Stuv 21 Series User manual

STUV 21:

SPECIFICATIONS &

MANUFACTURER

INSTALLATION

GUIDE

^

PAGE 2 STUV 21 | MODEL SPECIFICATIONS

^

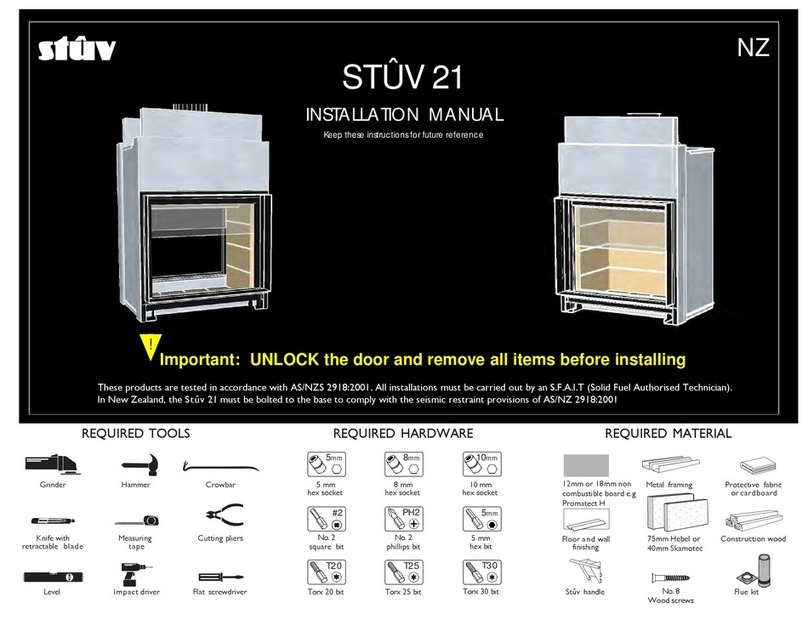

1. PRELIMINARY INSTALL INFORMATIONS

In relation to the installation and use of this appliance, the installer and the user should strictly

adhere to local and national regulations as well as Australian & New Zealand Standards AS/NZS

2918:2001. They should also follow the instructions detailed in the Stuv 21 installation and user

manual. Safe operation of the fireplace is directly dependent thereon. The liability of the manufacturer

can neither be retained nor assured following failure of installation or incorrect use which is not

compliant with AS/NZS 2918:2001.

As each installation is different, a qualified and licensed trades professional should take all required

preliminary precautions depending on the technical elements inherent to each job.

In-observance of the assembly instructions in conjunction with AS/NZS 2918:2001 entails the liability

of the person who carries it out.

Fireplace structure and finishes shall be to your own design providing the exact and minimum

dimensions are maintained.

The floor must have adequate strength to support the fireplace. N.B. Timber floors may require

additional reinforcing.

Construction of the fireplace structure from floor to ceiling shall be: solid brick (110mm minimum),

Silca 250KM board (40mm), stone (100mm minimum) or Hebel aerated blocks (150mm minimum).

When installed on a combustible floor surface the Stuv 21 firebox must be fitted on a raised platform

(height 150mm minimum) constructed of non combustible materials.

As a result of faulty assembly, use of parts or additional components not supplied by the

manufacturer/distributor, and/or modifying of the appliance or components will result in inferior or

unsafe operation. Should this occur the manufacturer/distributor bears no liability, and will result in a

null and void product warranty.

PAGE 3 STUV 21 | MODEL SPECIFICATIONS

^

2. SPECIFICATIONS

DETERMINED UNDER TEST CONDITIONS:

D

Q

S

T

R

E

GF

A

H

I

U

Ø6” Ø4”

P

W

V

X

Y

B

C

J

N

M

O

K

L

Combustion air intake box (optional)

SINGLE SIDED MODELS WITH ZERO CLEARANCE CASING - DIMENSIONS (mm)

PAGE 4 STUV 21 | MODEL SPECIFICATIONS

^

2. SPECIFICATIONS

SINGLE SIDED MODELS WITH ZERO CLEARANCE CASING - DIMENSIONS (mm)

SINGLE SIDED MODELS - OTHER DETAILS

STUV 21 / 95 SF STUV 21 / 105 SF STUV 21 / 125 SF STUV 21 / 135 SF

A699 610 679 610

B210 165 200 162

C178 171 200 171

D1108 1210 1410 1508

E556 603 705 756

F184 203 203 203

G762 800 1000 1102

H298 279 298 283

I1613 1426 1499 1426

J1429 1241 1318 1241

K629 479 616 479

L886 984 1181 1299

M619 378 540 403

N772 870 1070 1184

O700 752

P378 340 368 308

Q464 511 610 660

R327 344 400 419

S930 743 822 743

T152 152 152 152

U48 48 48 48

V394 302 371 308

W397 302 371 308

X397 440 540 591

Y171 171 171 171

STUV 21 / 95 SF STUV 21 / 105 SF STUV 21 / 125 SF STUV 21 / 135 SF

MATERIAL

Steel, ceramic bricks,

glass, galvanised steel ,

rockwool

Steel, ceramic bricks,

glass, galvanised steel ,

rockwool

Steel, ceramic bricks,

glass, galvanised steel ,

rockwool

Steel, ceramic bricks,

glass, galvanised steel ,

rockwool

OUTPUT KW 10kw to 18kw 7kw to 19kw 11kw to 23kw 11kw to 21kw

HEATING CAPACITY 120m2125m2145m2130m2

MINIMUM FLUE HEIGHT 4.5m 4.5m 4.5m 4.5m

WEIGHT (excluding zero clearance casing) 292kg 224kg 305kg 286kg

MAX LOG SIZE 60cm 80cm 100cm 100cm

ACTIVE FLUE SIZE 10” 8” 10” 10”

PAGE 5 STUV 21 | MODEL SPECIFICATIONS

^

2. SPECIFICATIONS

DOUBLE SIDED MODELS WITH ZERO CLEARANCE CASING - DIMENSIONS (mm)

8

I

J

K

H

A

B

DC

E

M

L

F

G

N

O

P

Combustion air intake box (optional)

PAGE 6 STUV 21 | MODEL SPECIFICATIONS

^

DOUBLE SIDED MODELS WITH ZERO CLEARANCE CASING- DIMENSIONS (mm)

STUV 21 / 95 DF STUV 21 / 125 DF

A1108 1410

B556 705

C184 203

D762 1000

E752 752

F248 248

G175 200

H337 337

I930 822

J149 149

K41 41

L1429 1470

M1613 1499

N629 616

O772 1070

P619 540

2. SPECIFICATIONS

DOUBLE SIDED MODELS - OTHER DETAILS

STUV 21 / 95 DF STUV 21 / 125 DF

MATERIAL Steel, ceramic bricks,

glass, galvanised steel ,

rockwool

Steel, ceramic bricks,

glass, galvanised steel ,

rockwool

OUTPUT KW 12kw to 27kw 14kw to 27kw

HEATING CAPACITY 165m2165m2

MINIMUM FLUE HEIGHT 4.5m 4.5m

WEIGHT (excluding zero clearance casing) 297kg 310kg

MAX LOG SIZE 70cm 100cm

ACTIVE FLUE SIZE 12” 12”

PAGE 7 STUV 21 | MODEL SPECIFICATIONS

^

2. SPECIFICATIONS

SINGLE SIDED MODELS WITHOUT CLEARANCE CASING - DIMENSIONS (mm)

D

A

Ø L*

A

B

65

Ø L*

M

C

J

F

250

P

C

J J

F

250

M

E

F

Flat exhaust plate Conical exhaust plate

SINGLE SIDED MODELS WITHOUT ZERO CLEARANCE CASING - DIMENSIONS (mm)

STUV 21 / 95 SF STUV 21 / 105 SF STUV 21 / 125 SF STUV 21 / 135 SF

A950 1050 1250 1350

B1225 1040 1115 1040

C590 496 563 500

D1455 1295

E770 870 1070 1170

F615 400 535 400

PAGE 8 STUV 21 | MODEL SPECIFICATIONS

^

2. SPECIFICATIONS

DOUBLE SIDED MODELS WITHOUT CLEARANCE CASING - DIMENSIONS (mm)

D

A

Ø L*

A

B

65

Ø L*

M

C

J

F

250

P

C

J J

F

250

M

E

F

D

A

Ø L*

A

B

65

Ø L*

M

C

J

F

250

P

C

J J

F

250

M

E

F

Flat exhaust plate Conical exhaust plate

SINGLE SIDED MODELS WITHOUT ZERO CLEARANCE CASING - DIMENSIONS (mm)

STUV 21 / 95 DF STUV 21 / 125 DF

A950 1250

B1225 1115

C670 670

D1455 1295

E770 1070

F615 535

PAGE 9 STUV 21 | MODEL SPECIFICATIONS

^

STANDARD INCLUSIONS

OPTIONAL INCLUSIONS

Combustion air intake box

(optional and only for 95 and 105 models)

EXPLODED DIAGRAM - SINGLE SIDED MODEL (WITH ZERO CLEARANCE CASING)

2. SPECIFICATIONS

PAGE 10 STUV 21 | MODEL SPECIFICATIONS

^

3. CLEARANCES

When installed on a floor made from combustible material, the appliance and enclosure must sit on a raised

platform consisting of a non-combustible framework, no less than 150mm high with a solid 18mm non-

combustible top (minimum). The raised platform must be at least the same width and depth of the appliance

(including the zero clearance box). The fireplace height can then be adjusted as desired using the adjustable

feet. (Fig A)

When installed on a non combustible floor the fireplace can be installed directly onto the floor and adjusted in

height using the adjustable feet. (Fig B)

In situations with combustible walls and when using the insulating casing the sides and rear wall of the

enclosure shall be no closer than 150mm to the appliance. (Fig A, B, C & D)

In situations with non combustible walls (brickwork or Silca boards) the sides and rear wall of the enclosure

shall be no closer than 50mm to the appliance. There is no need to use the insulating casing in such situations.

(Fig E, F, G & H)

Only non-combustible material shall be used on the front wall of the enclosure.

All internal framework above the appliance shall be made of non-combustible material.

When using the insulating casing a 40mm thick Silca board matching the width and depth of the appliance must

be fitted to the top of the appliance to stop heat transfer onto the ceiling and walls. (Fig A & B)

The cavity above the appliance must not be capped and must have a minimum of 2500cm2 of venting.

(Fig C & D)

The appliance must be fitted with the specially designed Stuv 21 four casing flue kit.

The appliance must be fitted with a minimum of two heat transfer ducts and two room air inlet ducts.

In situations with non combustible walls and when the insulating casing is not used a cavity lid made using

40mm Silca board is required to sit 600mm above the appliance and no less than 300mm below the combustible

ceiling. (Fig E, F, G & H)

To conform with the requirement of the joint AS/NZS 2918:2001 the appliance must be fitted with a minimum two

heat transfer ducts and two room air inlet ducts.

PAGE 11 STUV 21 | MODEL SPECIFICATIONS

^

COMBUSTIBLE WALL

30mm

SILCA PLATE

18mm

NON COMBUSTIBLE

BOARD

RAISED PLATFORM

CONSTRUCTED WITH NON COMBUSTIBLE MATERIALS

MIN HIGHT 150mm

COMBUSTIBLE FLOOR

COMBUSTIBLE WALL

150mm

MINIMUM 150mm

150mm

SPECIALLY DESIGNED STUV21

QUADRUPLE CASING FLUE

COMBUSTIBLE WALL

30mm

SILCA PLATE

NON COMBUSTIBLE FLOOR

COMBUSTIBLE WALL

150mm

ADJUSTABLE HEIGHT 16 to 60cm

150mm

SPECIALLY DESIGNED STUV21

QUADRUPLE CASING FLUE

Figure B: front view (non combustible floor)

CLEARANCES TO COMBUSTIBLES (USING THE INSULATING CASING)

3. CLEARANCES

Figure A: front view (combustible floor)

PAGE 12 STUV 21 | MODEL SPECIFICATIONS

^

COMBUSTIBLE WALL

COMBUSTIBLE FLOOR

Combustible floor

150mm

30mm

SILCA PLATE

500mm

150mm

CAVITY ABOVE THE APPLIANCE

MUST BE A MINIMUM OF 2500CM2

NON COMBUSTIBLE BOARD

18mm

NON COMBUSTIBLE

BOARD

FRONT

BACK

Non combustible hearth

(floor protector)

Non combustible hearth

(floor protector) FIREPLACE

300mm300mm

500mm

COMBUSTIBLE WALL

NON COMBUSTIBLE FLOOR

Non combustible floor

150mm

30mm

SILCA PLATE

CAVITY ABOVE THE APPLIANCE

MUST BE A MINIMUM OF 2500CM2

NON COMBUSTIBLE BOARD

FRONT

BACK

FIREPLACE

Figure D: side and top views (non combustible floor)

CLEARANCES TO COMBUSTIBLES (USING THE ZERO CLEARANCE CASING)

3. CLEARANCES

Figure C: side and top views (combustible floor)

PAGE 13 STUV 21 | MODEL SPECIFICATIONS

^

CLEARANCES TO NON-COMBUSTIBLES

3. CLEARANCES

P

NON COMBUSTIBLE BOARD

FRONT

BACK

BRICK WORK

50mm air gap

50mm air gap

BRICK WORK

NON-COMBUSTIBLE FLOOR

NON-COMBUSTIBLE FLOOR

Standard triple skin flue

CAVITY LID

made with Silca 40mm board

600mm above the appliance

and min 300mm below the ceiling.

CAVITY LID

Figure F: side view

CLEARANCES TO MASONRY (NO ZERO CLEARANCE CASING)

Figure E: front view

PAGE 14 STUV 21 | MODEL SPECIFICATIONS

^

P

SILICATE BOARD

30mm or 40mm Silca board

FRONT

BACK

50mm air gap

50mm air gap

NON-COMBUSTIBLE FLOOR

NON-COMBUSTIBLE FLOOR

CAVITY LID

made with Silca 40mm board

600mm above the appliance

and min 300mm below the ceiling.

Silca 40mm board

Silca 40mm board

Standard triple skin flue

3. CLEARANCES

CLEARANCES TO NON-COMBUSTIBLES

Figure H: side view

CLEARANCES TO SILICATE BOARD (NO ZERO CLEARANCE CASING)

Figure G: front view

PAGE 15 STUV 21 | MODEL SPECIFICATIONS

^

COMBUSTIBLE SHELF

3. CLEARANCES

A

100mm 400mm

PAGE 16 STUV 21 | MODEL SPECIFICATIONS

^

4. C0NVECTION

Convection air inlets are through single wall flexible ducts.

Convection air outlets must be through insulated double wall ducts.

It is important that the air flow is continuous. It is therefore forbidden to remove the air from a room and

send it to another airtight room.

Use a minimum of 2 fresh air inlets and 2 hot air outlets.

The distance between the ceiling and the center of the hot convection grill must be at least 35cm.

The horizontal distance between the hot air convection grill and the appliance cannot be greater than 3m.

The vertival distance between the hot air convection grill and the appliance is not limited.

See fig I and J.

35cm (minimum)

35cm (maximum)

155cm (minimum - from the base of the appliance)

CONVECTION AIR OUTLET

CONVECTION AIR INLET

Figure I

PAGE 17 STUV 21 | MODEL SPECIFICATIONS

^

CONVECTION AIR CIRCULATION CONVECTION AIR INLET CONVECTION AIR INLET

The convection air never comes into contact with the fire. The convection is an independant air channel.

The air circulates around the combustion chamber, gets hot and goes out through convection grates in

the same room or in other rooms.

4. C0NVECTION

∞

3000mm max

HOT AIR OUTLETS

CONVECTION AIR CIRCULATION

Figure J

PAGE 18 STUV 21 | MODEL SPECIFICATIONS

^

5. C0MBUSTION

When operating with an open fire, the Stuv 21 consumes a large amount of air. Therefore, we recommend

providing an external air supply, although this is not mandatory.

A sufficient air inlet must be created under the stove, at the front. When not using the air intake box with

connected duct, the base of the fire must be supplied with fresh air. The fresh air must come from a ventilated

empty space, a ventilated room or from outside the house (mandatory for passive/air tight buildings).

ONLY DUCT THE FRESH AIR INLET TO THE APLLIANCE USING THE INTAKE BOX.

The air intake, which varies depending on the model, should ideally be located beneath the front of the unit

and incorporate a shut-off register (fig a).

Ideally the fresh air inlet would be fitted with a closure valve (fig e and f) to prevent the room from becoming

cold when the appliance is not in use. It should ideally be located as close as possible to the outside wall and

controlled from inside the room.

26

Ø6”

Ø4”

Ø6”

Ø4”

Ø6”

11

8

12

9 10

Le conduit qui amène cet air...

... sera protégé à l'extérieur par une grille dont la section

de passage libre est au moins équivalente à la section

d'arrivée d'air. Attention aux infiltrations d'eau et à

l'influence des vents qui peuvent annihiler le système.

... sera le plus court possible pour éviter des pertes de

charges et pour ne pas refroidir la maison.

... sera idéalement équipé d'un clapet de fermeture [figure

8] pour éviter de refroidir la pièce quand le foyer n'est

pas en fonctionnement. Celui-ci sera placé idéalement au

plus près du mur extérieur. Il pourra être commandé de

l'intérieur s'il n'est pas trop éloigné du foyer (longueur du

câble= 47").

S'il n'est pas possible d'amener de l'air extérieur à

proximité du foyer (cas le plus défavorable)...

...il faut puiser l'air dans la pièce où est installé le foyer

[schéma 10 & 12]. Dans ce cas, il faut s'assurer que le

renouvellement d’air dans la pièce sera toujours suffisant

quand le foyer est en fonctionnement.

Note

Attention aux systèmes d’extraction actifs d’air (hotte de

cuisine, air-conditionné, ventilation mécanique contrôlée,

autre foyer…) situés dans le même espace ou dans une

pièce contigüe. Ils consomment eux aussi beaucoup d'air,

pourraient créer une dépression dans le local et perturber

le bon fonctionnement du foyer (risque de refoulement).

The duct carrying this air...

... will be protected on the outside by a grill the free

passage section of which is at least equivalent to the

section of the air inlet. Please note that the infiltration of

water and the effect of the wind can damage the system.

... will be as short as possible to prevent pressure loss and

to prevent making the house cold.

... will ideally be fitted with a closure valve [photo 8] to

prevent the room from becoming cold when the stove is

not in use. It should ideally be located as close as possible

to the outside wall. It can be controlled from inside if it is

not too far away from the stove (cable length = 47").

If it is not possible to bring in outside air near the

stove (most unfavourable case)...

the necessary air for combustion will be taken from the

room. In that case make sure the air renewal is sufficient

when the fireplace is in function.

Please note

Be careful with air extraction systems (kitchen hoods, air

conditioning, mechanically-controlled ventilation, other

stoves) in operation in the same space or in an adjacent

room. They also use lots of air and can cause a depression

in the room and prevent the stove from operating correctly

(risk of draughtback). They can affect the operation of the

stove even if it is connected to an outside air inlet.

STUV 21

CLOSURE VALVE

a. COMBUSTION AIR CIRCULATION

d. COMBUSTION AIR INTAKE BOX e. EXTERNAL COMBUSTION AIR INTAKE f. EXTERNAL COMBUSTION AIR INTAKE

b. COMBUSTION AIR INLET c. COMBUSTION AIR INLET WITH DUCTED INTAKE BOX

PAGE 19 STUV 21 | MODEL SPECIFICATIONS

^

5. C0MBUSTION

COMBUSTION AIR INLET

INLET

DIAMETER

STUV 21 / 95 SF 6 inches

STUV 21 / 105 SF 6 inches

STUV 21 / 125 SF 6 inches

STUV 21 / 135 SF 6 inches

STUV 21 / 95 DF 6 inches

STUV 21 / 125 DF 6 inches

Ø6”

Ø4”

Ø6”

Ø4”

Ø6”

EXTERNAL COMBUSTION AIR (INTAKE BOX) EXTERNAL COMBUSTION AIR (NO INTAKE BOX) INTERNAL COMBUSTION AIR (INTAKE BOX)

PAGE 20 STUV 21 | MODEL SPECIFICATIONS

^

6. TEST REPORT

TEST REPORT NO ASFT18044 (PRELIMINARY REPORT)

TESTING LABORATORY: Australian Solid Fuel Testing

MANUFACTURER: Stuv

MODEL: Stuv 21

WORK REQUESTED: Compliance with AS/NZS2918:2001 Standards

ISSUE DATE: 4/05/2018

INVESTIGATING OFFICER: Steve Marland

CONCLUSION:

The Stuv 21 Inbuilt appliance installed with a triple skin flue system, conforms to the requirements

of Australian/New Zealand Standard 2918:2001, with respect to floor, side wall and rear wall

surface temperatures, when tested in the test position shown in p11, p14 and 15p of this report in accordance

with Appendix B of AS/NZS2918;2001.

This manual suits for next models

4

Table of contents

Other Stuv Wood Stove manuals

Popular Wood Stove manuals by other brands

Jøtul

Jøtul 3 USA Installation and operating instructions

Henley

Henley THE DRUID user manual

Osburn

Osburn 1800 owner's manual

HETAS

HETAS 8 Installation and operating instructions

Dovre

Dovre 350CB Installation instructions and operating manual

Sierra Flame

Sierra Flame Lynwood W76 Installation and operation instructions

Nibe

Nibe Contura Style 896G manual

Quadra-Fire

Quadra-Fire 4300 Series Installation, operation & maintenance instructions

Enerzone

Enerzone Solution 2.9 manual

Unforgettable Fire

Unforgettable Fire Kimberly owner's manual

RIKA

RIKA Tavo operating instructions

Efel

Efel STANFORD 80 Installation, operating and maintenance instructions