Stonehealth DOFF SM User manual

THE STONEHEALTH

DOFF SM USER GUIDE

User Guide

SUPERHEATED WATER / STEAM CLEANING SYSTEM

STONEHEALTH.COM

Index

SAFETY INFORMATION PAGE 02

SAFETY INFORMATION CHECKLIST PAGE 03

SPECIFICATION AND SITE REQUIREMENTS PAGE 04

CHECKLIST OF PARTS REQUIRED PAGE 05

CONTROL PANEL - A DETAILED VIEW PAGE 06

QUICK SET UP GUIDE PAGE 07 - 09

ROUTINE MAINTENANCE PAGE 10

EC DECLARATION OF CONFORMITY PAGE 11

CONTACT DETAILS PAGE 14

ORIGINAL INSTRUCTIONS

Safety Informa on

CONSIDERATIONS WHEN USING THE DOFF SYSTEM

Symbols in this sec on are displayed

in accordance with CE requirements

Only Stonehealth inducted and authorised operators may use the equipment. A nominated person adjacent, other than the

Operator, should be aware of how to safely shut down the system in unforeseen circumstances. Whilst personnel working

in the vicinity need not be inducted into the working of the system, they should be made aware of the poten al hazards –

heat, ven la on, the temperature of metal/rubber components etc.

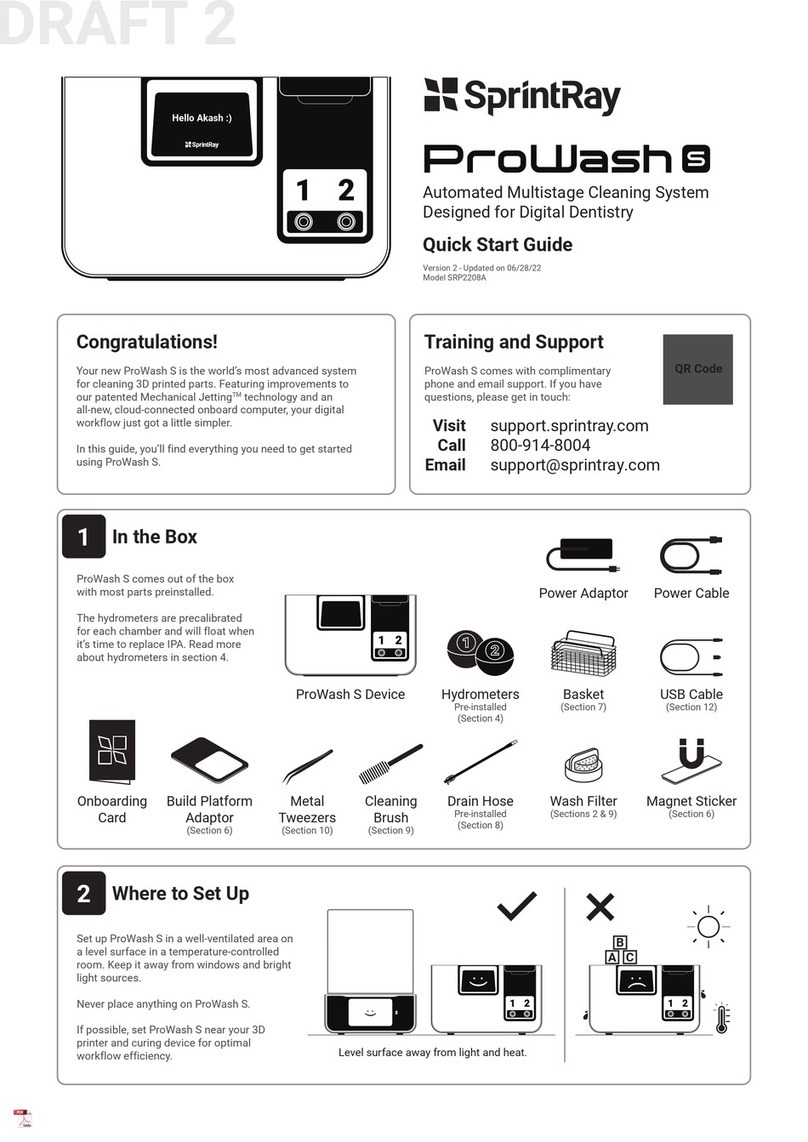

FRONT VIEW OF THE DOFF SKID MOUNT

DIESEL JERRY

CAN STORE

FRONT

CONNECTOR

02

OIL LEVEL

ACCESS

CONTROL

PANEL

FORK LIFT

POINTS

WATER

PUMP

AIR

FILTER

YANMAR

ENGINE

EMERGENCY

STOP THERMOSTAT

PUMP PRESSURE

ADJUSTMENT

PRESSURE

GAUGE

ORIGINAL INSTRUCTIONS

Safety Informaon Checklist

Equipment should be placed in a well venlated area away from ammable materials. The exhaust must not be covered

or obscured.

Visually check all equipment before use, if damage is noted the equipment should not be used.

The fuel for the DOFF Skid Mount is light gas oil. Never Petrol, Gasoline or Spirit Fuels!

Acid Descaler supplied with product should be handled with care: see product Health & Safety Data Sheet.

Maintain access of an appropriate re exnguisher.

Switch o equipment when not aended.

WHILST STONEHEALTH HAVE MADE EVERY EFFORT TO GIVE APPROPRIATE GENERAL GUIDANCE

THE EQUIPMENT MUST COMPLY WITH AND BE USED IN ACCORDANCE WITH ANY REGULATION

APPROPRIATE TO THE SITE ON WHICH IT IS IN USE.

The DOFF Skid Mount system is manufactured to ‘CE’ requirements. Any interference or modicaon to the product

may render the ‘CE’ mark and any warranty null and void.

In the event of accident or breakdown: Release the trigger, operate the emergency stop.

ORIGINAL INSTRUCTIONS

Specifi ca on

MASS 250KG

DIMENSIONS L: 1100mm W: 600mm H: 900mm

FLOW RATE 7 - 10L Per Minute

OUTPUT TEMPERATURE 150°c

PUMP PRESSURE 20 - 150 bar

NOISE LEVEL 95.4 dB Max

IP RATING 23

HEATER OUTPUT 74KW

FUEL Diesel Only

Ambient temperature range for operaon and storage is 5 Degrees C to 40 Degrees C.

04

Site Requirements

YOU WILL NEED:

Clean, cold water supply with a posi ve pressure. Approximately 10 Litres per minute ow

Clean uncontaminated fuel – Diesel - NEVER PETROL OR GASOLINE

Suitable PPE for the task being performed

CONTAMINATED FUEL AND INADEQUATE ELECTRICAL OR WATER SUPPLIES CAUSE THE

MAJORITY OF ALL FAILURES.

ORIGINAL INSTRUCTIONS

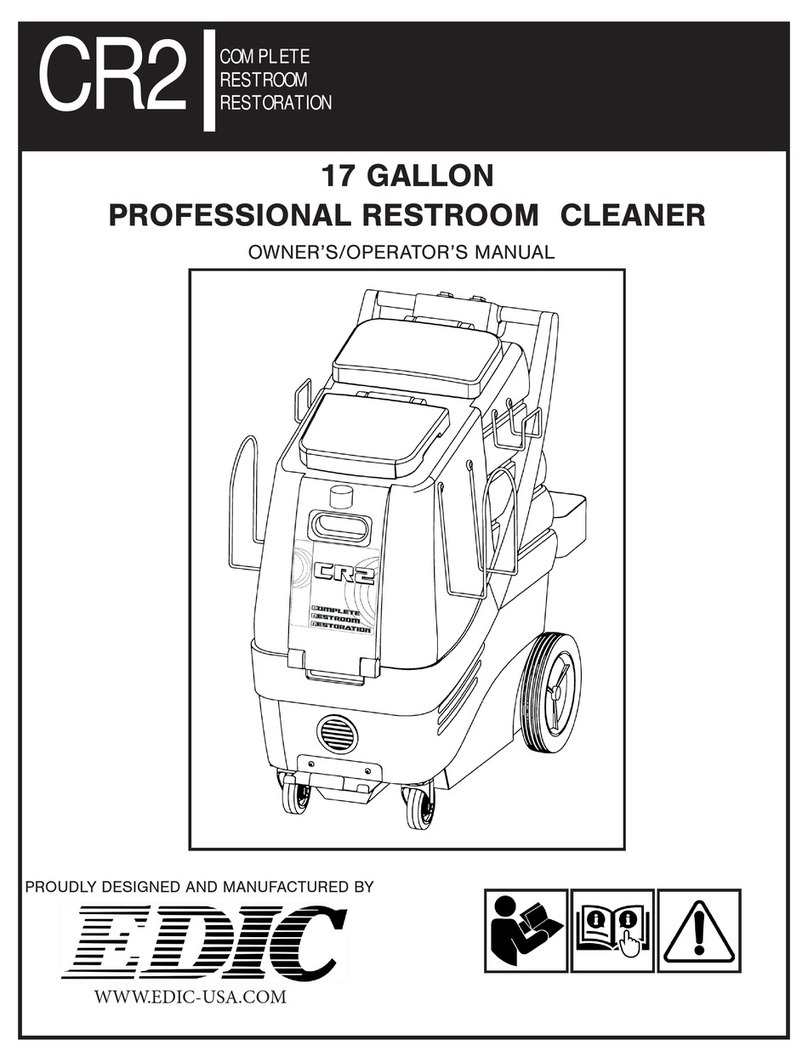

01

02

04

03

05

06

08

09

07

Checklist of Parts Required

DOFF SKID MOUNT • 01

JERRY CAN • 02

HOSE • 03

EXTENSION HOSE • 04

TRIGGER • 05

LANCE x2 • 06

SPARE FUEL FILTER • 07

DE-SCALER HOSE • 08

25 LITRES OF DOFF DESCALER • 09

ORIGINAL INSTRUCTIONS

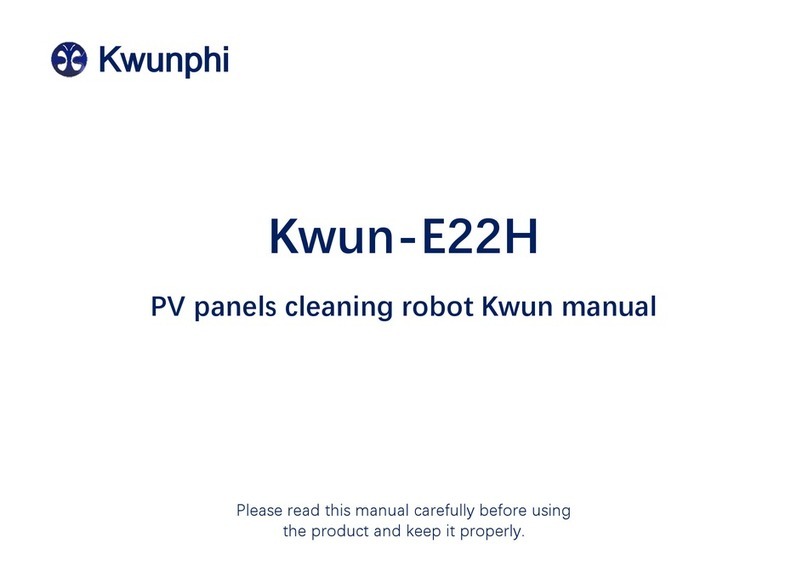

06

Control Panel - Detailed View

EMERGENCY STOP • 01

OIL LIGHT • 02

COOL DOWN LIGHT • 03

ON/OFF • 04

THERMOSTAT RESET • 05

THERMOSTAT • 06

PUMP PRESSURE ADJUSTMENT • 07

PRESSURE GAUGE • 08

01

02

04

03

05

06

08

07

ORIGINAL INSTRUCTIONS

E

M

E

R

G

E

N

C

Y

S

T

O

P

WARNING

Quick Setup Guide

1) To operate the DOFF Skid Mount, you will need a clean, cold water supply

providing no less than 7 - 10 litres of water per minute.

Next, connect the water supply.

3) Now connect the hot hose to the connector on the DOFF Skid Mount.

4)

2) To begin, connect the fuel connectors. The DOFF Skid Mount funcons using

diesel only. Never fuel the DOFF with petrol under any circumstances.

ORIGINAL INSTRUCTIONS

Quick Setup Guide

5) Then, connect the Trigger to the hot hose.To power on the DOFF Skid Mount, pull the emergency stop buon out fully

and then turn the key clockwise to the one o’clock posion.

6)

7) Once the system has been ushed, you can safely connect the lance to the DOFF

trigger. Lances can be supplied in dierent lengths to suite your requirements.

8) Adjust the controls to the desired heat and pressure. You are now ready to

start using the DOFF Skid Mount.

08 ORIGINAL INSTRUCTIONS

WARNING

DO NOT RUN WITHOUT

WATER CONNECTED

CHECK ENGINE & PUMP OIL

DAILY

Quick Setup Guide

9) To power o the DOFF, turn the temperature dial down to the ‘o’ posion and

wait for the blue light to turn on. Then, turn the key to the twelve o’clock posion.

It’s important to check the oil level of the DOFF daily. To do this, rotate the

ap located in the boom corner of the DOFF to reveal the oil dip sck.

10)

Here you can check the oil level and replenish accordingly, if required.

11)

You are now ready to start using the DOFF Skid

Mount. For more detailed operaon instrucons,

scan the QR code or visit stonehealth.com/seng-up-

the-stonehealth-do-skid-mount/

ORIGINAL INSTRUCTIONS

Roune Maintenance

Always ush system through COLD WITHOUT LANCE ON TRIGGER UNIT before using the DOFF

Periodically apply silicone grease to seals, threads and couplings

Nozzles can wear which will aect the performance of the machine. Replace nozzle if spray jet becomes defused or

dened jets appear at the edges of the spray.

Always cool down DOFF system when not in use (we recommend cooling for any break in operaon of more than 2

minutes)

Stonehealth stock a full range of spare parts. Due to the nature of the system, we recommend only using parts

supplied by Stonehealth and will need to be ed by a competent person.

DESCALE - In hard water areas we recommend descaling every two days of operaon. For descaling procedure please

refer to your training or the online Inducon video. hp://www.stonehealth.com/seng-up-the-stonehealth-do-system/

OIL LEVEL - Check the oil level daily in the sight-glass window. This must be done with the pump switched o and the

pump cold or having rested for a minimum of 10 minutes.

PUMP INLET FILTER - Check inlet lter for debris daily.

ALWAYS USE THE DOFF SYSTEM AS PER THE STONEHEALTH APPROVED INDUCTION TRAINING AND SAFETY

RECOMMENDATIONS.

Spare parts, accessories and chemicals are available to order online at www.stonehealth.com or by contacng the

Stonehealth team on 01453 540 600.

10 ORIGINAL INSTRUCTIONS

EC Declara on of Conformity

What does a Declara on of Conformity mean?

It is a formal declara on by a manufacturer, or the manufacturer’s

representa ve, that the product to which it applies meets all

relevant requirements of all product safety direc ves applicable

to that product. It is a sign that a product has been designed and

constructed for compliance with relevant essen al requirements,

and has been through the appropriate conformity assessment

processes.

A Declara on of Conformity is not a guarantee for safety.

However, when properly drawn up along with CE marking on the

product, conformity of the product with the Direc ve(s) quoted

on the Declara on of Conformity may be presumed by suppliers

in the distribu on chain and by the end customer, provided there

are no obvious or known defects. Addi onally, market surveillance

authori es, must presume that CE marked products, accompanied

by a Declara on of Conformity comply with the provisions of the

Direc ve(s) men oned, unless they have evidence to the contrary

(for example by examining or tes ng the product).

Products subject to more than one Direc ve may come with

a single Declara on of Conformity declaring conformity with

two or more Direc ves, or there may be several Declara ons,

one for each Direc ve. However, where a CE marked product is

incorporated in another, such as a safety interlock in a machine,

the Declara on of Conformity for the nal product may only

declare conformity of the overall nal product. In this case the

Declara on(s) for any CE marked component parts should form

part of the technical le for the complete product.

UK/

EC Declaration of Conformity

In accordance with EN ISO 17050-1:2004

in accordance with the following Directives:

hereby declare under our sole responsibility that:

is in conformity with the applicable requirements of the following documents:

Noise measurements have been made in accordance with Directive 2000/14/EC Annex III.B.27 with internal control of

production (Schedule 8/Annex V). The declared noise values are as follows:

I hereby declare that the equipment named above has been designed to comply with the relevant sections of the above

referenced specifications and is in accordance with the requirements of the Directives.

Signed by: ...........................................................................................................................................................................

The technical documentation for the machinery is available from the above address.

We

Stonehealth Ltd

of

G4/5 Draycott Business Park, Cam, Dursley, Gloucestershire, GL11 5DQ, UK

2004/108/EC

The Electromagnetic Compatibility Directive

2006/42/EC

The Machinery Directive

2000/14/EC

The Noise Emission in the Environment by Equipment for Use Outdoors Directive

2011/65/EU

The Restriction of Hazardous Substances Directive

Equipment

Specialist Steam Cleaning Equipment.

Model

DOFF Integra

Serial Number

D2 – as per dash name plate.

Ref. No.

Title

Edition/date

BS EN ISO 12100

Safety of machinery. General principles for design. Risk assessment and risk reduction

2010

BS EN 60335-2-79

Household and similar electrical appliances. Safety. Particular requirements for high

pressure cleaners and steam cleaners

2012

BS EN 61000-6-1

Electromagnetic compatibility (EMC). Generic standards. Immunity for residential,

commercial and light-industrial environments

2007

BS EN 61000-6-3

Electromagnetic compatibility (EMC). Generic standards. Emission standard for

residential, commercial and light-industrial environments

2007 +

A1:2011

Measured sound power level

Guaranteed sound power level

89 dB L

wa

92 dB L

wa

Name:

Mr Brian Crowe

Position:

Executive Chairman

Done at:

Stonehealth Cam

On:

01/01/2018

Document ref. No.

6162/15D1904

Specialist Steam Cleaning Equipment

DOFF Skid Mount

DSMH - as per dash name plate

NOTES

ORIGINAL INSTRUCTIONS

14

NOTES

ORIGINAL INSTRUCTIONS

01453 540 600

www.stonehealth.com

Like us on Facebook

Follow us on Twitter

Stonehealth Ltd | G4/5 | Draycott Business Park | Cam | Dursley | GL11 5DQ

As RIBA/CPD Registered Providers, Stonehealth’s expertise contributes to the conservation of

historical buildings. It supports conservation and environmental organisations, including the

National Trust, English Heritage, Historic Scotland, CADW and other worldwide conservation

bodies. Stonehealth is proud of its reputation in providing solutions with integrity and setting

new standards of restoration and technology excellence in the stone industry.

THE STONEHEALTH

DOFF SM USER GUIDE

STONEHEALTH.COM

Table of contents

Other Stonehealth Cleaning Equipment manuals