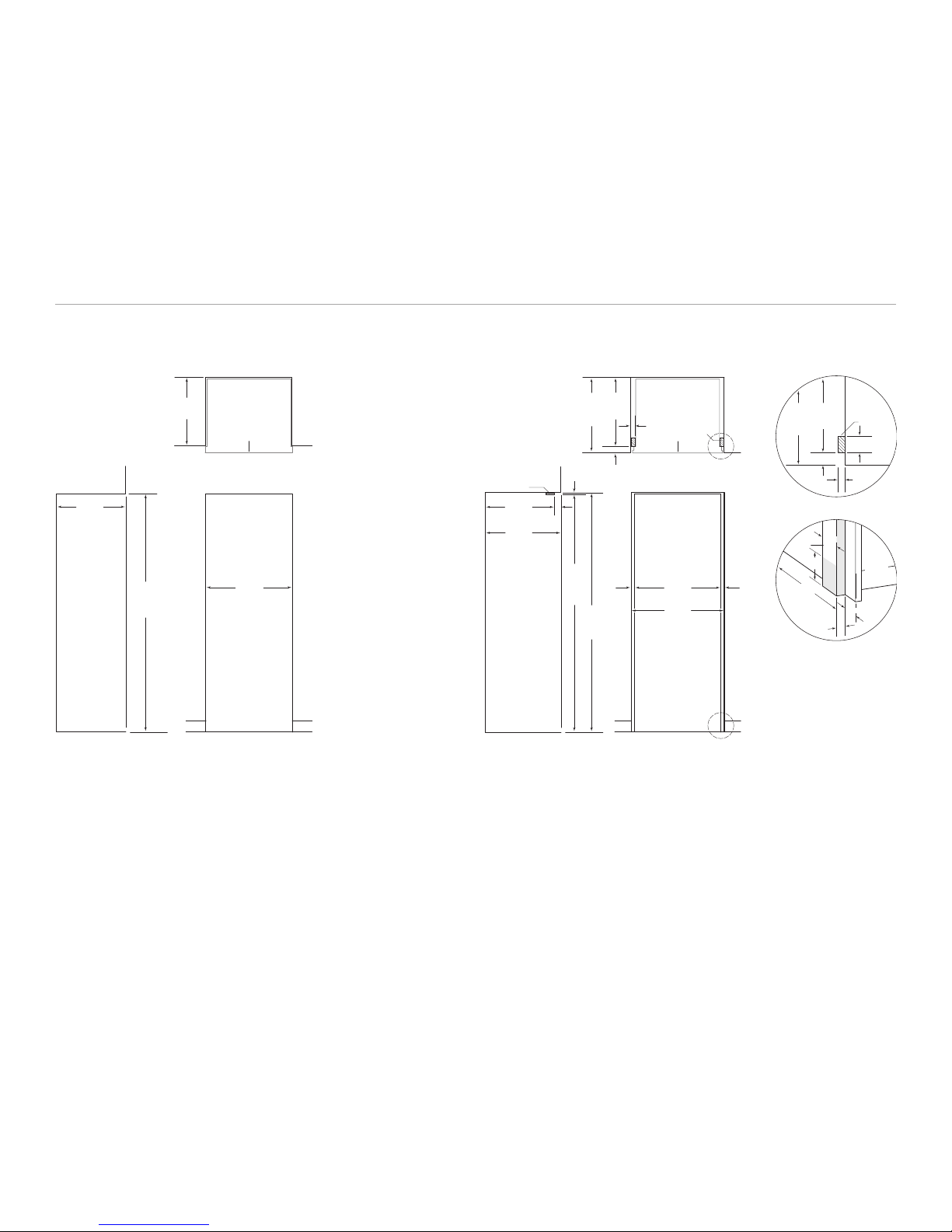

Overlay Panels

If your customer has chosen an overlay design applica-

tion, make sure that the panels you are about to install

match dimensions listed in the overlay panel specifica-

tions to the right. Additional panel design information can

be found in the Sub-Zero wine storage design guide and

on our website, subzero.com.

IMPORTANT NOTE: The size of the overlay panel is

critical. It must fit over the door frame. The weight of the

overlay panel must not exceed 34 kg and the panel must

be a minimum of 16 mm thick.

Overlay models are shipped without handle hardware. The

cabinet manufacturer or designer will need to provide

handle hardware to match the overall decorating scheme.

To install overlay panels, first remove the door trim

molding. Insert a screwdriver tip into the top corner slot on

the handle side and pop out the trim molding. Refer to the

illustration below. Remove the screws and frame.

Sub-Zero allows a 6 mm space to slide the backing

material into place in the frame. If your material is thicker

than a 6 mm, either rout an edge around the panel to get a

proper fit or mount the decorative overlay panel on a sheet

of 6 mm thick material and insert the backing material into

the channel.

You must allow for 3 mm space between the backer board

and the decorative panel, so the panel will slide easily into

the door frame.

The illustrations above provide a cross section view of the

three panel assembly showing placement of the trim and a

rear view of the three panel assembly with critical dimen-

sions, standard for all models.

Install the handle hardware before inserting the panel. We

recommend a larger D-style pull. The use of a small, one-

piece knob is not recommended. If you use screws with

thick heads, you will need to countersink the screws into

the backer panel before sliding the assembly into place.

Slide the panel into the frame on the door. With the panel

in position, replace the frame end. Be sure the panel is

inserted completely into the channel for proper fit and

alignment.

To reinstall the trim molding, insert the top of the trim

molding into the grooves at the top of the door and work

downward, snapping the trim molding into the clips on the

frame.

GRILLE PANEL ASSEMBLY

Remove the grille panel assembly as described on page

13. Remove the top two corner screws and pull away the

top frame. Slide the panel into position in the grille frame.

If you are using a grille panel 6 mm or thinner, you will

need to install a filler.

Reattach the top frame by reinstalling the two top corner

screws. Install the grille panel assembly onto the unit,

by reversing the grille removal procedure outlined on

page 13.

Refer to specifications for overlay grille panels and the

illustrations to the left for the exact sizing of all three

panels.

Do not exceed the panel dimensions listed for the

appropriate overlay grille panel you are specifying.

The overlay decorative panel cannot be any larger or

it may restrict the air flow to the compressor area

and cause problems with the operation of the

Sub-Zero unit.

Overlay Panels Specifications

Grille panel dimensions listed are for a standard 2134 mm

overall height of the unit. For a 2108 mm overall height,

subtract 25 mm from grille panel height dimensions. For a

2235 mm overall height, add 102 mm to height dimensions.

Width dimensions do not vary.

A solid panel must not be installed on a glass door

unit, as this may cause moisture to form behind the

panel.

Model ICBWS-30

DOOR W H

Overlay Panel 762 mm 1772 mm

Spacer Panel 740 mm 1751 mm

Backer Panel 756 mm 1767 mm

GRILLE WH

Overlay Panel 762 mm 235 mm

Spacer Panel 740 mm 211 mm

Backer Panel 756 mm 227 mm

WINDOW W H

Cut-Out 597 mm 1607 mm

A

Location 83 mm