KM 94 RC

English

6

To reduce the risk of fire, do not smoke

while operating or standing near your

power tool. Note that combustible fuel

vapor may escape from the fuel system.

The dusts, vapor and smoke produced

during operation may be dangerous to

health. Wear a suitable respirator in very

dusty or smoky conditions.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting".

Check the fuel system in particular for

leaks and make sure the safety devices

are working properly. Do not continue

operating your power tool if it is

damaged. In case of doubt, consult your

servicing dealer.

Before leaving the power tool

unattended: Shut off the engine.

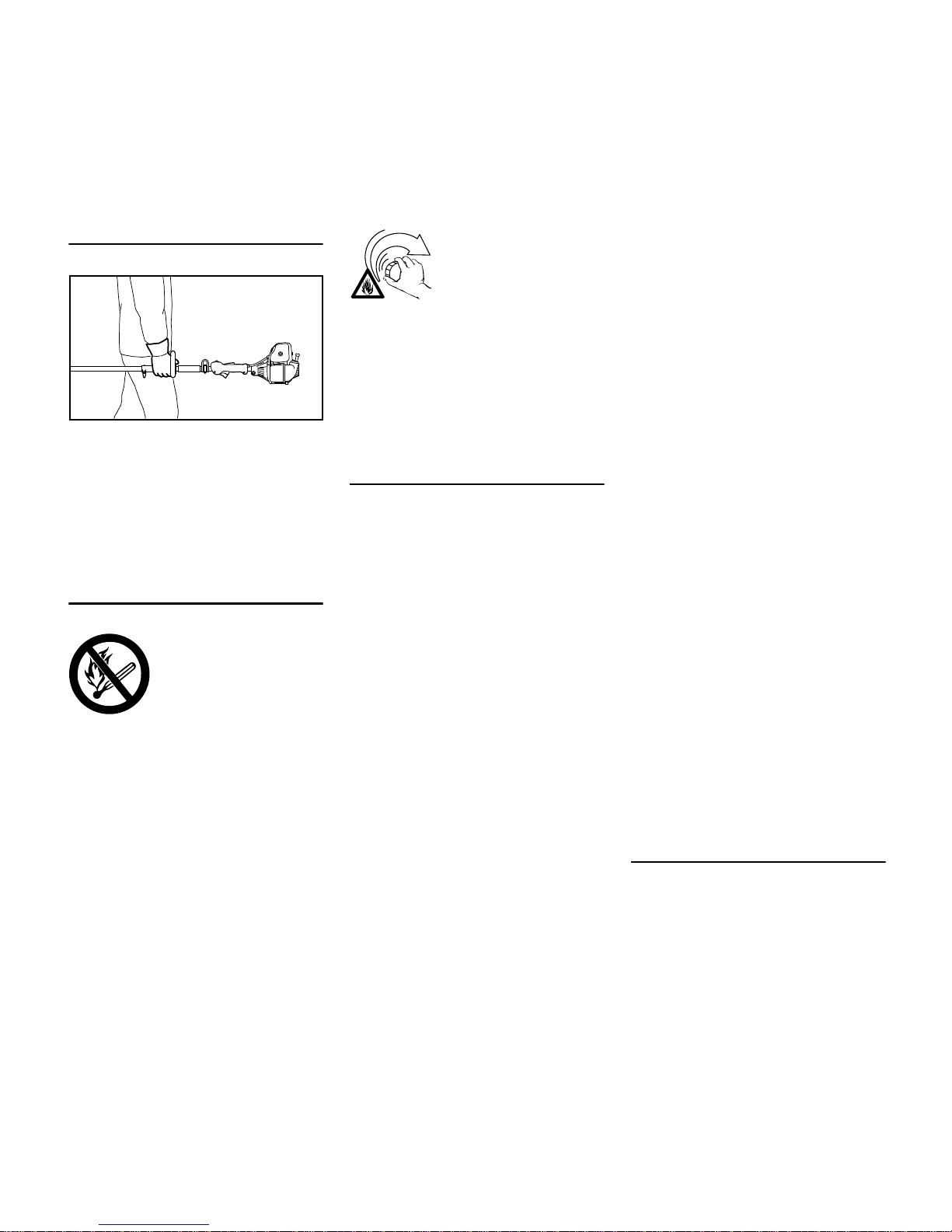

To reduce the risk of injury, always shut

off the engine before changing the

KombiTool or attachment.

Vibrations

Prolonged use of the power tool may

result in vibration-induced circulation

problems in the hands (whitefinger

disease).

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

–Hand protection (wearing warm

gloves)

–Work breaks

The period of usage is shortened by:

–Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, tingling

sensations).

–Low outside temperatures.

–The force with which the handles

are held (a tight grip restricts

circulation).

Continual and regular users should

monitor closely the condition of their

hands and fingers. If any of the above

symptoms appear (e.g. tingling

sensation in fingers), seek medical

advice.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of original

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

To reduce the risk of injury from

unintentional engine startup, always

shut off the engine and disconnect the

spark plug boot before performing any

repairs, maintenance or cleaning work. –

Exception: Carburetor and idle speed

adjustments.

Do not turn the engine over on the

starter with the spark plug boot or spark

plug removed since there is otherwise a

risk of fire from uncontained sparking.

To reduce the risk of fire, do not service

or store your machine near open flames.

Check the fuel filler cap for leaks at

regular intervals.

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition – see "Specifications".

Inspect the ignition lead (insulation in

good condition, secure connection).

Check the condition of the muffler.

To reduce the risk of fire and damage to

hearing, do not operate your machine if

the muffler is damaged or missing. –

Do not touch a hot muffler since burn

injury will result.

Vibration behavior is influenced by the

condition of the AV elements – check the

AV elements at regular intervals.