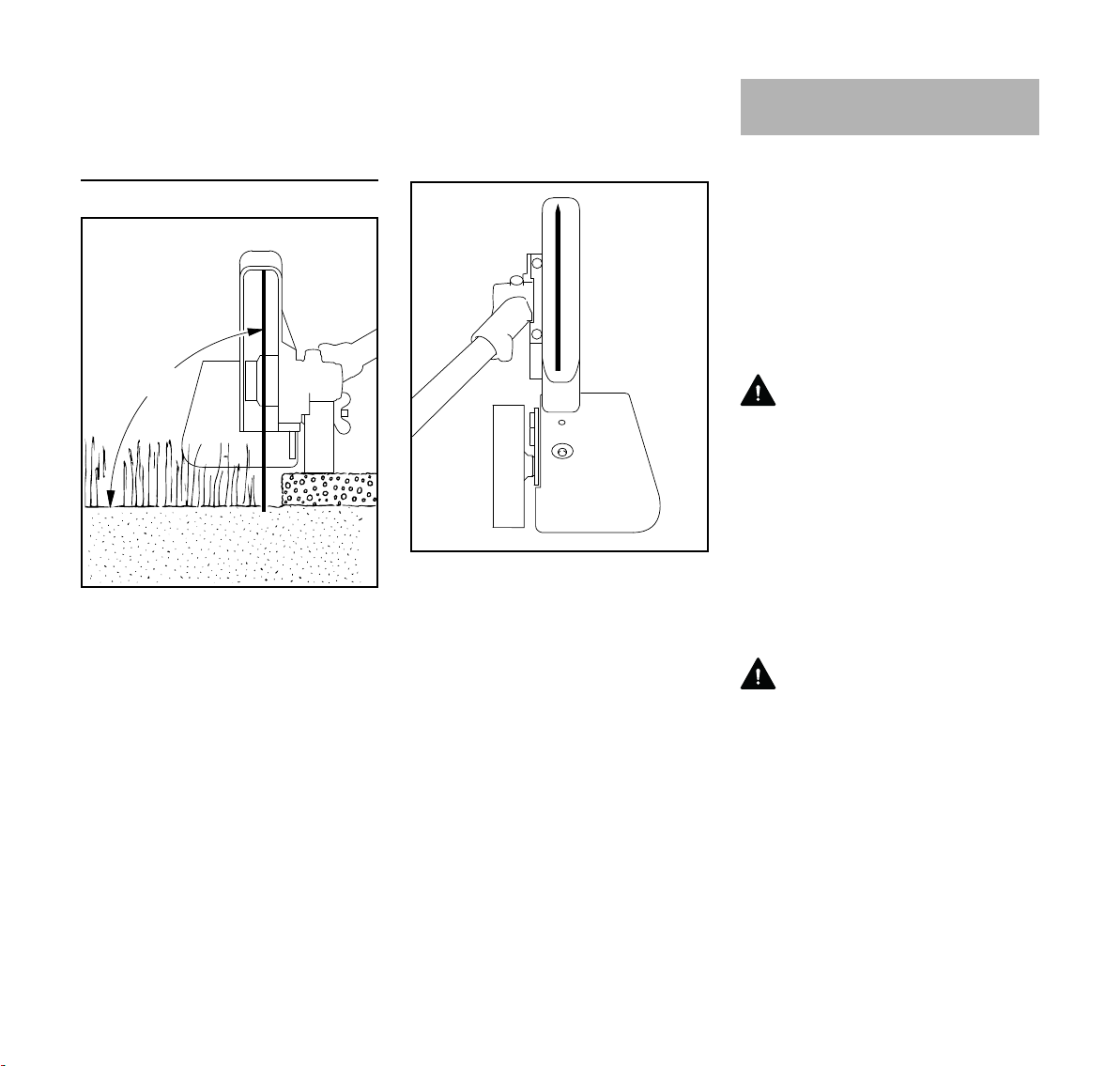

To avoid the risk of elec-

tric shock, never use your

power tool in areas where

electrical lines are laid on

the surface or buried just

below the surface. Strik-

ing and damaging such

lines with the KombiTool

could cause serious or

even fatal injury.