To reduce the risk of injury from thrown objects

or contact with the attachment, never operate the

unit without a properly mounted deflector

designed specifically for the unit and the attach‐

ment.

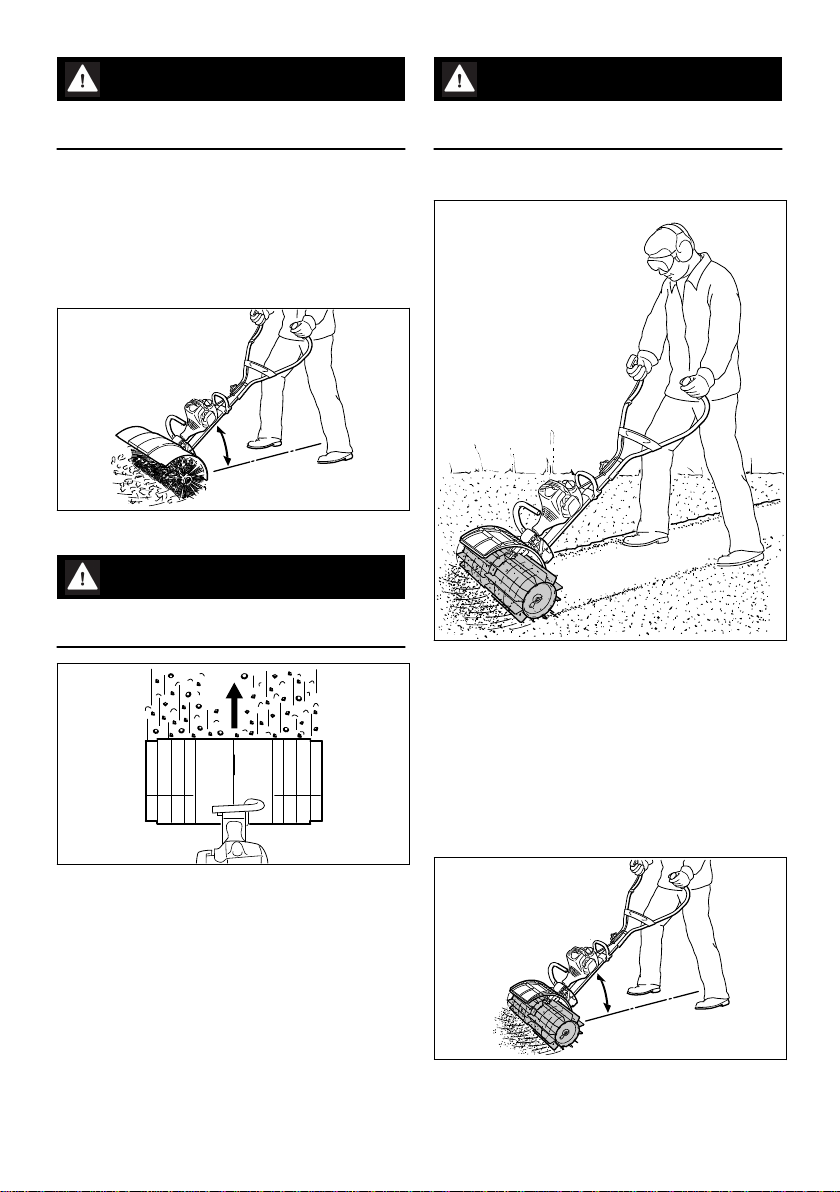

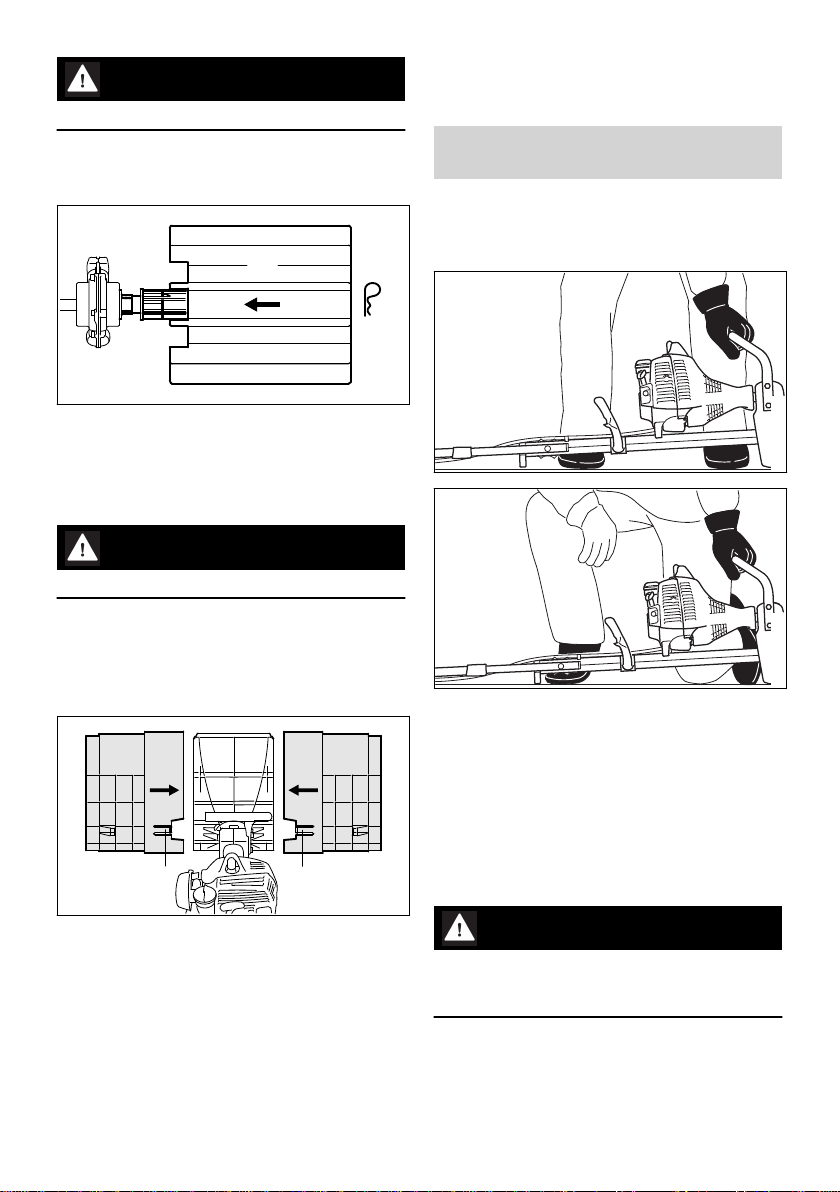

Always stand behind the deflector or to one side

of the machine during operation – never in front

of the attachment.

Electrostatic charges may build up when working

on synthetic surfaces – risk of electric shock and

accidents!

Dust, fumes and smoke produced

while working may be hazardous to

health! If dust levels are high, wear a

suitable respirator.

To reduce the risk of a dust explo‐

sion, spray very dusty surfaces with

water before sweeping.

Take special care in slippery conditions – damp,

snow, ice, on slopes or uneven ground!

To reduce the risk of accidents or injury, remove

all obstacles and objects from the work area.

Check the work site – rocks, metal

objects etc. may be caught up and

ejected – risk of injury!

Operate your power tool at normal walking pace

only.

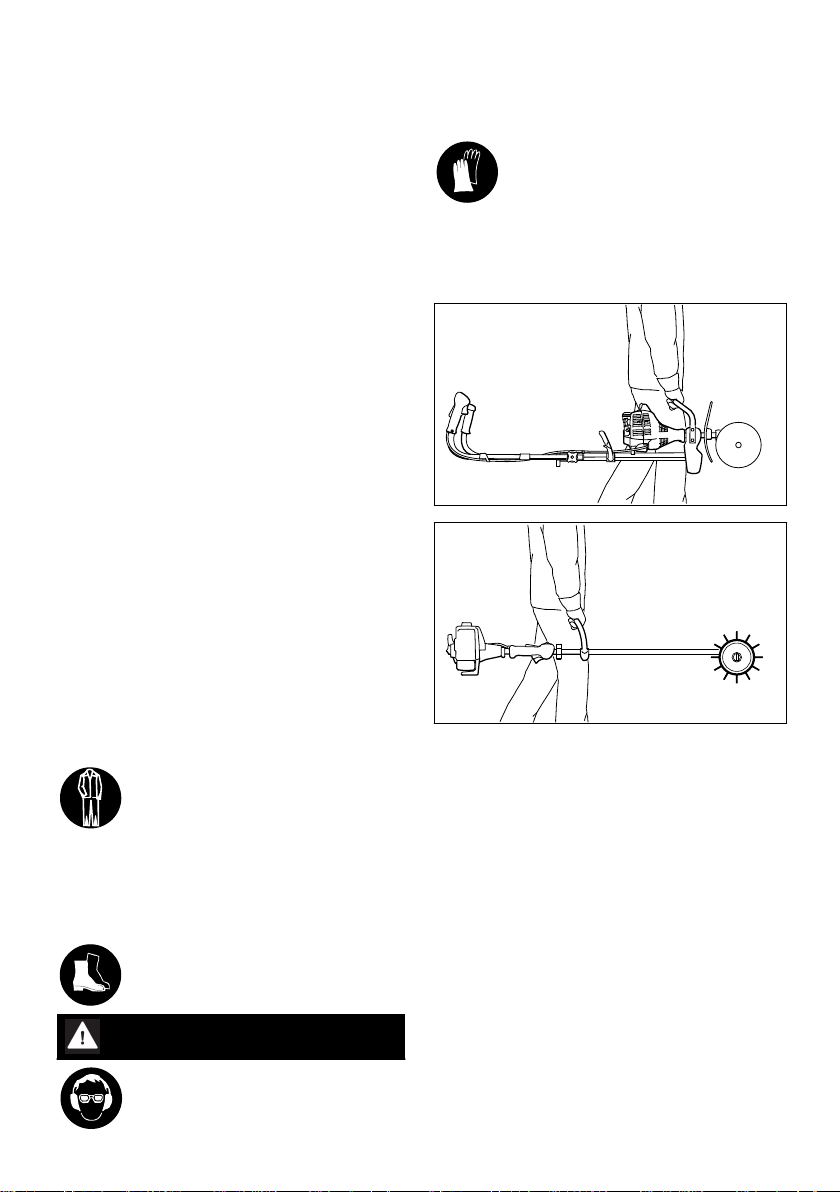

Be extremely cautious when pulling the power

tool towards you because of the risk of injury

from contact with the rotating attachment.

Make sure you always have a firm and secure

footing.

Be extremely cautious when changing direction

with the power tool – especially on slopes.

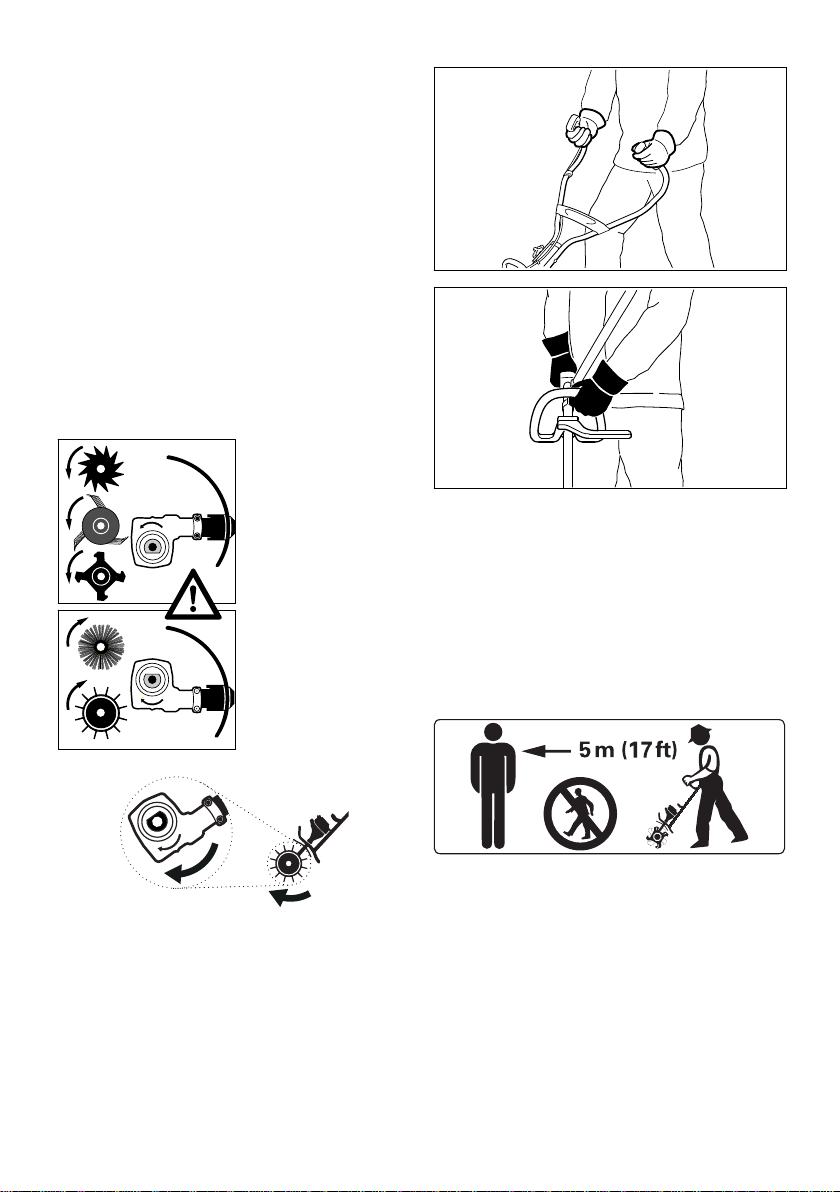

On slopes, always work parallel to the gradient to

reduce the risk of injury from slipping or contact

with the attachment.

Never work on steep slopes because of the risk

of injury through loss of control of the power tool.

Special care must be taken when working in

overgrown terrain.

When clearing leaves, take care not to harm

small animals.

Be particularly alert and cautious when wearing

ear protection because your ability to hear warn‐

ings (shouts, alarms, etc.) is impaired.

Take breaks when you start getting tired or feel‐

ing fatigue – risk of accidents!

Work calmly and carefully – in daylight conditions

and only when visibility is good. Proceed with

caution, do not put others in danger.

If your power tool is subjected to unusually high

loads for which it was not designed (e.g. heavy

impact or a fall), always check that it is in good

condition before continuing work – see also

"Before Starting". Make sure the safety devices

are working properly. Never use a power tool

that is no longer safe to operate. In case of

doubt, contact a dealer.

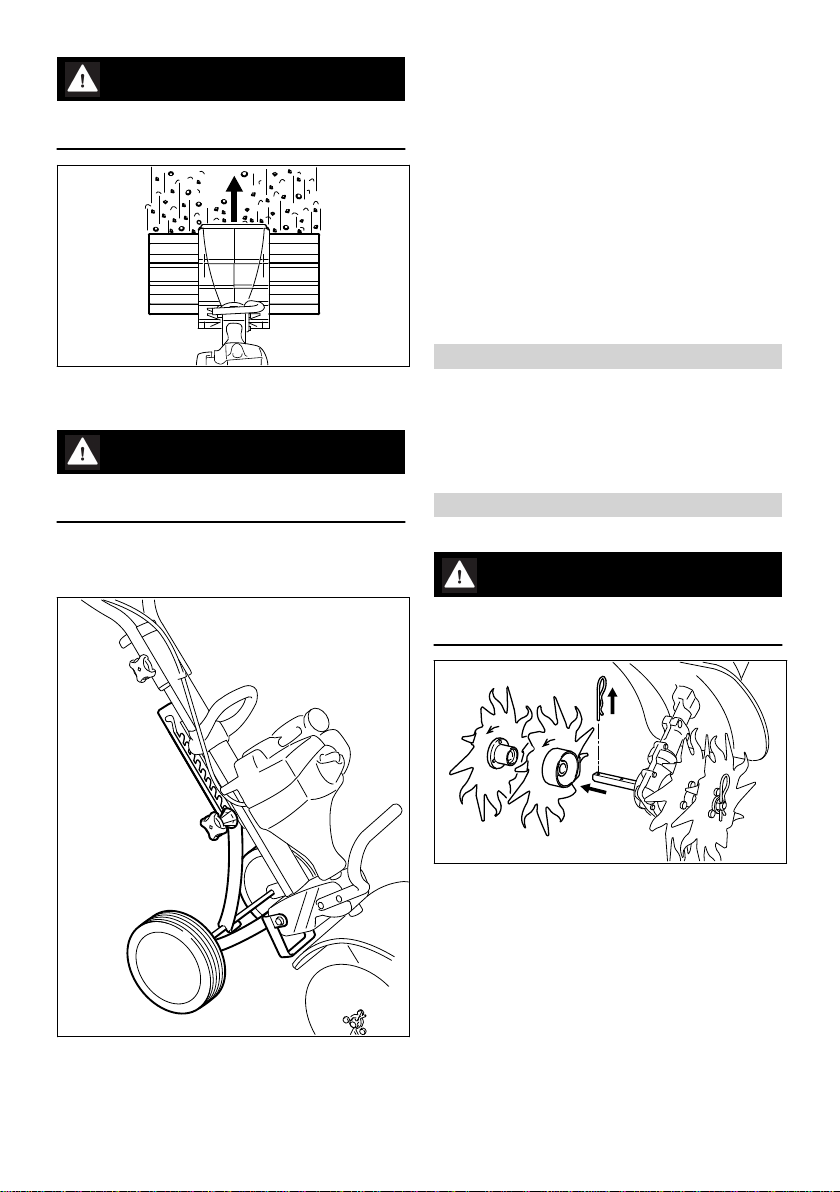

Do not touch the attachment while the

engine is running. If the attachment

becomes jammed by an obstruction,

switch off the engine immediately

before attempting to remove the

obstruction – otherwise, risk of injury!

Opening the throttle while the attachment is

blocked increases the load and reduces engine

speed. The clutch then slips continuously and

this causes overheating and damage to impor‐

tant components (e.g. clutch, polymer housing

components) – and this can increase the risk of

injury from the attachment moving while the

engine is idling.

Check the sweeping attachments at regular short

intervals during operation or immediately if there

is a sudden change in behavior:

–Shut off the engine, hold the machine

securely.

–Check condition and proper mounting.

–Replace damaged sweeping attachments

immediately.

Clean the attachment and deflector at regular

intervals during operation.

–Shut off the engine

–Use gloves

–Remove debris from between the sweeping

attachments and from the area around the

gearbox and deflector.

To reduce the risk of injury, shut off the engine

before changing attachments.

3.6 After Finishing Work

After finishing work or before leaving the power

tool unattended: Shut off the engine.

3.7 Maintenance and Repairs

Service the machine regularly. Do not attempt

any maintenance or repair work not described in

the MultiTool and MultiEngine instruction man‐

uals. Have all other work performed by a servic‐

ing dealer.

3 Safety Precautions and Working Techniques English

0458-486-0121-B 5