2-2

#7040748 - Revision A - September, 2016

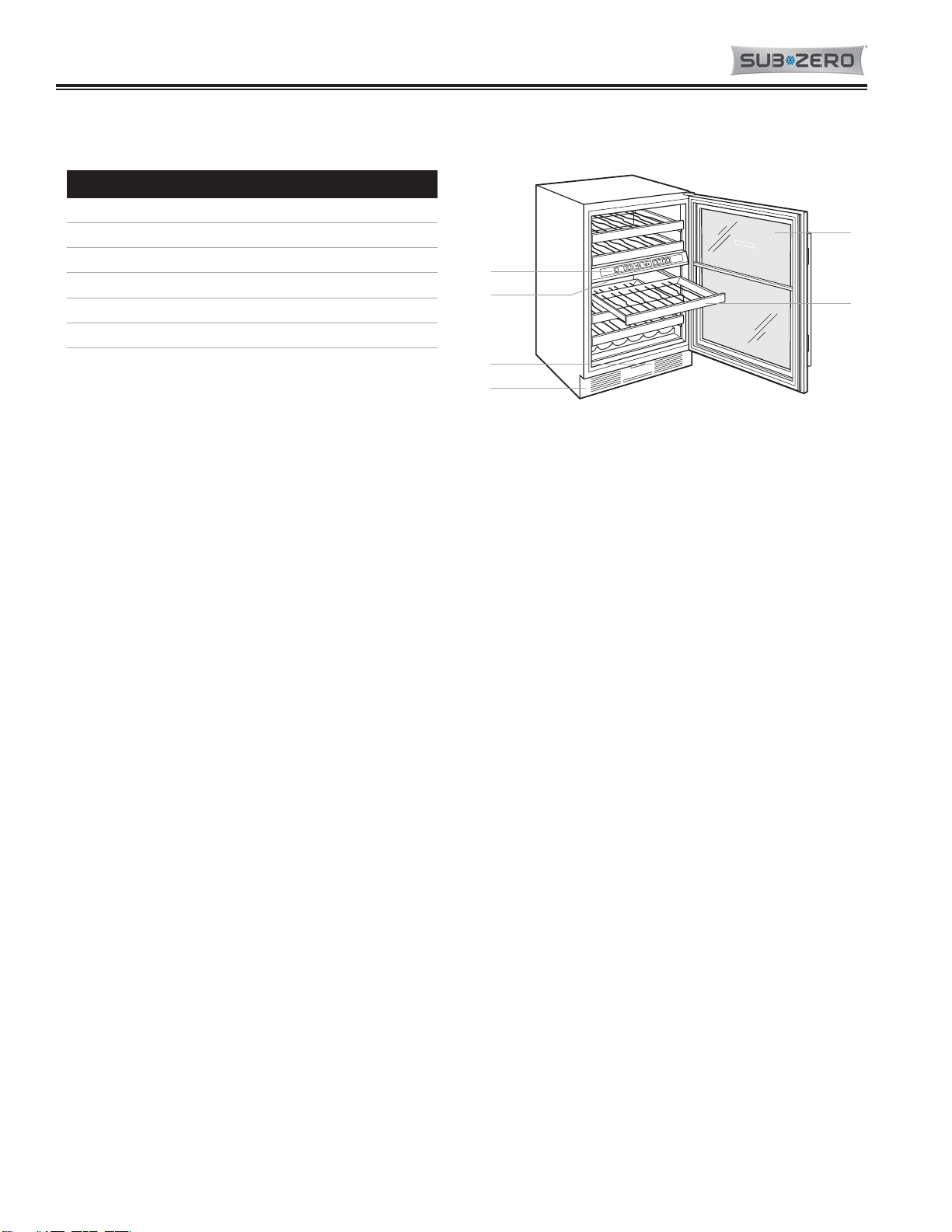

Electronic Control System MODEL UW-24

MODEL UW-24

MODEL UW-24 ELECTRONIC CONTROL TERMINOLOGY & COMPONENT DESCRIPTIONS

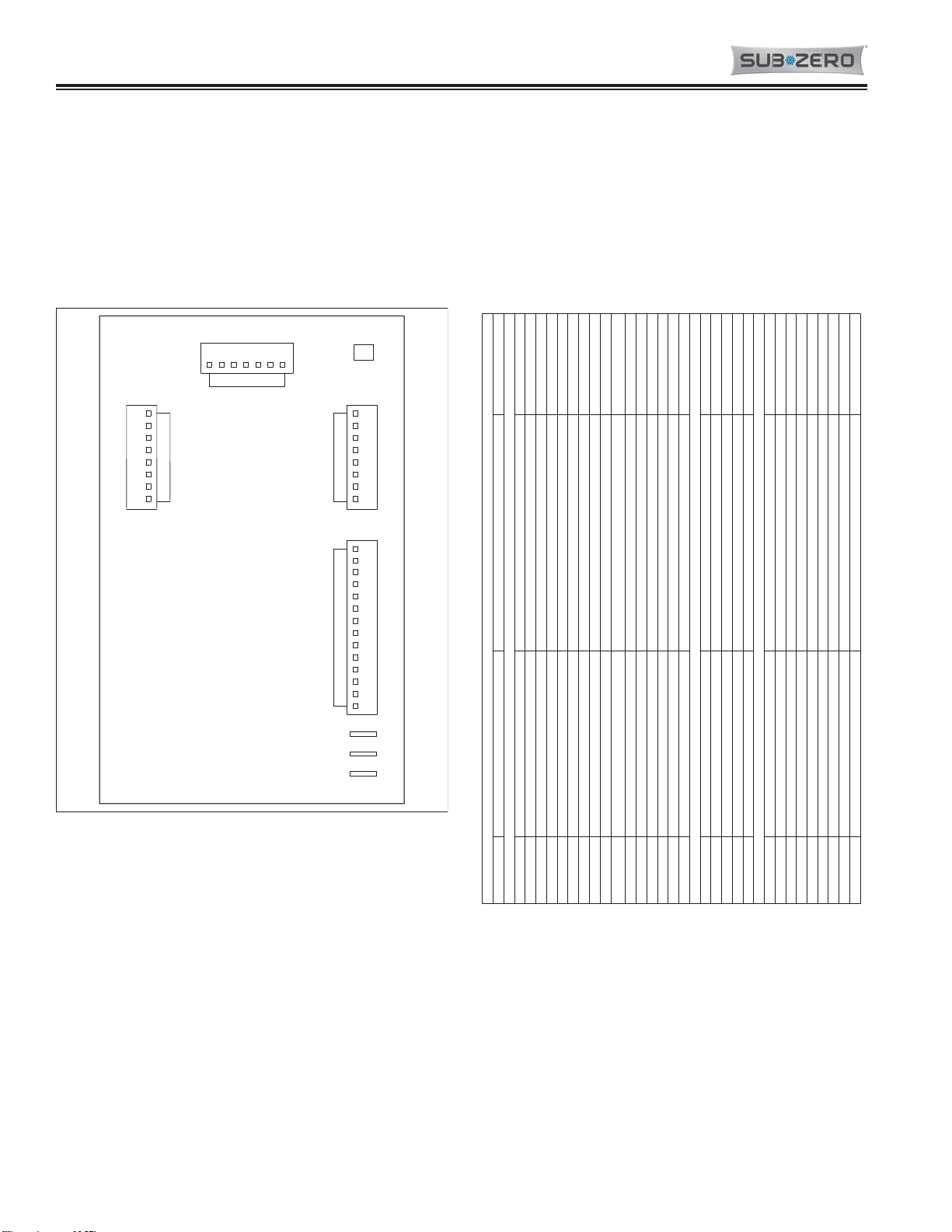

The UW-24 utilizes an electronic control system which monitors, regulates, controls and displays a variety of func-

tions and operations in the appliance.

The table below defines some of the basic electronic control system terminology.

Term/Component Definition / Description

Main Control Board ……....….. The printed-circuit board (PC Board) which contains a microprocessor, relays, and

electrical connections that monitor and control all functions of the appliance.

Microprocessor ………......…... An electrical component on the control board which receives electrical signals from

other components, processes the information, then sends electrical signals to relays

on the board to open or close, switching components in the appliance ON or OFF.

Relay …………………….……. An electrical component on the control board which switches other components in

the appliance ON or OFF when instructed to do so by the microprocessor.

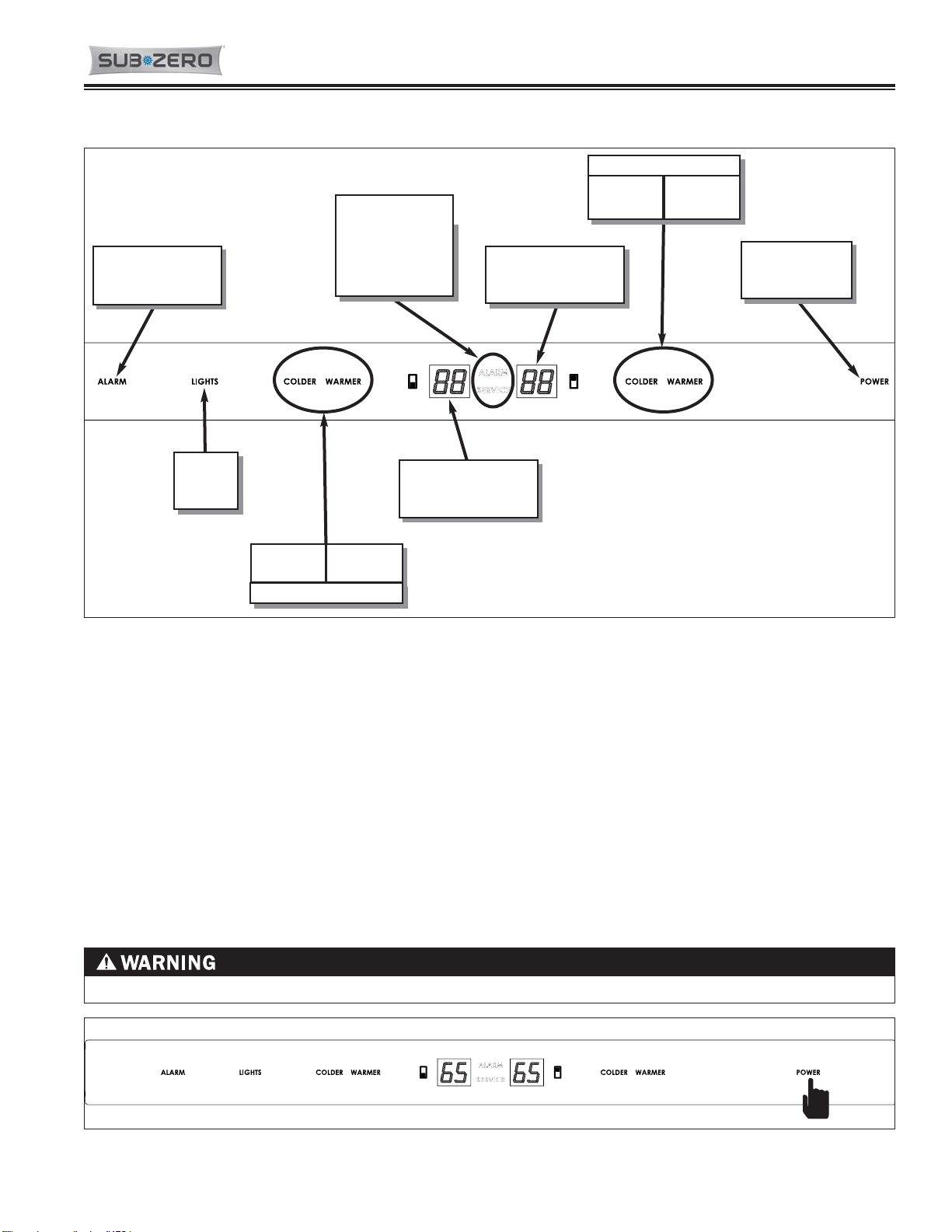

Control Panel Assembly …….. That part of the electronic control system where manual commands are entered via

key-strokes and information is displayed; located between the two wine storage

zones.

Membrane Switch ………..….. An integral part of the control panel assembly consisting of the function keys used

for all input commands to the electronic control system.

Keys (Function Keys) ………… The keys or buttons on the control panel assembly used for manual input opera-

tions.

LED (Light-Emitting Diode) ….. A semiconductor diode that emits light when power is supplied to it. In the control

panel assembly, LED’s are arranged to show values and codes. They are also used

as back-lighting for icons and indicators in the control panel.

Icons/Indicators ……........…..... The words, numbers and symbols visible at and on the control panel assembly.

(Example: temperatures, alarm symbol, service symbol, error/fault codes, etc.)

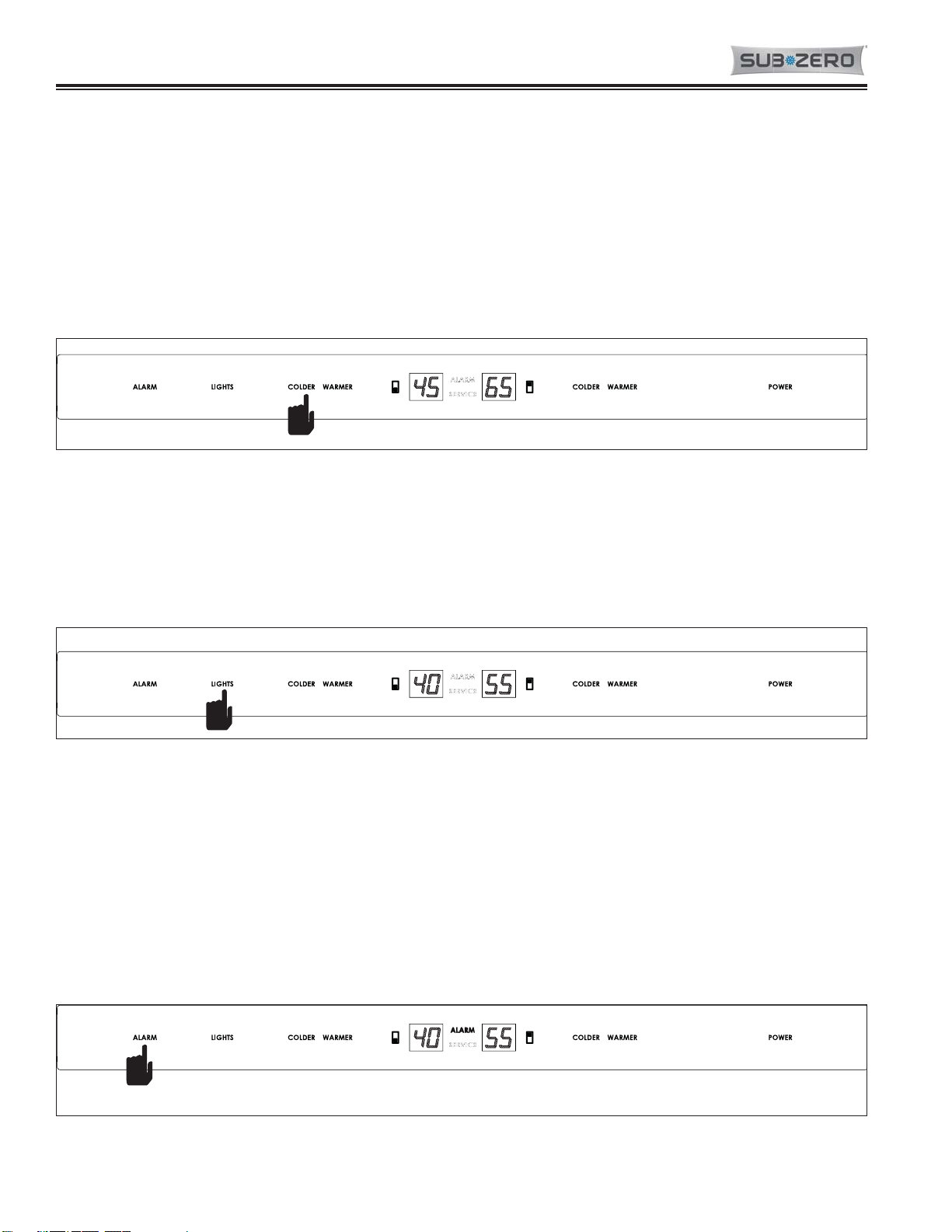

Set-Point ……………………..... The desired zone temperature, established by pressing the COLDER and/or

WARMER keys.

High Offset (Cut-in)…..……..... During normal operation of a wine storage unit, it is the maximum evaporator tem-

perature the electronic control system will allow before calling for cooling.

Low Offset (Cut-out)……...…... During normal operation of a wine storage unit, it is the minimum compartment air

temperature the electronic control system will allow before interrupting cooling.

Offset Temperature Range …... The difference between the low offset and the high offset.

Thermistor ..........................….. A thermistor or Temperature Sensor is a resistor with which resistance changes as

temperature around it changes. For electronic control system purposes, the micro-

processor detects, monitors and processes this resistance value in order to control

cooling functions as well as displays it as a temperature reading at the control

panel.

Display Units of Measure…….. Temperatures displayed at the control panel may be in Celsius (°C) or Fahrenheit

(°F) units of measure. Switching from one to the other display units of measure is

accomplished through a series of key strokes.

Error (Fault) Codes .………..... The codes that appear at the control panel display windows if the unit experienced

specific problems related to electrical signals supplied to the microprocessor.

Electrical “Pulse”....................... A non-constant supply of voltage, or electrical signal, the duration of which is often

measured in milliseconds.

Electrical Polarity....................... The positive ( + ) and negative ( - ) sides of the alternating current sinewave.