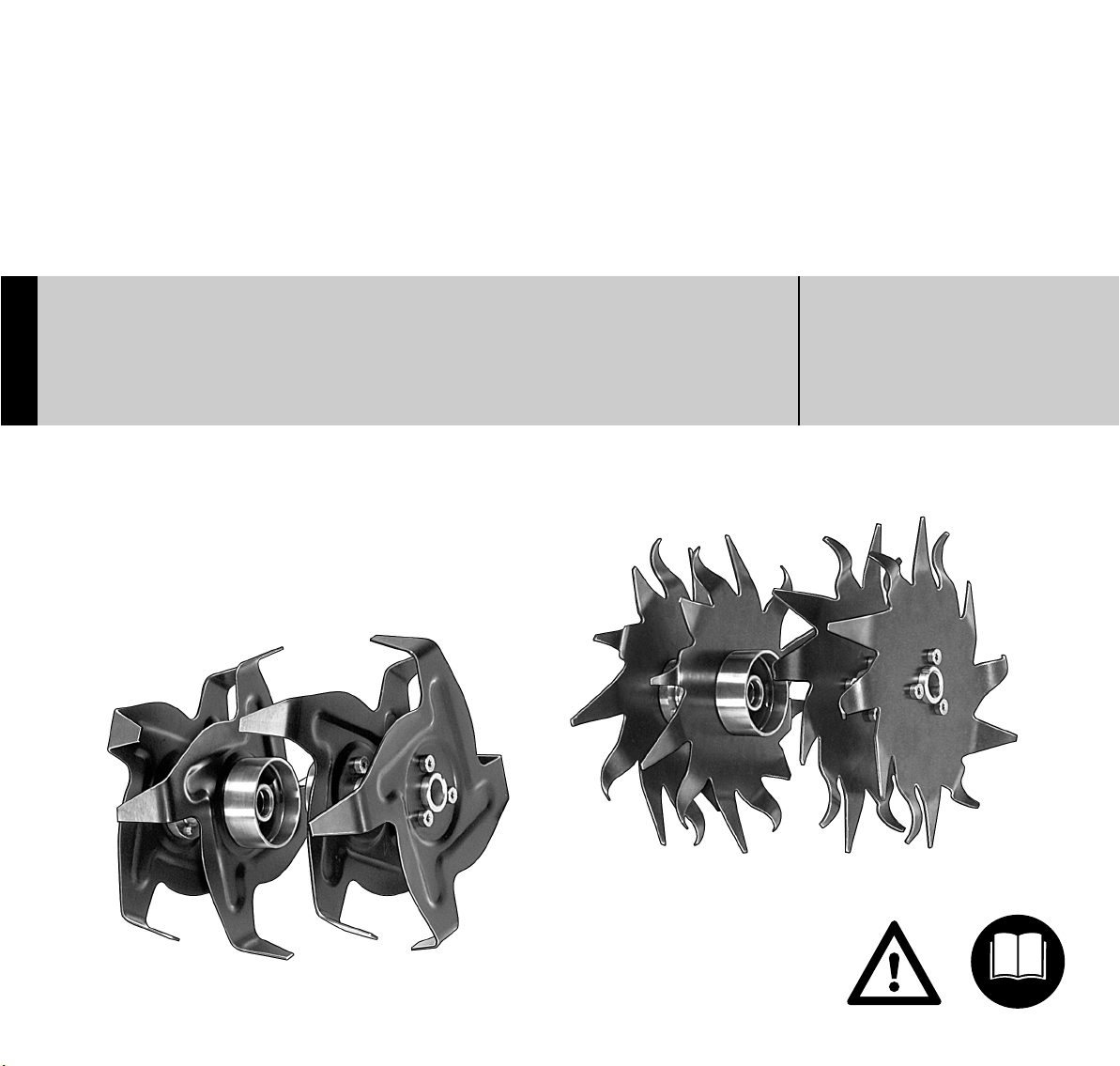

3BF-MM, BK-MM

English

Equipment and features

This instruction manual may refer to

several models with different

features. Components that are not

installed on all models and related

applications are marked with an

asterisk (*). Such components may

be available as special accessories

from your STIHL dealer.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore some changes, modifications

and improvements may not be covered

in this manual.

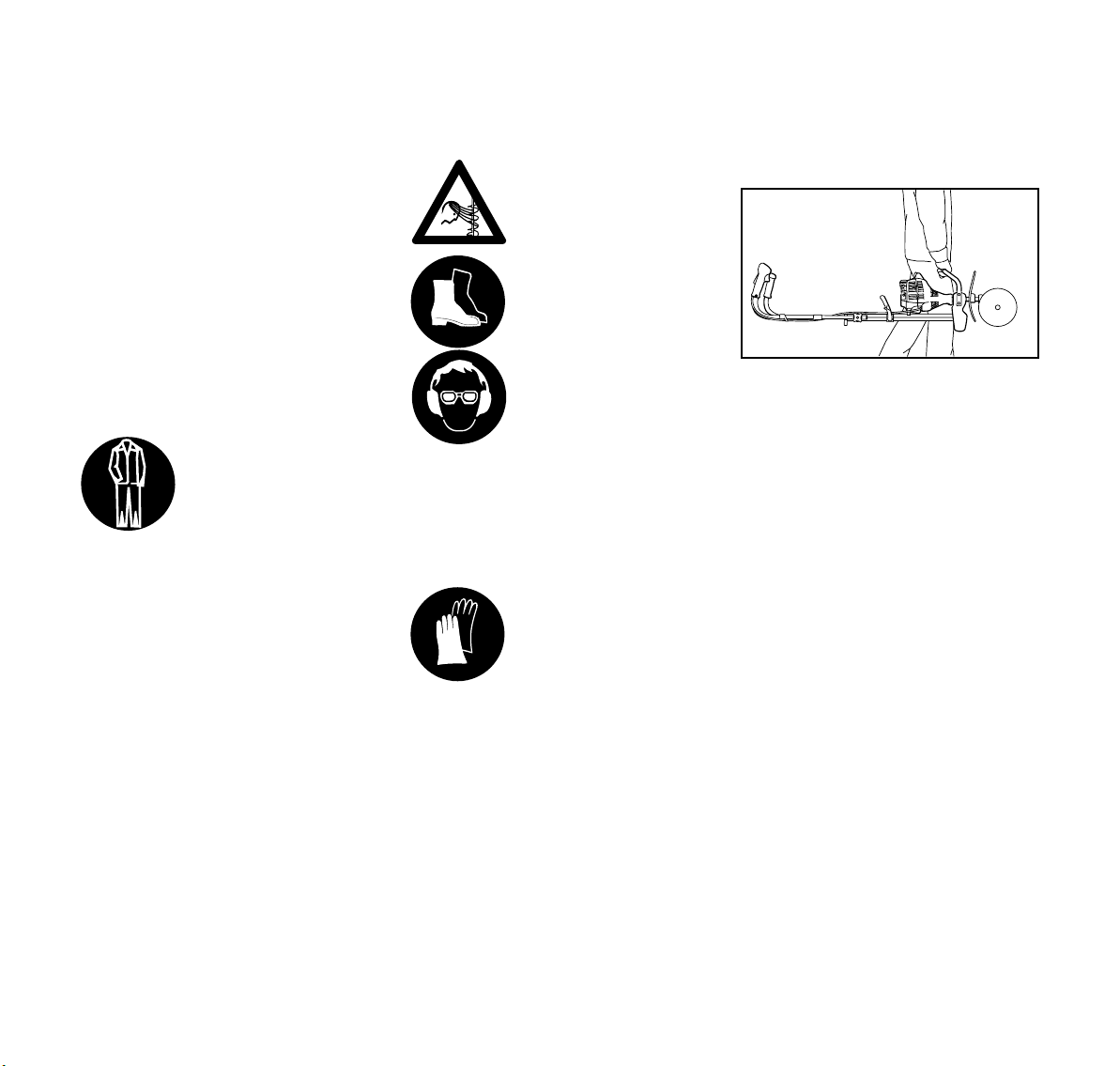

Because a cultivator is a

high-speed power tool

with rotating blades,

special safety

precautions must be

observed in addition to

those that generally apply when working

with a hoe.

It is important that you

read and understand

both instruction manuals

(MultiEngine and

MultiTool) before using

the unit for the first time.

Keep the manuals in a safe place for

future reference.

Non-observance of the safety

precautions in the instruction manuals

may cause serious or even fatal injury.

Always observe local safety regulations,

standards and ordinances.

If you have never used this power

tool model before: Have your STIHL

dealer show you how to operate your

power tool or attend a special course

of training in power tool operation.

Do not lend or rent your power tool

combination without the instruction

manuals. Be sure that anyone using

your power tool understands the

information contained in both manuals

(MultiEngine and MultiTool).

Minors should never be allowed to use a

power tool. Children, bystanders and

animals should not be allowed in the

area where a power tool is in use.

The power tool user is responsible for

avoiding injury to third parties or damage

to their property.

To operate the power tool you must be in

good physical condition and mental

health and not under the influence of any

substance (drugs, alcohol) which might

impair vision, dexterity or judgment.

Use the power tool only for deep tilling

previously cultivated, packed or loose

soil, furrowing, weeding and working

mulches into loosened soil. It must not

be used for any other purpose because

of the increased risk of accidents.

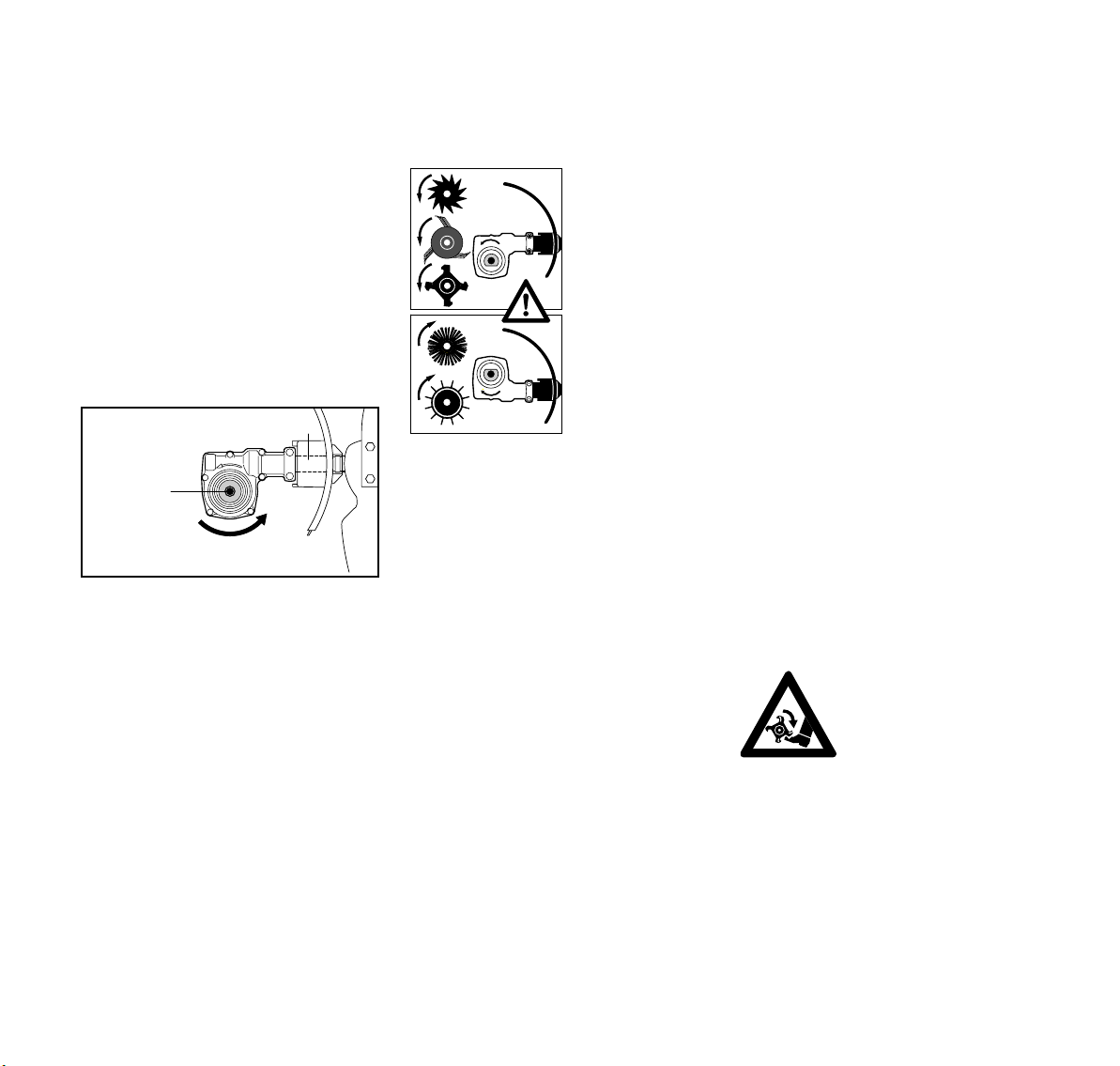

Only rotor blades supplied by STIHL or

expressly approved by STIHL for use

with your specific model are authorized.

Other rotor blades must not be used

because of the increased risk of

accidents.

Safety Precautions