10 | Sub-Zero Customer Care 800.222.7820

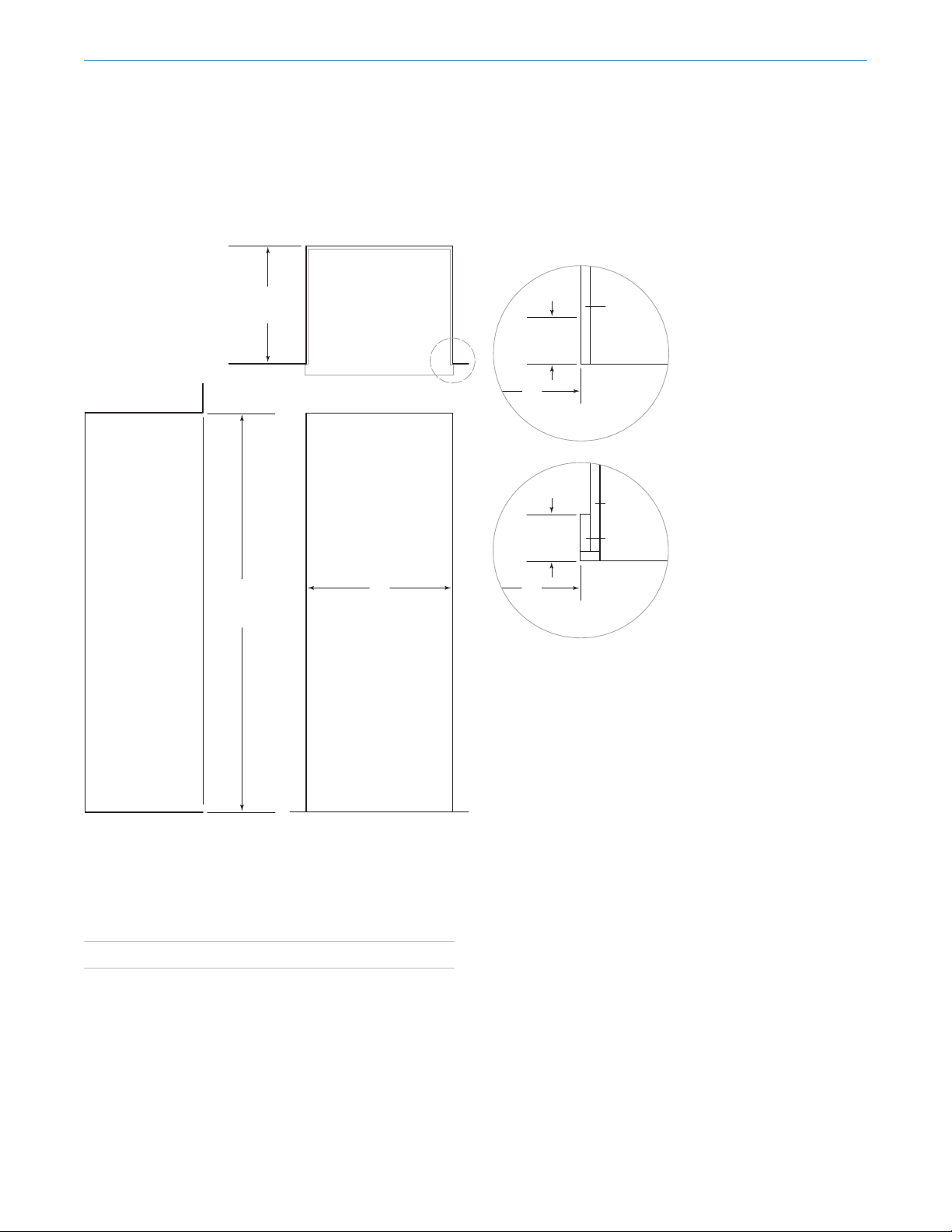

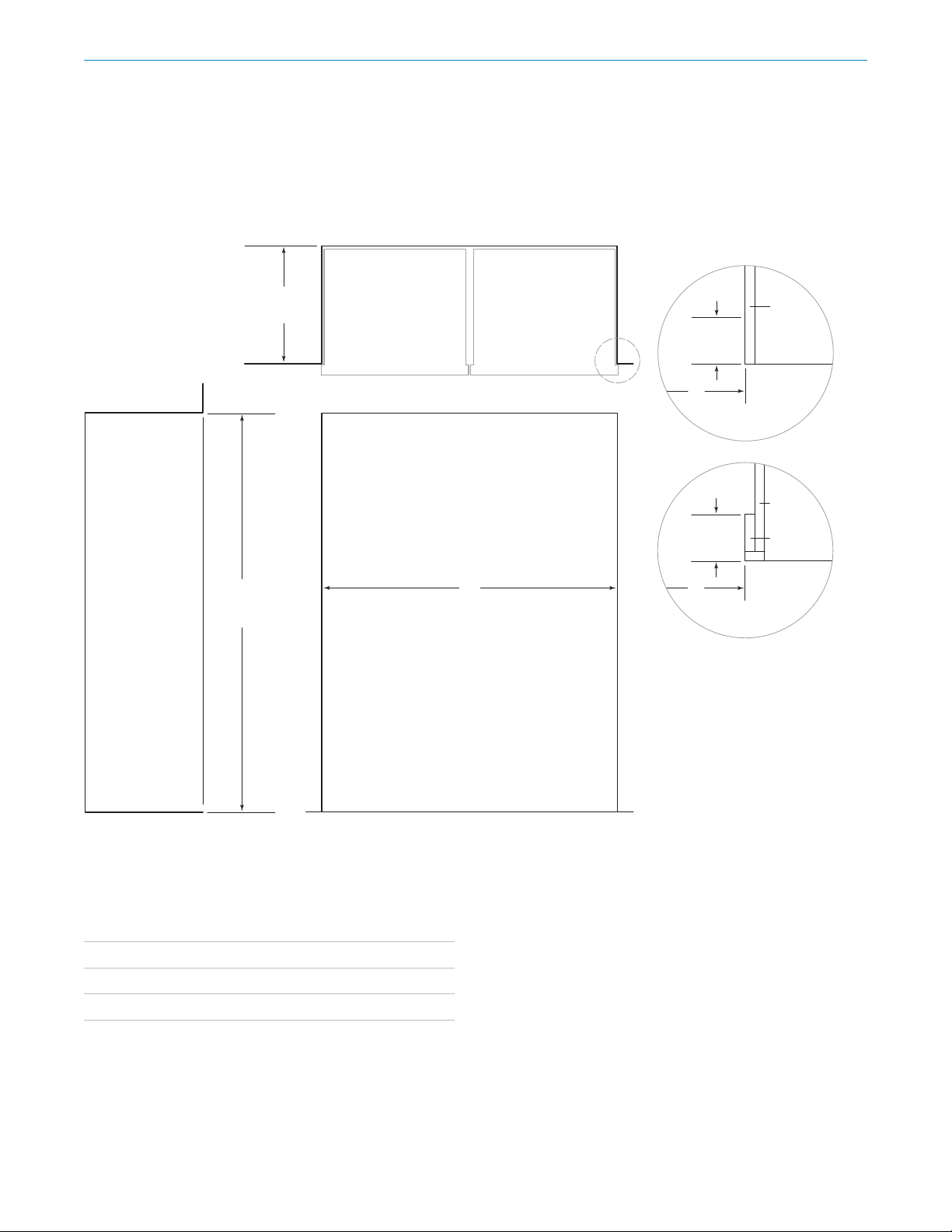

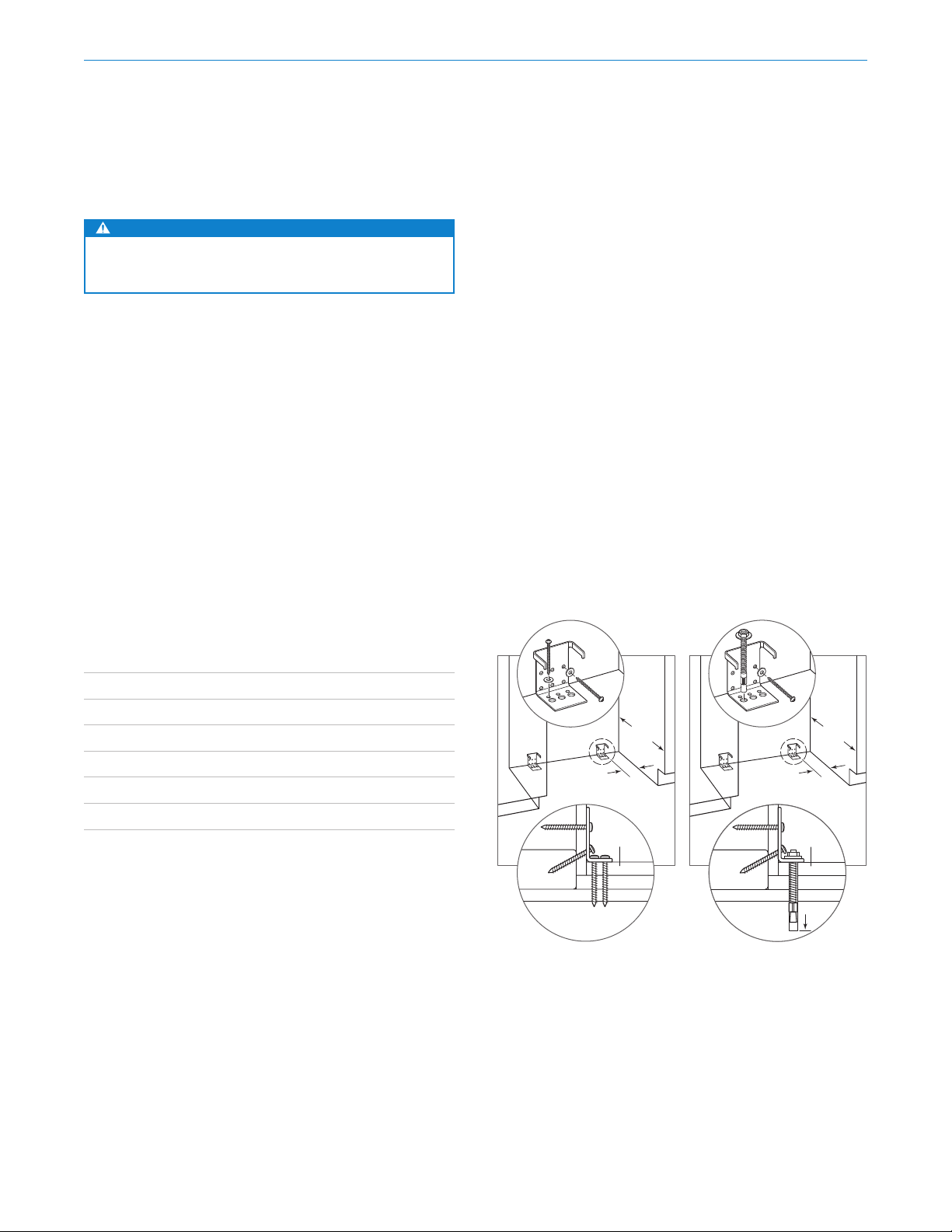

WOOD FLOOR APPLICATION

After properly locating the anti-tip brackets in the open-

ing, drill pilot holes ⁄" (5) diameter maximum in the wall

studs or wall plate. Use the #12 screws and washers to

secure the brackets. Verify the screws penetrate through

the flooring material and into the wall studs or wall plate a

minimum of ⁄" (19). Refer to the illustration below.

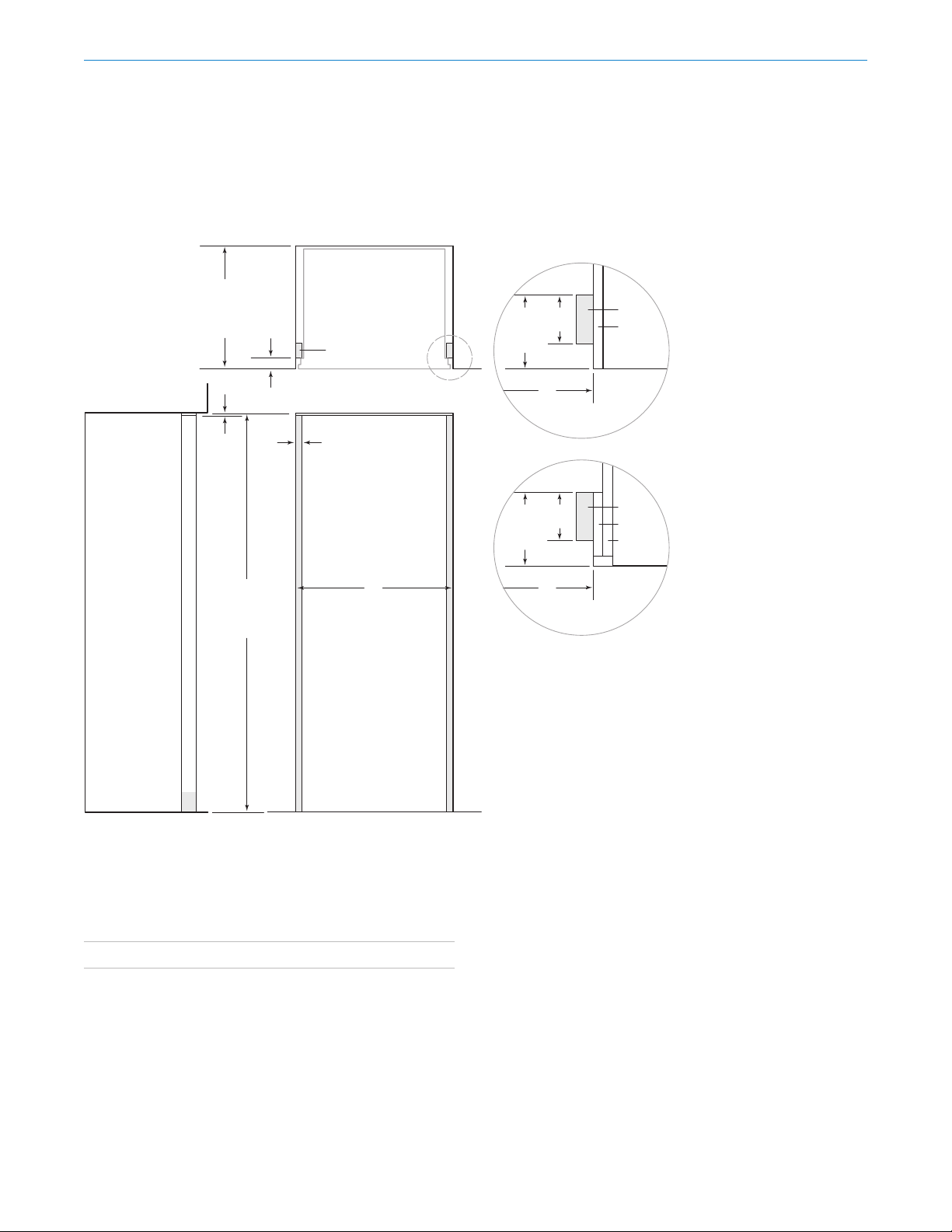

CONCRETE FLOOR APPLICATION

After properly locating the anti-tip brackets in the opening,

drill pilot holes ⁄" (5) diameter maximum in the wall studs

or wall plate. Drill ⁄" (10) diameter holes into the concrete

a minimum of 1⁄" (38) deep. Use the #12 screws and

washers to secure the brackets to the wall, and use the ⁄"

wedge anchors to secure the brackets to the floor. Verify

the screws penetrate the wall studs or wall plate a mini-

mum of ⁄" (19). Refer to the illustration below.

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

brackets must be installed.

The two anti-tip brackets must be installed exactly 24"

(610) from the front of the opening to the back of the

brackets and a minimum of 4" (102) from the sides of the

opening. This depth will increase to 26⁄" (665) for a flush

inset installation based on ⁄" (19) thick panels. Failure to

properly position the anti-tip brackets will prevent proper

engagement.

Use all anti-tip bracket hardware as instructed for wood or

concrete floors.

IMPORTANT NOTE: For wood or concrete floor applica-

tions, if the #12 screws do not hit a wall stud or wall plate,

use the #8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subflooring

or finished floor may necessitate angling the screws used

to fasten the anti-tip brackets to the back wall.

ANTI-TIP HARDWARE

2Anti-tip brackets

12 #12 x 2⁄" pan head screws

4⁄"–16 x 3⁄" wedge anchors

12 #12 flat washers

4#8–18 x 1⁄" truss head screws

4Nylon Zip-it® wall anchors

Site Preparation

4" (102)

MIN

24"

(610)

SUBFLOORING

WOOD FLOOR

WALL PLATE

FINISHED

FLOORING

4" (102)

MIN

24"

(610)

SUBFLOORING

CONCRETE

FLOOR

WALL PLATE

FINISHED

FLOORING

11/2"(38)

min

SUBFLOORING

CONCRETE

FLOOR

WALL PLATE

FINISHED

FLOORING

11/2"(38)

MIN

Wood floor

Concrete floor