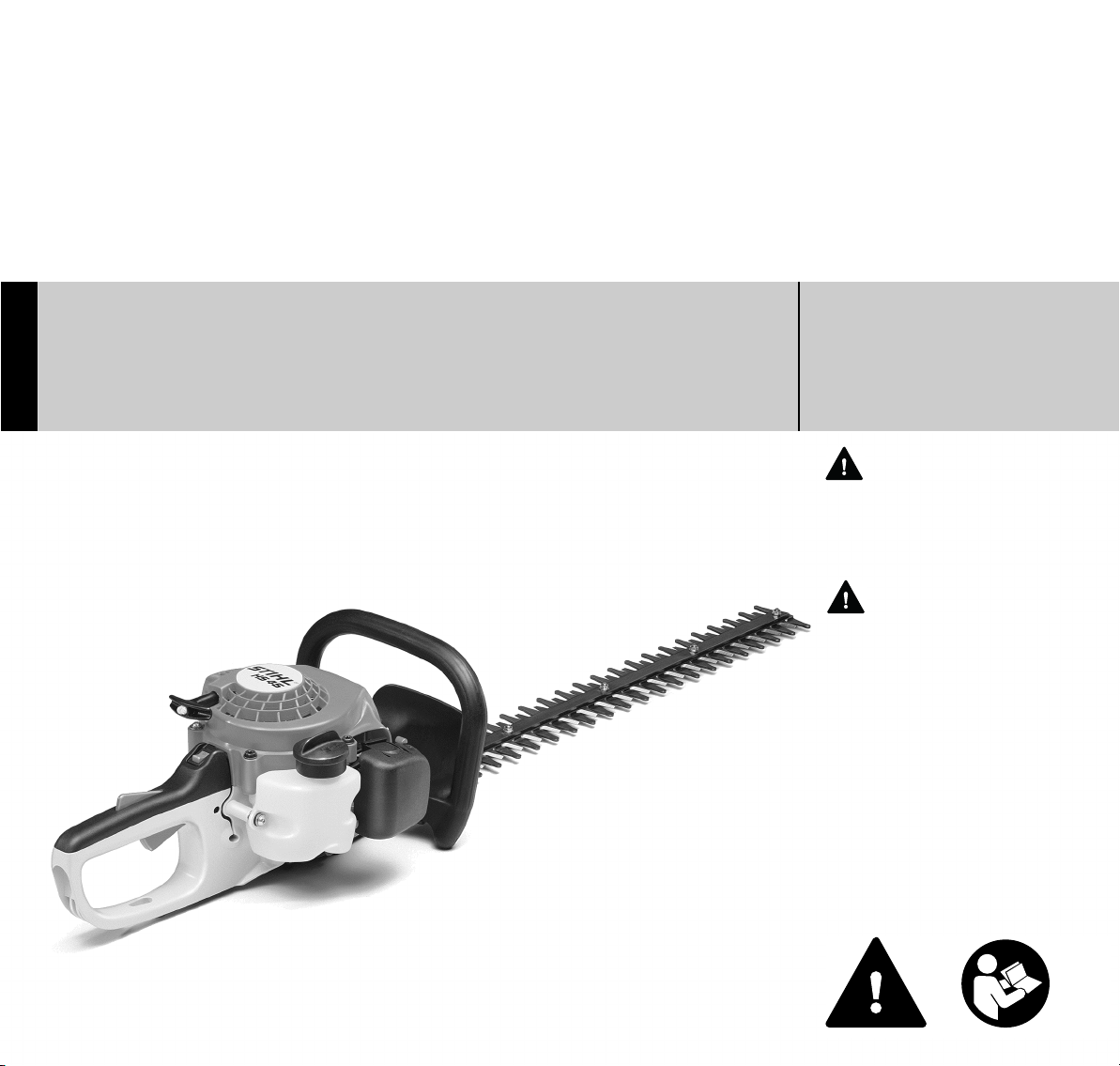

HS 45

English

7

Before Starting

WARNING

Always check your power tool for proper

condition and operation before starting,

particularly the throttle trigger, throttle

trigger lockout, stop switch and cutting

tool. The throttle trigger (if applicable)

must move freely and always spring

back to the idle position. Never attempt

to modify the controls or safety devices.

WARNING

Check fuel system for leaks, especially

the visible parts, e.g., filler cap, hose

connections, manual fuel pump (only for

power tools equipped with a manual fuel

pump). Do not start the engine if there

are leaks or damage – risk of fire! Have

the machine repaired by a servicing

dealer before using it.

WARNING

Never use a power tool that is damaged

or not properly maintained.

WARNING

Check that the spark plug boot is

securely mounted on the spark plug – a

loose boot may cause arcing that could

ignite combustible fumes and cause a

fire.

Keep the handles clean and dry at all

times; it is particularly important to keep

them free of moisture, pitch, oil, fuel mix,

grease or resin in order for you to

maintain a firm grip and properly control

your power tool.

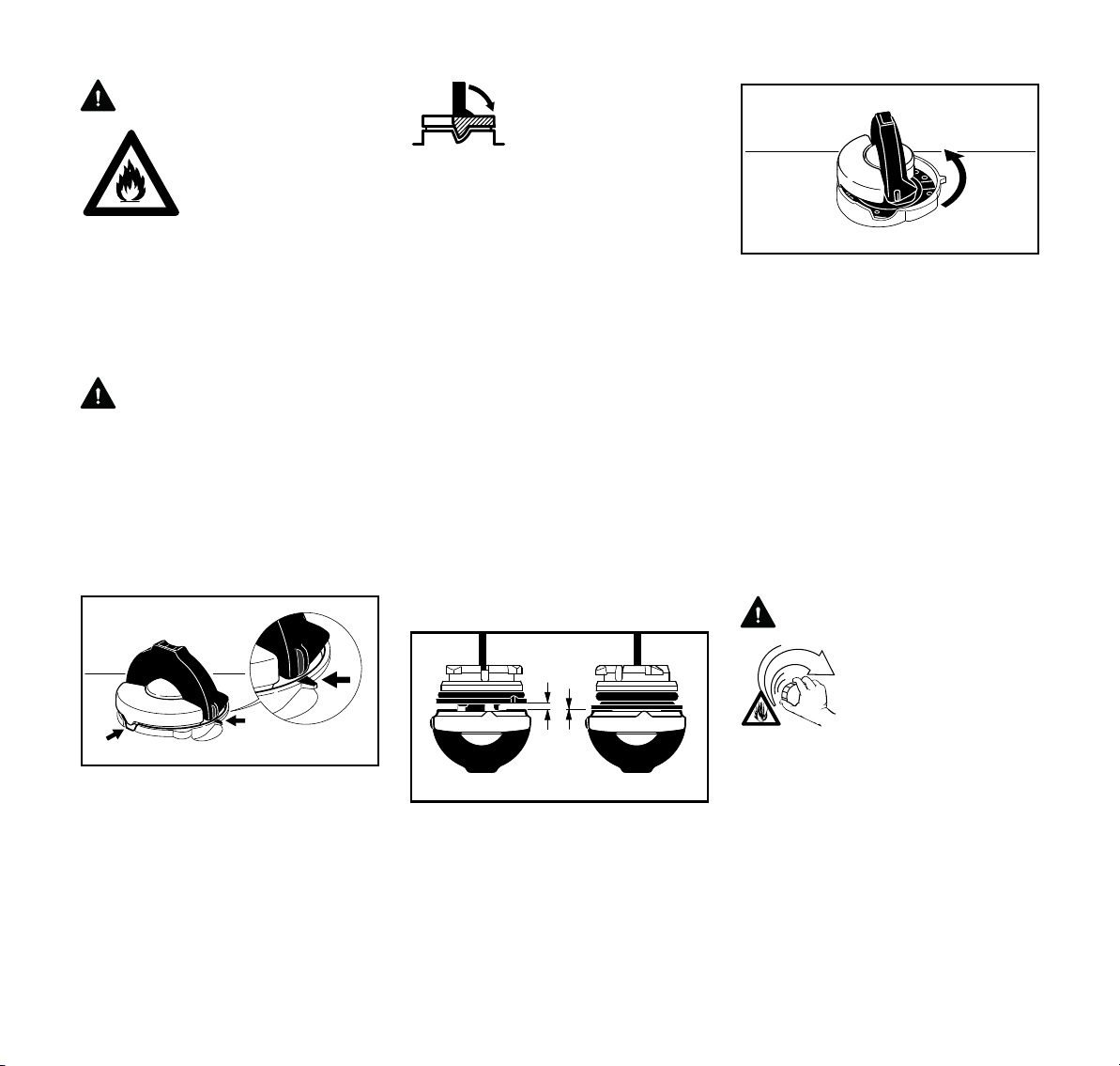

WARNING

The cutting tool must be properly

tightened and in safe operating

condition. Inspect for loose parts (nuts,

screws, etc.) and for cracked, bent,

warped or damaged blades. Regularly

check the condition and tightness of the

cutter blades – with the engine stopped!

Replace damaged cutter blades before

using the power tool. Always keep

blades sharp.

STIHL recommends that you always

spray the cutter blades with STIHL resin

solvent before starting work – with the

engine stopped! You can obtain this

protective spray from your dealer. Apply

generously.

Starting

Start the engine at least 10 feet (3 m)

from the fueling spot, outdoors only.

For specific starting instructions, see the

appropriate section of your manual.

Place the power tool on firm ground or

other solid surface in an open area.

Maintain good balance and secure

footing.

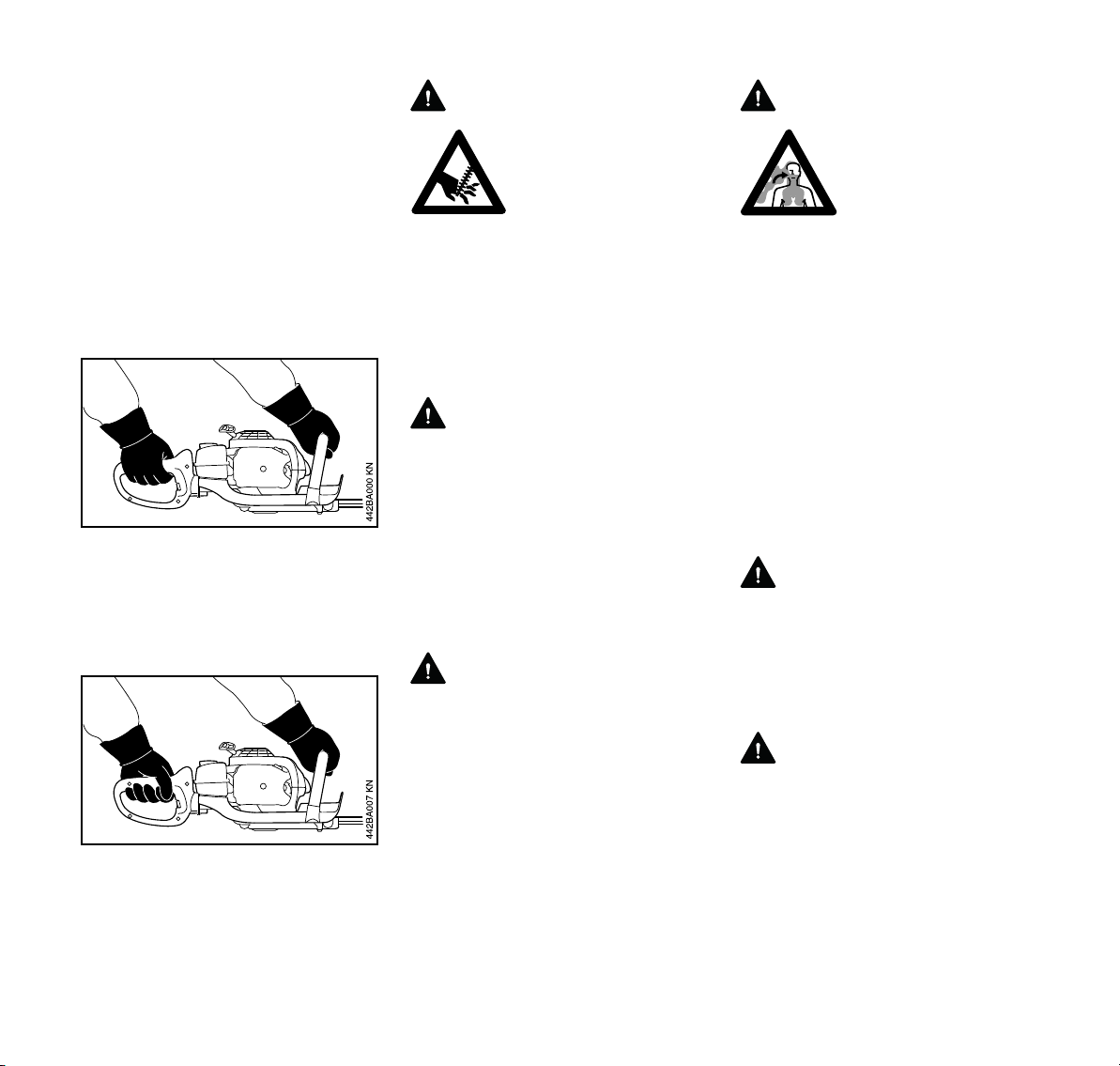

WARNING

To reduce the risk of injury from blade

contact, be absolutely sure that the

cutting tool is clear of you and all other

obstructions and objects, including the

ground, because when the engine starts

at starting-throttle, engine speed will be

fast enough for the clutch to engage and

move the blades on the cutting tool.

Once the engine has started,

immediately blip the throttle trigger,

which should release the starting throttle

and allow the engine to slow down to

idle.

WARNING

Your power tool is a one-person

machine. Do not allow other persons in

the general work area, even when

starting.

WARNING

To reduce the risk of injury from loss of

control, do not attempt to "drop start"

your power tool.

WARNING

When you pull the starter grip, do not

wrap the starter rope around your hand.

Do not let the grip snap back, but guide

the starter rope to rewind it properly.

Failure to follow this procedure may

result in injury to your hand or fingers

and may damage the starter

mechanism.

Important Adjustments

WARNING

To reduce the risk of personal injury

from loss of control or contact with the

running cutting tool, do not use your unit

with incorrect idle adjustment. At correct

idle speed, the cutting tool should not

move. For directions on how to adjust

idle speed, see the appropriate section

of your instruction manual.